JP4177107B2 - 電気的縁取りプレス - Google Patents

電気的縁取りプレス Download PDFInfo

- Publication number

- JP4177107B2 JP4177107B2 JP2002557535A JP2002557535A JP4177107B2 JP 4177107 B2 JP4177107 B2 JP 4177107B2 JP 2002557535 A JP2002557535 A JP 2002557535A JP 2002557535 A JP2002557535 A JP 2002557535A JP 4177107 B2 JP4177107 B2 JP 4177107B2

- Authority

- JP

- Japan

- Prior art keywords

- press

- edging

- press ram

- crown

- rod

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000007688 edging Methods 0.000 claims description 58

- 239000002184 metal Substances 0.000 claims description 18

- 229910000831 Steel Inorganic materials 0.000 claims description 8

- 239000012530 fluid Substances 0.000 claims description 8

- 239000010959 steel Substances 0.000 claims description 8

- 238000007667 floating Methods 0.000 claims description 5

- 238000009432 framing Methods 0.000 claims 1

- 238000000034 method Methods 0.000 description 18

- 230000008569 process Effects 0.000 description 15

- 230000008901 benefit Effects 0.000 description 3

- 230000005284 excitation Effects 0.000 description 2

- 238000003754 machining Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- 239000000758 substrate Substances 0.000 description 2

- OINMNSFDYTYXEQ-UHFFFAOYSA-M 2-bromoethyl(trimethyl)azanium;bromide Chemical group [Br-].C[N+](C)(C)CCBr OINMNSFDYTYXEQ-UHFFFAOYSA-M 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000008878 coupling Effects 0.000 description 1

- 238000010168 coupling process Methods 0.000 description 1

- 238000005859 coupling reaction Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- KWORUUGOSLYAGD-YPPDDXJESA-N esomeprazole magnesium Chemical compound [Mg+2].C([S@](=O)C=1[N-]C2=CC=C(C=C2N=1)OC)C1=NC=C(C)C(OC)=C1C.C([S@](=O)C=1[N-]C2=CC=C(C=C2N=1)OC)C1=NC=C(C)C(OC)=C1C KWORUUGOSLYAGD-YPPDDXJESA-N 0.000 description 1

- 238000009957 hemming Methods 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000004080 punching Methods 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

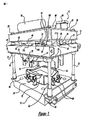

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D39/00—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders

- B21D39/02—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders of sheet metal by folding, e.g. connecting edges of a sheet to form a cylinder

- B21D39/021—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders of sheet metal by folding, e.g. connecting edges of a sheet to form a cylinder for panels, e.g. vehicle doors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D39/00—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders

- B21D39/02—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders of sheet metal by folding, e.g. connecting edges of a sheet to form a cylinder

- B21D39/021—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders of sheet metal by folding, e.g. connecting edges of a sheet to form a cylinder for panels, e.g. vehicle doors

- B21D39/023—Application of procedures in order to connect objects or parts, e.g. coating with sheet metal otherwise than by plating; Tube expanders of sheet metal by folding, e.g. connecting edges of a sheet to form a cylinder for panels, e.g. vehicle doors using rollers

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T29/00—Metal working

- Y10T29/53—Means to assemble or disassemble

- Y10T29/53709—Overedge assembling means

- Y10T29/53787—Binding or covering

- Y10T29/53791—Edge binding

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Press Drives And Press Lines (AREA)

- Control Of Presses (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US25843000P | 2000-12-27 | 2000-12-27 | |

| US10/017,795 US6640601B2 (en) | 2000-12-27 | 2001-12-14 | Electric hemming press |

| PCT/US2001/050679 WO2002057033A2 (en) | 2000-12-27 | 2001-12-27 | Electric hemming press |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2004517733A JP2004517733A (ja) | 2004-06-17 |

| JP2004517733A5 JP2004517733A5 (enExample) | 2005-06-02 |

| JP4177107B2 true JP4177107B2 (ja) | 2008-11-05 |

Family

ID=26690323

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002557535A Expired - Fee Related JP4177107B2 (ja) | 2000-12-27 | 2001-12-27 | 電気的縁取りプレス |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US6640601B2 (enExample) |

| JP (1) | JP4177107B2 (enExample) |

| AU (1) | AU2002246879A1 (enExample) |

| DE (1) | DE10197111B4 (enExample) |

| WO (1) | WO2002057033A2 (enExample) |

Families Citing this family (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6959474B2 (en) * | 2002-08-29 | 2005-11-01 | Campian Jonathon R | Nest and hold station for the joining of sheet materials |

| US7748308B2 (en) * | 2005-09-26 | 2010-07-06 | Unico, Inc. | Pneumatic biasing of a linear actuator and implementations thereof |

| US7607331B2 (en) * | 2007-02-01 | 2009-10-27 | Gm Global Technology Operations, Inc. | Method and apparatus for hemming panels together |

| JP5555172B2 (ja) * | 2007-11-09 | 2014-07-23 | ヴァムコ・インターナショナル・インコーポレイテッド | プレス機用駆動装置及び方法 |

