JP4361811B2 - 半導体製造装置 - Google Patents

半導体製造装置 Download PDFInfo

- Publication number

- JP4361811B2 JP4361811B2 JP2004004483A JP2004004483A JP4361811B2 JP 4361811 B2 JP4361811 B2 JP 4361811B2 JP 2004004483 A JP2004004483 A JP 2004004483A JP 2004004483 A JP2004004483 A JP 2004004483A JP 4361811 B2 JP4361811 B2 JP 4361811B2

- Authority

- JP

- Japan

- Prior art keywords

- mist

- temperature

- processing

- semiconductor manufacturing

- gas

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000004065 semiconductor Substances 0.000 title description 23

- 238000004519 manufacturing process Methods 0.000 title description 19

- 239000003595 mist Substances 0.000 description 130

- 238000012545 processing Methods 0.000 description 81

- 239000007789 gas Substances 0.000 description 55

- 239000007788 liquid Substances 0.000 description 30

- 239000012159 carrier gas Substances 0.000 description 24

- 238000010438 heat treatment Methods 0.000 description 23

- 238000001816 cooling Methods 0.000 description 19

- 235000012431 wafers Nutrition 0.000 description 15

- 238000006243 chemical reaction Methods 0.000 description 14

- 239000000758 substrate Substances 0.000 description 12

- 238000001514 detection method Methods 0.000 description 10

- 239000003507 refrigerant Substances 0.000 description 9

- 239000010453 quartz Substances 0.000 description 7

- 238000000926 separation method Methods 0.000 description 7

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N silicon dioxide Inorganic materials O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 7

- 238000009834 vaporization Methods 0.000 description 7

- 230000008016 vaporization Effects 0.000 description 7

- 230000000052 comparative effect Effects 0.000 description 5

- 238000000034 method Methods 0.000 description 5

- 230000008569 process Effects 0.000 description 5

- 239000000470 constituent Substances 0.000 description 4

- 239000000498 cooling water Substances 0.000 description 4

- 238000010586 diagram Methods 0.000 description 4

- 230000008859 change Effects 0.000 description 3

- 230000007423 decrease Effects 0.000 description 3

- 238000005530 etching Methods 0.000 description 3

- 239000010408 film Substances 0.000 description 3

- 239000012212 insulator Substances 0.000 description 3

- 238000011084 recovery Methods 0.000 description 3

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 2

- 238000000137 annealing Methods 0.000 description 2

- 230000005540 biological transmission Effects 0.000 description 2

- 230000015572 biosynthetic process Effects 0.000 description 2

- 239000004020 conductor Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000006870 function Effects 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 230000003647 oxidation Effects 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 238000012546 transfer Methods 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 1

- 238000010521 absorption reaction Methods 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 229910021529 ammonia Inorganic materials 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 230000006837 decompression Effects 0.000 description 1

- 239000003989 dielectric material Substances 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 150000002366 halogen compounds Chemical class 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 238000012544 monitoring process Methods 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 238000001020 plasma etching Methods 0.000 description 1

- 238000005389 semiconductor device fabrication Methods 0.000 description 1

- 239000010409 thin film Substances 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

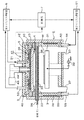

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67098—Apparatus for thermal treatment

- H01L21/67109—Apparatus for thermal treatment mainly by convection

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/4411—Cooling of the reaction chamber walls

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32431—Constructional details of the reactor

- H01J37/32458—Vessel

- H01J37/32522—Temperature

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67017—Apparatus for fluid treatment

- H01L21/67063—Apparatus for fluid treatment for etching

- H01L21/67069—Apparatus for fluid treatment for etching for drying etching

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67011—Apparatus for manufacture or treatment

- H01L21/67098—Apparatus for thermal treatment

- H01L21/67103—Apparatus for thermal treatment mainly by conduction

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/67—Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components ; Apparatus not specifically provided for elsewhere

- H01L21/67005—Apparatus not specifically provided for elsewhere

- H01L21/67242—Apparatus for monitoring, sorting or marking

- H01L21/67248—Temperature monitoring

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Power Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Computer Hardware Design (AREA)

- Manufacturing & Machinery (AREA)

- Organic Chemistry (AREA)

- Analytical Chemistry (AREA)

- Plasma & Fusion (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Mechanical Engineering (AREA)

- Chemical Vapour Deposition (AREA)

- Drying Of Semiconductors (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004004483A JP4361811B2 (ja) | 2004-01-09 | 2004-01-09 | 半導体製造装置 |

| KR1020067015082A KR100876692B1 (ko) | 2004-01-09 | 2004-12-24 | 기판처리장치 |

| PCT/JP2004/019418 WO2005067023A1 (ja) | 2004-01-09 | 2004-12-24 | 基板処理装置 |

| CNB2004800400808A CN100440451C (zh) | 2004-01-09 | 2004-12-24 | 基板处理装置 |

| US10/585,408 US20070163502A1 (en) | 2004-01-09 | 2004-12-24 | Substrate processing apparatus |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004004483A JP4361811B2 (ja) | 2004-01-09 | 2004-01-09 | 半導体製造装置 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2005197600A JP2005197600A (ja) | 2005-07-21 |

| JP2005197600A5 JP2005197600A5 (enExample) | 2007-02-15 |

| JP4361811B2 true JP4361811B2 (ja) | 2009-11-11 |

Family

ID=34747122

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004004483A Expired - Fee Related JP4361811B2 (ja) | 2004-01-09 | 2004-01-09 | 半導体製造装置 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20070163502A1 (enExample) |

| JP (1) | JP4361811B2 (enExample) |

| KR (1) | KR100876692B1 (enExample) |

| CN (1) | CN100440451C (enExample) |

| WO (1) | WO2005067023A1 (enExample) |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4597847B2 (ja) * | 2005-11-28 | 2010-12-15 | 株式会社フジクラ | 成膜装置 |

| JP5337482B2 (ja) | 2006-05-09 | 2013-11-06 | 株式会社アルバック | 薄膜製造装置 |

| US20080006044A1 (en) * | 2006-07-10 | 2008-01-10 | Ziming Tan | Method for controlling temperature |

| CN101558185B (zh) * | 2007-03-29 | 2011-09-07 | 新明和工业株式会社 | 传感器安装结构以及真空成膜装置 |

| CN102077320B (zh) * | 2008-07-04 | 2013-01-23 | 东京毅力科创株式会社 | 等离子体处理装置、等离子体处理方法和介电体窗的温度调节机构 |

| JP5281148B2 (ja) * | 2009-04-03 | 2013-09-04 | 東京エレクトロン株式会社 | 蒸着ヘッドおよび成膜装置 |

| JP2012169552A (ja) * | 2011-02-16 | 2012-09-06 | Tokyo Electron Ltd | 冷却機構、処理室、処理室内部品及び冷却方法 |

| JP5947023B2 (ja) * | 2011-11-14 | 2016-07-06 | 東京エレクトロン株式会社 | 温度制御装置、プラズマ処理装置、処理装置及び温度制御方法 |

| KR20140106668A (ko) | 2011-12-09 | 2014-09-03 | 어플라이드 머티어리얼스, 인코포레이티드 | 가열 튜브를 냉각시키기 위한 열 교환기 및 그 냉각 방법 |

| WO2013141371A1 (ja) * | 2012-03-22 | 2013-09-26 | 株式会社日立国際電気 | 基板処理装置、半導体装置の製造方法および基板処理方法 |

| JP2013243218A (ja) * | 2012-05-18 | 2013-12-05 | Tokyo Electron Ltd | プラズマ処理装置、及びプラズマ処理方法 |

| JP6014661B2 (ja) * | 2012-05-25 | 2016-10-25 | 東京エレクトロン株式会社 | プラズマ処理装置、及びプラズマ処理方法 |

| JP6579974B2 (ja) * | 2015-02-25 | 2019-09-25 | 株式会社Kokusai Electric | 基板処理装置、温度センサ及び半導体装置の製造方法 |

| US10150184B2 (en) | 2015-10-21 | 2018-12-11 | Siemens Energy, Inc. | Method of forming a cladding layer having an integral channel |

| US11017984B2 (en) | 2016-04-28 | 2021-05-25 | Applied Materials, Inc. | Ceramic coated quartz lid for processing chamber |

| JP6875336B2 (ja) | 2018-08-27 | 2021-05-26 | 信越化学工業株式会社 | 成膜方法 |

| JP7306195B2 (ja) | 2019-09-27 | 2023-07-11 | 東京エレクトロン株式会社 | 基板を処理する装置及びステージをクリーニングする方法 |

| JP7514478B2 (ja) * | 2020-12-04 | 2024-07-11 | 株式会社デンソー | ウエハ処理装置及びウエハ処理方法 |

| GB2609624A (en) * | 2021-08-06 | 2023-02-15 | Leybold Gmbh | Cooling device, method for cooling a cooling element and layer deposition apparatus |

| CN113659022B (zh) * | 2021-08-16 | 2023-07-21 | 广东贝尔试验设备有限公司 | 一种光伏电池划刻加工用电池芯片温度检测装置 |

| WO2025069789A1 (ja) * | 2023-09-29 | 2025-04-03 | 東京エレクトロン株式会社 | 基板処理装置及び冷却方法 |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2631165B1 (fr) * | 1988-05-05 | 1992-02-21 | Moulene Daniel | Support conditionneur de temperature pour petits objets tels que des composants semi-conducteurs et procede de regulation thermique utilisant ce support |

| JPH0255292A (ja) * | 1988-08-19 | 1990-02-23 | Fujitsu Ltd | 反応管の冷却方法 |

| US5316579A (en) * | 1988-12-27 | 1994-05-31 | Symetrix Corporation | Apparatus for forming a thin film with a mist forming means |

| EP0634778A1 (en) * | 1993-07-12 | 1995-01-18 | The Boc Group, Inc. | Hollow cathode array |

| EP0827186A3 (en) * | 1996-08-29 | 1999-12-15 | Tokyo Electron Limited | Substrate treatment system |

| JP4053173B2 (ja) * | 1999-03-29 | 2008-02-27 | 東京エレクトロン株式会社 | マイクロ波プラズマ処理装置及び方法 |

| CN1251294C (zh) * | 1999-11-15 | 2006-04-12 | 兰姆研究有限公司 | 等离子体加工装置的温度控制系统 |

| JP2001156047A (ja) * | 1999-11-30 | 2001-06-08 | Mitsubishi Electric Corp | 半導体製造装置 |

| JP2003059884A (ja) * | 2001-08-20 | 2003-02-28 | Tokyo Electron Ltd | 基板処理装置及び基板処理方法 |

| JP2003174016A (ja) * | 2001-12-07 | 2003-06-20 | Tokyo Electron Ltd | 真空処理装置 |

| US6916502B2 (en) * | 2002-02-11 | 2005-07-12 | Battelle Energy Alliance, Llc | Systems and methods for coating conduit interior surfaces utilizing a thermal spray gun with extension arm |

| JP4022459B2 (ja) * | 2002-09-30 | 2007-12-19 | 助川電気工業株式会社 | 冷却器付加熱装置 |

-

2004

- 2004-01-09 JP JP2004004483A patent/JP4361811B2/ja not_active Expired - Fee Related

- 2004-12-24 WO PCT/JP2004/019418 patent/WO2005067023A1/ja not_active Ceased

- 2004-12-24 US US10/585,408 patent/US20070163502A1/en not_active Abandoned

- 2004-12-24 CN CNB2004800400808A patent/CN100440451C/zh not_active Expired - Fee Related

- 2004-12-24 KR KR1020067015082A patent/KR100876692B1/ko not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JP2005197600A (ja) | 2005-07-21 |

| KR100876692B1 (ko) | 2008-12-31 |

| WO2005067023A1 (ja) | 2005-07-21 |

| US20070163502A1 (en) | 2007-07-19 |

| CN100440451C (zh) | 2008-12-03 |

| CN1902737A (zh) | 2007-01-24 |

| KR20060129318A (ko) | 2006-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4361811B2 (ja) | 半導体製造装置 | |

| CN100494821C (zh) | 热介质循环装置及使用其的热处理装置 | |

| US6776874B2 (en) | Processing method and apparatus for removing oxide film | |

| TWI645469B (zh) | 使用氣體分配板熱之溫度躍升 | |

| KR100748820B1 (ko) | 열처리 방법 및 열처리 장치 | |

| CN103890917B (zh) | 半导体处理中的边缘环的热管理 | |

| CN100444308C (zh) | 宽温度范围的卡盘系统 | |

| TWI890688B (zh) | 載置台及電漿處理裝置 | |

| KR20190116402A (ko) | 기판 처리 장치, 반도체 장치의 제조 방법, 및 프로그램 | |

| US9786528B2 (en) | Substrate supporting table, substrate processing apparatus, and manufacture method for semiconductor device | |

| JP2007335709A (ja) | 基板処理装置 | |

| US11745231B2 (en) | Cleaning method and processing apparatus | |

| JP2018056182A (ja) | 基板処理装置および基板処理方法 | |

| TW201511129A (zh) | 用於昇華蝕刻製程之低溫電漿退火製程 | |

| JP6162980B2 (ja) | プラズマ処理装置及びプラズマ処理方法 | |

| WO2004020692A1 (ja) | 基板処理装置 | |

| KR102683732B1 (ko) | 지지 유닛 및 기판 처리 장치 | |

| JP2004014752A (ja) | 静電チャック、被処理体載置台およびプラズマ処理装置 | |

| JP5977617B2 (ja) | 被処理体のマイクロ波処理方法及びマイクロ波処理装置 | |

| WO2015011829A1 (ja) | 基板処理装置及び半導体装置の製造方法 | |

| US20240149289A1 (en) | Substrate processing apparatus | |

| KR101016028B1 (ko) | 반도체 플라즈마 형성 장치 | |

| JP2024146068A (ja) | 基板処理装置 | |

| JP5364314B2 (ja) | 熱処理装置 | |

| JP2014067800A (ja) | 加熱装置及び温度制御方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20061226 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20061226 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20090804 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20090813 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120821 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20150821 Year of fee payment: 6 |

|

| LAPS | Cancellation because of no payment of annual fees |