JP3775335B2 - 窒化ケイ素質焼結体および窒化ケイ素質焼結体の製造方法、並びにそれを用いた回路基板 - Google Patents

窒化ケイ素質焼結体および窒化ケイ素質焼結体の製造方法、並びにそれを用いた回路基板 Download PDFInfo

- Publication number

- JP3775335B2 JP3775335B2 JP2002121345A JP2002121345A JP3775335B2 JP 3775335 B2 JP3775335 B2 JP 3775335B2 JP 2002121345 A JP2002121345 A JP 2002121345A JP 2002121345 A JP2002121345 A JP 2002121345A JP 3775335 B2 JP3775335 B2 JP 3775335B2

- Authority

- JP

- Japan

- Prior art keywords

- silicon nitride

- sintered body

- thermal conductivity

- particles

- sintering

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 229910052581 Si3N4 Inorganic materials 0.000 title claims description 189

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 title claims description 188

- 238000004519 manufacturing process Methods 0.000 title claims description 17

- 239000002245 particle Substances 0.000 claims description 99

- 238000005245 sintering Methods 0.000 claims description 57

- 239000000843 powder Substances 0.000 claims description 49

- 229910052760 oxygen Inorganic materials 0.000 claims description 33

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 32

- 239000001301 oxygen Substances 0.000 claims description 32

- 229910052761 rare earth metal Inorganic materials 0.000 claims description 30

- 239000011777 magnesium Substances 0.000 claims description 25

- 238000010438 heat treatment Methods 0.000 claims description 22

- CPLXHLVBOLITMK-UHFFFAOYSA-N magnesium oxide Inorganic materials [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 claims description 21

- 239000000395 magnesium oxide Substances 0.000 claims description 21

- AXZKOIWUVFPNLO-UHFFFAOYSA-N magnesium;oxygen(2-) Chemical compound [O-2].[Mg+2] AXZKOIWUVFPNLO-UHFFFAOYSA-N 0.000 claims description 21

- 229910001404 rare earth metal oxide Inorganic materials 0.000 claims description 16

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims description 11

- 229910052757 nitrogen Inorganic materials 0.000 claims description 7

- 239000012298 atmosphere Substances 0.000 claims description 5

- 239000010419 fine particle Substances 0.000 description 54

- 238000000034 method Methods 0.000 description 31

- 239000000758 substrate Substances 0.000 description 27

- 239000012071 phase Substances 0.000 description 20

- 230000008569 process Effects 0.000 description 20

- 239000000203 mixture Substances 0.000 description 16

- 230000000694 effects Effects 0.000 description 12

- 239000004065 semiconductor Substances 0.000 description 12

- 239000006104 solid solution Substances 0.000 description 12

- 229910052710 silicon Inorganic materials 0.000 description 10

- 230000005540 biological transmission Effects 0.000 description 9

- 238000010304 firing Methods 0.000 description 9

- 229910052782 aluminium Inorganic materials 0.000 description 8

- 230000002093 peripheral effect Effects 0.000 description 8

- 229910052688 Gadolinium Inorganic materials 0.000 description 7

- 229910052769 Ytterbium Inorganic materials 0.000 description 7

- 238000005452 bending Methods 0.000 description 7

- 229910052749 magnesium Inorganic materials 0.000 description 7

- 239000000463 material Substances 0.000 description 7

- 238000001556 precipitation Methods 0.000 description 7

- 239000000919 ceramic Substances 0.000 description 6

- 239000012535 impurity Substances 0.000 description 6

- 229910052746 lanthanum Inorganic materials 0.000 description 6

- 229910052751 metal Inorganic materials 0.000 description 6

- 239000002184 metal Substances 0.000 description 6

- 230000035939 shock Effects 0.000 description 6

- 239000010703 silicon Substances 0.000 description 6

- FIXNOXLJNSSSLJ-UHFFFAOYSA-N ytterbium(III) oxide Inorganic materials O=[Yb]O[Yb]=O FIXNOXLJNSSSLJ-UHFFFAOYSA-N 0.000 description 6

- 230000000052 comparative effect Effects 0.000 description 5

- 229910001873 dinitrogen Inorganic materials 0.000 description 5

- 238000011156 evaluation Methods 0.000 description 5

- 230000006872 improvement Effects 0.000 description 5

- 229910052742 iron Inorganic materials 0.000 description 5

- 235000012245 magnesium oxide Nutrition 0.000 description 5

- 239000002244 precipitate Substances 0.000 description 5

- 238000012546 transfer Methods 0.000 description 5

- 229910052727 yttrium Inorganic materials 0.000 description 5

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 4

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 4

- 238000004458 analytical method Methods 0.000 description 4

- 230000015572 biosynthetic process Effects 0.000 description 4

- 229910052802 copper Inorganic materials 0.000 description 4

- 239000010949 copper Substances 0.000 description 4

- PMHQVHHXPFUNSP-UHFFFAOYSA-M copper(1+);methylsulfanylmethane;bromide Chemical compound Br[Cu].CSC PMHQVHHXPFUNSP-UHFFFAOYSA-M 0.000 description 4

- 230000007423 decrease Effects 0.000 description 4

- 238000000280 densification Methods 0.000 description 4

- 239000011521 glass Substances 0.000 description 4

- 230000017525 heat dissipation Effects 0.000 description 4

- 230000002401 inhibitory effect Effects 0.000 description 4

- MRELNEQAGSRDBK-UHFFFAOYSA-N lanthanum oxide Inorganic materials [O-2].[O-2].[O-2].[La+3].[La+3] MRELNEQAGSRDBK-UHFFFAOYSA-N 0.000 description 4

- 239000007791 liquid phase Substances 0.000 description 4

- 239000011812 mixed powder Substances 0.000 description 4

- KTUFCUMIWABKDW-UHFFFAOYSA-N oxo(oxolanthaniooxy)lanthanum Chemical compound O=[La]O[La]=O KTUFCUMIWABKDW-UHFFFAOYSA-N 0.000 description 4

- 238000013001 point bending Methods 0.000 description 4

- 238000000851 scanning transmission electron micrograph Methods 0.000 description 4

- 238000012360 testing method Methods 0.000 description 4

- 229910052684 Cerium Inorganic materials 0.000 description 3

- 229910052692 Dysprosium Inorganic materials 0.000 description 3

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 3

- 238000006243 chemical reaction Methods 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- 238000005336 cracking Methods 0.000 description 3

- 238000010292 electrical insulation Methods 0.000 description 3

- CMIHHWBVHJVIGI-UHFFFAOYSA-N gadolinium(III) oxide Inorganic materials [O-2].[O-2].[O-2].[Gd+3].[Gd+3] CMIHHWBVHJVIGI-UHFFFAOYSA-N 0.000 description 3

- 238000001889 high-resolution electron micrograph Methods 0.000 description 3

- 238000010335 hydrothermal treatment Methods 0.000 description 3

- 238000000465 moulding Methods 0.000 description 3

- LIVNPJMFVYWSIS-UHFFFAOYSA-N silicon monoxide Chemical class [Si-]#[O+] LIVNPJMFVYWSIS-UHFFFAOYSA-N 0.000 description 3

- NIQCNGHVCWTJSM-UHFFFAOYSA-N Dimethyl phthalate Chemical compound COC(=O)C1=CC=CC=C1C(=O)OC NIQCNGHVCWTJSM-UHFFFAOYSA-N 0.000 description 2

- 229910052691 Erbium Inorganic materials 0.000 description 2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-N Ethanol Chemical compound CCO LFQSCWFLJHTTHZ-UHFFFAOYSA-N 0.000 description 2

- 208000025599 Heat Stress disease Diseases 0.000 description 2

- 229910052689 Holmium Inorganic materials 0.000 description 2

- LRHPLDYGYMQRHN-UHFFFAOYSA-N N-Butanol Chemical compound CCCCO LRHPLDYGYMQRHN-UHFFFAOYSA-N 0.000 description 2

- 229910052779 Neodymium Inorganic materials 0.000 description 2

- 229910052777 Praseodymium Inorganic materials 0.000 description 2

- 229910052772 Samarium Inorganic materials 0.000 description 2

- 229910018557 Si O Inorganic materials 0.000 description 2

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 2

- 230000002159 abnormal effect Effects 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 2

- 230000009471 action Effects 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 230000008901 benefit Effects 0.000 description 2

- 239000011230 binding agent Substances 0.000 description 2

- 238000005219 brazing Methods 0.000 description 2

- 229910052791 calcium Inorganic materials 0.000 description 2

- 238000011161 development Methods 0.000 description 2

- 239000002270 dispersing agent Substances 0.000 description 2

- 238000007606 doctor blade method Methods 0.000 description 2

- 150000002739 metals Chemical class 0.000 description 2

- 238000002156 mixing Methods 0.000 description 2

- 239000012299 nitrogen atmosphere Substances 0.000 description 2

- 239000000047 product Substances 0.000 description 2

- 238000000746 purification Methods 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 230000000630 rising effect Effects 0.000 description 2

- 239000002002 slurry Substances 0.000 description 2

- 238000004544 sputter deposition Methods 0.000 description 2

- 230000008646 thermal stress Effects 0.000 description 2

- 229910052725 zinc Inorganic materials 0.000 description 2

- 239000011701 zinc Substances 0.000 description 2

- PZZOEXPDTYIBPI-UHFFFAOYSA-N 2-[[2-(4-hydroxyphenyl)ethylamino]methyl]-3,4-dihydro-2H-naphthalen-1-one Chemical compound C1=CC(O)=CC=C1CCNCC1C(=O)C2=CC=CC=C2CC1 PZZOEXPDTYIBPI-UHFFFAOYSA-N 0.000 description 1

- 229910052693 Europium Inorganic materials 0.000 description 1

- CWYNVVGOOAEACU-UHFFFAOYSA-N Fe2+ Chemical compound [Fe+2] CWYNVVGOOAEACU-UHFFFAOYSA-N 0.000 description 1

- 229910052765 Lutetium Inorganic materials 0.000 description 1

- 229910004298 SiO 2 Inorganic materials 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 238000003917 TEM image Methods 0.000 description 1

- 229910052771 Terbium Inorganic materials 0.000 description 1

- 229910052775 Thulium Inorganic materials 0.000 description 1

- 238000002441 X-ray diffraction Methods 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 150000001412 amines Chemical class 0.000 description 1

- 239000012752 auxiliary agent Substances 0.000 description 1

- 229910052788 barium Inorganic materials 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 239000011575 calcium Substances 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 230000002301 combined effect Effects 0.000 description 1

- 239000000306 component Substances 0.000 description 1

- 239000004020 conductor Substances 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 238000004512 die casting Methods 0.000 description 1

- FBSAITBEAPNWJG-UHFFFAOYSA-N dimethyl phthalate Natural products CC(=O)OC1=CC=CC=C1OC(C)=O FBSAITBEAPNWJG-UHFFFAOYSA-N 0.000 description 1

- 229960001826 dimethylphthalate Drugs 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 238000002003 electron diffraction Methods 0.000 description 1

- 238000002149 energy-dispersive X-ray emission spectroscopy Methods 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 239000007789 gas Substances 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 230000009036 growth inhibition Effects 0.000 description 1

- 229910052735 hafnium Inorganic materials 0.000 description 1

- 125000001475 halogen functional group Chemical group 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 150000003949 imides Chemical class 0.000 description 1

- 239000011810 insulating material Substances 0.000 description 1

- 230000010354 integration Effects 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 150000004767 nitrides Chemical class 0.000 description 1

- 238000005121 nitriding Methods 0.000 description 1

- 239000004014 plasticizer Substances 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 239000011148 porous material Substances 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 238000012545 processing Methods 0.000 description 1

- 230000001737 promoting effect Effects 0.000 description 1

- 238000011002 quantification Methods 0.000 description 1

- 238000001226 reprecipitation Methods 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 229910052814 silicon oxide Inorganic materials 0.000 description 1

- 239000011856 silicon-based particle Substances 0.000 description 1

- 238000010583 slow cooling Methods 0.000 description 1

- 238000005476 soldering Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000000243 solution Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 238000009628 steelmaking Methods 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 229910052712 strontium Inorganic materials 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

- 238000009834 vaporization Methods 0.000 description 1

- 230000008016 vaporization Effects 0.000 description 1

- 229920002554 vinyl polymer Polymers 0.000 description 1

- 230000000007 visual effect Effects 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 238000005491 wire drawing Methods 0.000 description 1

- 229910052726 zirconium Inorganic materials 0.000 description 1

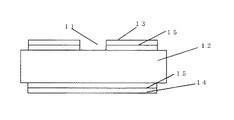

Images

Landscapes

- Ceramic Products (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002121345A JP3775335B2 (ja) | 2002-04-23 | 2002-04-23 | 窒化ケイ素質焼結体および窒化ケイ素質焼結体の製造方法、並びにそれを用いた回路基板 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2002121345A JP3775335B2 (ja) | 2002-04-23 | 2002-04-23 | 窒化ケイ素質焼結体および窒化ケイ素質焼結体の製造方法、並びにそれを用いた回路基板 |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2005373302A Division JP4518020B2 (ja) | 2005-12-26 | 2005-12-26 | 窒化ケイ素質焼結体およびそれを用いた回路基板。 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2003313079A JP2003313079A (ja) | 2003-11-06 |

| JP2003313079A5 JP2003313079A5 (enExample) | 2005-10-06 |

| JP3775335B2 true JP3775335B2 (ja) | 2006-05-17 |

Family

ID=29537306

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2002121345A Expired - Lifetime JP3775335B2 (ja) | 2002-04-23 | 2002-04-23 | 窒化ケイ素質焼結体および窒化ケイ素質焼結体の製造方法、並びにそれを用いた回路基板 |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3775335B2 (enExample) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4556162B2 (ja) * | 2004-03-11 | 2010-10-06 | 日立金属株式会社 | 窒化珪素質焼結体及びその製造方法、並びにそれを用いた回路基板 |

| WO2006118003A1 (ja) * | 2005-04-28 | 2006-11-09 | Hitachi Metals, Ltd. | 窒化珪素基板、その製造方法、それを用いた窒化珪素配線基板及び半導体モジュール |

| US8492300B2 (en) | 2007-03-22 | 2013-07-23 | Ngk Spark Plug Co., Ltd. | Insert and cutting tool |

| KR101582704B1 (ko) * | 2008-07-03 | 2016-01-05 | 히타치 긴조쿠 가부시키가이샤 | 질화 규소 기판 및 그 제조 방법과 그것을 사용한 질화 규소 회로 기판 및 반도체 모듈 |

| JP5142889B2 (ja) * | 2008-08-27 | 2013-02-13 | 京セラ株式会社 | 窒化珪素質焼結体およびその製法ならびに回路基板、パワー半導体モジュール |

| JPWO2013121861A1 (ja) * | 2012-02-13 | 2015-05-11 | 三井金属鉱業株式会社 | 窒化珪素焼結体及びその製造方法 |

| WO2013146789A1 (ja) * | 2012-03-26 | 2013-10-03 | 日立金属株式会社 | 窒化珪素焼結体基板及びその製造方法 |

| EP3831799A4 (en) * | 2018-08-03 | 2022-04-27 | Kabushiki Kaisha Toshiba | SILICON NITRIDE DISINTER BODY, SILICON NITRIDE SUBSTRATE AND SILICON NITRIDE CIRCUIT SUBSTRATE |

| WO2020045431A1 (ja) * | 2018-08-28 | 2020-03-05 | 京セラ株式会社 | インサートおよび切削工具 |

| CN114787105B (zh) * | 2019-12-11 | 2024-03-05 | Ube 株式会社 | 板状的氮化硅质烧结体及其制造方法 |

| CN112811922B (zh) * | 2021-01-20 | 2021-11-02 | 中国科学院上海硅酸盐研究所 | 一种覆铜板的氮化硅陶瓷基片及其制备方法 |

| JPWO2024111402A1 (enExample) * | 2022-11-21 | 2024-05-30 | ||

| WO2024177400A1 (ko) * | 2023-02-24 | 2024-08-29 | 주식회사 아모센스 | 질화규소 기판 제조용 조성물 및 이를 통해 제조된 질화규소 기판 |

-

2002

- 2002-04-23 JP JP2002121345A patent/JP3775335B2/ja not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| JP2003313079A (ja) | 2003-11-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR100836150B1 (ko) | 질화규소 소결체, 질화규소 소결체의 제조 방법 및 질화규소 소결체 기판, 이러한 질화 규소 소결체 기판을 포함하는 회로 기판 | |

| KR101751531B1 (ko) | 질화 규소 기판 제조방법 | |

| JP5444384B2 (ja) | 高熱伝導性窒化アルミニウム焼結体 | |

| JP7062229B2 (ja) | 板状の窒化ケイ素質焼結体およびその製造方法 | |

| JP3565425B2 (ja) | 窒化ケイ素質粉末の製造方法および窒化ケイ素質焼結体の製造方法 | |

| JP3775335B2 (ja) | 窒化ケイ素質焼結体および窒化ケイ素質焼結体の製造方法、並びにそれを用いた回路基板 | |

| JP2018184333A (ja) | 窒化珪素基板の製造方法、及び窒化珪素基板 | |

| JP7062230B2 (ja) | 板状の窒化ケイ素質焼結体およびその製造方法 | |

| JP4089974B2 (ja) | 窒化ケイ素質粉末、窒化ケイ素質焼結体及びこれを用いた電子部品用回路基板 | |

| CN114787105A (zh) | 板状的氮化硅质烧结体及其制造方法 | |

| JP2002293642A (ja) | 高熱伝導窒化ケイ素質焼結体およびその製造方法と回路基板 | |

| JP2002097005A5 (enExample) | ||

| JP3472585B2 (ja) | 窒化アルミニウム焼結体 | |

| JP4556162B2 (ja) | 窒化珪素質焼結体及びその製造方法、並びにそれを用いた回路基板 | |

| JP3002642B2 (ja) | 窒化珪素粉末、窒化珪素焼結体及びそれを用いた回路基板 | |

| JP2002265276A (ja) | 窒化ケイ素粉末および窒化ケイ素焼結体 | |

| JP4518020B2 (ja) | 窒化ケイ素質焼結体およびそれを用いた回路基板。 | |

| JP4529102B2 (ja) | 高熱伝導窒化ケイ素質焼結体およびその製造方法 | |

| JP4859267B2 (ja) | 窒化アルミニウム焼結体とその製造方法 | |

| JPH11100274A (ja) | 窒化珪素質焼結体、その製造方法及びそれを用いた回路基板 | |

| JP4348659B2 (ja) | 高熱伝導窒化ケイ素質焼結体およびそれを用いた基板、半導体素子用回路基板 | |

| JP4332828B2 (ja) | 高熱伝導窒化ケイ素質焼結体およびそれを用いた基板、半導体素子用回路基板 | |

| JP3929335B2 (ja) | 窒化アルミニウム焼結体およびその製造方法 | |

| JP4332824B2 (ja) | 高熱伝導窒化ケイ素質焼結体の製造方法およびその焼結体、基板、半導体素子用回路基板 | |

| JP4564257B2 (ja) | 高熱伝導性窒化アルミニウム焼結体 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050526 |

|

| A871 | Explanation of circumstances concerning accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A871 Effective date: 20050526 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050608 |

|

| A975 | Report on accelerated examination |

Free format text: JAPANESE INTERMEDIATE CODE: A971005 Effective date: 20050614 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20050623 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050822 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20050822 |

|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20050822 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050912 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20051025 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20051124 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20060112 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20060131 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20060213 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 3775335 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100303 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20100303 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20110303 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130303 Year of fee payment: 7 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130303 Year of fee payment: 7 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20140303 Year of fee payment: 8 |

|

| EXPY | Cancellation because of completion of term |