| US20110185785A1 (en) * | 2010-02-04 | 2011-08-04 | Eagle Press & Equipment Co. Ltd. | Servo Hemming Press |

| JP5541977B2 (ja) * | 2010-06-18 | 2014-07-09 | 北斗株式会社 | ヘミングプレス装置 |

| JP2012000657A (ja) * | 2010-06-18 | 2012-01-05 | Hokuto Corp | ヘミングプレス装置 |

| JP5672308B2 (ja) | 2010-11-29 | 2015-02-18 | トヨタ自動車株式会社 | ローラヘミング装置 |

| JP4815019B1 (ja) * | 2011-01-24 | 2011-11-16 | 享栄エンジニアリング株式会社 | ハイブリッド式プレス装置 |

| EP2689865B1 (de) * | 2012-07-27 | 2016-09-14 | FFT Produktionssysteme GmbH & Co. KG | Bördelpresse |

| JP6086481B2 (ja) * | 2013-03-28 | 2017-03-01 | ダイハツ工業株式会社 | ヘミング加工装置 |

| US9205479B2 (en) * | 2013-05-30 | 2015-12-08 | Hirotec America, Inc. | Triangular hemming and stamping apparatus |

| CN103909668B (zh) * | 2014-04-02 | 2015-11-25 | 西安交通大学 | 一种机械式空行程与无油泵电动增压的伺服节能液压机 |

| US9689251B2 (en) | 2014-05-08 | 2017-06-27 | Unico, Inc. | Subterranean pump with pump cleaning mode |

| CN107107162A (zh) * | 2014-12-18 | 2017-08-29 | 麦格纳国际公司 | 连续冲压线组件 |

| FR3031466B1 (fr) * | 2015-01-13 | 2017-07-28 | Peugeot Citroen Automobiles Sa | Machine de sertissage a matrice adaptative |

| US11752720B2 (en) | 2021-09-08 | 2023-09-12 | PDInnovative LLC | Press machine with modular linear actuator system |

| US11819906B2 (en) | 2021-09-21 | 2023-11-21 | PDInnovative LLC | Linear-actuated press machine having multiple motors and clutch system for multi-speed drive functionality |

| US11541618B1 (en) | 2021-09-21 | 2023-01-03 | PDInnovative LLC | Linear-actuated press machine having multiple motors and clutch system for multi-speed drive functionality |

Family Cites Families (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US280929A (en) | 1883-07-10 | Fulling mill | ||

| US2357508A (en) * | 1942-10-01 | 1944-09-05 | Hydraulic Dev Corp Inc | Hydraulic press |

| US2642111A (en) | 1946-02-23 | 1953-06-16 | Bindszus William | Razor blade backing machine |

| DE1627421A1 (de) * | 1967-08-01 | 1970-11-05 | Otto Dr Ing Georg | Sowohl als Hammer als auch als Presse betreibbare Umformmaschine |

| US3512476A (en) * | 1967-09-13 | 1970-05-19 | Otto Georg | Screw press with two or more screws |

| US3824757A (en) | 1971-01-18 | 1974-07-23 | Snyder B | Method of joining sheet metal, and sheet metal joints |

| JPS49113079U (enExample) | 1973-01-31 | 1974-09-26 | ||

| JPS49113078U (enExample) | 1973-01-31 | 1974-09-26 | ||

| JPS49113077U (enExample) | 1973-01-31 | 1974-09-26 | ||

| JPS49115446U (enExample) | 1973-01-31 | 1974-10-02 | ||

| US3883940A (en) | 1973-04-09 | 1975-05-20 | Dayco Corp | Apparatus for fastening a holding bar on a printing blanket |

| US4510660A (en) | 1980-08-15 | 1985-04-16 | Snyder General Corporation | Method of manufacturing a two-plate heat exchanger |

| IT1197795B (it) * | 1985-08-05 | 1988-12-06 | Kubushiki Kaisha Mitsuishi Fuk | Pressa a vite |

| US4891912A (en) | 1987-07-07 | 1990-01-09 | Ardco, Inc. | Refrigerator door assembly with multiple gasket sealing arrangement |

| US4897912A (en) | 1987-07-08 | 1990-02-06 | Weldex, Inc. | Method and apparatus for forming joints |

| JPH02280929A (ja) | 1989-04-20 | 1990-11-16 | Nissan Motor Co Ltd | ヘミングプレス成形装置 |

| US5083355A (en) | 1990-04-30 | 1992-01-28 | Utica Enterprises, Inc. | Hemming apparatus |

| US5237734A (en) | 1991-04-01 | 1993-08-24 | General Motors Corporation | Method of interlocking hemmed together panels |

| US5150508A (en) | 1991-06-28 | 1992-09-29 | E. R. St. Denis & Sons, Limited | Hemming machine and method |

| US5273606A (en) | 1991-12-16 | 1993-12-28 | The Budd Company | Bonding technique for a multi-panel device |

| US5272903A (en) | 1992-07-15 | 1993-12-28 | Craftmation, Inc. | Hemming machine |

| US5457981A (en) | 1992-10-14 | 1995-10-17 | Western Atlas, Inc. | Hemming press |

| US5454261A (en) | 1993-06-17 | 1995-10-03 | Campian; Jon R. | Hemming machine and method of operation |

| AU1587795A (en) | 1994-02-14 | 1995-08-29 | Western Atlas Uk Limited | Improved hemming machine |

| GB9402760D0 (en) | 1994-02-14 | 1994-04-06 | Western Atlas Uk Ltd | Improved hemming machine |

| JPH07284858A (ja) | 1994-04-11 | 1995-10-31 | Hokuto Kk | ヘミングプレス装置 |

| IT1278350B1 (it) | 1995-02-02 | 1997-11-20 | Comau Spa | Dispositivo per la graffatura di elementi di lamiera metallica stampata. |

| US5897796A (en) * | 1997-06-16 | 1999-04-27 | Chrysler Corporation | Method and apparatus for in-situ laser welding of hemmed joints |

| US6154942A (en) * | 1997-09-26 | 2000-12-05 | Tesco Engineering, Inc. | Closure panel hemming apparatus |

| JPH11254063A (ja) | 1998-03-14 | 1999-09-21 | Kanto Auto Works Ltd | プレスヘミング機 |

| US6487888B1 (en) * | 2000-10-05 | 2002-12-03 | Valiant Corporation | Hemming machine |

-

2001

- 2001-12-14 US US10/017,795 patent/US6640601B2/en not_active Expired - Lifetime

- 2001-12-27 DE DE10197111T patent/DE10197111B4/de not_active Expired - Fee Related

- 2001-12-27 WO PCT/US2001/050679 patent/WO2002057033A2/en not_active Ceased

- 2001-12-27 JP JP2002557535A patent/JP4177107B2/ja not_active Expired - Fee Related

- 2001-12-27 AU AU2002246879A patent/AU2002246879A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| DE10197111T5 (de) | 2004-04-22 |

| DE10197111B4 (de) | 2011-06-09 |

| AU2002246879A1 (en) | 2002-07-30 |

| WO2002057033A3 (en) | 2002-10-31 |

| US6640601B2 (en) | 2003-11-04 |

| US20020078730A1 (en) | 2002-06-27 |

| WO2002057033A2 (en) | 2002-07-25 |

| WO2002057033A8 (en) | 2003-07-17 |

| JP2004517733A (ja) | 2004-06-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4177107B2 (ja) | 電気的縁取りプレス | |

| JP5021095B2 (ja) | 金属板の加工装置及び加工方法 | |

| CN102164691B (zh) | 封闭结构构件的制造方法、冲压成形装置和封闭结构构件 | |

| KR100236867B1 (ko) | 신장 제어식 성형 기구와 금속 블랭크 성형 방법 | |

| CA2304238C (en) | Draw stamping die for stamping body panels for motor vehicles | |

| CN102164692B (zh) | 封闭结构构件的制造方法、冲压成形装置和封闭结构构件 | |

| US20160221068A1 (en) | Hat-shaped cross-section component manufacturing apparatus | |

| AU681982B2 (en) | Stretch controlled forming mechanism and method for forming multiple guage welded blanks | |

| CA2699318A1 (en) | Deep-drawing device | |

| CN102574190A (zh) | 用粘结剂中间层制成片构件接合部的方法及设备 | |

| JP3863146B2 (ja) | カッティングブレードの溝加工装置 | |

| DE102008009625A1 (de) | Vorrichtung zum Blechumformen | |

| CN100484658C (zh) | 卷边机的弯边系统 | |

| US6418771B1 (en) | Interior hemming machine | |

| JPH04162925A (ja) | 孔加工装置 | |

| CN222370052U (zh) | 一种簧片生产用同步折弯的压切机 | |

| CN217570318U (zh) | 一种无人机结构件加工用工装 | |

| CN218425255U (zh) | 一种用于钣金件加工的折弯机 | |

| EP2636518A2 (de) | Einrichtung zur spanlosen Formgebung/Umformung eines flächigen Werkstücks | |

| KR200389986Y1 (ko) | 프레스 금형 | |

| JP2023107719A (ja) | 折り曲げ装置、これを用いた構造部材の製造方法、及び構造部材 | |

| JP2532382Y2 (ja) | 切り曲げ加工用プレス装置 | |

| CN120816035A (zh) | 基于安全导向进给的汽车钣金料成型剪板机 | |

| JP6504103B2 (ja) | 閉断面形状部品のプレス成形方法および製造方法、並びにプレス装置 | |

| JPS6310180Y2 (enExample) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20041216 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20060915 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20060926 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20061226 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20070109 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070326 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20070703 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20071003 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20071011 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20071024 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20080115 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080415 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20080722 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20080821 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110829 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110829 Year of fee payment: 3 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120829 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20120829 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130829 Year of fee payment: 5 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |