JP4895465B2 - 1軸形ガスタービンの火炎温度の制御及び調節システム - Google Patents

1軸形ガスタービンの火炎温度の制御及び調節システム Download PDFInfo

- Publication number

- JP4895465B2 JP4895465B2 JP2003161427A JP2003161427A JP4895465B2 JP 4895465 B2 JP4895465 B2 JP 4895465B2 JP 2003161427 A JP2003161427 A JP 2003161427A JP 2003161427 A JP2003161427 A JP 2003161427A JP 4895465 B2 JP4895465 B2 JP 4895465B2

- Authority

- JP

- Japan

- Prior art keywords

- turbine

- temperature

- gas

- gas turbine

- branch

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000002485 combustion reaction Methods 0.000 claims description 21

- 230000009471 action Effects 0.000 claims description 10

- 230000033228 biological regulation Effects 0.000 claims description 10

- 239000000446 fuel Substances 0.000 claims description 10

- 238000004364 calculation method Methods 0.000 claims description 5

- 238000001816 cooling Methods 0.000 claims description 5

- 238000013178 mathematical model Methods 0.000 claims description 5

- 230000008439 repair process Effects 0.000 claims description 4

- 230000001052 transient effect Effects 0.000 claims description 2

- 238000007620 mathematical function Methods 0.000 claims 2

- 230000001629 suppression Effects 0.000 claims 1

- 239000007789 gas Substances 0.000 description 41

- 239000007788 liquid Substances 0.000 description 4

- 238000012937 correction Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 238000010586 diagram Methods 0.000 description 2

- 239000003344 environmental pollutant Substances 0.000 description 2

- 238000012423 maintenance Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 231100000719 pollutant Toxicity 0.000 description 2

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000000567 combustion gas Substances 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 230000005611 electricity Effects 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000010248 power generation Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000004088 simulation Methods 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

- 229910000601 superalloy Inorganic materials 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C9/00—Controlling gas-turbine plants; Controlling fuel supply in air- breathing jet-propulsion plants

- F02C9/48—Control of fuel supply conjointly with another control of the plant

- F02C9/50—Control of fuel supply conjointly with another control of the plant with control of working fluid flow

- F02C9/54—Control of fuel supply conjointly with another control of the plant with control of working fluid flow by throttling the working fluid, by adjusting vanes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C9/00—Controlling gas-turbine plants; Controlling fuel supply in air- breathing jet-propulsion plants

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

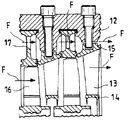

- F01D17/00—Regulating or controlling by varying flow

- F01D17/10—Final actuators

- F01D17/12—Final actuators arranged in stator parts

- F01D17/14—Final actuators arranged in stator parts varying effective cross-sectional area of nozzles or guide conduits

- F01D17/16—Final actuators arranged in stator parts varying effective cross-sectional area of nozzles or guide conduits by means of nozzle vanes

- F01D17/162—Final actuators arranged in stator parts varying effective cross-sectional area of nozzles or guide conduits by means of nozzle vanes for axial flow, i.e. the vanes turning around axes which are essentially perpendicular to the rotor centre line

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C9/00—Controlling gas-turbine plants; Controlling fuel supply in air- breathing jet-propulsion plants

- F02C9/16—Control of working fluid flow

- F02C9/20—Control of working fluid flow by throttling; by adjusting vanes

- F02C9/22—Control of working fluid flow by throttling; by adjusting vanes by adjusting turbine vanes

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02C—GAS-TURBINE PLANTS; AIR INTAKES FOR JET-PROPULSION PLANTS; CONTROLLING FUEL SUPPLY IN AIR-BREATHING JET-PROPULSION PLANTS

- F02C9/00—Controlling gas-turbine plants; Controlling fuel supply in air- breathing jet-propulsion plants

- F02C9/26—Control of fuel supply

- F02C9/28—Regulating systems responsive to plant or ambient parameters, e.g. temperature, pressure, rotor speed

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2270/00—Control

- F05D2270/01—Purpose of the control system

- F05D2270/08—Purpose of the control system to produce clean exhaust gases

- F05D2270/083—Purpose of the control system to produce clean exhaust gases by monitoring combustion conditions

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2270/00—Control

- F05D2270/01—Purpose of the control system

- F05D2270/09—Purpose of the control system to cope with emergencies

- F05D2270/095—Purpose of the control system to cope with emergencies by temporary overriding set control limits

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2270/00—Control

- F05D2270/01—Purpose of the control system

- F05D2270/11—Purpose of the control system to prolong engine life

- F05D2270/112—Purpose of the control system to prolong engine life by limiting temperatures

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2270/00—Control

- F05D2270/50—Control logic embodiments

- F05D2270/54—Control logic embodiments by electronic means, e.g. electronic tubes, transistors or IC's within an electronic circuit

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N2223/00—Signal processing; Details thereof

- F23N2223/36—PID signal processing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N2241/00—Applications

- F23N2241/20—Gas turbines

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N5/00—Systems for controlling combustion

- F23N5/02—Systems for controlling combustion using devices responsive to thermal changes or to thermal expansion of a medium

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23N—REGULATING OR CONTROLLING COMBUSTION

- F23N5/00—Systems for controlling combustion

- F23N5/18—Systems for controlling combustion using detectors sensitive to rate of flow of air or fuel

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Control Of Turbines (AREA)

- Turbine Rotor Nozzle Sealing (AREA)

- Control Of Combustion (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| IT2002MI001231A ITMI20021231A1 (it) | 2002-06-06 | 2002-06-06 | Sistema di controllo e regolazione della temperatura di fiamma per turbine a gas monoalbero |

| ITMI2002A001231 | 2002-06-06 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2004028098A JP2004028098A (ja) | 2004-01-29 |

| JP2004028098A5 JP2004028098A5 (enExample) | 2006-07-20 |

| JP4895465B2 true JP4895465B2 (ja) | 2012-03-14 |

Family

ID=27590463

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2003161427A Expired - Fee Related JP4895465B2 (ja) | 2002-06-06 | 2003-06-06 | 1軸形ガスタービンの火炎温度の制御及び調節システム |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US7003940B2 (enExample) |

| EP (1) | EP1369563B1 (enExample) |

| JP (1) | JP4895465B2 (enExample) |

| KR (1) | KR100785546B1 (enExample) |

| CN (1) | CN1330866C (enExample) |

| CA (1) | CA2430441C (enExample) |

| IT (1) | ITMI20021231A1 (enExample) |

| NO (1) | NO338996B1 (enExample) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7280950B2 (en) * | 2004-01-22 | 2007-10-09 | Electro-Motive Diesel, Inc. | Locomotive diesel engine turbocharger and turbine stage constructed with turbine blade vibration suppression methodology |

| US7762084B2 (en) * | 2004-11-12 | 2010-07-27 | Rolls-Royce Canada, Ltd. | System and method for controlling the working line position in a gas turbine engine compressor |

| JP4952025B2 (ja) * | 2006-03-31 | 2012-06-13 | 株式会社日立製作所 | 運転制御方法,運転制御装置及び運転制御システム |

| US7762081B2 (en) * | 2007-07-25 | 2010-07-27 | Honeywell International Inc. | Compressor inlet guide vane de-ice control system and method |

| US20100005657A1 (en) * | 2008-07-10 | 2010-01-14 | Van Vactor David R | Methods and systems to facilitate over-speed protection |

| US8224552B2 (en) * | 2008-07-10 | 2012-07-17 | General Electric Company | Methods and systems to facilitate over-speed protection |

| US8321119B2 (en) * | 2008-07-10 | 2012-11-27 | General Electric Company | Methods and systems to facilitate over-speed protection |

| US9423781B2 (en) | 2013-03-29 | 2016-08-23 | General Electric Company | Model based control with engine perturbation feedback |

| EP2848370A1 (de) | 2013-09-12 | 2015-03-18 | HILTI Aktiengesellschaft | Handwerkzeugmaschine |

| JP6652853B2 (ja) * | 2016-02-12 | 2020-02-26 | 三菱日立パワーシステムズ株式会社 | ガスタービン制御装置、制御方法、プログラム |

| US10227932B2 (en) * | 2016-11-30 | 2019-03-12 | General Electric Company | Emissions modeling for gas turbine engines for selecting an actual fuel split |

| CN112432793A (zh) * | 2020-11-23 | 2021-03-02 | 东方电气集团东方汽轮机有限公司 | 一种燃气轮机轮盘抽气试验件及模化试验参数设计方法 |

Family Cites Families (33)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5938422B2 (ja) * | 1971-10-15 | 1984-09-17 | ウエスチングハウス・エレクトリツク・コーポレーシヨン | ガスタ−ビン式パワ−・プラント |

| US4258545A (en) * | 1978-06-15 | 1981-03-31 | General Electric Company | Optimal control for a gas turbine engine |

| JPS5838328A (ja) | 1981-08-28 | 1983-03-05 | Hitachi Ltd | インレツトガイドベ−ン制御装置 |

| JPH0713472B2 (ja) * | 1985-01-25 | 1995-02-15 | 株式会社日立製作所 | タービンの運転制御方法、および複合サイクル原動機プラント |

| JPS61182425A (ja) * | 1985-02-08 | 1986-08-15 | Hitachi Ltd | ガスタ−ビン圧縮機入口案内翼の開度制御方法 |

| JPS6397835A (ja) * | 1986-10-13 | 1988-04-28 | Hitachi Ltd | ガスタ−ビン温度制御装置 |

| JPS63192919A (ja) * | 1987-02-04 | 1988-08-10 | Toshiba Corp | 石炭ガス化コンバインドプラントの制御装置 |

| GB8800904D0 (en) * | 1988-01-15 | 1988-02-17 | Rolls Royce Plc | Fuel control system |

| JPH048829A (ja) * | 1990-04-24 | 1992-01-13 | Toshiba Corp | ガスタービン制御装置 |

| JP2954754B2 (ja) * | 1991-07-22 | 1999-09-27 | 株式会社日立製作所 | ガスタービンシステムの運転制御装置及び加圧流動床ボイラ発電プラント |

| JP3040560B2 (ja) * | 1991-10-29 | 2000-05-15 | 三菱重工業株式会社 | 静翼シュラウド一体型タービン |

| US5257496A (en) * | 1992-05-05 | 1993-11-02 | General Electric Company | Combustion control for producing low NOx emissions through use of flame spectroscopy |

| JPH06241062A (ja) * | 1993-02-18 | 1994-08-30 | Hitachi Ltd | ガスタービン発電設備及びその運転方法 |

| US5394689A (en) * | 1993-09-22 | 1995-03-07 | General Electric Company | Gas turbine engine control system having integral flight Mach number synthesis method |

| JPH07281706A (ja) * | 1994-04-08 | 1995-10-27 | Mitsubishi Heavy Ind Ltd | 先行要素自動付加,除外制御装置 |

| JP3730275B2 (ja) * | 1994-07-14 | 2005-12-21 | 株式会社東芝 | ガスタービンの可変案内翼制御装置 |

| US5986736A (en) * | 1995-04-26 | 1999-11-16 | Canon Kabushiki Kaisha | Liquid crystal device, image display apparatus and image forming apparatus |

| JP3733574B2 (ja) * | 1995-05-19 | 2006-01-11 | 石川島播磨重工業株式会社 | ガスタービン用可変静翼のすべり軸受 |

| JP2805600B2 (ja) * | 1995-08-07 | 1998-09-30 | 川崎重工業株式会社 | ガスタービン用ノズル回転装置 |

| JP3716018B2 (ja) * | 1995-11-02 | 2005-11-16 | 三菱重工業株式会社 | 可変入口案内翼制御方法 |

| US6071114A (en) * | 1996-06-19 | 2000-06-06 | Meggitt Avionics, Inc. | Method and apparatus for characterizing a combustion flame |

| US5896736A (en) | 1997-03-06 | 1999-04-27 | General Electric Company | Load rejection rapid acting fuel-air controller for gas turbine |

| US5931636A (en) * | 1997-08-28 | 1999-08-03 | General Electric Company | Variable area turbine nozzle |

| JPH11200890A (ja) * | 1998-01-14 | 1999-07-27 | Toshiba Corp | ガスタービン装置の空気供給装置 |

| JP3783442B2 (ja) * | 1999-01-08 | 2006-06-07 | 株式会社日立製作所 | ガスタービンの制御方法 |

| US6164057A (en) * | 1999-03-16 | 2000-12-26 | General Electric Co. | Gas turbine generator having reserve capacity controller |

| US6073445A (en) * | 1999-03-30 | 2000-06-13 | Johnson; Arthur | Methods for producing hydro-electric power |

| JP3677536B2 (ja) * | 1999-10-27 | 2005-08-03 | 株式会社日立製作所 | ガスタービン発電制御装置 |

| JP3479672B2 (ja) * | 1999-12-28 | 2003-12-15 | 川崎重工業株式会社 | ガスタービンの制御方法および制御装置 |

| JP3849071B2 (ja) * | 2000-01-18 | 2006-11-22 | 株式会社日立製作所 | ガスタービン設備の運転方法 |

| US6449953B1 (en) * | 2000-04-28 | 2002-09-17 | General Electric Company | Methods for reducing gas turbine engine emissions |

| US6408611B1 (en) * | 2000-08-10 | 2002-06-25 | Honeywell International, Inc. | Fuel control method for gas turbine |

| JP2003278561A (ja) | 2002-03-26 | 2003-10-02 | Mitsubishi Heavy Ind Ltd | 入口案内翼制御装置 |

-

2002

- 2002-06-06 IT IT2002MI001231A patent/ITMI20021231A1/it unknown

-

2003

- 2003-05-29 CA CA2430441A patent/CA2430441C/en not_active Expired - Lifetime

- 2003-06-03 US US10/452,922 patent/US7003940B2/en not_active Expired - Lifetime

- 2003-06-04 EP EP03253528.8A patent/EP1369563B1/en not_active Expired - Lifetime

- 2003-06-05 KR KR1020030036215A patent/KR100785546B1/ko not_active Expired - Fee Related

- 2003-06-05 NO NO20032557A patent/NO338996B1/no not_active IP Right Cessation

- 2003-06-06 JP JP2003161427A patent/JP4895465B2/ja not_active Expired - Fee Related

- 2003-06-06 CN CNB031476961A patent/CN1330866C/zh not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CA2430441A1 (en) | 2003-12-06 |

| ITMI20021231A1 (it) | 2003-12-09 |

| NO20032557L (no) | 2003-12-08 |

| US20040040279A1 (en) | 2004-03-04 |

| JP2004028098A (ja) | 2004-01-29 |

| KR20030095283A (ko) | 2003-12-18 |

| EP1369563A2 (en) | 2003-12-10 |

| CN1330866C (zh) | 2007-08-08 |

| NO20032557D0 (no) | 2003-06-05 |

| EP1369563B1 (en) | 2015-09-02 |

| CN1495351A (zh) | 2004-05-12 |

| EP1369563A3 (en) | 2010-03-10 |

| NO338996B1 (no) | 2016-11-07 |

| US7003940B2 (en) | 2006-02-28 |

| KR100785546B1 (ko) | 2007-12-12 |

| CA2430441C (en) | 2010-02-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US11073084B2 (en) | Turbocooled vane of a gas turbine engine | |

| US6226974B1 (en) | Method of operation of industrial gas turbine for optimal performance | |

| CN106762158B (zh) | 用于操作燃气涡轮的同时维持排放标准的系统和方法 | |

| US5697209A (en) | Power plant with steam injection | |

| JP4895465B2 (ja) | 1軸形ガスタービンの火炎温度の制御及び調節システム | |

| JP2013140003A (ja) | タービンエンジン及びタービンエンジンにおいて空気を流す方法 | |

| JP2013140003A5 (enExample) | ||

| US10072573B2 (en) | Power plant including an ejector and steam generating system via turbine extraction | |

| JP4885199B2 (ja) | ガスタービン運転制御装置及び方法 | |

| US20160273396A1 (en) | Power generation system having compressor creating excess air flow and heat exchanger therefor | |

| JP2021193298A (ja) | ガスタービンエンジンの拡張された排出量適合動作のためのシステムおよび方法 | |

| WO2019162168A1 (en) | Controller and method | |

| CA3089687C (en) | Controller and method | |

| US20170058770A1 (en) | System and method for decoupling steam production dependency from gas turbine load level | |

| Boyce | Advanced industrial gas turbines for power generation | |

| US20170058771A1 (en) | System and method for generating steam during gas turbine low-load conditions | |

| JP3551215B2 (ja) | 蒸気注入ガスタービンとその制御方法 | |

| CN107429613B (zh) | 燃气涡轮发动机的涡轮冷却叶片 | |

| KR101891449B1 (ko) | 가스 터빈 | |

| US20160312649A1 (en) | High performance robust gas turbine exhaust with variable (adaptive) exhaust diffuser geometry | |

| Diakunchak et al. | The history of the Siemens gas turbine | |

| JPH08270407A (ja) | 1軸式複合プラントのガスタービン制御方法 | |

| JP5675527B2 (ja) | ガスタービン制御装置及びガスタービン制御方法 | |

| JP2025076355A (ja) | 待機モードで動作するガスタービンエンジンの予熱のためのシステムおよび関連方法 | |

| WO2017052794A2 (en) | Turbocooled vane of a gas turbine engine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060601 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060601 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20081028 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20090127 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20090130 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090427 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20090427 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20090427 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20091201 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100301 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20101005 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20101227 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20110105 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20110329 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20110802 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20111101 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20111122 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20111220 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4895465 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150106 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |