JP5517610B2 - α−ヒドロキシカルボン酸エステルの製造法 - Google Patents

α−ヒドロキシカルボン酸エステルの製造法 Download PDFInfo

- Publication number

- JP5517610B2 JP5517610B2 JP2009510374A JP2009510374A JP5517610B2 JP 5517610 B2 JP5517610 B2 JP 5517610B2 JP 2009510374 A JP2009510374 A JP 2009510374A JP 2009510374 A JP2009510374 A JP 2009510374A JP 5517610 B2 JP5517610 B2 JP 5517610B2

- Authority

- JP

- Japan

- Prior art keywords

- pressure

- bar

- ammonia

- alcohol

- reaction

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000004519 manufacturing process Methods 0.000 title description 10

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 claims description 190

- 238000006243 chemical reaction Methods 0.000 claims description 98

- OKKJLVBELUTLKV-UHFFFAOYSA-N Methanol Chemical compound OC OKKJLVBELUTLKV-UHFFFAOYSA-N 0.000 claims description 96

- 229910021529 ammonia Inorganic materials 0.000 claims description 95

- 238000000034 method Methods 0.000 claims description 83

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 claims description 82

- 239000000203 mixture Substances 0.000 claims description 77

- 239000003054 catalyst Substances 0.000 claims description 64

- 238000004821 distillation Methods 0.000 claims description 46

- 150000001408 amides Chemical class 0.000 claims description 32

- DRYMMXUBDRJPDS-UHFFFAOYSA-N 2-hydroxy-2-methylpropanamide Chemical compound CC(C)(O)C(N)=O DRYMMXUBDRJPDS-UHFFFAOYSA-N 0.000 claims description 15

- 150000002601 lanthanoid compounds Chemical class 0.000 claims description 14

- 239000000376 reactant Substances 0.000 claims description 14

- 229910052751 metal Inorganic materials 0.000 claims description 12

- 239000002184 metal Substances 0.000 claims description 12

- 238000000066 reactive distillation Methods 0.000 claims description 10

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 10

- 238000010924 continuous production Methods 0.000 claims description 9

- 229910052719 titanium Inorganic materials 0.000 claims description 9

- 239000010936 titanium Substances 0.000 claims description 9

- 229910052718 tin Inorganic materials 0.000 claims description 7

- 229910052720 vanadium Inorganic materials 0.000 claims description 6

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 claims description 5

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 claims description 5

- 229910052746 lanthanum Inorganic materials 0.000 claims description 5

- ITMCEJHCFYSIIV-UHFFFAOYSA-M triflate Chemical compound [O-]S(=O)(=O)C(F)(F)F ITMCEJHCFYSIIV-UHFFFAOYSA-M 0.000 claims description 5

- 229910052804 chromium Inorganic materials 0.000 claims description 4

- 229910052802 copper Inorganic materials 0.000 claims description 4

- 229910052735 hafnium Inorganic materials 0.000 claims description 4

- 229910052742 iron Inorganic materials 0.000 claims description 4

- 229910052750 molybdenum Inorganic materials 0.000 claims description 4

- 229910052759 nickel Inorganic materials 0.000 claims description 4

- 229910052758 niobium Inorganic materials 0.000 claims description 4

- 229910052715 tantalum Inorganic materials 0.000 claims description 4

- 229910052721 tungsten Inorganic materials 0.000 claims description 4

- 229910052726 zirconium Inorganic materials 0.000 claims description 4

- 229910052684 Cerium Inorganic materials 0.000 claims description 3

- 229910052782 aluminium Inorganic materials 0.000 claims description 3

- 229910052797 bismuth Inorganic materials 0.000 claims description 3

- 230000003647 oxidation Effects 0.000 claims description 3

- 238000007254 oxidation reaction Methods 0.000 claims description 3

- 238000002360 preparation method Methods 0.000 claims description 3

- 150000003839 salts Chemical class 0.000 claims description 3

- 229910052787 antimony Inorganic materials 0.000 claims description 2

- 150000004696 coordination complex Chemical class 0.000 claims description 2

- 229910052733 gallium Inorganic materials 0.000 claims description 2

- 229910052738 indium Inorganic materials 0.000 claims description 2

- 229910052747 lanthanoid Inorganic materials 0.000 claims description 2

- 150000002602 lanthanoids Chemical class 0.000 claims description 2

- FZLIPJUXYLNCLC-UHFFFAOYSA-N lanthanum atom Chemical compound [La] FZLIPJUXYLNCLC-UHFFFAOYSA-N 0.000 claims description 2

- 229910052745 lead Inorganic materials 0.000 claims description 2

- 229910044991 metal oxide Inorganic materials 0.000 claims description 2

- 150000004706 metal oxides Chemical class 0.000 claims description 2

- 230000000737 periodic effect Effects 0.000 claims description 2

- 229910052702 rhenium Inorganic materials 0.000 claims description 2

- 229910052706 scandium Inorganic materials 0.000 claims description 2

- 229910052710 silicon Inorganic materials 0.000 claims description 2

- 229910052713 technetium Inorganic materials 0.000 claims description 2

- 229910052714 tellurium Inorganic materials 0.000 claims description 2

- BVKZGUZCCUSVTD-UHFFFAOYSA-N carbonic acid Chemical class OC(O)=O BVKZGUZCCUSVTD-UHFFFAOYSA-N 0.000 claims 1

- 238000011038 discontinuous diafiltration by volume reduction Methods 0.000 claims 1

- BDHFUVZGWQCTTF-UHFFFAOYSA-M sulfonate Chemical compound [O-]S(=O)=O BDHFUVZGWQCTTF-UHFFFAOYSA-M 0.000 claims 1

- 239000000047 product Substances 0.000 description 39

- 238000000926 separation method Methods 0.000 description 19

- -1 bisphenone Natural products 0.000 description 15

- 125000004432 carbon atom Chemical group C* 0.000 description 15

- 239000006227 byproduct Substances 0.000 description 12

- 150000002148 esters Chemical class 0.000 description 12

- 125000000217 alkyl group Chemical group 0.000 description 11

- 238000006136 alcoholysis reaction Methods 0.000 description 9

- 238000012856 packing Methods 0.000 description 9

- 239000011541 reaction mixture Substances 0.000 description 9

- 239000007789 gas Substances 0.000 description 8

- 238000009835 boiling Methods 0.000 description 7

- XSCHRSMBECNVNS-UHFFFAOYSA-N quinoxaline Chemical compound N1=CC=NC2=CC=CC=C21 XSCHRSMBECNVNS-UHFFFAOYSA-N 0.000 description 7

- 239000000243 solution Substances 0.000 description 7

- 239000002253 acid Substances 0.000 description 6

- 150000001298 alcohols Chemical class 0.000 description 6

- LELOWRISYMNNSU-UHFFFAOYSA-N hydrogen cyanide Chemical compound N#C LELOWRISYMNNSU-UHFFFAOYSA-N 0.000 description 6

- XYVQFUJDGOBPQI-UHFFFAOYSA-N Methyl-2-hydoxyisobutyric acid Chemical compound COC(=O)C(C)(C)O XYVQFUJDGOBPQI-UHFFFAOYSA-N 0.000 description 5

- 125000003118 aryl group Chemical group 0.000 description 5

- 230000015572 biosynthetic process Effects 0.000 description 5

- 239000011261 inert gas Substances 0.000 description 5

- 239000010409 thin film Substances 0.000 description 5

- UJOBWOGCFQCDNV-UHFFFAOYSA-N 9H-carbazole Chemical compound C1=CC=C2C3=CC=CC=C3NC2=C1 UJOBWOGCFQCDNV-UHFFFAOYSA-N 0.000 description 4

- CSCPPACGZOOCGX-UHFFFAOYSA-N Acetone Chemical compound CC(C)=O CSCPPACGZOOCGX-UHFFFAOYSA-N 0.000 description 4

- SIKJAQJRHWYJAI-UHFFFAOYSA-N Indole Chemical compound C1=CC=C2NC=CC2=C1 SIKJAQJRHWYJAI-UHFFFAOYSA-N 0.000 description 4

- LRHPLDYGYMQRHN-UHFFFAOYSA-N N-Butanol Chemical compound CCCCO LRHPLDYGYMQRHN-UHFFFAOYSA-N 0.000 description 4

- SMWDFEZZVXVKRB-UHFFFAOYSA-N Quinoline Chemical compound N1=CC=CC2=CC=CC=C21 SMWDFEZZVXVKRB-UHFFFAOYSA-N 0.000 description 4

- 125000003545 alkoxy group Chemical group 0.000 description 4

- 150000001875 compounds Chemical class 0.000 description 4

- 125000000753 cycloalkyl group Chemical group 0.000 description 4

- USIUVYZYUHIAEV-UHFFFAOYSA-N diphenyl ether Chemical class C=1C=CC=CC=1OC1=CC=CC=C1 USIUVYZYUHIAEV-UHFFFAOYSA-N 0.000 description 4

- 230000000694 effects Effects 0.000 description 4

- 238000007429 general method Methods 0.000 description 4

- 239000002815 homogeneous catalyst Substances 0.000 description 4

- AMWRITDGCCNYAT-UHFFFAOYSA-L hydroxy(oxo)manganese;manganese Chemical compound [Mn].O[Mn]=O.O[Mn]=O AMWRITDGCCNYAT-UHFFFAOYSA-L 0.000 description 4

- 238000003786 synthesis reaction Methods 0.000 description 4

- 238000012360 testing method Methods 0.000 description 4

- KDCGOANMDULRCW-UHFFFAOYSA-N 7H-purine Chemical compound N1=CNC2=NC=NC2=C1 KDCGOANMDULRCW-UHFFFAOYSA-N 0.000 description 3

- 150000001252 acrylic acid derivatives Chemical class 0.000 description 3

- 150000001732 carboxylic acid derivatives Chemical class 0.000 description 3

- 238000004817 gas chromatography Methods 0.000 description 3

- 125000001072 heteroaryl group Chemical group 0.000 description 3

- 239000002638 heterogeneous catalyst Substances 0.000 description 3

- RAXXELZNTBOGNW-UHFFFAOYSA-N imidazole Natural products C1=CNC=N1 RAXXELZNTBOGNW-UHFFFAOYSA-N 0.000 description 3

- 238000009533 lab test Methods 0.000 description 3

- 239000007791 liquid phase Substances 0.000 description 3

- 238000006140 methanolysis reaction Methods 0.000 description 3

- 229910052760 oxygen Inorganic materials 0.000 description 3

- 239000012071 phase Substances 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- VMLKTERJLVWEJJ-UHFFFAOYSA-N 1,5-naphthyridine Chemical compound C1=CC=NC2=CC=CN=C21 VMLKTERJLVWEJJ-UHFFFAOYSA-N 0.000 description 2

- KBPLFHHGFOOTCA-UHFFFAOYSA-N 1-Octanol Chemical compound CCCCCCCCO KBPLFHHGFOOTCA-UHFFFAOYSA-N 0.000 description 2

- IANQTJSKSUMEQM-UHFFFAOYSA-N 1-benzofuran Chemical compound C1=CC=C2OC=CC2=C1 IANQTJSKSUMEQM-UHFFFAOYSA-N 0.000 description 2

- FCEHBMOGCRZNNI-UHFFFAOYSA-N 1-benzothiophene Chemical compound C1=CC=C2SC=CC2=C1 FCEHBMOGCRZNNI-UHFFFAOYSA-N 0.000 description 2

- BBMCTIGTTCKYKF-UHFFFAOYSA-N 1-heptanol Chemical compound CCCCCCCO BBMCTIGTTCKYKF-UHFFFAOYSA-N 0.000 description 2

- YIWUKEYIRIRTPP-UHFFFAOYSA-N 2-ethylhexan-1-ol Chemical compound CCCCC(CC)CO YIWUKEYIRIRTPP-UHFFFAOYSA-N 0.000 description 2

- NSPMIYGKQJPBQR-UHFFFAOYSA-N 4H-1,2,4-triazole Chemical compound C=1N=CNN=1 NSPMIYGKQJPBQR-UHFFFAOYSA-N 0.000 description 2

- IKHGUXGNUITLKF-UHFFFAOYSA-N Acetaldehyde Chemical compound CC=O IKHGUXGNUITLKF-UHFFFAOYSA-N 0.000 description 2

- XFXPMWWXUTWYJX-UHFFFAOYSA-N Cyanide Chemical compound N#[C-] XFXPMWWXUTWYJX-UHFFFAOYSA-N 0.000 description 2

- 108090000790 Enzymes Proteins 0.000 description 2

- 102000004190 Enzymes Human genes 0.000 description 2

- YLQBMQCUIZJEEH-UHFFFAOYSA-N Furan Chemical compound C=1C=COC=1 YLQBMQCUIZJEEH-UHFFFAOYSA-N 0.000 description 2

- VQTUBCCKSQIDNK-UHFFFAOYSA-N Isobutene Chemical compound CC(C)=C VQTUBCCKSQIDNK-UHFFFAOYSA-N 0.000 description 2

- AMQJEAYHLZJPGS-UHFFFAOYSA-N N-Pentanol Chemical compound CCCCCO AMQJEAYHLZJPGS-UHFFFAOYSA-N 0.000 description 2

- UFWIBTONFRDIAS-UHFFFAOYSA-N Naphthalene Chemical class C1=CC=CC2=CC=CC=C21 UFWIBTONFRDIAS-UHFFFAOYSA-N 0.000 description 2

- 108010024026 Nitrile hydratase Proteins 0.000 description 2

- PCNDJXKNXGMECE-UHFFFAOYSA-N Phenazine Natural products C1=CC=CC2=NC3=CC=CC=C3N=C21 PCNDJXKNXGMECE-UHFFFAOYSA-N 0.000 description 2

- QQONPFPTGQHPMA-UHFFFAOYSA-N Propene Chemical compound CC=C QQONPFPTGQHPMA-UHFFFAOYSA-N 0.000 description 2

- NBBJYMSMWIIQGU-UHFFFAOYSA-N Propionic aldehyde Chemical compound CCC=O NBBJYMSMWIIQGU-UHFFFAOYSA-N 0.000 description 2

- KYQCOXFCLRTKLS-UHFFFAOYSA-N Pyrazine Chemical compound C1=CN=CC=N1 KYQCOXFCLRTKLS-UHFFFAOYSA-N 0.000 description 2

- WTKZEGDFNFYCGP-UHFFFAOYSA-N Pyrazole Chemical compound C=1C=NNC=1 WTKZEGDFNFYCGP-UHFFFAOYSA-N 0.000 description 2

- JUJWROOIHBZHMG-UHFFFAOYSA-N Pyridine Chemical compound C1=CC=NC=C1 JUJWROOIHBZHMG-UHFFFAOYSA-N 0.000 description 2

- KAESVJOAVNADME-UHFFFAOYSA-N Pyrrole Chemical compound C=1C=CNC=1 KAESVJOAVNADME-UHFFFAOYSA-N 0.000 description 2

- QAOWNCQODCNURD-UHFFFAOYSA-N Sulfuric acid Chemical compound OS(O)(=O)=O QAOWNCQODCNURD-UHFFFAOYSA-N 0.000 description 2

- YTPLMLYBLZKORZ-UHFFFAOYSA-N Thiophene Chemical compound C=1C=CSC=1 YTPLMLYBLZKORZ-UHFFFAOYSA-N 0.000 description 2

- 150000001299 aldehydes Chemical class 0.000 description 2

- 229910052783 alkali metal Inorganic materials 0.000 description 2

- 150000001340 alkali metals Chemical class 0.000 description 2

- 125000003342 alkenyl group Chemical group 0.000 description 2

- MWPLVEDNUUSJAV-UHFFFAOYSA-N anthracene Chemical compound C1=CC=CC2=CC3=CC=CC=C3C=C21 MWPLVEDNUUSJAV-UHFFFAOYSA-N 0.000 description 2

- WZJYKHNJTSNBHV-UHFFFAOYSA-N benzo[h]quinoline Chemical compound C1=CN=C2C3=CC=CC=C3C=CC2=C1 WZJYKHNJTSNBHV-UHFFFAOYSA-N 0.000 description 2

- IOJUPLGTWVMSFF-UHFFFAOYSA-N benzothiazole Chemical compound C1=CC=C2SC=NC2=C1 IOJUPLGTWVMSFF-UHFFFAOYSA-N 0.000 description 2

- 230000003197 catalytic effect Effects 0.000 description 2

- 125000000000 cycloalkoxy group Chemical group 0.000 description 2

- MWKFXSUHUHTGQN-UHFFFAOYSA-N decan-1-ol Chemical compound CCCCCCCCCCO MWKFXSUHUHTGQN-UHFFFAOYSA-N 0.000 description 2

- 238000000354 decomposition reaction Methods 0.000 description 2

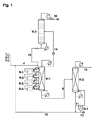

- 238000010586 diagram Methods 0.000 description 2

- TXCDCPKCNAJMEE-UHFFFAOYSA-N dibenzofuran Chemical compound C1=CC=C2C3=CC=CC=C3OC2=C1 TXCDCPKCNAJMEE-UHFFFAOYSA-N 0.000 description 2

- IYYZUPMFVPLQIF-UHFFFAOYSA-N dibenzothiophene Chemical compound C1=CC=C2C3=CC=CC=C3SC2=C1 IYYZUPMFVPLQIF-UHFFFAOYSA-N 0.000 description 2

- ZUOUZKKEUPVFJK-UHFFFAOYSA-N diphenyl Chemical class C1=CC=CC=C1C1=CC=CC=C1 ZUOUZKKEUPVFJK-UHFFFAOYSA-N 0.000 description 2

- KZTYYGOKRVBIMI-UHFFFAOYSA-N diphenyl sulfone Chemical compound C=1C=CC=CC=1S(=O)(=O)C1=CC=CC=C1 KZTYYGOKRVBIMI-UHFFFAOYSA-N 0.000 description 2

- ZSIAUFGUXNUGDI-UHFFFAOYSA-N hexan-1-ol Chemical compound CCCCCCO ZSIAUFGUXNUGDI-UHFFFAOYSA-N 0.000 description 2

- 238000006460 hydrolysis reaction Methods 0.000 description 2

- 125000002887 hydroxy group Chemical group [H]O* 0.000 description 2

- ZXEKIIBDNHEJCQ-UHFFFAOYSA-N isobutanol Chemical compound CC(C)CO ZXEKIIBDNHEJCQ-UHFFFAOYSA-N 0.000 description 2

- AWJUIBRHMBBTKR-UHFFFAOYSA-N isoquinoline Chemical compound C1=NC=CC2=CC=CC=C21 AWJUIBRHMBBTKR-UHFFFAOYSA-N 0.000 description 2

- 150000002576 ketones Chemical class 0.000 description 2

- NUJOXMJBOLGQSY-UHFFFAOYSA-N manganese dioxide Chemical compound O=[Mn]=O NUJOXMJBOLGQSY-UHFFFAOYSA-N 0.000 description 2

- 229940099596 manganese sulfate Drugs 0.000 description 2

- 239000011702 manganese sulphate Substances 0.000 description 2

- 235000007079 manganese sulphate Nutrition 0.000 description 2

- SQQMAOCOWKFBNP-UHFFFAOYSA-L manganese(II) sulfate Chemical compound [Mn+2].[O-]S([O-])(=O)=O SQQMAOCOWKFBNP-UHFFFAOYSA-L 0.000 description 2

- 125000005397 methacrylic acid ester group Chemical group 0.000 description 2

- VNWKTOKETHGBQD-UHFFFAOYSA-N methane Chemical compound C VNWKTOKETHGBQD-UHFFFAOYSA-N 0.000 description 2

- UHOVQNZJYSORNB-UHFFFAOYSA-N monobenzene Natural products C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 description 2

- ZWRUINPWMLAQRD-UHFFFAOYSA-N nonan-1-ol Chemical compound CCCCCCCCCO ZWRUINPWMLAQRD-UHFFFAOYSA-N 0.000 description 2

- YNPNZTXNASCQKK-UHFFFAOYSA-N phenanthrene Chemical compound C1=CC=C2C3=CC=CC=C3C=CC2=C1 YNPNZTXNASCQKK-UHFFFAOYSA-N 0.000 description 2

- 239000002243 precursor Substances 0.000 description 2

- CPNGPNLZQNNVQM-UHFFFAOYSA-N pteridine Chemical compound N1=CN=CC2=NC=CN=C21 CPNGPNLZQNNVQM-UHFFFAOYSA-N 0.000 description 2

- 238000000746 purification Methods 0.000 description 2

- JWVCLYRUEFBMGU-UHFFFAOYSA-N quinazoline Chemical compound N1=CN=CC2=CC=CC=C21 JWVCLYRUEFBMGU-UHFFFAOYSA-N 0.000 description 2

- 125000001424 substituent group Chemical group 0.000 description 2

- 229910052717 sulfur Inorganic materials 0.000 description 2

- FIDRAVVQGKNYQK-UHFFFAOYSA-N 1,2,3,4-tetrahydrotriazine Chemical compound C1NNNC=C1 FIDRAVVQGKNYQK-UHFFFAOYSA-N 0.000 description 1

- FNQJDLTXOVEEFB-UHFFFAOYSA-N 1,2,3-benzothiadiazole Chemical compound C1=CC=C2SN=NC2=C1 FNQJDLTXOVEEFB-UHFFFAOYSA-N 0.000 description 1

- OWQPOVKKUWUEKE-UHFFFAOYSA-N 1,2,3-benzotriazine Chemical compound N1=NN=CC2=CC=CC=C21 OWQPOVKKUWUEKE-UHFFFAOYSA-N 0.000 description 1

- SLLFVLKNXABYGI-UHFFFAOYSA-N 1,2,3-benzoxadiazole Chemical compound C1=CC=C2ON=NC2=C1 SLLFVLKNXABYGI-UHFFFAOYSA-N 0.000 description 1

- BBVIDBNAYOIXOE-UHFFFAOYSA-N 1,2,4-oxadiazole Chemical compound C=1N=CON=1 BBVIDBNAYOIXOE-UHFFFAOYSA-N 0.000 description 1

- YGTAZGSLCXNBQL-UHFFFAOYSA-N 1,2,4-thiadiazole Chemical compound C=1N=CSN=1 YGTAZGSLCXNBQL-UHFFFAOYSA-N 0.000 description 1

- FYADHXFMURLYQI-UHFFFAOYSA-N 1,2,4-triazine Chemical compound C1=CN=NC=N1 FYADHXFMURLYQI-UHFFFAOYSA-N 0.000 description 1

- CSNIZNHTOVFARY-UHFFFAOYSA-N 1,2-benzothiazole Chemical compound C1=CC=C2C=NSC2=C1 CSNIZNHTOVFARY-UHFFFAOYSA-N 0.000 description 1

- KTZQTRPPVKQPFO-UHFFFAOYSA-N 1,2-benzoxazole Chemical compound C1=CC=C2C=NOC2=C1 KTZQTRPPVKQPFO-UHFFFAOYSA-N 0.000 description 1

- FKASFBLJDCHBNZ-UHFFFAOYSA-N 1,3,4-oxadiazole Chemical compound C1=NN=CO1 FKASFBLJDCHBNZ-UHFFFAOYSA-N 0.000 description 1

- MBIZXFATKUQOOA-UHFFFAOYSA-N 1,3,4-thiadiazole Chemical compound C1=NN=CS1 MBIZXFATKUQOOA-UHFFFAOYSA-N 0.000 description 1

- JIHQDMXYYFUGFV-UHFFFAOYSA-N 1,3,5-triazine Chemical compound C1=NC=NC=N1 JIHQDMXYYFUGFV-UHFFFAOYSA-N 0.000 description 1

- BCMCBBGGLRIHSE-UHFFFAOYSA-N 1,3-benzoxazole Chemical compound C1=CC=C2OC=NC2=C1 BCMCBBGGLRIHSE-UHFFFAOYSA-N 0.000 description 1

- VSOSXKMEQPYESP-UHFFFAOYSA-N 1,6-naphthyridine Chemical compound C1=CN=CC2=CC=CN=C21 VSOSXKMEQPYESP-UHFFFAOYSA-N 0.000 description 1

- MXBVNILGVJVVMH-UHFFFAOYSA-N 1,7-naphthyridine Chemical compound C1=NC=CC2=CC=CN=C21 MXBVNILGVJVVMH-UHFFFAOYSA-N 0.000 description 1

- FLBAYUMRQUHISI-UHFFFAOYSA-N 1,8-naphthyridine Chemical compound N1=CC=CC2=CC=CN=C21 FLBAYUMRQUHISI-UHFFFAOYSA-N 0.000 description 1

- WJFKNYWRSNBZNX-UHFFFAOYSA-N 10H-phenothiazine Chemical compound C1=CC=C2NC3=CC=CC=C3SC2=C1 WJFKNYWRSNBZNX-UHFFFAOYSA-N 0.000 description 1

- TZMSYXZUNZXBOL-UHFFFAOYSA-N 10H-phenoxazine Chemical compound C1=CC=C2NC3=CC=CC=C3OC2=C1 TZMSYXZUNZXBOL-UHFFFAOYSA-N 0.000 description 1

- HYZJCKYKOHLVJF-UHFFFAOYSA-N 1H-benzimidazole Chemical compound C1=CC=C2NC=NC2=C1 HYZJCKYKOHLVJF-UHFFFAOYSA-N 0.000 description 1

- BAXOFTOLAUCFNW-UHFFFAOYSA-N 1H-indazole Chemical compound C1=CC=C2C=NNC2=C1 BAXOFTOLAUCFNW-UHFFFAOYSA-N 0.000 description 1

- KJUGUADJHNHALS-UHFFFAOYSA-N 1H-tetrazole Chemical compound C=1N=NNN=1 KJUGUADJHNHALS-UHFFFAOYSA-N 0.000 description 1

- VEPOHXYIFQMVHW-XOZOLZJESA-N 2,3-dihydroxybutanedioic acid (2S,3S)-3,4-dimethyl-2-phenylmorpholine Chemical compound OC(C(O)C(O)=O)C(O)=O.C[C@H]1[C@@H](OCCN1C)c1ccccc1 VEPOHXYIFQMVHW-XOZOLZJESA-N 0.000 description 1

- DCJKUXYSYJBBRD-UHFFFAOYSA-N 2,5-diphenyl-1,3,4-oxadiazole Chemical compound C1=CC=CC=C1C1=NN=C(C=2C=CC=CC=2)O1 DCJKUXYSYJBBRD-UHFFFAOYSA-N 0.000 description 1

- UXGVMFHEKMGWMA-UHFFFAOYSA-N 2-benzofuran Chemical compound C1=CC=CC2=COC=C21 UXGVMFHEKMGWMA-UHFFFAOYSA-N 0.000 description 1

- LYTMVABTDYMBQK-UHFFFAOYSA-N 2-benzothiophene Chemical compound C1=CC=CC2=CSC=C21 LYTMVABTDYMBQK-UHFFFAOYSA-N 0.000 description 1

- 125000004974 2-butenyl group Chemical group C(C=CC)* 0.000 description 1

- 125000004493 2-methylbut-1-yl group Chemical group CC(C*)CC 0.000 description 1

- 125000006024 2-pentenyl group Chemical group 0.000 description 1

- MILSYCKGLDDVLM-UHFFFAOYSA-N 2-phenylpropan-2-ylbenzene Chemical class C=1C=CC=CC=1C(C)(C)C1=CC=CC=C1 MILSYCKGLDDVLM-UHFFFAOYSA-N 0.000 description 1

- 125000003903 2-propenyl group Chemical group [H]C([*])([H])C([H])=C([H])[H] 0.000 description 1

- VHMICKWLTGFITH-UHFFFAOYSA-N 2H-isoindole Chemical compound C1=CC=CC2=CNC=C21 VHMICKWLTGFITH-UHFFFAOYSA-N 0.000 description 1

- LLTSIOOHJBUDCP-UHFFFAOYSA-N 3,4,5-triphenyl-1,2,4-triazole Chemical compound C1=CC=CC=C1C(N1C=2C=CC=CC=2)=NN=C1C1=CC=CC=C1 LLTSIOOHJBUDCP-UHFFFAOYSA-N 0.000 description 1

- KPKQWXGFEKRQQA-UHFFFAOYSA-N 3,5-diphenyl-1h-1,2,4-triazole Chemical compound C1=CC=CC=C1C1=NNC(C=2C=CC=CC=2)=N1 KPKQWXGFEKRQQA-UHFFFAOYSA-N 0.000 description 1

- DBXBTMSZEOQQDU-UHFFFAOYSA-N 3-hydroxyisobutyric acid Chemical compound OCC(C)C(O)=O DBXBTMSZEOQQDU-UHFFFAOYSA-N 0.000 description 1

- 239000005964 Acibenzolar-S-methyl Substances 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 description 1

- NLHHRLWOUZZQLW-UHFFFAOYSA-N Acrylonitrile Chemical compound C=CC#N NLHHRLWOUZZQLW-UHFFFAOYSA-N 0.000 description 1

- ROFVEXUMMXZLPA-UHFFFAOYSA-N Bipyridyl Chemical compound N1=CC=CC=C1C1=CC=CC=N1 ROFVEXUMMXZLPA-UHFFFAOYSA-N 0.000 description 1

- WKBOTKDWSSQWDR-UHFFFAOYSA-N Bromine atom Chemical compound [Br] WKBOTKDWSSQWDR-UHFFFAOYSA-N 0.000 description 1

- ZTQSAGDEMFDKMZ-UHFFFAOYSA-N Butyraldehyde Chemical compound CCCC=O ZTQSAGDEMFDKMZ-UHFFFAOYSA-N 0.000 description 1

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 1

- ZAMOUSCENKQFHK-UHFFFAOYSA-N Chlorine atom Chemical compound [Cl] ZAMOUSCENKQFHK-UHFFFAOYSA-N 0.000 description 1

- 229910052692 Dysprosium Inorganic materials 0.000 description 1

- 229910052691 Erbium Inorganic materials 0.000 description 1

- 229910052693 Europium Inorganic materials 0.000 description 1

- PXGOKWXKJXAPGV-UHFFFAOYSA-N Fluorine Chemical compound FF PXGOKWXKJXAPGV-UHFFFAOYSA-N 0.000 description 1

- 229910052688 Gadolinium Inorganic materials 0.000 description 1

- 229910052689 Holmium Inorganic materials 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- VVQNEPGJFQJSBK-UHFFFAOYSA-N Methyl methacrylate Chemical compound COC(=O)C(C)=C VVQNEPGJFQJSBK-UHFFFAOYSA-N 0.000 description 1

- 229910052779 Neodymium Inorganic materials 0.000 description 1

- ZCQWOFVYLHDMMC-UHFFFAOYSA-N Oxazole Chemical compound C1=COC=N1 ZCQWOFVYLHDMMC-UHFFFAOYSA-N 0.000 description 1

- 229910052777 Praseodymium Inorganic materials 0.000 description 1

- CZPWVGJYEJSRLH-UHFFFAOYSA-N Pyrimidine Chemical compound C1=CN=CN=C1 CZPWVGJYEJSRLH-UHFFFAOYSA-N 0.000 description 1

- 229910052772 Samarium Inorganic materials 0.000 description 1

- DPOPAJRDYZGTIR-UHFFFAOYSA-N Tetrazine Chemical compound C1=CN=NN=N1 DPOPAJRDYZGTIR-UHFFFAOYSA-N 0.000 description 1

- FZWLAAWBMGSTSO-UHFFFAOYSA-N Thiazole Chemical compound C1=CSC=N1 FZWLAAWBMGSTSO-UHFFFAOYSA-N 0.000 description 1

- 241000736892 Thujopsis dolabrata Species 0.000 description 1

- 229910052775 Thulium Inorganic materials 0.000 description 1

- 238000006887 Ullmann reaction Methods 0.000 description 1

- 229910052769 Ytterbium Inorganic materials 0.000 description 1

- DGEZNRSVGBDHLK-UHFFFAOYSA-N [1,10]phenanthroline Chemical compound C1=CN=C2C3=NC=CC=C3C=CC2=C1 DGEZNRSVGBDHLK-UHFFFAOYSA-N 0.000 description 1

- IKHGUXGNUITLKF-XPULMUKRSA-N acetaldehyde Chemical compound [14CH]([14CH3])=O IKHGUXGNUITLKF-XPULMUKRSA-N 0.000 description 1

- 230000002378 acidificating effect Effects 0.000 description 1

- 150000007513 acids Chemical class 0.000 description 1

- 125000005396 acrylic acid ester group Chemical group 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 1

- 125000001931 aliphatic group Chemical group 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 150000001412 amines Chemical class 0.000 description 1

- 239000007864 aqueous solution Substances 0.000 description 1

- 125000001204 arachidyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 150000001491 aromatic compounds Chemical class 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 150000001555 benzenes Chemical class 0.000 description 1

- BTZVACANDIHKJX-UHFFFAOYSA-N benzo[g]pteridine Chemical compound N1=CN=CC2=NC3=CC=CC=C3N=C21 BTZVACANDIHKJX-UHFFFAOYSA-N 0.000 description 1

- QRUDEWIWKLJBPS-UHFFFAOYSA-N benzotriazole Chemical compound C1=CC=C2N[N][N]C2=C1 QRUDEWIWKLJBPS-UHFFFAOYSA-N 0.000 description 1

- 239000012964 benzotriazole Substances 0.000 description 1

- 239000004305 biphenyl Chemical class 0.000 description 1

- 235000010290 biphenyl Nutrition 0.000 description 1

- GDTBXPJZTBHREO-UHFFFAOYSA-N bromine Substances BrBr GDTBXPJZTBHREO-UHFFFAOYSA-N 0.000 description 1

- 229910052794 bromium Inorganic materials 0.000 description 1

- BRPQOXSCLDDYGP-UHFFFAOYSA-N calcium oxide Chemical compound [O-2].[Ca+2] BRPQOXSCLDDYGP-UHFFFAOYSA-N 0.000 description 1

- 239000000292 calcium oxide Substances 0.000 description 1

- ODINCKMPIJJUCX-UHFFFAOYSA-N calcium oxide Inorganic materials [Ca]=O ODINCKMPIJJUCX-UHFFFAOYSA-N 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 229910002091 carbon monoxide Inorganic materials 0.000 description 1

- 150000001728 carbonyl compounds Chemical class 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 238000006555 catalytic reaction Methods 0.000 description 1

- 238000012512 characterization method Methods 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 239000000460 chlorine Substances 0.000 description 1

- 229910052801 chlorine Inorganic materials 0.000 description 1

- WCZVZNOTHYJIEI-UHFFFAOYSA-N cinnoline Chemical compound N1=NC=CC2=CC=CC=C21 WCZVZNOTHYJIEI-UHFFFAOYSA-N 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 229920001577 copolymer Polymers 0.000 description 1

- 125000005366 cycloalkylthio group Chemical group 0.000 description 1

- 125000001995 cyclobutyl group Chemical group [H]C1([H])C([H])([H])C([H])(*)C1([H])[H] 0.000 description 1

- 125000000582 cycloheptyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C1([H])[H] 0.000 description 1

- 125000000113 cyclohexyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C1([H])[H] 0.000 description 1

- 125000000640 cyclooctyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])([H])C([H])(*)C([H])([H])C([H])([H])C1([H])[H] 0.000 description 1

- 125000001511 cyclopentyl group Chemical group [H]C1([H])C([H])([H])C([H])([H])C([H])(*)C1([H])[H] 0.000 description 1

- 125000001559 cyclopropyl group Chemical group [H]C1([H])C([H])([H])C1([H])* 0.000 description 1

- 230000007812 deficiency Effects 0.000 description 1

- 238000006731 degradation reaction Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- CZZYITDELCSZES-UHFFFAOYSA-N diphenylmethane Chemical class C=1C=CC=CC=1CC1=CC=CC=C1 CZZYITDELCSZES-UHFFFAOYSA-N 0.000 description 1

- 125000003438 dodecyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 238000005265 energy consumption Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 125000001495 ethyl group Chemical group [H]C([H])([H])C([H])([H])* 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 229910052731 fluorine Inorganic materials 0.000 description 1

- 239000011737 fluorine Substances 0.000 description 1

- 239000008187 granular material Substances 0.000 description 1

- 229910052736 halogen Inorganic materials 0.000 description 1

- 150000002367 halogens Chemical class 0.000 description 1

- 125000003187 heptyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 125000004051 hexyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 238000011065 in-situ storage Methods 0.000 description 1

- PZOUSPYUWWUPPK-UHFFFAOYSA-N indole Natural products CC1=CC=CC2=C1C=CN2 PZOUSPYUWWUPPK-UHFFFAOYSA-N 0.000 description 1

- RKJUIXBNRJVNHR-UHFFFAOYSA-N indolenine Natural products C1=CC=C2CC=NC2=C1 RKJUIXBNRJVNHR-UHFFFAOYSA-N 0.000 description 1

- HOBCFUWDNJPFHB-UHFFFAOYSA-N indolizine Chemical compound C1=CC=CN2C=CC=C21 HOBCFUWDNJPFHB-UHFFFAOYSA-N 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 125000000959 isobutyl group Chemical group [H]C([H])([H])C([H])(C([H])([H])[H])C([H])([H])* 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 125000001449 isopropyl group Chemical group [H]C([H])([H])C([H])(*)C([H])([H])[H] 0.000 description 1

- ZLTPDFXIESTBQG-UHFFFAOYSA-N isothiazole Chemical compound C=1C=NSC=1 ZLTPDFXIESTBQG-UHFFFAOYSA-N 0.000 description 1

- CTAPFRYPJLPFDF-UHFFFAOYSA-N isoxazole Chemical compound C=1C=NOC=1 CTAPFRYPJLPFDF-UHFFFAOYSA-N 0.000 description 1

- 150000002604 lanthanum compounds Chemical class 0.000 description 1

- 150000002611 lead compounds Chemical class 0.000 description 1

- 239000000395 magnesium oxide Substances 0.000 description 1

- CPLXHLVBOLITMK-UHFFFAOYSA-N magnesium oxide Inorganic materials [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 description 1

- AXZKOIWUVFPNLO-UHFFFAOYSA-N magnesium;oxygen(2-) Chemical compound [O-2].[Mg+2] AXZKOIWUVFPNLO-UHFFFAOYSA-N 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 125000002496 methyl group Chemical group [H]C([H])([H])* 0.000 description 1

- 125000001570 methylene group Chemical group [H]C([H])([*:1])[*:2] 0.000 description 1

- 125000004108 n-butyl group Chemical group [H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])* 0.000 description 1

- 125000001400 nonyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 125000002347 octyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 150000002894 organic compounds Chemical class 0.000 description 1

- 150000002902 organometallic compounds Chemical class 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 125000002958 pentadecyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 125000001147 pentyl group Chemical group C(CCCC)* 0.000 description 1

- 229950000688 phenothiazine Drugs 0.000 description 1

- LFSXCDWNBUNEEM-UHFFFAOYSA-N phthalazine Chemical compound C1=NN=CC2=CC=CC=C21 LFSXCDWNBUNEEM-UHFFFAOYSA-N 0.000 description 1

- 229920000642 polymer Polymers 0.000 description 1

- 230000008092 positive effect Effects 0.000 description 1

- 239000012286 potassium permanganate Substances 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- BDERNNFJNOPAEC-UHFFFAOYSA-N propan-1-ol Chemical compound CCCO BDERNNFJNOPAEC-UHFFFAOYSA-N 0.000 description 1

- 125000001436 propyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- PBMFSQRYOILNGV-UHFFFAOYSA-N pyridazine Chemical compound C1=CC=NN=C1 PBMFSQRYOILNGV-UHFFFAOYSA-N 0.000 description 1

- UMJSCPRVCHMLSP-UHFFFAOYSA-N pyridine Natural products COC1=CC=CN=C1 UMJSCPRVCHMLSP-UHFFFAOYSA-N 0.000 description 1

- BWESROVQGZSBRX-UHFFFAOYSA-N pyrido[3,2-d]pyrimidine Chemical compound C1=NC=NC2=CC=CN=C21 BWESROVQGZSBRX-UHFFFAOYSA-N 0.000 description 1

- 150000003254 radicals Chemical class 0.000 description 1

- 238000012216 screening Methods 0.000 description 1

- 125000002914 sec-butyl group Chemical group [H]C([H])([H])C([H])([H])C([H])(*)C([H])([H])[H] 0.000 description 1

- 238000001577 simple distillation Methods 0.000 description 1

- 239000002002 slurry Substances 0.000 description 1

- 230000002194 synthesizing effect Effects 0.000 description 1

- 125000000999 tert-butyl group Chemical group [H]C([H])([H])C(*)(C([H])([H])[H])C([H])([H])[H] 0.000 description 1

- 125000001973 tert-pentyl group Chemical group [H]C([H])([H])C([H])([H])C(*)(C([H])([H])[H])C([H])([H])[H] 0.000 description 1

- 229930192474 thiophene Natural products 0.000 description 1

- 125000002948 undecyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 description 1

- 125000000391 vinyl group Chemical group [H]C([*])=C([H])[H] 0.000 description 1

- 229920002554 vinyl polymer Polymers 0.000 description 1

- 238000010626 work up procedure Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C67/00—Preparation of carboxylic acid esters

- C07C67/18—Preparation of carboxylic acid esters by conversion of a group containing nitrogen into an ester group

- C07C67/20—Preparation of carboxylic acid esters by conversion of a group containing nitrogen into an ester group from amides or lactams

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C67/00—Preparation of carboxylic acid esters

- C07C67/48—Separation; Purification; Stabilisation; Use of additives

- C07C67/52—Separation; Purification; Stabilisation; Use of additives by change in the physical state, e.g. crystallisation

- C07C67/54—Separation; Purification; Stabilisation; Use of additives by change in the physical state, e.g. crystallisation by distillation

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C69/00—Esters of carboxylic acids; Esters of carbonic or haloformic acids

- C07C69/66—Esters of carboxylic acids having esterified carboxylic groups bound to acyclic carbon atoms and having any of the groups OH, O—metal, —CHO, keto, ether, acyloxy, groups, groups, or in the acid moiety

- C07C69/67—Esters of carboxylic acids having esterified carboxylic groups bound to acyclic carbon atoms and having any of the groups OH, O—metal, —CHO, keto, ether, acyloxy, groups, groups, or in the acid moiety of saturated acids

- C07C69/675—Esters of carboxylic acids having esterified carboxylic groups bound to acyclic carbon atoms and having any of the groups OH, O—metal, —CHO, keto, ether, acyloxy, groups, groups, or in the acid moiety of saturated acids of saturated hydroxy-carboxylic acids

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/10—Process efficiency

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Crystallography & Structural Chemistry (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

- Low-Molecular Organic Synthesis Reactions Using Catalysts (AREA)

Applications Claiming Priority (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102006022896.0 | 2006-05-15 | ||

| DE200610022896 DE102006022896A1 (de) | 2006-05-15 | 2006-05-15 | Verfahren zur Herstellung von Alpha-Hydroxycarbonsäuren |

| US89378807P | 2007-03-08 | 2007-03-08 | |

| US60/893,788 | 2007-03-08 | ||

| DE102007011706.1 | 2007-03-08 | ||

| DE102007011706A DE102007011706A1 (de) | 2007-03-08 | 2007-03-08 | Verfahren zur Herstellung von Alpha-Hydroxycarbonsäuren |

| PCT/EP2007/052951 WO2007131829A1 (de) | 2006-05-15 | 2007-03-28 | Verfahren zur herstellung von alpha-hydroxycarbonsäureestern |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2009537471A JP2009537471A (ja) | 2009-10-29 |

| JP2009537471A5 JP2009537471A5 (enExample) | 2013-07-11 |

| JP5517610B2 true JP5517610B2 (ja) | 2014-06-11 |

Family

ID=38180532

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009510374A Expired - Fee Related JP5517610B2 (ja) | 2006-05-15 | 2007-03-28 | α−ヒドロキシカルボン酸エステルの製造法 |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US8569539B2 (enExample) |

| EP (1) | EP2018362A1 (enExample) |

| JP (1) | JP5517610B2 (enExample) |

| KR (1) | KR101365790B1 (enExample) |

| CA (1) | CA2652315A1 (enExample) |

| MX (1) | MX2008014641A (enExample) |

| TW (1) | TWI414512B (enExample) |

| WO (1) | WO2007131829A1 (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102006025821A1 (de) * | 2006-06-02 | 2007-12-06 | Degussa Gmbh | Ein Enzym zur Herstellung von Mehylmalonatsemialdehyd oder Malonatsemialdehyd |

| DE102007015583A1 (de) * | 2007-03-29 | 2008-10-02 | Albert-Ludwigs-Universität Freiburg | Ein Enzym zur Herstellung von Methylmalonyl-Coenzym A oder Ethylmalonyl-Coenzym A sowie dessen Verwendung |

| DE102008001319A1 (de) * | 2008-04-22 | 2009-10-29 | Evonik Röhm Gmbh | Katalysator zur Umsetzung von Carbonsäurenitrilen |

| DE102008044218A1 (de) | 2008-12-01 | 2010-06-02 | Evonik Röhm Gmbh | Verfahren zur Herstellung von einem Carbonsäureamid aus einer Carbonylverbindung und Blausäure |

| DE102011081256A1 (de) * | 2011-08-19 | 2013-02-21 | Evonik Röhm Gmbh | Verfahren zur Herstellung von Alpha-Hydroxycarbonsäureestern |

| DE102013000602A1 (de) | 2013-01-16 | 2014-07-17 | Evonik Industries Ag | Verfahren zur Herstellung von Acrylsäure |

| DE102014205304A1 (de) | 2014-03-21 | 2015-09-24 | Evonik Industries Ag | Verfahren zur Abtrennung von Ammoniak aus alkoholischer Lösung in Gegenwart von Kohlensäureverbindungen |

| US10227284B2 (en) | 2014-09-10 | 2019-03-12 | Evonik Roehm Gmbh | Method for preparing alpha-hydroxycarboxylic acid esters in which ammonia is recycled |

| DE102016210285A1 (de) | 2016-06-10 | 2017-12-14 | Evonik Röhm Gmbh | Verfahren zur Herstellung von Methacrylaten und Methacrylsäure |

| KR20250054251A (ko) | 2023-10-13 | 2025-04-23 | 복미경 | 보령머드를 이용한 반려동물 아토피 피부 개선용 머드 테라피 및 이의 제조방법 및 이를 통한 머드로 펫 케어 서비스 제공방법. |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2315498A1 (fr) * | 1975-06-26 | 1977-01-21 | Roehm Gmbh | Procede de preparation d'esters d'acides carboxyliques a partir d'amines d'acides carboxyliques |

| JPS5855444A (ja) * | 1981-09-25 | 1983-04-01 | Mitsubishi Gas Chem Co Inc | カルボン酸エステルの製造法 |

| ES2200429T3 (es) | 1998-03-25 | 2004-03-01 | Mitsubishi Gas Chemical Company, Inc. | Procedimiento de preparacion de alfa-hidroxicarboxilato. |

| KR19990078213A (ko) * | 1998-03-25 | 1999-10-25 | 오오히라 아키라 | α-히드록시카르복실산에스테르의 제조방법 |

| JP4139927B2 (ja) * | 1998-12-03 | 2008-08-27 | 三菱瓦斯化学株式会社 | α−ヒドロキシカルボン酸エステルの製造方法 |

| DE10034194A1 (de) | 2000-07-13 | 2003-09-11 | Roehm Gmbh | Verfahren zur Herstellung von Cyanwasserstoff |

| DE10200171A1 (de) | 2002-01-04 | 2003-07-10 | Roehm Gmbh | Verfahren zur kontinuierlichen Herstellung von Alkyl(meth)acrylaten |

| DE10301007A1 (de) | 2003-01-13 | 2004-07-22 | Röhm GmbH & Co. KG | Verbessertes Verfahren zur kontinuierlichen Herstellung von Alkyl(meth)acrylaten mit mehrfacher Katalysatorrezyklierung. |

| DE102004013847A1 (de) | 2004-03-20 | 2005-10-06 | Degussa Ag | Cyanidtolerante Nitrilhydratasen |

| DE102004013824A1 (de) | 2004-03-20 | 2005-10-13 | Degussa Ag | Nitrilhydratasen aus Rhodococcus opacus |

| DE102005023976A1 (de) | 2005-05-20 | 2006-11-23 | Röhm Gmbh | Verfahren zur Umesterung |

| DE102005023975A1 (de) | 2005-05-20 | 2006-11-23 | Röhm Gmbh | Verfahren zur Herstellung von Alkyl(meth)acrylaten |

| DE102005043719A1 (de) | 2005-09-13 | 2007-03-15 | Röhm Gmbh | Vorrichtung und Verfahren für kontinuierlich durchgeführte Gleichgewichtsreaktionen |

| DE102006029318B3 (de) | 2006-06-23 | 2007-10-11 | Röhm Gmbh | Verfahren zur kontinuierlichen Herstellung von ungesättigten Carbonsäureanhydriden |

| DE102008001319A1 (de) | 2008-04-22 | 2009-10-29 | Evonik Röhm Gmbh | Katalysator zur Umsetzung von Carbonsäurenitrilen |

| DE102008044218A1 (de) | 2008-12-01 | 2010-06-02 | Evonik Röhm Gmbh | Verfahren zur Herstellung von einem Carbonsäureamid aus einer Carbonylverbindung und Blausäure |

-

2007

- 2007-03-28 MX MX2008014641A patent/MX2008014641A/es active IP Right Grant

- 2007-03-28 US US12/298,034 patent/US8569539B2/en not_active Expired - Fee Related

- 2007-03-28 KR KR1020087027958A patent/KR101365790B1/ko not_active Expired - Fee Related

- 2007-03-28 JP JP2009510374A patent/JP5517610B2/ja not_active Expired - Fee Related

- 2007-03-28 WO PCT/EP2007/052951 patent/WO2007131829A1/de not_active Ceased

- 2007-03-28 CA CA002652315A patent/CA2652315A1/en not_active Abandoned

- 2007-03-28 EP EP07727424A patent/EP2018362A1/de not_active Withdrawn

- 2007-05-10 TW TW096116683A patent/TWI414512B/zh active

Also Published As

| Publication number | Publication date |

|---|---|

| TWI414512B (zh) | 2013-11-11 |

| KR20090009869A (ko) | 2009-01-23 |

| TW200812957A (en) | 2008-03-16 |

| US20090182167A1 (en) | 2009-07-16 |

| EP2018362A1 (de) | 2009-01-28 |

| CA2652315A1 (en) | 2007-11-22 |

| US8569539B2 (en) | 2013-10-29 |

| JP2009537471A (ja) | 2009-10-29 |

| WO2007131829A1 (de) | 2007-11-22 |

| KR101365790B1 (ko) | 2014-02-20 |

| MX2008014641A (es) | 2008-11-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5517610B2 (ja) | α−ヒドロキシカルボン酸エステルの製造法 | |

| US20090209781A1 (en) | Process for preparing alpha-hydroxycarboxylic acids | |

| TWI471291B (zh) | 由羰基化合物和氰化氫製備羧醯胺的方法 | |

| JP2014531410A (ja) | α−ヒドロキシカルボン酸エステルの製造法 | |

| CN101448774B (zh) | 制备α-羟基羧酸的方法 | |

| US20160137583A1 (en) | Method for producing alpha-hydroxycarboxylic acid esters | |

| RU2454399C2 (ru) | Способ получения альфа-гидроксикарбоновых кислот | |

| DE102007011706A1 (de) | Verfahren zur Herstellung von Alpha-Hydroxycarbonsäuren | |

| US10227284B2 (en) | Method for preparing alpha-hydroxycarboxylic acid esters in which ammonia is recycled | |

| US9809530B2 (en) | Method for producing alpha-hydroxy carboxylic esters in the gas phase |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100318 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20101228 Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20101227 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20121024 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20121102 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130204 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130212 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20130304 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20130311 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20130326 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20130805 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20131205 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20131205 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20140108 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20140303 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140401 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5517610 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| S531 | Written request for registration of change of domicile |

Free format text: JAPANESE INTERMEDIATE CODE: R313531 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |