JP5032030B2 - マイクロマシニング型の構成素子の製造方法 - Google Patents

マイクロマシニング型の構成素子の製造方法 Download PDFInfo

- Publication number

- JP5032030B2 JP5032030B2 JP2006026589A JP2006026589A JP5032030B2 JP 5032030 B2 JP5032030 B2 JP 5032030B2 JP 2006026589 A JP2006026589 A JP 2006026589A JP 2006026589 A JP2006026589 A JP 2006026589A JP 5032030 B2 JP5032030 B2 JP 5032030B2

- Authority

- JP

- Japan

- Prior art keywords

- diaphragm

- layer

- etching

- sacrificial layer

- substrate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B81—MICROSTRUCTURAL TECHNOLOGY

- B81B—MICROSTRUCTURAL DEVICES OR SYSTEMS, e.g. MICROMECHANICAL DEVICES

- B81B3/00—Devices comprising flexible or deformable elements, e.g. comprising elastic tongues or membranes

- B81B3/0064—Constitution or structural means for improving or controlling the physical properties of a device

- B81B3/0086—Electrical characteristics, e.g. reducing driving voltage, improving resistance to peak voltage

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01L—MEASURING FORCE, STRESS, TORQUE, WORK, MECHANICAL POWER, MECHANICAL EFFICIENCY, OR FLUID PRESSURE

- G01L9/00—Measuring steady of quasi-steady pressure of fluid or fluent solid material by electric or magnetic pressure-sensitive elements; Transmitting or indicating the displacement of mechanical pressure-sensitive elements, used to measure the steady or quasi-steady pressure of a fluid or fluent solid material, by electric or magnetic means

- G01L9/0041—Transmitting or indicating the displacement of flexible diaphragms

- G01L9/0042—Constructional details associated with semiconductive diaphragm sensors, e.g. etching, or constructional details of non-semiconductive diaphragms

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01L—MEASURING FORCE, STRESS, TORQUE, WORK, MECHANICAL POWER, MECHANICAL EFFICIENCY, OR FLUID PRESSURE

- G01L9/00—Measuring steady of quasi-steady pressure of fluid or fluent solid material by electric or magnetic pressure-sensitive elements; Transmitting or indicating the displacement of mechanical pressure-sensitive elements, used to measure the steady or quasi-steady pressure of a fluid or fluent solid material, by electric or magnetic means

- G01L9/0041—Transmitting or indicating the displacement of flexible diaphragms

- G01L9/0072—Transmitting or indicating the displacement of flexible diaphragms using variations in capacitance

- G01L9/0073—Transmitting or indicating the displacement of flexible diaphragms using variations in capacitance using a semiconductive diaphragm

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B81—MICROSTRUCTURAL TECHNOLOGY

- B81B—MICROSTRUCTURAL DEVICES OR SYSTEMS, e.g. MICROMECHANICAL DEVICES

- B81B2201/00—Specific applications of microelectromechanical systems

- B81B2201/02—Sensors

- B81B2201/0264—Pressure sensors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B81—MICROSTRUCTURAL TECHNOLOGY

- B81B—MICROSTRUCTURAL DEVICES OR SYSTEMS, e.g. MICROMECHANICAL DEVICES

- B81B2203/00—Basic microelectromechanical structures

- B81B2203/01—Suspended structures, i.e. structures allowing a movement

- B81B2203/0109—Bridges

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Measuring Fluid Pressure (AREA)

- Pressure Sensors (AREA)

- Micromachines (AREA)

Description

少なくとも所定の範囲で導電性である基板を準備し;

弾性的に変位可能な、少なくとも所定の範囲で導電性であるダイヤフラムを製造し、該ダイヤフラムを、湾曲させてかつ基板から電気的に絶縁させて基板の表面の上方に設け、ただし該ダイヤフラムは内側範囲と縁範囲とを有しており;

基板とダイヤフラムとの間に空隙を設け;

ダイヤフラムの内側範囲が、縁範囲に対して変えられた横断面を有し、これにより内側範囲の撓みが、同一横断面の場合に比べて減じられるようにダイヤフラムを形成する;

を実施するようにした。

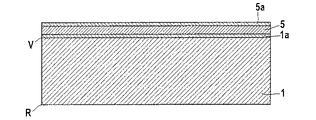

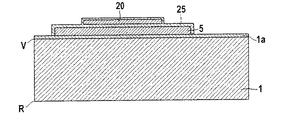

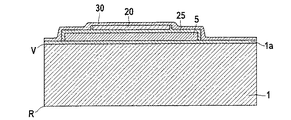

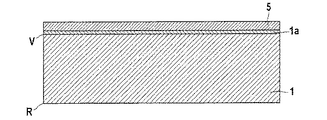

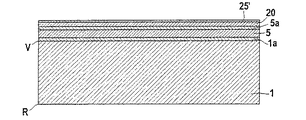

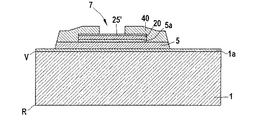

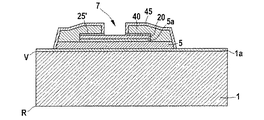

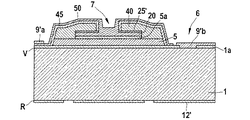

1a シリコン酸化物層

5 犠牲層

5a SiGe酸化物層

6 窓

7 窓

9´a,9´b 導電性の層

12´ マスク層

15´´´ パーフォレーション孔

20 ポリシリコン層

25,25´ 酸化物層

30 ポリシリコン層

40 犠牲層

45 酸化物層

50 ポリシリコン層

I,I´ 内側範囲

RB,RB´ 縁範囲

KP,KP´ コンデンサプレート

M ダイヤフラム

V ウェーハ表面

R ウェーハ裏面

H 空隙

Claims (7)

- マイクロマシニング型の構成素子のための製造方法において、以下のステップ:

少なくとも所定の範囲で導電性である基板(1)を準備し;

弾性的に変位可能な、少なくとも所定の範囲で導電性であるダイヤフラム(M)を製造し、該ダイヤフラム(M)を、基板(1)から電気的に絶縁させて基板(1)の表面(V)の上方に設け、ただし該ダイヤフラム(M)は内側範囲(I´)と縁範囲(RB´)とを有しており;

基板(1)とダイヤフラム(M)との間に空隙(H)を設け;

ダイヤフラム(M)の内側範囲(I´)が、縁範囲(RB´)に対して変えられた横断面を有し、これにより内側範囲(I´)の撓みが、同一横断面の場合に比べて減じられるようにダイヤフラム(M)を形成し、

しかもダイヤフラム(M)の内側範囲(I´)に、縁範囲(RB´)に比べて空隙(H)内へ懸吊された範囲(KP´)を設ける;

を実施し、

ただし、ダイヤフラム(M)を、基板(1)上に設けられた犠牲層範囲(5;5,40)の上方で、構造化された多数の層(20,25,30;5a,20,25´,45,50)を設けることによって前成形し、

この場合、犠牲層(5;5,40)として、Si 1−x Ge x (ただし、x=0.1〜0.8である)を使用し、

犠牲層(5;5,40)であるSiGe層と、基板(1)であるSi層との間にエッチングストップおよび拡散バリヤとして酸化物層(1a)を被着させるか、または熱酸化により成長させ、

引き続きダイヤフラム(M)に対して選択的なエッチングプロセスにより犠牲層範囲(5;5,40)を除去する、

ことを特徴とする、マイクロマシニング型の構成素子のための製造方法。 - 犠牲層エッチングのためのエッチングガスとして、ClF3、ClF5、XeF2、BrF3、IF3またはIF5を使用する、請求項1記載の製造方法。

- 犠牲層範囲(5;5,40)内のGe含量を、SiGeから成る犠牲層の熱による酸化により該犠牲層の上に形成された、熱により成長されたSiGe酸化物層がGeを含有しないか、またはGeをほとんど含有しないように低く設定する、請求項1記載の製造方法。

- 犠牲層範囲(5;5,40)内のGe含量を、熱による酸化物層の成長速度がシリコン上での成長に比べて1.5〜10倍だけ加速されて行われるように高く設定する、請求項1記載の製造方法。

- 犠牲層範囲(5;5,40)内のGe含量が0.3〜0.4at%である、請求項1記載の製造方法。

- ダイヤフラム(M)の内側範囲(I)に、縁範囲(RB´)に比べて付加的な層(5a)を設ける、請求項1記載の製造方法。

- 空隙(H)を媒体で充填し、ダイヤフラム(M)の下で基板(1)を貫いて延びる1つまたは複数のパーフォレーション開口(15´´´)を設け、この場合、該パーフォレーション開口(15´´´)が、基板(1)の裏面(R)から空隙(H)内へ通じた進入路を提供して、空隙(H)内に存在する媒体の容量がダイヤフラム(M)の変位時に可変となる、請求項6記載の製造方法。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102005004878.1 | 2005-02-03 | ||

| DE102005004878.1A DE102005004878B4 (de) | 2005-02-03 | 2005-02-03 | Mikromechanischer kapazitiver Drucksensor und entsprechendes Herstellungsverfahren |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2006212773A JP2006212773A (ja) | 2006-08-17 |

| JP2006212773A5 JP2006212773A5 (ja) | 2009-03-19 |

| JP5032030B2 true JP5032030B2 (ja) | 2012-09-26 |

Family

ID=36709616

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2006026589A Expired - Fee Related JP5032030B2 (ja) | 2005-02-03 | 2006-02-03 | マイクロマシニング型の構成素子の製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US7262071B2 (ja) |

| JP (1) | JP5032030B2 (ja) |

| DE (1) | DE102005004878B4 (ja) |

| FR (1) | FR2882996B1 (ja) |

Families Citing this family (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7772657B2 (en) * | 2004-12-28 | 2010-08-10 | Vladimir Vaganov | Three-dimensional force input control device and fabrication |

| US8350345B2 (en) | 2003-12-29 | 2013-01-08 | Vladimir Vaganov | Three-dimensional input control device |

| US9034666B2 (en) | 2003-12-29 | 2015-05-19 | Vladimir Vaganov | Method of testing of MEMS devices on a wafer level |

| US7554167B2 (en) * | 2003-12-29 | 2009-06-30 | Vladimir Vaganov | Three-dimensional analog input control device |

| US7880247B2 (en) * | 2003-12-29 | 2011-02-01 | Vladimir Vaganov | Semiconductor input control device |

| DE102005047081B4 (de) * | 2005-09-30 | 2019-01-31 | Robert Bosch Gmbh | Verfahren zum plasmalosen Ätzen von Silizium mit dem Ätzgas ClF3 oder XeF2 |

| WO2007139730A2 (en) * | 2006-05-22 | 2007-12-06 | Vladimir Vaganov | Semiconductor input control device |

| WO2007139695A2 (en) * | 2006-05-24 | 2007-12-06 | Vladimir Vaganov | Force input control device and method of fabrication |

| DE102006024668A1 (de) * | 2006-05-26 | 2007-11-29 | Robert Bosch Gmbh | Mikromechanisches Bauelement und Verfahren zu dessen Herstellung |

| KR20090125087A (ko) * | 2007-02-20 | 2009-12-03 | 퀄컴 엠이엠스 테크놀로지스, 인크. | 마이크로전자기계 시스템〔mems〕의 에칭장치 및 에칭 방법 |

| WO2008124372A2 (en) * | 2007-04-04 | 2008-10-16 | Qualcomm Mems Technologies, Inc. | Eliminate release etch attack by interface modification in sacrificial layers |

| DE102007029414A1 (de) | 2007-06-26 | 2009-01-08 | Robert Bosch Gmbh | Kapazitiver Drucksensor |

| WO2009036215A2 (en) * | 2007-09-14 | 2009-03-19 | Qualcomm Mems Technologies, Inc. | Etching processes used in mems production |

| DE102007046017B4 (de) * | 2007-09-26 | 2021-07-01 | Robert Bosch Gmbh | Sensorelement |

| US8258591B2 (en) * | 2008-01-16 | 2012-09-04 | Solid State System Co., Ltd. | Micro-electro-mechanical systems (MEMS) device |

| JP5473253B2 (ja) * | 2008-06-02 | 2014-04-16 | キヤノン株式会社 | 複数の導電性領域を有する構造体、及びその製造方法 |

| DE102009000071A1 (de) | 2009-01-08 | 2010-07-15 | Robert Bosch Gmbh | Kapazitiver Drucksensor |

| WO2010122953A1 (ja) * | 2009-04-24 | 2010-10-28 | 株式会社村田製作所 | Mems素子およびその製造方法 |

| DE102010003488A1 (de) * | 2010-03-30 | 2011-10-06 | Ihp Gmbh - Innovations For High Performance Microelectronics / Leibniz-Institut Für Innovative Mikroelektronik | Verkapselung eines BiCMOS kompatiblen RFMEMS Schalters |

| KR101215919B1 (ko) * | 2010-08-13 | 2012-12-27 | 전자부품연구원 | 정전용량형 압력센서 및 그의 제조방법 |

| JP5778914B2 (ja) * | 2010-11-04 | 2015-09-16 | キヤノン株式会社 | 電気機械変換装置の製造方法 |

| CN102539055B (zh) * | 2012-02-13 | 2014-04-09 | 苏州文智芯微系统技术有限公司 | 基于智能剥离硅隔离芯片的耐高温抗腐蚀压力传感器 |

| US8748999B2 (en) | 2012-04-20 | 2014-06-10 | Taiwan Semiconductor Manufacturing Company, Ltd. | Capacitive sensors and methods for forming the same |

| FR2999948B1 (fr) | 2012-12-20 | 2016-04-29 | Aerogroupe | Plateforme mobile dans une structure cylindrique |

| US8900975B2 (en) * | 2013-01-03 | 2014-12-02 | International Business Machines Corporation | Nanopore sensor device |

| US9216897B2 (en) | 2013-06-05 | 2015-12-22 | Invensense, Inc. | Capacitive sensing structure with embedded acoustic channels |

| KR102198663B1 (ko) * | 2013-12-27 | 2021-01-05 | 인텔 코포레이션 | 게이트 올 어라운드 아키텍처들에 대한 선택적 에칭 |

| US9630837B1 (en) * | 2016-01-15 | 2017-04-25 | Taiwan Semiconductor Manufacturing Company Ltd. | MEMS structure and manufacturing method thereof |

| US10554153B2 (en) * | 2016-06-17 | 2020-02-04 | Globalfoundries Singapore Pte. Ltd. | MEMS device for harvesting sound energy and methods for fabricating same |

| JP6812880B2 (ja) * | 2017-03-29 | 2021-01-13 | 東京エレクトロン株式会社 | 基板処理方法及び記憶媒体。 |

| JP2020151796A (ja) * | 2019-03-19 | 2020-09-24 | 株式会社リコー | 振動素子基板の製造方法及び振動素子基板 |

| US11791155B2 (en) * | 2020-08-27 | 2023-10-17 | Applied Materials, Inc. | Diffusion barriers for germanium |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH05231970A (ja) * | 1992-02-25 | 1993-09-07 | Matsushita Electric Works Ltd | 薄膜体ブリッジ構造 |

| DE4241045C1 (de) | 1992-12-05 | 1994-05-26 | Bosch Gmbh Robert | Verfahren zum anisotropen Ätzen von Silicium |

| JPH06347353A (ja) * | 1993-06-11 | 1994-12-22 | Fujikura Ltd | 半導体圧力センサ |

| US7460291B2 (en) * | 1994-05-05 | 2008-12-02 | Idc, Llc | Separable modulator |

| WO1999023832A1 (en) * | 1997-10-31 | 1999-05-14 | Daewoo Electronics Co., Ltd. | Method for manufacturing thin film actuated mirror array in an optical projection system |

| JP2000022172A (ja) * | 1998-06-30 | 2000-01-21 | Matsushita Electric Ind Co Ltd | 変換装置及びその製造方法 |

| JP3362714B2 (ja) * | 1998-11-16 | 2003-01-07 | 株式会社豊田中央研究所 | 静電容量型圧力センサおよびその製造方法 |

| US6229190B1 (en) * | 1998-12-18 | 2001-05-08 | Maxim Integrated Products, Inc. | Compensated semiconductor pressure sensor |

| AU3346000A (en) * | 1999-01-15 | 2000-08-01 | Regents Of The University Of California, The | Polycrystalline silicon germanium films for forming micro-electromechanical systems |

| DE10024266B4 (de) * | 2000-05-17 | 2010-06-17 | Robert Bosch Gmbh | Verfahren zur Herstellung eines mikromechanischen Bauelements |

| US6355498B1 (en) * | 2000-08-11 | 2002-03-12 | Agere Systems Guartian Corp. | Thin film resonators fabricated on membranes created by front side releasing |

| DE10047500B4 (de) * | 2000-09-26 | 2009-11-26 | Robert Bosch Gmbh | Mikromechanische Membran und Verfahren zu ihrer Herstellung |

| DE10122765A1 (de) * | 2001-05-10 | 2002-12-05 | Campus Micro Technologies Gmbh | Elektroakustischer Wandler zur Erzeugung oder Erfassung von Ultraschall, Wandler-Array und Verfahren zur Herstellung der Wandler bzw. der Wandler-Arrays |

| US6635519B2 (en) * | 2002-01-10 | 2003-10-21 | Agere Systems, Inc. | Structurally supported thin film resonator and method of fabrication |

| DE10230252B4 (de) * | 2002-07-04 | 2013-10-17 | Robert Bosch Gmbh | Verfahren zur Herstellung integrierter Mikrosysteme |

| DE10239306B4 (de) * | 2002-08-27 | 2006-08-31 | Hahn-Schickard-Gesellschaft für angewandte Forschung e.V. | Verfahren zum selektiven Verbinden von Substraten |

-

2005

- 2005-02-03 DE DE102005004878.1A patent/DE102005004878B4/de not_active Expired - Lifetime

-

2006

- 2006-01-30 US US11/343,613 patent/US7262071B2/en active Active

- 2006-02-02 FR FR0650366A patent/FR2882996B1/fr not_active Expired - Fee Related

- 2006-02-03 JP JP2006026589A patent/JP5032030B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| FR2882996B1 (fr) | 2015-12-25 |

| DE102005004878B4 (de) | 2015-01-08 |

| US20060170012A1 (en) | 2006-08-03 |

| DE102005004878A1 (de) | 2006-08-10 |

| US7262071B2 (en) | 2007-08-28 |

| FR2882996A1 (fr) | 2006-09-15 |

| JP2006212773A (ja) | 2006-08-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5032030B2 (ja) | マイクロマシニング型の構成素子の製造方法 | |

| US9938133B2 (en) | System and method for a comb-drive MEMS device | |

| US7834409B2 (en) | Micromechanical component and corresponding method for its manufacture | |

| JP4603740B2 (ja) | 精密機械的な構造要素、及びその製造方法 | |

| US8794075B2 (en) | Multilayered NONON membrane in a MEMS sensor | |

| EP1826174B1 (en) | Method for forming thin film structure having small tensile stress | |

| CN1970434A (zh) | 在soi硅片上制造压阻式微悬臂梁传感器的方法 | |

| US11533565B2 (en) | Dual back-plate and diaphragm microphone | |

| CN113710608B (zh) | 用于电容式传感器或开关装置的微机械构件 | |

| CN107850505A (zh) | Mems电容式压力传感器以及制造方法 | |

| US6521965B1 (en) | Integrated pressure sensor | |

| JP5129456B2 (ja) | 梁部を備えた構造体の製造方法およびmemsデバイス | |

| US20180340901A1 (en) | Gas sensor platform and the method of making the same | |

| JP5975457B2 (ja) | 三次元構造体及びセンサ | |

| JP2005246601A (ja) | マイクロマシニング型の構成エレメントおよび相応の製作法 | |

| CN1243576A (zh) | 微机械半导体装置及制造微机械半导体装置的方法 | |

| JP4529431B2 (ja) | マイクロ構造体の製造方法 | |

| CN114014259B (zh) | 一种半导体结构的制造方法 | |

| JP6218330B2 (ja) | 圧力センサ及びその製造方法 | |

| CN209559360U (zh) | 一种温度传感器 | |

| JP5939168B2 (ja) | 半導体装置 | |

| Vähänissi | Xenon difluoride etching of sacrificial layers for fabrication of microelectromechanical devices | |

| JP2007144611A (ja) | 半導体装置、及び半導体装置の作製方法 | |

| JP2015194443A (ja) | 差圧検出素子の製造方法 | |

| RU2827958C1 (ru) | Мэмс-датчик давления |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090202 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20090202 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110817 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20111117 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20111122 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111219 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20120530 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20120628 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5032030 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150706 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |