JP4418363B2 - 嵌着品を有するガセット式フレキシブル・ボトルの製造方法 - Google Patents

嵌着品を有するガセット式フレキシブル・ボトルの製造方法 Download PDFInfo

- Publication number

- JP4418363B2 JP4418363B2 JP2004501273A JP2004501273A JP4418363B2 JP 4418363 B2 JP4418363 B2 JP 4418363B2 JP 2004501273 A JP2004501273 A JP 2004501273A JP 2004501273 A JP2004501273 A JP 2004501273A JP 4418363 B2 JP4418363 B2 JP 4418363B2

- Authority

- JP

- Japan

- Prior art keywords

- fitting

- bottle

- base

- web

- neck

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000004519 manufacturing process Methods 0.000 title claims description 50

- 238000000034 method Methods 0.000 title claims description 26

- 239000000463 material Substances 0.000 claims description 33

- 238000007789 sealing Methods 0.000 claims description 27

- 230000002093 peripheral effect Effects 0.000 claims description 18

- 238000005520 cutting process Methods 0.000 claims description 9

- 230000007704 transition Effects 0.000 claims description 7

- 238000003780 insertion Methods 0.000 claims description 3

- 230000037431 insertion Effects 0.000 claims description 3

- 230000005855 radiation Effects 0.000 claims description 3

- 239000012528 membrane Substances 0.000 claims description 2

- 238000004826 seaming Methods 0.000 claims description 2

- 238000003825 pressing Methods 0.000 claims 4

- XEEYBQQBJWHFJM-FTXFMUIASA-N iron-51 Chemical compound [51Fe] XEEYBQQBJWHFJM-FTXFMUIASA-N 0.000 description 8

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 6

- 238000010586 diagram Methods 0.000 description 6

- 230000008569 process Effects 0.000 description 6

- 238000013461 design Methods 0.000 description 5

- 239000000047 product Substances 0.000 description 5

- 230000009471 action Effects 0.000 description 4

- 229920001684 low density polyethylene Polymers 0.000 description 4

- 239000004702 low-density polyethylene Substances 0.000 description 4

- 239000000203 mixture Substances 0.000 description 4

- 238000000576 coating method Methods 0.000 description 3

- 239000011888 foil Substances 0.000 description 3

- 229910052742 iron Inorganic materials 0.000 description 3

- 239000007788 liquid Substances 0.000 description 3

- 229920003023 plastic Polymers 0.000 description 3

- 239000004033 plastic Substances 0.000 description 3

- 229920000728 polyester Polymers 0.000 description 3

- 230000001154 acute effect Effects 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 239000000470 constituent Substances 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 239000000123 paper Substances 0.000 description 2

- 230000037303 wrinkles Effects 0.000 description 2

- 238000013459 approach Methods 0.000 description 1

- 238000005452 bending Methods 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000012467 final product Substances 0.000 description 1

- 238000009459 flexible packaging Methods 0.000 description 1

- 229920002457 flexible plastic Polymers 0.000 description 1

- 238000012804 iterative process Methods 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 238000004806 packaging method and process Methods 0.000 description 1

- 239000002910 solid waste Substances 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 230000007723 transport mechanism Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D75/00—Packages comprising articles or materials partially or wholly enclosed in strips, sheets, blanks, tubes, or webs of flexible sheet material, e.g. in folded wrappers

- B65D75/52—Details

- B65D75/58—Opening or contents-removing devices added or incorporated during package manufacture

- B65D75/5861—Spouts

- B65D75/5872—Non-integral spouts

- B65D75/5883—Non-integral spouts connected to the package at the sealed junction of two package walls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/78—Means for handling the parts to be joined, e.g. for making containers or hollow articles, e.g. means for handling sheets, plates, web-like materials, tubular articles, hollow articles or elements to be joined therewith; Means for discharging the joined articles from the joining apparatus

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/78—Means for handling the parts to be joined, e.g. for making containers or hollow articles, e.g. means for handling sheets, plates, web-like materials, tubular articles, hollow articles or elements to be joined therewith; Means for discharging the joined articles from the joining apparatus

- B29C65/7855—Provisory fixing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/78—Means for handling the parts to be joined, e.g. for making containers or hollow articles, e.g. means for handling sheets, plates, web-like materials, tubular articles, hollow articles or elements to be joined therewith; Means for discharging the joined articles from the joining apparatus

- B29C65/7858—Means for handling the parts to be joined, e.g. for making containers or hollow articles, e.g. means for handling sheets, plates, web-like materials, tubular articles, hollow articles or elements to be joined therewith; Means for discharging the joined articles from the joining apparatus characterised by the feeding movement of the parts to be joined

- B29C65/7879—Means for handling the parts to be joined, e.g. for making containers or hollow articles, e.g. means for handling sheets, plates, web-like materials, tubular articles, hollow articles or elements to be joined therewith; Means for discharging the joined articles from the joining apparatus characterised by the feeding movement of the parts to be joined said parts to be joined moving in a closed path, e.g. a rectangular path

- B29C65/7882—Means for handling the parts to be joined, e.g. for making containers or hollow articles, e.g. means for handling sheets, plates, web-like materials, tubular articles, hollow articles or elements to be joined therewith; Means for discharging the joined articles from the joining apparatus characterised by the feeding movement of the parts to be joined said parts to be joined moving in a closed path, e.g. a rectangular path said parts to be joined moving in a circular path

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/004—Preventing sticking together, e.g. of some areas of the parts to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/345—Progressively making the joint, e.g. starting from the middle

- B29C66/3452—Making complete joints by combining partial joints

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/40—General aspects of joining substantially flat articles, e.g. plates, sheets or web-like materials; Making flat seams in tubular or hollow articles; Joining single elements to substantially flat surfaces

- B29C66/41—Joining substantially flat articles ; Making flat seams in tubular or hollow articles

- B29C66/43—Joining a relatively small portion of the surface of said articles

- B29C66/431—Joining the articles to themselves

- B29C66/4312—Joining the articles to themselves for making flat seams in tubular or hollow articles, e.g. transversal seams

- B29C66/43121—Closing the ends of tubular or hollow single articles, e.g. closing the ends of bags

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/50—General aspects of joining tubular articles; General aspects of joining long products, i.e. bars or profiled elements; General aspects of joining single elements to tubular articles, hollow articles or bars; General aspects of joining several hollow-preforms to form hollow or tubular articles

- B29C66/51—Joining tubular articles, profiled elements or bars; Joining single elements to tubular articles, hollow articles or bars; Joining several hollow-preforms to form hollow or tubular articles

- B29C66/53—Joining single elements to tubular articles, hollow articles or bars

- B29C66/532—Joining single elements to the wall of tubular articles, hollow articles or bars

- B29C66/5324—Joining single elements to the wall of tubular articles, hollow articles or bars said single elements being substantially annular, i.e. of finite length

- B29C66/53245—Joining single elements to the wall of tubular articles, hollow articles or bars said single elements being substantially annular, i.e. of finite length said articles being hollow

- B29C66/53246—Joining single elements to the wall of tubular articles, hollow articles or bars said single elements being substantially annular, i.e. of finite length said articles being hollow said single elements being spouts, e.g. joining spouts to containers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/50—General aspects of joining tubular articles; General aspects of joining long products, i.e. bars or profiled elements; General aspects of joining single elements to tubular articles, hollow articles or bars; General aspects of joining several hollow-preforms to form hollow or tubular articles

- B29C66/61—Joining from or joining on the inside

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/50—General aspects of joining tubular articles; General aspects of joining long products, i.e. bars or profiled elements; General aspects of joining single elements to tubular articles, hollow articles or bars; General aspects of joining several hollow-preforms to form hollow or tubular articles

- B29C66/61—Joining from or joining on the inside

- B29C66/612—Making circumferential joints

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/50—General aspects of joining tubular articles; General aspects of joining long products, i.e. bars or profiled elements; General aspects of joining single elements to tubular articles, hollow articles or bars; General aspects of joining several hollow-preforms to form hollow or tubular articles

- B29C66/63—Internally supporting the article during joining

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/80—General aspects of machine operations or constructions and parts thereof

- B29C66/83—General aspects of machine operations or constructions and parts thereof characterised by the movement of the joining or pressing tools

- B29C66/832—Reciprocating joining or pressing tools

- B29C66/8322—Joining or pressing tools reciprocating along one axis

- B29C66/83221—Joining or pressing tools reciprocating along one axis cooperating reciprocating tools, each tool reciprocating along one axis

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B31—MAKING ARTICLES OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER; WORKING PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B—MAKING CONTAINERS OF PAPER, CARDBOARD OR MATERIAL WORKED IN A MANNER ANALOGOUS TO PAPER

- B31B50/00—Making rigid or semi-rigid containers, e.g. boxes or cartons

- B31B50/74—Auxiliary operations

- B31B50/81—Forming or attaching accessories, e.g. opening devices, closures or tear strings

- B31B50/84—Forming or attaching means for filling or dispensing contents, e.g. valves or spouts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D11/00—Containers having bodies formed by interconnecting or uniting two or more rigid, or substantially rigid, components made wholly or mainly of plastics material

- B65D11/02—Containers having bodies formed by interconnecting or uniting two or more rigid, or substantially rigid, components made wholly or mainly of plastics material of curved cross-section

- B65D11/04—Bottles or similar containers with necks or like restricted apertures designed for pouring contents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D75/00—Packages comprising articles or materials partially or wholly enclosed in strips, sheets, blanks, tubes, or webs of flexible sheet material, e.g. in folded wrappers

- B65D75/008—Standing pouches, i.e. "Standbeutel"

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2793/00—Shaping techniques involving a cutting or machining operation

- B29C2793/0009—Cutting out

- B29C2793/0018—Cutting out for making a hole

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

- B29C65/08—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure using ultrasonic vibrations

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/02—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure

- B29C65/18—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by heating, with or without pressure using heated tools

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C65/00—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor

- B29C65/74—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by welding and severing, or by joining and severing, the severing being performed in the area to be joined, next to the area to be joined, in the joint area or next to the joint area

- B29C65/743—Joining or sealing of preformed parts, e.g. welding of plastics materials; Apparatus therefor by welding and severing, or by joining and severing, the severing being performed in the area to be joined, next to the area to be joined, in the joint area or next to the joint area using the same tool for both joining and severing, said tool being monobloc or formed by several parts mounted together and forming a monobloc

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/10—Particular design of joint configurations particular design of the joint cross-sections

- B29C66/11—Joint cross-sections comprising a single joint-segment, i.e. one of the parts to be joined comprising a single joint-segment in the joint cross-section

- B29C66/112—Single lapped joints

- B29C66/1122—Single lap to lap joints, i.e. overlap joints

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/01—General aspects dealing with the joint area or with the area to be joined

- B29C66/05—Particular design of joint configurations

- B29C66/20—Particular design of joint configurations particular design of the joint lines, e.g. of the weld lines

- B29C66/24—Particular design of joint configurations particular design of the joint lines, e.g. of the weld lines said joint lines being closed or non-straight

- B29C66/242—Particular design of joint configurations particular design of the joint lines, e.g. of the weld lines said joint lines being closed or non-straight said joint lines being closed, i.e. forming closed contours

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/71—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the composition of the plastics material of the parts to be joined

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/71—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the composition of the plastics material of the parts to be joined

- B29C66/712—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the composition of the plastics material of the parts to be joined the composition of one of the parts to be joined being different from the composition of the other part

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/70—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material

- B29C66/72—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the structure of the material of the parts to be joined

- B29C66/723—General aspects of processes or apparatus for joining preformed parts characterised by the composition, physical properties or the structure of the material of the parts to be joined; Joining with non-plastics material characterised by the structure of the material of the parts to be joined being multi-layered

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C66/00—General aspects of processes or apparatus for joining preformed parts

- B29C66/90—Measuring or controlling the joining process

- B29C66/91—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux

- B29C66/914—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux

- B29C66/9141—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux by controlling or regulating the temperature

- B29C66/91441—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux by controlling or regulating the temperature the temperature being non-constant over time

- B29C66/91443—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux by controlling or regulating the temperature the temperature being non-constant over time following a temperature-time profile

- B29C66/91445—Measuring or controlling the joining process by measuring or controlling the temperature, the heat or the thermal flux by controlling or regulating the temperature, the heat or the thermal flux by controlling or regulating the temperature the temperature being non-constant over time following a temperature-time profile by steps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2023/00—Use of polyalkenes or derivatives thereof as moulding material

- B29K2023/04—Polymers of ethylene

- B29K2023/06—PE, i.e. polyethylene

- B29K2023/0608—PE, i.e. polyethylene characterised by its density

- B29K2023/0633—LDPE, i.e. low density polyethylene

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2067/00—Use of polyesters or derivatives thereof, as moulding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2009/00—Layered products

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2009/00—Layered products

- B29L2009/005—Layered products coated

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2022/00—Hollow articles

- B29L2022/02—Inflatable articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/46—Knobs or handles, push-buttons, grips

- B29L2031/463—Grips, handles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/712—Containers; Packaging elements or accessories, Packages

- B29L2031/7128—Bags, sacks, sachets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29L—INDEXING SCHEME ASSOCIATED WITH SUBCLASS B29C, RELATING TO PARTICULAR ARTICLES

- B29L2031/00—Other particular articles

- B29L2031/712—Containers; Packaging elements or accessories, Packages

- B29L2031/7158—Bottles

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Making Paper Articles (AREA)

- Bag Frames (AREA)

Description

1.一対のガセットを含む2枚またはそれ以上の材料ウェブを、面を互いに接触させて製造機の中に給送するステップと、

2.ボトルとするためにボトルのネック部分を含む周辺の一部をシールし、ウェブの縁部における区域を切り離すことによってボトルを形成するステップと、

3.入って来るウェブの少なくとも1つを、ネック部分の上流にあるウェブの残りから分離して、嵌着品をボトルのネック部分の中に挿入するステップであって、挿入動作は結局ボトルの底部になる部分を通るステップと、

4.ボトルの周辺シールの残りを形成するステップと、

5.ボトルをウェブから切断するステップと、

6.加熱した締付け手段によってボトル材料を嵌着品に締め付けて、ボトル材料と嵌着品との間にシールを形成するステップと、

7.異なる放射角度で加熱したクランプによってボトル材料を嵌着品に対して2回目の締付けを行うステップと

を備える。

1.ボトルの頂部分を形成する周辺継ぎ部を(熱と圧力を加えることによって、または代替案として超音波またはその他の手段によって)形成し、同時に、ネックと遷移区画の周りの余分な材料を、ウェブの縁部を「切り込む」ことによって除去する。

2.嵌着品を挿入する。

3.次に、部分的に形成されたボトルを前方に動かし、ある適切な搬送機構、例えば図に示す「大観覧車状装置(フェリス・ホイール)」に取り付ける。

4.周辺継ぎ部の残りを形成し(すなわち、次のボトルの底部分と頂部分)、ボトルをウェブから取り外す。

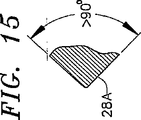

5.生成中のボトルを次のステーションに移動させ(すなわち、フェリス・ホイールが回転する)、ボトルのネックと嵌着品との間の接合部を2つの動作でシールし、シール動作の間でボトルを(好ましくは約)90°だけ回す。代替案として、もちろん、複数のシール機構(単一機構であることも可能)が異なる角度から圧力を加えることができる。

Claims (4)

- 嵌着品を含むネック区画と、遷移区画と、本体区画と、底区画とを含むフレキシブル・ボトルの製造方法であって、

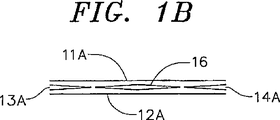

ウェブを製造機の中に給送するステップであって、前記ウェブはフレキシブル薄膜から構成され、前記ウェブはi)それぞれが上面と下面とを有する一対の折り曲げたガセットと、ii)その折り曲げたガセットの上面と下面とにそれぞれ突き合わされている頂部積層と底部積層であって、前記ガセットの折り目は互いに隣接している頂部積層と底部積層とを含む第1のステップと、

少なくとも前記ネック区画と前記遷移区画との側部に周辺継ぎ部を形成するステップであって、ただし前記底区画は含まず、前記ネック区画は前記機械に最初に給送された前記ボトルの部分であり、前記周辺継ぎ部が前記頂部積層を前記ガセットの上面に取り付け、前記底部積層を前記ガセットの下面に取り付ける第2のステップと、

前記ネック区画と前記遷移区画との領域における前記周辺継ぎ部の外側の材料を切り離す第3のステップと、

継ぎ合わされていない底区画を通じて嵌着品をネック区画の中に挿入するステップであって、その挿入は前記ウェブが給送される方向に行われる第4のステップと、

先の周辺継ぎ合せステップで形成されなかった前記底区画を含む前記ボトルの部分の周りに周辺継ぎ部を形成するステップであって、前記周辺継ぎ部は前記頂部積層を前記ガセットの上面に取り付け、前記底部積層を前記ガセットの下面に取り付ける第5のステップと、

前記ボトルを前記ウェブから切断する第6のステップと、

前記ネック区画を前記嵌着品に密封する第7のステップと

を含む方法であり、

かつ、前記ネック区画の前記嵌着品への前記密封が、前記嵌着品に対して前記ネック区画に熱と圧力を加えることによって達成され、

前記ネック区画と前記嵌着品との間の境界に熱と圧力を加えるステップが2回以上実施され、前記の熱と圧力の適用の少なくとも2回が異なる放射角度で行われる、フレキシブル・ボトルの製造方法。 - 前記の異なる放射角度が約90度である請求項1に記載のフレキシブル・ボトルの製造方法。

- 前記ネック区画の前記嵌着品への前記密封の方法が、

前記嵌着品を中に置くことができるネック部分を有する容器の中で嵌着品のベースを密封する方法であって、

前記ベースの形状に実質的に対応する内部形状を有する、少なくとも1つの加熱されるスプリット・クランプを備えるステップと、

前記ネック部分の中に前記嵌着品のベースを挿入するステップと、

1回目に、前記クランプの1つに、前記ベースに対して前記ネック部分への圧力を加えるステップと、

2回目に、前記クランプの1つに、前記ベースに対して前記ネック部分へ圧力を加えるステップであって、前記2回目の加圧は前記ベースについて異なる角方向に行われるステップと

を含む方法であり、

前記第1、第2加圧が異なるクランプによって達成される、容器の中に嵌着品のベースを密封する方法である請求項1に記載のフレキシブル・ボトルの製造方法。 - 前記ネック区画の前記嵌着品への前記密封の方法が、

前記嵌着品を中に置くことができるネック部分を有する容器の中で嵌着品のベースを密封する方法であって、

前記ベースの形状に実質的に対応する内部形状を有する、少なくとも1つの加熱されるスプリット・クランプを備えるステップと、

前記ネック部分の中に前記嵌着品のベースを挿入するステップと、

1回目に、前記クランプの1つに、前記ベースに対して前記ネック部分への圧力を加えるステップと、

2回目に、前記クランプの1つに、前記ベースに対して前記ネック部分へ圧力を加えるステップであって、前記2回目の加圧は前記ベースについて異なる角方向に行われるステップと

を含む方法であり、

前記第1、第2加圧が同じクランプによって達成され、

前記第1、第2加圧の間で前記容器を回転させるステップをさらに含む請求項1に記載のフレキシブル・ボトルの製造方法。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US13343602A | 2002-04-27 | 2002-04-27 | |

| US10/195,097 US6832852B2 (en) | 2002-04-27 | 2002-07-11 | Gusseted flexible bottle with fitment and method of fabrication |

| PCT/US2003/010905 WO2003093126A1 (en) | 2002-04-27 | 2003-04-09 | Gusseted flexible bottle with fitment and method of fabrication |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009169552A Division JP5005736B2 (ja) | 2002-04-27 | 2009-07-17 | 嵌着品を有するガセット式フレキシブル・ボトルとその製造方法 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2005523853A JP2005523853A (ja) | 2005-08-11 |

| JP2005523853A5 JP2005523853A5 (ja) | 2009-03-26 |

| JP4418363B2 true JP4418363B2 (ja) | 2010-02-17 |

Family

ID=29406228

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004501273A Expired - Fee Related JP4418363B2 (ja) | 2002-04-27 | 2003-04-09 | 嵌着品を有するガセット式フレキシブル・ボトルの製造方法 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US7147597B2 (ja) |

| EP (1) | EP1501736B1 (ja) |

| JP (1) | JP4418363B2 (ja) |

| AU (1) | AU2003224903A1 (ja) |

| DK (1) | DK2573004T3 (ja) |

| WO (1) | WO2003093126A1 (ja) |

Families Citing this family (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2008526632A (ja) * | 2005-01-07 | 2008-07-24 | ケーアールダブリュ・コンサルティング・エルエルシイ | 付属品付きの三角形状可撓性ボトルとその製造方法 |

| US7794149B2 (en) * | 2005-05-31 | 2010-09-14 | Smart Bottle Inc. | Container of selectively expanded plastic film with fitment |

| US7328543B2 (en) * | 2006-05-17 | 2008-02-12 | Plitek, L.L.C. | Apparatus and method for the application of pressure relief valves |

| US8945459B2 (en) * | 2008-09-24 | 2015-02-03 | Smart Bottle Inc. | Container made from expanded plastic film |

| ES2451505T3 (es) * | 2009-04-29 | 2014-03-27 | Smq Group B.V. | Bolsa plegable y método para fabricar una bolsa plegable |

| US8468779B2 (en) * | 2009-05-05 | 2013-06-25 | Sealed Air Corporation (Us) | Method and apparatus for positioning, inflating, and sealing a mailer comprising an inner inflatable liner |

| BR112012005309B1 (pt) * | 2009-09-10 | 2021-06-01 | Smart Bottle Inc. | Recipiente flexível com estruturas de alça superior e inferior flexível, recipiente flexível com uma estrutura de alça superior flexível e método de transferência de substância fluida de um recipiente flexível |

| US8348509B2 (en) * | 2009-09-10 | 2013-01-08 | Smart Bottle, Inc. | Flexible container with fitment and handle |

| US20110083402A1 (en) * | 2009-10-09 | 2011-04-14 | Larry Dee Walker | Vertical form, fill, and seal system for hot fill liquids |

| US20110192121A1 (en) | 2010-02-08 | 2011-08-11 | Sealed Air Corporation (Us) | Inflatable Mailer, Apparatus, and Method for Making the Same |

| US8388886B2 (en) | 2010-06-10 | 2013-03-05 | Smart Bottle, Inc. | Blow-molded plastic bottle and method of manufacture |

| BR112013020797A2 (pt) * | 2011-02-17 | 2019-09-24 | Nihon Yamamura Glass Co Ltd | recipiente equipado com bomba, e, bomba de distribuição usada para o mesmo |

| US9284106B2 (en) * | 2011-10-24 | 2016-03-15 | Smart Bottle, Inc. | Bottle registration feature |

| DE202011109209U1 (de) | 2011-12-16 | 2012-07-24 | Bischof + Klein Gmbh & Co. Kg | Seitenfaltenbeutel aus Folie |

| WO2015160735A1 (en) | 2014-04-15 | 2015-10-22 | Intelligent Energy Limited | Elastomeric hydrogen reactor with clog-less filter |

| JP6454732B2 (ja) | 2014-05-05 | 2019-01-16 | ダウ グローバル テクノロジーズ エルエルシー | 可撓性容器 |

| KR20170031706A (ko) * | 2014-07-16 | 2017-03-21 | 다우 글로벌 테크놀로지스 엘엘씨 | 피트먼트를 갖는 유연성 용기 및 그의 제조방법 |

| TR201908500T4 (tr) | 2014-07-16 | 2019-07-22 | Dow Global Technologies Llc | Donanımlı esnek kap ve aynısını üretmek için işlem. |

| WO2016016720A1 (en) | 2014-07-29 | 2016-02-04 | Intelligent Energy Limited | Performance balancing elastomeric hydrogen reactor |

| WO2016030766A2 (en) * | 2014-08-29 | 2016-03-03 | Intelligent Energy Limited | Flexible volumetric container |

| EP3784485A1 (en) | 2018-04-26 | 2021-03-03 | Dow Global Technologies LLC | Method for sealing a fitment to a flexible container and flexible container comprising a fitment |

| EP3959144A4 (en) * | 2019-04-23 | 2023-01-25 | Smart Bottle, Inc | FLEXIBLE CONTAINER AND METHOD FOR INSTALLING AN ACCESSORY IN IT |

| WO2021046019A1 (en) | 2019-09-06 | 2021-03-11 | Dow Global Technologies Llc | Flexible film fluid-dispensing liner member |

| WO2024049936A1 (en) | 2022-08-31 | 2024-03-07 | Dow Global Technologies Llc | Method for making molded polymer foam |

Family Cites Families (28)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1306328A (fr) * | 1961-11-14 | 1962-10-13 | Procédé de fabrication de sacs à valve en matière plastique | |

| NL126868C (ja) | 1962-11-14 | 1900-01-01 | ||

| US4669124A (en) * | 1984-05-23 | 1987-05-26 | Yoken Co., Ltd. | Beverage container with tamperproof screwthread cap |

| EP0221893A4 (en) * | 1985-04-22 | 1988-09-07 | Inpaco Inc | FIXING METHOD IN HORIZONTAL DEVICES FOR ACCESSORIES FOR POURING, FILLING AND CLOSING. |

| DE3612196A1 (de) * | 1986-04-11 | 1987-10-22 | Bosch Gmbh Robert | Vorrichtung zum herstellen von beutelpackungen mit entnahmestutzen |

| US4658434A (en) * | 1986-05-29 | 1987-04-14 | Grain Security Foundation Ltd. | Laminates and laminated articles |

| US5087235A (en) * | 1990-09-11 | 1992-02-11 | Custom Packaging Systems, Inc. | Method for making a collapsible bag with spout |

| FR2672033A1 (fr) * | 1991-01-25 | 1992-07-31 | Bottari Pierre | Sac polygonal a paroi transversale plane et dispositif pour sa mise en óoeuvre. |

| US5324233A (en) * | 1992-09-09 | 1994-06-28 | W. R. Grace & Co.-Conn. | Method and apparatus for sealing fitment tubes into pouches |

| US5348525A (en) * | 1993-08-09 | 1994-09-20 | Jebco Packaging Systems, Inc. | Method of constructing flexible containers with tubular fitments |

| JPH07323478A (ja) * | 1994-05-31 | 1995-12-12 | Sumitomo Bakelite Co Ltd | 注出栓溶着方法及びその装置 |

| IL111114A0 (en) * | 1994-09-30 | 1994-11-28 | Geller Avner | Package having a rectangular base and its manufacture |

| JP3048888B2 (ja) * | 1995-06-28 | 2000-06-05 | 株式会社細川洋行 | 液体充填容器およびその製造方法 |

| US5918984A (en) | 1996-08-29 | 1999-07-06 | Custom Packaging Systems, Inc. | Collapsible bag with handle |

| JP3336878B2 (ja) * | 1996-09-27 | 2002-10-21 | 花王株式会社 | ガゼット袋 |

| DE59808635D1 (de) * | 1997-03-12 | 2003-07-10 | Obrist & Co Ag Reinach H | Beuteltube |

| JPH1143155A (ja) * | 1997-07-23 | 1999-02-16 | Hosokawa Yoko Co Ltd | 液体容器 |

| US5855544A (en) * | 1997-08-12 | 1999-01-05 | Technical Developers, Inc. | Flexible container with tubular fitment and method and apparatus for assembling same |

| JPH11208676A (ja) * | 1998-01-27 | 1999-08-03 | Toppan Printing Co Ltd | スパウト付きガゼット袋 |

| JP2000025793A (ja) * | 1998-07-09 | 2000-01-25 | Toyo Seikan Kaisha Ltd | 吊り環付パウチ |

| JP2000072161A (ja) * | 1998-08-28 | 2000-03-07 | Mitsubishi Heavy Ind Ltd | 口栓付不定形容器 |

| US6220702B1 (en) * | 1998-12-24 | 2001-04-24 | Seiko Epson Corporation | Ink bag for ink jet type recording apparatus and package suitable for packing such ink bag |

| US6549744B2 (en) | 2000-01-07 | 2003-04-15 | Ricoh Company, Ltd. | Powder container for an image forming apparatus and powder discharging device |

| US6612466B1 (en) * | 2000-08-21 | 2003-09-02 | Illinois Tool Works Inc. | Thin wall fitment for spouted pouch |

| US6695757B2 (en) * | 2001-01-12 | 2004-02-24 | Scholle Corporation | Method of manufacturing a standup bag |

| US6810636B2 (en) * | 2001-01-30 | 2004-11-02 | Fogg Filler Company | Container and spout assembly apparatus and method of assembly |

| US6860406B2 (en) * | 2001-08-13 | 2005-03-01 | Illinois Tool Works Inc. | Flexible pouch fitment structure |

| US7407326B2 (en) * | 2003-12-08 | 2008-08-05 | Wilkes Kenneth R | Triangularly shaped flexible bottle with fitment, and method of fabrication |

-

2003

- 2003-04-09 EP EP03721596A patent/EP1501736B1/en not_active Expired - Lifetime

- 2003-04-09 DK DK12192751.1T patent/DK2573004T3/en active

- 2003-04-09 AU AU2003224903A patent/AU2003224903A1/en not_active Abandoned

- 2003-04-09 WO PCT/US2003/010905 patent/WO2003093126A1/en active Application Filing

- 2003-04-09 JP JP2004501273A patent/JP4418363B2/ja not_active Expired - Fee Related

-

2004

- 2004-09-01 US US10/932,516 patent/US7147597B2/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| US7147597B2 (en) | 2006-12-12 |

| JP2005523853A (ja) | 2005-08-11 |

| WO2003093126A1 (en) | 2003-11-13 |

| DK2573004T3 (en) | 2017-07-17 |

| EP1501736B1 (en) | 2012-11-21 |

| EP1501736A4 (en) | 2011-05-25 |

| US20050026761A1 (en) | 2005-02-03 |

| EP1501736A1 (en) | 2005-02-02 |

| AU2003224903A1 (en) | 2003-11-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5005736B2 (ja) | 嵌着品を有するガセット式フレキシブル・ボトルとその製造方法 | |

| JP4418363B2 (ja) | 嵌着品を有するガセット式フレキシブル・ボトルの製造方法 | |

| US8468782B2 (en) | Method for producing a bottle-like or tubular container, particularly a tubular bag, comprising a sealed-in bottom, and a correspondingly produced tubular bag | |

| US3511435A (en) | Laminated container and method of making a laminated container | |

| EP0032257B1 (en) | Method for the continuous manufacture of packing containers | |

| US6805261B1 (en) | Flexible tube and method of manufacture | |

| US20160046400A1 (en) | Easy to Open Package | |

| US7407326B2 (en) | Triangularly shaped flexible bottle with fitment, and method of fabrication | |

| US20170197771A1 (en) | Stand-up flexible container with top and bottom handles | |

| JP2005523853A5 (ja) | ||

| JP7203553B2 (ja) | 角底包装袋、包装体、および角底包装袋の製造方法 | |

| WO2021193759A1 (ja) | 角底包装袋の製造方法、角底包装袋の製造装置、包装体の製造方法及び包装体の製造装置 | |

| KR102090228B1 (ko) | 파우치 또는 용기를 제조하기 위한 시스템 및 방법 | |

| JP2003300540A (ja) | ジッパー付きガセット付き扁平袋及びその製造方法 | |

| JP2005178843A (ja) | 自立袋およびその製造方法 | |

| JP2019006435A (ja) | スパウト付包装袋及びその製造方法、並びに内容物入りスパウト付包装袋 | |

| JP3390147B2 (ja) | 自立袋連続製造方法 | |

| JP3247068B2 (ja) | 容器及びその製袋充填方法 | |

| WO2006073403A1 (en) | Triangularly shaped flexible bottle with fitment, and method of fabrication | |

| JP2004182309A (ja) | 小袋包装装置に対して供給される包装材料の繋ぎ方法 | |

| CA3006048A1 (en) | Bottom gusset package with folded gusset | |

| JP2523101Y2 (ja) | 大口径ラミネートフィルムチューブ | |

| JPH01199858A (ja) | ピロー包装体及びその製造方法 | |

| JP2002225879A (ja) | 自立袋 | |

| JPH092487A (ja) | プラスチックフィルム製袋及びこの製法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20050620 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20050620 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060209 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080715 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20081014 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20081021 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20081104 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20081111 |

|

| A711 | Notification of change in applicant |

Free format text: JAPANESE INTERMEDIATE CODE: A711 Effective date: 20090113 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090115 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20090115 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20090119 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20090119 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20090113 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20090401 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090717 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20090828 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20091111 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20091127 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4418363 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121204 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121204 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131204 Year of fee payment: 4 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131204 Year of fee payment: 4 |

|

| S533 | Written request for registration of change of name |

Free format text: JAPANESE INTERMEDIATE CODE: R313533 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131204 Year of fee payment: 4 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |