JP5457037B2 - 基板縁部への不活性ガスの注入 - Google Patents

基板縁部への不活性ガスの注入 Download PDFInfo

- Publication number

- JP5457037B2 JP5457037B2 JP2008556370A JP2008556370A JP5457037B2 JP 5457037 B2 JP5457037 B2 JP 5457037B2 JP 2008556370 A JP2008556370 A JP 2008556370A JP 2008556370 A JP2008556370 A JP 2008556370A JP 5457037 B2 JP5457037 B2 JP 5457037B2

- Authority

- JP

- Japan

- Prior art keywords

- gas

- substrate

- edge

- adjustment

- substrate support

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000758 substrate Substances 0.000 title claims description 159

- 238000002347 injection Methods 0.000 title claims description 47

- 239000007924 injection Substances 0.000 title claims description 47

- 239000011261 inert gas Substances 0.000 title claims description 21

- 239000007789 gas Substances 0.000 claims description 192

- 230000003750 conditioning effect Effects 0.000 claims description 57

- 238000000034 method Methods 0.000 claims description 25

- 230000001143 conditioned effect Effects 0.000 claims description 10

- 238000009826 distribution Methods 0.000 claims description 6

- 230000001105 regulatory effect Effects 0.000 claims description 5

- 238000005530 etching Methods 0.000 description 37

- 230000008021 deposition Effects 0.000 description 16

- 230000008569 process Effects 0.000 description 15

- 239000006227 byproduct Substances 0.000 description 11

- 239000000463 material Substances 0.000 description 7

- 230000008878 coupling Effects 0.000 description 6

- 238000010168 coupling process Methods 0.000 description 6

- 238000005859 coupling reaction Methods 0.000 description 6

- 239000004065 semiconductor Substances 0.000 description 6

- 230000007246 mechanism Effects 0.000 description 5

- 238000001020 plasma etching Methods 0.000 description 5

- 230000001965 increasing effect Effects 0.000 description 4

- 239000011810 insulating material Substances 0.000 description 4

- 239000012212 insulator Substances 0.000 description 4

- 238000001816 cooling Methods 0.000 description 3

- 230000001808 coupling effect Effects 0.000 description 3

- 238000010586 diagram Methods 0.000 description 3

- 230000009977 dual effect Effects 0.000 description 3

- 239000000203 mixture Substances 0.000 description 3

- 230000002093 peripheral effect Effects 0.000 description 3

- 229920000642 polymer Polymers 0.000 description 3

- 239000010453 quartz Substances 0.000 description 3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 3

- 125000006850 spacer group Chemical group 0.000 description 3

- 238000004380 ashing Methods 0.000 description 2

- 239000003989 dielectric material Substances 0.000 description 2

- 230000001939 inductive effect Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 229920002120 photoresistant polymer Polymers 0.000 description 2

- 238000009825 accumulation Methods 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 239000000919 ceramic Substances 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 238000005137 deposition process Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000007935 neutral effect Effects 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 238000006116 polymerization reaction Methods 0.000 description 1

- 239000000376 reactant Substances 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 238000005549 size reduction Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

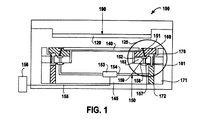

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67017—Apparatus for fluid treatment

- H01L21/67063—Apparatus for fluid treatment for etching

- H01L21/67069—Apparatus for fluid treatment for etching for drying etching

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23F—NON-MECHANICAL REMOVAL OF METALLIC MATERIAL FROM SURFACE; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL; MULTI-STEP PROCESSES FOR SURFACE TREATMENT OF METALLIC MATERIAL INVOLVING AT LEAST ONE PROCESS PROVIDED FOR IN CLASS C23 AND AT LEAST ONE PROCESS COVERED BY SUBCLASS C21D OR C22F OR CLASS C25

- C23F1/00—Etching metallic material by chemical means

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/455—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for introducing gases into reaction chamber or for modifying gas flows in reaction chamber

- C23C16/45519—Inert gas curtains

- C23C16/45521—Inert gas curtains the gas, other than thermal contact gas, being introduced the rear of the substrate to flow around its periphery

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/458—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating characterised by the method used for supporting substrates in the reaction chamber

- C23C16/4582—Rigid and flat substrates, e.g. plates or discs

- C23C16/4583—Rigid and flat substrates, e.g. plates or discs the substrate being supported substantially horizontally

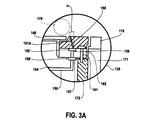

- C23C16/4585—Devices at or outside the perimeter of the substrate support, e.g. clamping rings, shrouds

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32431—Constructional details of the reactor

- H01J37/3244—Gas supply means

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/306—Chemical or electrical treatment, e.g. electrolytic etching

- H01L21/3065—Plasma etching; Reactive-ion etching

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/683—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping

- H01L21/687—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches

- H01L21/68714—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support

- H01L21/68735—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere for supporting or gripping using mechanical means, e.g. chucks, clamps or pinches the wafers being placed on a susceptor, stage or support characterised by edge profile or support profile

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Organic Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- General Physics & Mathematics (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Plasma & Fusion (AREA)

- Analytical Chemistry (AREA)

- Drying Of Semiconductors (AREA)

- Chemical Vapour Deposition (AREA)

- Plasma Technology (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US11/359,300 | 2006-02-21 | ||

| US11/359,300 US8097120B2 (en) | 2006-02-21 | 2006-02-21 | Process tuning gas injection from the substrate edge |

| PCT/US2007/004225 WO2007098071A2 (en) | 2006-02-21 | 2007-02-16 | Process tuning gas injection from the substrate edge |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013118462A Division JP2013211586A (ja) | 2006-02-21 | 2013-06-05 | 基板縁部からの処理調整ガスの注入 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2009527921A JP2009527921A (ja) | 2009-07-30 |

| JP2009527921A5 JP2009527921A5 (enExample) | 2010-04-02 |

| JP5457037B2 true JP5457037B2 (ja) | 2014-04-02 |

Family

ID=38426959

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008556370A Active JP5457037B2 (ja) | 2006-02-21 | 2007-02-16 | 基板縁部への不活性ガスの注入 |

| JP2013118462A Pending JP2013211586A (ja) | 2006-02-21 | 2013-06-05 | 基板縁部からの処理調整ガスの注入 |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2013118462A Pending JP2013211586A (ja) | 2006-02-21 | 2013-06-05 | 基板縁部からの処理調整ガスの注入 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US8097120B2 (enExample) |

| JP (2) | JP5457037B2 (enExample) |

| KR (1) | KR101336446B1 (enExample) |

| CN (1) | CN101389788A (enExample) |

| SG (1) | SG170007A1 (enExample) |

| TW (1) | TWI364791B (enExample) |

| WO (1) | WO2007098071A2 (enExample) |

Families Citing this family (39)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4584722B2 (ja) * | 2005-01-13 | 2010-11-24 | シャープ株式会社 | プラズマ処理装置および同装置により製造された半導体素子 |

| US8097120B2 (en) * | 2006-02-21 | 2012-01-17 | Lam Research Corporation | Process tuning gas injection from the substrate edge |

| US7572737B1 (en) * | 2006-06-30 | 2009-08-11 | Lam Research Corporation | Apparatus and methods for adjusting an edge ring potential substrate processing |

| US20080194112A1 (en) * | 2007-02-09 | 2008-08-14 | International Business Machines Corporation | Method and system for plasma etching having improved across-wafer etch uniformity |

| JP5179482B2 (ja) * | 2007-05-09 | 2013-04-10 | 株式会社アルバック | パージガスアセンブリ |

| KR101437522B1 (ko) * | 2007-09-05 | 2014-09-03 | 어플라이드 머티어리얼스, 인코포레이티드 | 플라즈마 반응기 챔버에서 웨이퍼 에지 가스 주입부를 갖는캐소드 라이너 |

| US7832354B2 (en) * | 2007-09-05 | 2010-11-16 | Applied Materials, Inc. | Cathode liner with wafer edge gas injection in a plasma reactor chamber |

| US7879250B2 (en) | 2007-09-05 | 2011-02-01 | Applied Materials, Inc. | Method of processing a workpiece in a plasma reactor with independent wafer edge process gas injection |

| US8721836B2 (en) * | 2008-04-22 | 2014-05-13 | Micron Technology, Inc. | Plasma processing with preionized and predissociated tuning gases and associated systems and methods |

| US20110011534A1 (en) * | 2009-07-17 | 2011-01-20 | Rajinder Dhindsa | Apparatus for adjusting an edge ring potential during substrate processing |

| KR101092122B1 (ko) * | 2010-02-23 | 2011-12-12 | 주식회사 디엠에스 | 에칭 프로파일 제어를 위한 가스 인젝션 시스템 |

| JP2012049376A (ja) * | 2010-08-27 | 2012-03-08 | Hitachi High-Technologies Corp | プラズマ処理装置およびプラズマ処理方法 |

| JP5819154B2 (ja) * | 2011-10-06 | 2015-11-18 | 株式会社日立ハイテクノロジーズ | プラズマエッチング装置 |

| US9083182B2 (en) | 2011-11-21 | 2015-07-14 | Lam Research Corporation | Bypass capacitors for high voltage bias power in the mid frequency RF range |

| US9508530B2 (en) | 2011-11-21 | 2016-11-29 | Lam Research Corporation | Plasma processing chamber with flexible symmetric RF return strap |

| US9396908B2 (en) | 2011-11-22 | 2016-07-19 | Lam Research Corporation | Systems and methods for controlling a plasma edge region |

| US9263240B2 (en) | 2011-11-22 | 2016-02-16 | Lam Research Corporation | Dual zone temperature control of upper electrodes |

| US10586686B2 (en) | 2011-11-22 | 2020-03-10 | Law Research Corporation | Peripheral RF feed and symmetric RF return for symmetric RF delivery |

| KR101971312B1 (ko) * | 2011-11-23 | 2019-04-22 | 램 리써치 코포레이션 | 다중 존 가스 주입 상부 전극 시스템 |

| US20150162169A1 (en) * | 2013-12-05 | 2015-06-11 | Taiwan Semiconductor Manufacturing Co., Ltd. | Etching apparatus and method |

| JP6516436B2 (ja) * | 2014-10-24 | 2019-05-22 | 東京エレクトロン株式会社 | 成膜装置及び成膜方法 |

| CN107112275B (zh) * | 2014-12-19 | 2020-10-30 | 应用材料公司 | 用于基板处理腔室的边缘环 |

| US10410832B2 (en) * | 2016-08-19 | 2019-09-10 | Lam Research Corporation | Control of on-wafer CD uniformity with movable edge ring and gas injection adjustment |

| KR102641441B1 (ko) * | 2016-09-28 | 2024-02-29 | 삼성전자주식회사 | 링 어셈블리 및 이를 포함하는 척 어셈블리 |

| JP6837911B2 (ja) * | 2017-05-17 | 2021-03-03 | 株式会社Screenホールディングス | 熱処理装置 |

| US10851457B2 (en) * | 2017-08-31 | 2020-12-01 | Lam Research Corporation | PECVD deposition system for deposition on selective side of the substrate |

| CN109750279B (zh) * | 2017-11-07 | 2024-11-08 | 中微半导体设备(上海)股份有限公司 | 一种用于热化学气相沉积的基片托盘和反应器 |

| CN109600898B (zh) * | 2018-12-13 | 2020-04-17 | 大连理工大学 | 一种喷淋式电极及放电系统 |

| KR102695104B1 (ko) | 2019-08-16 | 2024-08-14 | 램 리써치 코포레이션 | 웨이퍼 내에서 차동 보우를 보상하기 위한 공간적으로 튜닝 가능한 증착 방법 및 장치 |

| KR102335472B1 (ko) * | 2019-09-04 | 2021-12-07 | 세메스 주식회사 | 기판 처리 장치 및 기판 처리 방법 |

| CN112992637B (zh) * | 2019-12-02 | 2025-06-10 | Asmip私人控股有限公司 | 衬底支撑板、包括它的衬底处理设备以及衬底处理方法 |

| CN112981372B (zh) * | 2019-12-12 | 2024-02-13 | Asm Ip私人控股有限公司 | 衬底支撑板、包括它的衬底处理设备以及衬底处理方法 |

| KR102791334B1 (ko) * | 2019-12-31 | 2025-04-08 | 삼성전자주식회사 | 에지 링 및 이를 갖는 기판 처리 장치 |

| WO2021202080A1 (en) * | 2020-04-02 | 2021-10-07 | Lam Research Corporation | Edge ring for localized delivery of tuning gas |

| KR102751528B1 (ko) * | 2020-09-01 | 2025-01-07 | 삼성전자주식회사 | 플라즈마 공정 장비 |

| WO2022108707A1 (en) * | 2020-11-23 | 2022-05-27 | Lam Research Corporation | Localized plasma arc prevention via purge ring |

| JP2022152246A (ja) * | 2021-03-29 | 2022-10-12 | 株式会社日立ハイテク | ウエハ処理装置 |

| CN112992743B (zh) * | 2021-05-17 | 2021-09-17 | 北京北方华创微电子装备有限公司 | 半导体工艺腔室及半导体工艺设备 |

| TW202417684A (zh) * | 2022-08-31 | 2024-05-01 | 荷蘭商Asm Ip私人控股有限公司 | 基座環總成、反應器系統、及用於氣體注入之方法 |

Family Cites Families (49)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4512283A (en) * | 1982-02-01 | 1985-04-23 | Texas Instruments Incorporated | Plasma reactor sidewall shield |

| US4513021A (en) * | 1982-02-01 | 1985-04-23 | Texas Instruments Incorporated | Plasma reactor with reduced chamber wall deposition |

| JPS6074626A (ja) * | 1983-09-30 | 1985-04-26 | Fujitsu Ltd | ウエハー処理方法及び装置 |

| US5578532A (en) * | 1990-07-16 | 1996-11-26 | Novellus Systems, Inc. | Wafer surface protection in a gas deposition process |

| JP2763222B2 (ja) * | 1991-12-13 | 1998-06-11 | 三菱電機株式会社 | 化学気相成長方法ならびにそのための化学気相成長処理システムおよび化学気相成長装置 |

| JP2894658B2 (ja) * | 1992-01-17 | 1999-05-24 | 株式会社東芝 | ドライエッチング方法およびその装置 |

| JP2870719B2 (ja) * | 1993-01-29 | 1999-03-17 | 東京エレクトロン株式会社 | 処理装置 |

| DE69432383D1 (de) * | 1993-05-27 | 2003-05-08 | Applied Materials Inc | Verbesserungen betreffend Substrathalter geeignet für den Gebrauch in Vorrichtungen für die chemische Abscheidung aus der Dampfphase |

| KR100274754B1 (ko) * | 1993-08-18 | 2000-12-15 | 히가시 데쓰로 | 성막장치 및 성막방법 |

| US5498313A (en) * | 1993-08-20 | 1996-03-12 | International Business Machines Corp. | Symmetrical etching ring with gas control |

| US5556476A (en) * | 1994-02-23 | 1996-09-17 | Applied Materials, Inc. | Controlling edge deposition on semiconductor substrates |

| TW283250B (en) * | 1995-07-10 | 1996-08-11 | Watkins Johnson Co | Plasma enhanced chemical processing reactor and method |

| TW286414B (en) * | 1995-07-10 | 1996-09-21 | Watkins Johnson Co | Electrostatic chuck assembly |

| TW356554B (en) * | 1995-10-23 | 1999-04-21 | Watkins Johnson Co | Gas injection system for semiconductor processing |

| US5772771A (en) * | 1995-12-13 | 1998-06-30 | Applied Materials, Inc. | Deposition chamber for improved deposition thickness uniformity |

| US6108189A (en) * | 1996-04-26 | 2000-08-22 | Applied Materials, Inc. | Electrostatic chuck having improved gas conduits |

| US6070551A (en) * | 1996-05-13 | 2000-06-06 | Applied Materials, Inc. | Deposition chamber and method for depositing low dielectric constant films |

| US6013155A (en) * | 1996-06-28 | 2000-01-11 | Lam Research Corporation | Gas injection system for plasma processing |

| US6042687A (en) * | 1997-06-30 | 2000-03-28 | Lam Research Corporation | Method and apparatus for improving etch and deposition uniformity in plasma semiconductor processing |

| KR100524204B1 (ko) * | 1998-01-07 | 2006-01-27 | 동경 엘렉트론 주식회사 | 가스 처리장치 |

| US6179924B1 (en) * | 1998-04-28 | 2001-01-30 | Applied Materials, Inc. | Heater for use in substrate processing apparatus to deposit tungsten |

| US6040011A (en) * | 1998-06-24 | 2000-03-21 | Applied Materials, Inc. | Substrate support member with a purge gas channel and pumping system |

| US6096135A (en) * | 1998-07-21 | 2000-08-01 | Applied Materials, Inc. | Method and apparatus for reducing contamination of a substrate in a substrate processing system |

| US6263829B1 (en) * | 1999-01-22 | 2001-07-24 | Applied Materials, Inc. | Process chamber having improved gas distributor and method of manufacture |

| JP4283366B2 (ja) * | 1999-03-01 | 2009-06-24 | キヤノンアネルバ株式会社 | プラズマ処理装置 |

| US6206976B1 (en) * | 1999-08-27 | 2001-03-27 | Lucent Technologies Inc. | Deposition apparatus and related method with controllable edge exclusion |

| US6432259B1 (en) * | 1999-12-14 | 2002-08-13 | Applied Materials, Inc. | Plasma reactor cooled ceiling with an array of thermally isolated plasma heated mini-gas distribution plates |

| JP2003529926A (ja) * | 2000-03-30 | 2003-10-07 | 東京エレクトロン株式会社 | プラズマ処理システム内への調整可能なガス注入のための方法及び装置 |

| KR100406173B1 (ko) * | 2000-06-13 | 2003-11-19 | 주식회사 하이닉스반도체 | 촉매 분사 수단을 구비한 히터 블록 |

| US6666920B1 (en) * | 2000-08-09 | 2003-12-23 | Itt Manufacturing Enterprises, Inc. | Gas collector for providing an even flow of gasses through a reaction chamber of an epitaxial reactor |

| US6325855B1 (en) * | 2000-08-09 | 2001-12-04 | Itt Manufacturing Enterprises, Inc. | Gas collector for epitaxial reactors |

| JP3741604B2 (ja) * | 2000-11-27 | 2006-02-01 | 東京エレクトロン株式会社 | 熱処理装置および熱処理方法 |

| JP4433614B2 (ja) * | 2001-01-17 | 2010-03-17 | ソニー株式会社 | エッチング装置 |

| US6676760B2 (en) * | 2001-08-16 | 2004-01-13 | Appiled Materials, Inc. | Process chamber having multiple gas distributors and method |

| US20030168174A1 (en) * | 2002-03-08 | 2003-09-11 | Foree Michael Todd | Gas cushion susceptor system |

| US6897155B2 (en) * | 2002-08-14 | 2005-05-24 | Applied Materials, Inc. | Method for etching high-aspect-ratio features |

| US6837967B1 (en) * | 2002-11-06 | 2005-01-04 | Lsi Logic Corporation | Method and apparatus for cleaning deposited films from the edge of a wafer |

| JP4108465B2 (ja) * | 2002-12-18 | 2008-06-25 | 東京エレクトロン株式会社 | 処理方法及び処理装置 |

| US7323231B2 (en) * | 2003-10-09 | 2008-01-29 | Micron Technology, Inc. | Apparatus and methods for plasma vapor deposition processes |

| US7410355B2 (en) * | 2003-10-31 | 2008-08-12 | Asm International N.V. | Method for the heat treatment of substrates |

| US7022627B2 (en) * | 2003-10-31 | 2006-04-04 | Asm International N.V. | Method for the heat treatment of substrates |

| US20050230350A1 (en) * | 2004-02-26 | 2005-10-20 | Applied Materials, Inc. | In-situ dry clean chamber for front end of line fabrication |

| US7879409B2 (en) * | 2004-07-23 | 2011-02-01 | Applied Materials, Inc. | Repeatability of CVD film deposition during sequential processing of substrates in a deposition chamber |

| US7217670B2 (en) * | 2004-11-22 | 2007-05-15 | Asm International N.V. | Dummy substrate for thermal reactor |

| JP4590363B2 (ja) * | 2005-03-16 | 2010-12-01 | 日本碍子株式会社 | ガス供給部材及びそれを用いた処理装置 |

| US7550381B2 (en) * | 2005-07-18 | 2009-06-23 | Applied Materials, Inc. | Contact clean by remote plasma and repair of silicide surface |

| US8097120B2 (en) * | 2006-02-21 | 2012-01-17 | Lam Research Corporation | Process tuning gas injection from the substrate edge |

| JP5074741B2 (ja) * | 2006-11-10 | 2012-11-14 | 株式会社日立ハイテクノロジーズ | 真空処理装置 |

| KR100998011B1 (ko) * | 2008-05-22 | 2010-12-03 | 삼성엘이디 주식회사 | 화학기상 증착장치 |

-

2006

- 2006-02-21 US US11/359,300 patent/US8097120B2/en not_active Expired - Fee Related

-

2007

- 2007-02-16 WO PCT/US2007/004225 patent/WO2007098071A2/en not_active Ceased

- 2007-02-16 JP JP2008556370A patent/JP5457037B2/ja active Active

- 2007-02-16 CN CNA2007800062311A patent/CN101389788A/zh active Pending

- 2007-02-16 KR KR1020087020510A patent/KR101336446B1/ko active Active

- 2007-02-16 SG SG201101193-9A patent/SG170007A1/en unknown

- 2007-02-26 TW TW096106432A patent/TWI364791B/zh active

-

2013

- 2013-06-05 JP JP2013118462A patent/JP2013211586A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| US8097120B2 (en) | 2012-01-17 |

| TW200805481A (en) | 2008-01-16 |

| US20070193688A1 (en) | 2007-08-23 |

| JP2009527921A (ja) | 2009-07-30 |

| TWI364791B (en) | 2012-05-21 |

| WO2007098071A3 (en) | 2008-04-24 |

| CN101389788A (zh) | 2009-03-18 |

| WO2007098071A2 (en) | 2007-08-30 |

| JP2013211586A (ja) | 2013-10-10 |

| SG170007A1 (en) | 2011-04-29 |

| KR101336446B1 (ko) | 2013-12-04 |

| KR20080106413A (ko) | 2008-12-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5457037B2 (ja) | 基板縁部への不活性ガスの注入 | |

| JP7259017B2 (ja) | Rfシールドが埋め込まれた半導体基板支持体 | |

| US8066895B2 (en) | Method to control uniformity using tri-zone showerhead | |

| CN101557885B (zh) | 具有多个电容性和电感性电源的等离子处理反应器 | |

| JP6679591B2 (ja) | プロセス均一性を高めるための方法およびシステム | |

| US11289308B2 (en) | Apparatus and method for processing substrate and method of manufacturing semiconductor device using the method | |

| US7832354B2 (en) | Cathode liner with wafer edge gas injection in a plasma reactor chamber | |

| US8383002B2 (en) | Method of processing a workpiece in a plasma reactor with independent wafer edge process gas injection | |

| CN102473634B (zh) | 等离子体处理装置和等离子体处理方法 | |

| KR101155837B1 (ko) | 기판 프로세싱용 에지 링 배열 | |

| US7282454B2 (en) | Switched uniformity control | |

| US20060196420A1 (en) | High density plasma chemical vapor deposition apparatus | |

| TW201836008A (zh) | 電漿處理裝置 | |

| CN101426949A (zh) | 用于等离子蚀刻室的集成的电容性和电感性电源 | |

| US20110203735A1 (en) | Gas injection system for etching profile control | |

| US20090126871A1 (en) | Plasma processing apparatus | |

| TWI890724B (zh) | 電漿增強型化學氣相沈積裝置及方法 | |

| JP2009529225A (ja) | プラズマ処理チャンバの選択的プレコーティングのための方法及び装置 | |

| KR20180006307A (ko) | 전기적 아크 및 발광을 방지하고 프로세스 균일도를 개선하기 위한 피처들을 갖는 정전 척 | |

| JP3748230B2 (ja) | プラズマエッチング装置及びシャワープレート | |

| US20040261714A1 (en) | Plasma processing apparatus | |

| KR101138609B1 (ko) | 효율적인 라디칼 생성을 위한 플라즈마 발생장치 | |

| KR100725614B1 (ko) | 플라즈마 처리 장치 | |

| TW202410158A (zh) | 具有改良均勻性之電漿噴灑頭 | |

| TW202502652A (zh) | 形成石墨烯膜的方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100215 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100215 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100604 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120306 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120601 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120807 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121105 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20130205 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130605 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20130605 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20130627 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130827 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130919 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20131224 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20140109 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5457037 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |