JP2019521020A - フルオロカーボン剥離コーティング - Google Patents

フルオロカーボン剥離コーティング Download PDFInfo

- Publication number

- JP2019521020A JP2019521020A JP2018568960A JP2018568960A JP2019521020A JP 2019521020 A JP2019521020 A JP 2019521020A JP 2018568960 A JP2018568960 A JP 2018568960A JP 2018568960 A JP2018568960 A JP 2018568960A JP 2019521020 A JP2019521020 A JP 2019521020A

- Authority

- JP

- Japan

- Prior art keywords

- coating

- oxygen

- substrate

- fluorocarbon

- fluorine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000576 coating method Methods 0.000 title claims abstract description 144

- 239000011248 coating agent Substances 0.000 title claims abstract description 129

- NBVXSUQYWXRMNV-UHFFFAOYSA-N fluoromethane Chemical compound FC NBVXSUQYWXRMNV-UHFFFAOYSA-N 0.000 title claims description 25

- 229910052760 oxygen Inorganic materials 0.000 claims abstract description 56

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims abstract description 55

- 239000001301 oxygen Substances 0.000 claims abstract description 55

- 239000000758 substrate Substances 0.000 claims abstract description 53

- 239000011737 fluorine Substances 0.000 claims abstract description 33

- 229910052731 fluorine Inorganic materials 0.000 claims abstract description 33

- YCKRFDGAMUMZLT-UHFFFAOYSA-N Fluorine atom Chemical compound [F] YCKRFDGAMUMZLT-UHFFFAOYSA-N 0.000 claims abstract description 32

- 239000000203 mixture Substances 0.000 claims abstract description 16

- 239000010410 layer Substances 0.000 claims description 43

- 238000000034 method Methods 0.000 claims description 43

- 150000004812 organic fluorine compounds Chemical class 0.000 claims description 33

- 239000011247 coating layer Substances 0.000 claims description 32

- 229920001577 copolymer Polymers 0.000 claims description 26

- 239000007789 gas Substances 0.000 claims description 25

- 239000010408 film Substances 0.000 claims description 23

- 229920000642 polymer Polymers 0.000 claims description 18

- 229920001774 Perfluoroether Polymers 0.000 claims description 16

- 229920006254 polymer film Polymers 0.000 claims description 14

- 229910052751 metal Inorganic materials 0.000 claims description 13

- 239000002184 metal Substances 0.000 claims description 13

- 230000004888 barrier function Effects 0.000 claims description 12

- 239000000376 reactant Substances 0.000 claims description 12

- NIXOWILDQLNWCW-UHFFFAOYSA-M Acrylate Chemical compound [O-]C(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-M 0.000 claims description 10

- 229910052782 aluminium Inorganic materials 0.000 claims description 9

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 9

- -1 fluoro compound Chemical class 0.000 claims description 8

- 229910044991 metal oxide Inorganic materials 0.000 claims description 7

- 150000004706 metal oxides Chemical class 0.000 claims description 7

- 239000010409 thin film Substances 0.000 claims description 6

- 239000004446 fluoropolymer coating Substances 0.000 claims description 4

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 10

- 239000000463 material Substances 0.000 description 9

- 238000012360 testing method Methods 0.000 description 9

- 238000000151 deposition Methods 0.000 description 8

- 239000000178 monomer Substances 0.000 description 8

- 238000004544 sputter deposition Methods 0.000 description 7

- 230000008021 deposition Effects 0.000 description 6

- 239000000126 substance Substances 0.000 description 6

- 229910052786 argon Inorganic materials 0.000 description 5

- 238000010894 electron beam technology Methods 0.000 description 5

- 229920002799 BoPET Polymers 0.000 description 4

- 238000004833 X-ray photoelectron spectroscopy Methods 0.000 description 4

- 150000001252 acrylic acid derivatives Chemical class 0.000 description 4

- 229920002313 fluoropolymer Polymers 0.000 description 4

- 239000004811 fluoropolymer Substances 0.000 description 4

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 3

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 3

- 239000000853 adhesive Substances 0.000 description 3

- 230000001070 adhesive effect Effects 0.000 description 3

- 125000001153 fluoro group Chemical group F* 0.000 description 3

- AMGQUBHHOARCQH-UHFFFAOYSA-N indium;oxotin Chemical compound [In].[Sn]=O AMGQUBHHOARCQH-UHFFFAOYSA-N 0.000 description 3

- 150000002739 metals Chemical class 0.000 description 3

- 229960004624 perflexane Drugs 0.000 description 3

- ZJIJAJXFLBMLCK-UHFFFAOYSA-N perfluorohexane Chemical compound FC(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)C(F)(F)F ZJIJAJXFLBMLCK-UHFFFAOYSA-N 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- 238000012876 topography Methods 0.000 description 3

- LEJBBGNFPAFPKQ-UHFFFAOYSA-N 2-(2-prop-2-enoyloxyethoxy)ethyl prop-2-enoate Chemical compound C=CC(=O)OCCOCCOC(=O)C=C LEJBBGNFPAFPKQ-UHFFFAOYSA-N 0.000 description 2

- PNEYBMLMFCGWSK-UHFFFAOYSA-N Alumina Chemical class [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 2

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 2

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 description 2

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 2

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 2

- IAXXETNIOYFMLW-GYSYKLTISA-N [(1r,3r,4r)-4,7,7-trimethyl-3-bicyclo[2.2.1]heptanyl] 2-methylprop-2-enoate Chemical compound C1C[C@@]2(C)[C@H](OC(=O)C(=C)C)C[C@@H]1C2(C)C IAXXETNIOYFMLW-GYSYKLTISA-N 0.000 description 2

- HVVWZTWDBSEWIH-UHFFFAOYSA-N [2-(hydroxymethyl)-3-prop-2-enoyloxy-2-(prop-2-enoyloxymethyl)propyl] prop-2-enoate Chemical compound C=CC(=O)OCC(CO)(COC(=O)C=C)COC(=O)C=C HVVWZTWDBSEWIH-UHFFFAOYSA-N 0.000 description 2

- 238000004458 analytical method Methods 0.000 description 2

- 238000005266 casting Methods 0.000 description 2

- 239000000919 ceramic Substances 0.000 description 2

- 238000005229 chemical vapour deposition Methods 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- 150000001875 compounds Chemical class 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 229910052734 helium Inorganic materials 0.000 description 2

- 239000001307 helium Substances 0.000 description 2

- SWQJXJOGLNCZEY-UHFFFAOYSA-N helium atom Chemical compound [He] SWQJXJOGLNCZEY-UHFFFAOYSA-N 0.000 description 2

- 239000001257 hydrogen Substances 0.000 description 2

- 229910052739 hydrogen Inorganic materials 0.000 description 2

- 229910003437 indium oxide Inorganic materials 0.000 description 2

- PJXISJQVUVHSOJ-UHFFFAOYSA-N indium(iii) oxide Chemical compound [O-2].[O-2].[O-2].[In+3].[In+3] PJXISJQVUVHSOJ-UHFFFAOYSA-N 0.000 description 2

- 239000002346 layers by function Substances 0.000 description 2

- 150000002734 metacrylic acid derivatives Chemical class 0.000 description 2

- 239000002086 nanomaterial Substances 0.000 description 2

- UJMWVICAENGCRF-UHFFFAOYSA-N oxygen difluoride Chemical compound FOF UJMWVICAENGCRF-UHFFFAOYSA-N 0.000 description 2

- 230000000737 periodic effect Effects 0.000 description 2

- 238000003825 pressing Methods 0.000 description 2

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 2

- 229910010271 silicon carbide Inorganic materials 0.000 description 2

- 229910052814 silicon oxide Inorganic materials 0.000 description 2

- MXFQRSUWYYSPOC-UHFFFAOYSA-N (2,2-dimethyl-3-prop-2-enoyloxypropyl) prop-2-enoate Chemical compound C=CC(=O)OCC(C)(C)COC(=O)C=C MXFQRSUWYYSPOC-UHFFFAOYSA-N 0.000 description 1

- PSGCQDPCAWOCSH-UHFFFAOYSA-N (4,7,7-trimethyl-3-bicyclo[2.2.1]heptanyl) prop-2-enoate Chemical compound C1CC2(C)C(OC(=O)C=C)CC1C2(C)C PSGCQDPCAWOCSH-UHFFFAOYSA-N 0.000 description 1

- NNNLYDWXTKOQQX-UHFFFAOYSA-N 1,1-di(prop-2-enoyloxy)propyl prop-2-enoate Chemical compound C=CC(=O)OC(CC)(OC(=O)C=C)OC(=O)C=C NNNLYDWXTKOQQX-UHFFFAOYSA-N 0.000 description 1

- MYWOJODOMFBVCB-UHFFFAOYSA-N 1,2,6-trimethylphenanthrene Chemical compound CC1=CC=C2C3=CC(C)=CC=C3C=CC2=C1C MYWOJODOMFBVCB-UHFFFAOYSA-N 0.000 description 1

- IPDYIFGHKYLTOM-UHFFFAOYSA-N 2-(2-prop-2-enoyloxypropoxy)propyl prop-2-enoate Chemical class C=CC(=O)OCC(C)OCC(C)OC(=O)C=C IPDYIFGHKYLTOM-UHFFFAOYSA-N 0.000 description 1

- FDSUVTROAWLVJA-UHFFFAOYSA-N 2-[[3-hydroxy-2,2-bis(hydroxymethyl)propoxy]methyl]-2-(hydroxymethyl)propane-1,3-diol;prop-2-enoic acid Chemical compound OC(=O)C=C.OC(=O)C=C.OC(=O)C=C.OC(=O)C=C.OC(=O)C=C.OCC(CO)(CO)COCC(CO)(CO)CO FDSUVTROAWLVJA-UHFFFAOYSA-N 0.000 description 1

- FQMIAEWUVYWVNB-UHFFFAOYSA-N 3-prop-2-enoyloxybutyl prop-2-enoate Chemical compound C=CC(=O)OC(C)CCOC(=O)C=C FQMIAEWUVYWVNB-UHFFFAOYSA-N 0.000 description 1

- MGWGWNFMUOTEHG-UHFFFAOYSA-N 4-(3,5-dimethylphenyl)-1,3-thiazol-2-amine Chemical compound CC1=CC(C)=CC(C=2N=C(N)SC=2)=C1 MGWGWNFMUOTEHG-UHFFFAOYSA-N 0.000 description 1

- 229910052580 B4C Inorganic materials 0.000 description 1

- 229910052582 BN Inorganic materials 0.000 description 1

- ZOXJGFHDIHLPTG-UHFFFAOYSA-N Boron Chemical compound [B] ZOXJGFHDIHLPTG-UHFFFAOYSA-N 0.000 description 1

- PZNSFCLAULLKQX-UHFFFAOYSA-N Boron nitride Chemical compound N#B PZNSFCLAULLKQX-UHFFFAOYSA-N 0.000 description 1

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 1

- 239000004831 Hot glue Substances 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- 239000004952 Polyamide Substances 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 239000004820 Pressure-sensitive adhesive Substances 0.000 description 1

- 229910052581 Si3N4 Inorganic materials 0.000 description 1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 1

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 1

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 1

- DAKWPKUUDNSNPN-UHFFFAOYSA-N Trimethylolpropane triacrylate Chemical compound C=CC(=O)OCC(CC)(COC(=O)C=C)COC(=O)C=C DAKWPKUUDNSNPN-UHFFFAOYSA-N 0.000 description 1

- 239000007983 Tris buffer Substances 0.000 description 1

- 239000012963 UV stabilizer Substances 0.000 description 1

- QCWXUUIWCKQGHC-UHFFFAOYSA-N Zirconium Chemical compound [Zr] QCWXUUIWCKQGHC-UHFFFAOYSA-N 0.000 description 1

- PSGCQDPCAWOCSH-BREBYQMCSA-N [(1r,3r,4r)-4,7,7-trimethyl-3-bicyclo[2.2.1]heptanyl] prop-2-enoate Chemical compound C1C[C@@]2(C)[C@H](OC(=O)C=C)C[C@@H]1C2(C)C PSGCQDPCAWOCSH-BREBYQMCSA-N 0.000 description 1

- XRMBQHTWUBGQDN-UHFFFAOYSA-N [2-[2,2-bis(prop-2-enoyloxymethyl)butoxymethyl]-2-(prop-2-enoyloxymethyl)butyl] prop-2-enoate Chemical compound C=CC(=O)OCC(COC(=O)C=C)(CC)COCC(CC)(COC(=O)C=C)COC(=O)C=C XRMBQHTWUBGQDN-UHFFFAOYSA-N 0.000 description 1

- 239000002253 acid Substances 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- QUZSUMLPWDHKCJ-UHFFFAOYSA-N bisphenol A dimethacrylate Chemical compound C1=CC(OC(=O)C(=C)C)=CC=C1C(C)(C)C1=CC=C(OC(=O)C(C)=C)C=C1 QUZSUMLPWDHKCJ-UHFFFAOYSA-N 0.000 description 1

- 229910052796 boron Inorganic materials 0.000 description 1

- INAHAJYZKVIDIZ-UHFFFAOYSA-N boron carbide Chemical compound B12B3B4C32B41 INAHAJYZKVIDIZ-UHFFFAOYSA-N 0.000 description 1

- 239000001569 carbon dioxide Substances 0.000 description 1

- 229910002092 carbon dioxide Inorganic materials 0.000 description 1

- 229910002091 carbon monoxide Inorganic materials 0.000 description 1

- 229910010293 ceramic material Inorganic materials 0.000 description 1

- 238000003486 chemical etching Methods 0.000 description 1

- 239000003153 chemical reaction reagent Substances 0.000 description 1

- 239000008199 coating composition Substances 0.000 description 1

- PMHQVHHXPFUNSP-UHFFFAOYSA-M copper(1+);methylsulfanylmethane;bromide Chemical compound Br[Cu].CSC PMHQVHHXPFUNSP-UHFFFAOYSA-M 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000001514 detection method Methods 0.000 description 1

- 230000009977 dual effect Effects 0.000 description 1

- 238000005566 electron beam evaporation Methods 0.000 description 1

- 239000000839 emulsion Substances 0.000 description 1

- 150000002148 esters Chemical class 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- UHESRSKEBRADOO-UHFFFAOYSA-N ethyl carbamate;prop-2-enoic acid Chemical class OC(=O)C=C.CCOC(N)=O UHESRSKEBRADOO-UHFFFAOYSA-N 0.000 description 1

- 238000011156 evaluation Methods 0.000 description 1

- 230000008020 evaporation Effects 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 238000009501 film coating Methods 0.000 description 1

- 239000003063 flame retardant Substances 0.000 description 1

- 125000000524 functional group Chemical group 0.000 description 1

- 239000008246 gaseous mixture Substances 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 1

- 229910052737 gold Inorganic materials 0.000 description 1

- 239000010931 gold Substances 0.000 description 1

- 150000002431 hydrogen Chemical class 0.000 description 1

- 239000011261 inert gas Substances 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 229910052742 iron Inorganic materials 0.000 description 1

- 229940119545 isobornyl methacrylate Drugs 0.000 description 1

- ZFSLODLOARCGLH-UHFFFAOYSA-N isocyanuric acid Chemical compound OC1=NC(O)=NC(O)=N1 ZFSLODLOARCGLH-UHFFFAOYSA-N 0.000 description 1

- 238000000608 laser ablation Methods 0.000 description 1

- 238000001755 magnetron sputter deposition Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 150000001247 metal acetylides Chemical class 0.000 description 1

- 238000001465 metallisation Methods 0.000 description 1

- YDKNBNOOCSNPNS-UHFFFAOYSA-N methyl 1,3-benzoxazole-2-carboxylate Chemical compound C1=CC=C2OC(C(=O)OC)=NC2=C1 YDKNBNOOCSNPNS-UHFFFAOYSA-N 0.000 description 1

- 238000005459 micromachining Methods 0.000 description 1

- 229910052759 nickel Inorganic materials 0.000 description 1

- 229910000484 niobium oxide Inorganic materials 0.000 description 1

- URLJKFSTXLNXLG-UHFFFAOYSA-N niobium(5+);oxygen(2-) Chemical compound [O-2].[O-2].[O-2].[O-2].[O-2].[Nb+5].[Nb+5] URLJKFSTXLNXLG-UHFFFAOYSA-N 0.000 description 1

- 150000004767 nitrides Chemical class 0.000 description 1

- 229910052757 nitrogen Inorganic materials 0.000 description 1

- JCXJVPUVTGWSNB-UHFFFAOYSA-N nitrogen dioxide Inorganic materials O=[N]=O JCXJVPUVTGWSNB-UHFFFAOYSA-N 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 1

- BPUBBGLMJRNUCC-UHFFFAOYSA-N oxygen(2-);tantalum(5+) Chemical compound [O-2].[O-2].[O-2].[O-2].[O-2].[Ta+5].[Ta+5] BPUBBGLMJRNUCC-UHFFFAOYSA-N 0.000 description 1

- RVTZCBVAJQQJTK-UHFFFAOYSA-N oxygen(2-);zirconium(4+) Chemical compound [O-2].[O-2].[Zr+4] RVTZCBVAJQQJTK-UHFFFAOYSA-N 0.000 description 1

- 239000000123 paper Substances 0.000 description 1

- 238000005192 partition Methods 0.000 description 1

- 239000010702 perfluoropolyether Substances 0.000 description 1

- 238000002186 photoelectron spectrum Methods 0.000 description 1

- 238000000206 photolithography Methods 0.000 description 1

- 238000005240 physical vapour deposition Methods 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 229920002647 polyamide Polymers 0.000 description 1

- 229920000515 polycarbonate Polymers 0.000 description 1

- 239000004417 polycarbonate Substances 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 229920000570 polyether Polymers 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 229920000139 polyethylene terephthalate Polymers 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 229920000098 polyolefin Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 229920002635 polyurethane Polymers 0.000 description 1

- 239000004814 polyurethane Substances 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 235000019422 polyvinyl alcohol Nutrition 0.000 description 1

- 229920000915 polyvinyl chloride Polymers 0.000 description 1

- 239000004800 polyvinyl chloride Substances 0.000 description 1

- 239000000843 powder Substances 0.000 description 1

- KCTAWXVAICEBSD-UHFFFAOYSA-N prop-2-enoyloxy prop-2-eneperoxoate Chemical compound C=CC(=O)OOOC(=O)C=C KCTAWXVAICEBSD-UHFFFAOYSA-N 0.000 description 1

- 238000005086 pumping Methods 0.000 description 1

- 239000012495 reaction gas Substances 0.000 description 1

- 238000005546 reactive sputtering Methods 0.000 description 1

- 229910052710 silicon Inorganic materials 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 239000000377 silicon dioxide Substances 0.000 description 1

- LIVNPJMFVYWSIS-UHFFFAOYSA-N silicon monoxide Chemical class [Si-]#[O+] LIVNPJMFVYWSIS-UHFFFAOYSA-N 0.000 description 1

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 230000003746 surface roughness Effects 0.000 description 1

- 229910001936 tantalum oxide Inorganic materials 0.000 description 1

- 238000010998 test method Methods 0.000 description 1

- XOLBLPGZBRYERU-UHFFFAOYSA-N tin dioxide Chemical compound O=[Sn]=O XOLBLPGZBRYERU-UHFFFAOYSA-N 0.000 description 1

- 229910001887 tin oxide Inorganic materials 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

- OGIDPMRJRNCKJF-UHFFFAOYSA-N titanium oxide Inorganic materials [Ti]=O OGIDPMRJRNCKJF-UHFFFAOYSA-N 0.000 description 1

- 230000001960 triggered effect Effects 0.000 description 1

- UONOETXJSWQNOL-UHFFFAOYSA-N tungsten carbide Chemical compound [W+]#[C-] UONOETXJSWQNOL-UHFFFAOYSA-N 0.000 description 1

- 238000001771 vacuum deposition Methods 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Chemical compound O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 238000004804 winding Methods 0.000 description 1

- 229910052726 zirconium Inorganic materials 0.000 description 1

- 229910001928 zirconium oxide Inorganic materials 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D1/00—Processes for applying liquids or other fluent materials

- B05D1/62—Plasma-deposition of organic layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D5/00—Processes for applying liquids or other fluent materials to surfaces to obtain special surface effects, finishes or structures

- B05D5/08—Processes for applying liquids or other fluent materials to surfaces to obtain special surface effects, finishes or structures to obtain an anti-friction or anti-adhesive surface

- B05D5/083—Processes for applying liquids or other fluent materials to surfaces to obtain special surface effects, finishes or structures to obtain an anti-friction or anti-adhesive surface involving the use of fluoropolymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D7/00—Processes, other than flocking, specially adapted for applying liquids or other fluent materials to particular surfaces or for applying particular liquids or other fluent materials

- B05D7/02—Processes, other than flocking, specially adapted for applying liquids or other fluent materials to particular surfaces or for applying particular liquids or other fluent materials to macromolecular substances, e.g. rubber

- B05D7/04—Processes, other than flocking, specially adapted for applying liquids or other fluent materials to particular surfaces or for applying particular liquids or other fluent materials to macromolecular substances, e.g. rubber to surfaces of films or sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D7/00—Processes, other than flocking, specially adapted for applying liquids or other fluent materials to particular surfaces or for applying particular liquids or other fluent materials

- B05D7/50—Multilayers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B1/00—Layered products having a non-planar shape

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/04—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B15/08—Layered products comprising a layer of metal comprising metal as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/304—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising vinyl halide (co)polymers, e.g. PVC, PVDC, PVF, PVDF

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/308—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising acrylic (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/30—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by a layer formed with recesses or projections, e.g. hollows, grooves, protuberances, ribs

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/0427—Coating with only one layer of a composition containing a polymer binder

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/043—Improving the adhesiveness of the coatings per se, e.g. forming primers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/048—Forming gas barrier coatings

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09D—COATING COMPOSITIONS, e.g. PAINTS, VARNISHES OR LACQUERS; FILLING PASTES; CHEMICAL PAINT OR INK REMOVERS; INKS; CORRECTING FLUIDS; WOODSTAINS; PASTES OR SOLIDS FOR COLOURING OR PRINTING; USE OF MATERIALS THEREFOR

- C09D127/00—Coating compositions based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Coating compositions based on derivatives of such polymers

- C09D127/02—Coating compositions based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Coating compositions based on derivatives of such polymers not modified by chemical after-treatment

- C09D127/12—Coating compositions based on homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Coating compositions based on derivatives of such polymers not modified by chemical after-treatment containing fluorine atoms

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D2252/00—Sheets

- B05D2252/02—Sheets of indefinite length

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D2506/00—Halogenated polymers

- B05D2506/10—Fluorinated polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D3/00—Pretreatment of surfaces to which liquids or other fluent materials are to be applied; After-treatment of applied coatings, e.g. intermediate treating of an applied coating preparatory to subsequent applications of liquids or other fluent materials

- B05D3/04—Pretreatment of surfaces to which liquids or other fluent materials are to be applied; After-treatment of applied coatings, e.g. intermediate treating of an applied coating preparatory to subsequent applications of liquids or other fluent materials by exposure to gases

- B05D3/0486—Operating the coating or treatment in a controlled atmosphere

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/748—Releasability

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2327/00—Polyvinylhalogenides

- B32B2327/12—Polyvinylhalogenides containing fluorine

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2367/00—Characterised by the use of polyesters obtained by reactions forming a carboxylic ester link in the main chain; Derivatives of such polymers

- C08J2367/02—Polyesters derived from dicarboxylic acids and dihydroxy compounds

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2427/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Derivatives of such polymers

- C08J2427/02—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Derivatives of such polymers not modified by chemical after-treatment

- C08J2427/12—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by a halogen; Derivatives of such polymers not modified by chemical after-treatment containing fluorine atoms

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Wood Science & Technology (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Laminated Bodies (AREA)

- Physical Vapour Deposition (AREA)

Abstract

Description

特に記載のない限り、実施例及び本明細書のその他の箇所における全ての部、百分率、比などは、重量によるものである。使用した溶媒及び他の試薬は、特に断りの無い限り、Sigma−Aldrich Chemical Company(Milwaukee,WI)から入手することができる。加えて、表1は、以下の実施例で使用された全ての材料についての略称及び供給元を提示するものである。

プラズマコーター方法

プラズマフルオロケミカル薄膜コーティングは、米国特許第5,888,594号(David et al.)に記載のプラズマ処理システムを、一部修正して使用することによって堆積した。全てのポンピングをターボ分子ポンプによって行うために、ドラム電極の幅を42.5インチ(108cm)まで大きくし、プラズマシステム内の2つのコンパートメント間の仕切りをなくした。

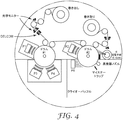

ロール・ツー・ロール真空コーターを図4に模式的に示す。これは、5箇所のスパッタ位置及び電子銃(eガン)硬化を使用する有機多層システムを備えたデュアルドラムスパッタシステムであった。酸化物堆積では、スパッタカソードの各側においてガスマニホールドを介してマスフローコントローラを使用して、アルゴン及び酸素をスパッタ堆積領域に導入した。有機蒸着では、アクリレートモノマーを高温でアトマイザーで蒸発させ、ウェブ上に導入し、電子銃(eガン)硬化を用いて架橋させた。

アルミニウムを、152mm×152mmの基材上に、マグネトロン物理蒸着により被覆した。フィルムを、バッチコーター内で76.2mmの円形アルミニウムターゲットからスパッタした。真空チャンバー内に据え付けられた基材ホルダーに基材をセットし、スパッタリング金属ターゲットは、基材ホルダーから上に228.6mmの高さに設置した。チャンバーを6×10−6トルのベース圧力まで排気した後、アルゴンのスパッタガスをチャンバー内部に入れ、チャンバーの全圧を5ミリトルに調整した。0.5キロワットの定電力レベルのDC電源を使用して、スパッタリングを開始した。

引き剥がし試験は、IMASS Peel Tester SP−101A(IMASS,Hingham,MA,USA)を使用してASTM D 3330/D 3330M−04の試験方法に従って行った。2インチ幅のサンプルのストリップを、被覆された側を上に向けて両面テープで試験機に取り付けた。次に、1インチの#8403テープのストリップを、ローラーを使用してサンプルに積層した。#8403テープの一端にクランピングロッドを取り付け、90インチ/分の速度で引き剥がし試験を行った。引き剥がし力は、複数のサンプルの平均として報告する。

2インチ幅の被覆されたサンプルのストリップを、被覆側を上に向けて両面テープでテーブルに取り付けた。次に、スコッチテープのストリップを、ローラーを使用してサンプルの上部表面に積層した。次に、スコッチテープをサンプルから引き剥がした。次にサンプル及びテープの表面を目視検査して、剥離特性を判定した。

図3に概略を示したロール・ツー・ロールプラズマコーティング装置を使用して、異なるレベルのO2流量で、フルオロカーボンプラズマコーティングをサンプルに被覆した。サンプルの表面を、X線光電子分光法(XPS)(化学分析用の電子分光法(ESCA)としても知られる)を使用して検査した。この技術により、試験片表面上の最も外側の3〜10ナノメートル(nm)の分析を得た。光電子スペクトルにより、固体表面上に存在する元素濃度及び化学(酸化状態及び/又は官能基)濃度に関する情報を得た。これは、水素及びヘリウムを除き、周期表中の全ての元素に対して感度がよく、ほとんどの種についての検出限界は0.1〜1原子%の濃度範囲であった。パーフルオロエーテル種がサンプル表面上に認められ、その原子%を決定し、図8においてO2流量に対してプロットした。

図5の概略図及び図3の装置を参照して、2milのPETフィルム202を、ロール・ツー・ロールプラズマコーティング装置を使用して酸素の存在下でプラズマ堆積したパーフルオロヘキサンで被覆した。

図7に概略を示すプロセスに従って、図4のロール・ツー・ロール真空コーターを使用して、SR833S層304を、2milの厚さのPETフィルム基材302上に堆積し重合させて、構造体305を形成した。SR833Sアクリレートモノマーを、熱蒸発器を介して真空チャンバー中に導入した。モノマー蒸気は、コーティングドラム近くに取り付けられたスリットダイを通過し、それが通り過ぎるときに基材上で凝結した。凝結したモノマーを硬化ゾーンに送り、電子ビームを使用して重合させた。電子ビーム高電圧は−7.1kVであり、グリッド電流は9.0mAであった。得られた層304のアクリレートの厚さは1.0マイクロメートルであった。

Claims (31)

- 基材の主表面上の有機フッ素コーティングであって、前記有機フッ素コーティングは、約5at%〜15at%の酸素及び約30at%〜50at%のフッ素の表面組成を有する、コーティング。

- 前記コーティングは、約500nm未満の厚さを有する、請求項1に記載のコーティング。

- 前記コーティングは、前記基材からの剥離引き剥がし力が約15グラム/インチ未満である、請求項1に記載のコーティング。

- 前記基材の前記主表面は、約10構造/mm2〜約10,000構造/mm2の密度で凸状又は凹状構造を含み、前記コーティングは前記構造に重なり、適合している、請求項1に記載のコーティング。

- 前記基材の前記主表面は、約2nm未満のRaを有する、請求項1に記載のコーティング。

- 前記基材の前記主表面は、約1nm未満のRaを有する、請求項1に記載のコーティング。

- フルオロエーテルの形態で0.25at%〜2.5at%の酸素を含む、有機フッ素薄膜。

- 前記薄膜は、約500nm未満の厚さを有する、請求項7に記載の薄膜。

- 主表面を有するポリマーフィルムを含む物品であって、前記ポリマーフィルムの前記主表面の少なくとも一部分は、約10構造/mm2〜約10,000構造/mm2の密度で凸状又は凹状構造と、前記構造上の有機フッ素コーティング層とを含み、前記コーティング層は、フルオロエーテル種を含み、かつ約5at%〜15at%の酸素及び約30at%〜約50原子%のフッ素の表面組成を含む、物品。

- 前記有機フッ素コーティング層は、約500nm未満の厚さを有する、請求項9に記載の物品。

- 基材の主表面上のフルオロポリマーコーティングであって、前記コーティングは、式CxFyを有するフルオロカーボン及び式CxFyOzを有するオキシフルオロカーボンのうちの少なくとも1つから得られるコポリマー繰り返し単位を含み、式中、x、y、及びzは、ゼロでない正の整数であり、x=1〜6、y=4〜14、及びz=1であり、x、y及びzの値は、前記コーティングが約5at%〜約15at%の酸素及び約30at%〜約50at%のフッ素を含むように選択される、コーティング。

- 前記フルオロカーボン及びオキシフルオロカーボンは、CF4、C2F6、C3F8、C4F10、及びC6F14、C6F12O、並びにこれらの組み合わせから選択される、請求項11に記載のコーティング。

- 前記フルオロカーボンはC6F14である、請求項12に記載のコーティング。

- 基材の主表面上のフルオロポリマーコーティングであって、前記コーティングは、約5at%〜約15at%の酸素及び約30at%〜約50at%のフッ素を含むコポリマーを提供するのに十分な量の酸素と反応させる、式CxFyを有するフルオロカーボン(式中、x=1〜6及びy=4〜14)から得られる、コーティング。

- 前記フルオロカーボンは、CF4、C2F6、C3F8、C4F10、及びC6F14、並びにこれらの組み合わせから選択される、請求項14に記載のコーティング。

- コーティングの製造方法であって、

反応チャンバー内に気体状フルオロカーボン反応物を導入することと、

プラズマ及び十分な酸素の存在下で前記気体状フルオロカーボン反応物を反応させて、基材の主表面上に有機フッ素コーティングを形成させることと、を含み、前記有機フッ素コーティングは約500nm未満の厚さを有し、前記コーティングは、フルオロエーテルの形態で約0.25at%〜約2.5at%の酸素を含む、方法。 - 酸素含有気体状反応物を前記反応チャンバー内に導入することを更に含む、請求項17に記載の方法。

- 前記酸素含有気体は酸素である、請求項17に記載の方法。

- 前記酸素含有気体は、式CxHyOzを有するオキシパーフルオロカーボン(式中、x、y、及びzはゼロでない正の整数であり、x=1〜6、y=4〜14、及びz=1である)である、請求項17に記載の方法。

- 前記気体状フルオロカーボン反応物はCxFy(式中、x=1〜6及びy=4〜14である)を含む、請求項16に記載の方法。

- 前記気体状フルオロカーボン反応物は、CF4、C2F6、C3F8、C4F10、及びC6F14、並びにこれらの組み合わせから選択される、請求項16に記載の方法。

- コーティングの製造方法であって、

少なくとも1種の気体状フルオロカーボン及び酸素含有気体を、プラズマ発生装置及びターゲット基材を含む反応チャンバー内に導入することを含み、前記フルオロ化合物及び前記酸素含有気体を、プラズマの存在下で前記基材上にフルオロエーテル種を含むフルオロカーボン含有コーティングを形成するのに十分な相対量で前記反応チャンバー内に導入し、前記有機フッ素フィルムは約500nm未満の厚さを有し、かつ約5at%〜15at%の酸素及び約30at%〜約50at%のフッ素を含む表面組成を有する、方法。 - 前記気体状フルオロカーボンは、CF4、C2F6、C3F8、C4F10、及びC6F14、並びにこれらの組み合わせから選択される、請求項22に記載の方法。

- 前記酸素含有気体は酸素である、請求項22に記載の方法。

- 前記フルオロカーボン化合物及び酸素を、約10:1〜約1:1の比で前記反応チャンバー内に導入する、請求項24に記載の方法。

- 前記フルオロカーボン及び酸素を、約4:1の比で前記反応チャンバー内に導入する、請求項24に記載の方法。

- 前記基材はポリマーフィルムを含む、請求項22に記載の方法。

- ポリマーフィルム基材の主表面上の有機フッ素剥離コーティングであって、前記有機フッ素コーティングは表面組成が約5at%〜15at%の酸素及び約30at%〜約50at%のフッ素である、剥離コーティングと、

前記剥離コーティング上のバリア機能性コーティングであって、前記バリア機能性コーティングは、前記剥離コーティング上のポリマー層及び前記ポリマー層上の金属酸化物層を含む、機能性コーティングと、

を含む物品。 - 前記ポリマー層はアクリレートを含み、前記金属酸化物層はITOを含む、請求項28に記載の物品。

- ポリマーフィルム基材と、

前記ポリマーフィルム基材上のポリマー層と、

ポリマー層の主表面上の有機フッ素剥離コーティングであって、前記有機フッ素コーティングは、表面組成が約5at%〜約15at%の酸素及び約30at%〜約50at%のフッ素である、剥離コーティングと、

前記剥離コーティング上の金属層と、

を含む物品。 - 前記ポリマー層はアクリレートを含み、前記金属層はアルミニウムを含む、請求項30に記載の物品。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201662357167P | 2016-06-30 | 2016-06-30 | |

| US62/357,167 | 2016-06-30 | ||

| PCT/US2017/037642 WO2018005109A1 (en) | 2016-06-30 | 2017-06-15 | Fluorocarbon release coating |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2019521020A true JP2019521020A (ja) | 2019-07-25 |

| JP2019521020A5 JP2019521020A5 (ja) | 2020-07-27 |

Family

ID=59337853

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2018568960A Pending JP2019521020A (ja) | 2016-06-30 | 2017-06-15 | フルオロカーボン剥離コーティング |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US10967399B2 (ja) |

| EP (1) | EP3478779B1 (ja) |

| JP (1) | JP2019521020A (ja) |

| CN (1) | CN109415584B (ja) |

| WO (1) | WO2018005109A1 (ja) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112385321B (zh) | 2018-06-28 | 2024-09-24 | 3M创新有限公司 | 在柔性基底上制备金属图案的方法 |

| US11104075B2 (en) | 2018-11-01 | 2021-08-31 | Stratasys, Inc. | System for window separation in an additive manufacturing process |

| JP3234940U (ja) | 2018-11-01 | 2021-11-11 | オリジン ラボラトリーズ, インコーポレイテッドOrigin Laboratories, Inc. | 付加製造システム |

| FR3126608B1 (fr) * | 2021-09-03 | 2023-09-08 | Seb Sa | Element de cuisson revetu par un film polymerique fluore antiadhesif pelable |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS62111739A (ja) * | 1985-11-11 | 1987-05-22 | 株式会社クラレ | 多層シ−ト状構造物及びその製造方法 |

| JPH08279134A (ja) * | 1995-04-04 | 1996-10-22 | Kao Corp | 磁気記録媒体 |

| US5674621A (en) * | 1996-01-29 | 1997-10-07 | Eastman Kodak Company | Fuser members with an outermost layer of a fluorinated diamond like carbon |

| WO2015112540A1 (en) * | 2014-01-24 | 2015-07-30 | 3M Innovative Properties Company | Abrasive material having a structured surface |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4781942A (en) | 1985-12-19 | 1988-11-01 | Hughes Aircraft Company | Process for the photochemical vapor deposition of siloxane polymers |

| JPH0675287B2 (ja) * | 1987-10-07 | 1994-09-21 | 富士写真フイルム株式会社 | 磁気記録媒体 |

| US4873140A (en) | 1988-04-27 | 1989-10-10 | Minnesota Mining And Manufacturing Company | Articles having low adhesion articles having coatings thereon |

| JP2547651B2 (ja) * | 1989-05-22 | 1996-10-23 | 日本板硝子株式会社 | 磁気記録媒体 |

| US5811183A (en) | 1995-04-06 | 1998-09-22 | Shaw; David G. | Acrylate polymer release coated sheet materials and method of production thereof |

| US5888594A (en) | 1996-11-05 | 1999-03-30 | Minnesota Mining And Manufacturing Company | Process for depositing a carbon-rich coating on a moving substrate |

| US7018713B2 (en) | 2003-04-02 | 2006-03-28 | 3M Innovative Properties Company | Flexible high-temperature ultrabarrier |

| US7041608B2 (en) * | 2004-02-06 | 2006-05-09 | Eastman Kodak Company | Providing fluorocarbon layers on conductive electrodes in making electronic devices such as OLED devices |

| JP4924038B2 (ja) * | 2004-11-02 | 2012-04-25 | 旭硝子株式会社 | フルオロカーボン膜の製造方法 |

| KR101915868B1 (ko) * | 2008-12-30 | 2018-11-06 | 쓰리엠 이노베이티브 프로퍼티즈 컴파니 | 반사방지 용품 및 이의 제조 방법 |

| TW201200345A (en) | 2010-06-25 | 2012-01-01 | Carnehammer Lars Bertil | Surface treatment of rubber using low pressure plasma |

| US8852693B2 (en) | 2011-05-19 | 2014-10-07 | Liquipel Ip Llc | Coated electronic devices and associated methods |

| US20140091379A1 (en) | 2012-10-01 | 2014-04-03 | Applied Materials, Inc. | Fluorocarbon coating having low refractive index |

| GB2534080B (en) | 2013-08-09 | 2017-05-03 | Innovia Films Ltd | Manufacturing a release liner |

| WO2017180502A1 (en) | 2016-04-15 | 2017-10-19 | 3M Innovative Properties Company | Preparation of electrical circuits by adhesive transfer |

-

2017

- 2017-06-15 CN CN201780040576.2A patent/CN109415584B/zh not_active Expired - Fee Related

- 2017-06-15 US US16/311,437 patent/US10967399B2/en active Active

- 2017-06-15 WO PCT/US2017/037642 patent/WO2018005109A1/en unknown

- 2017-06-15 EP EP17739761.9A patent/EP3478779B1/en active Active

- 2017-06-15 JP JP2018568960A patent/JP2019521020A/ja active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS62111739A (ja) * | 1985-11-11 | 1987-05-22 | 株式会社クラレ | 多層シ−ト状構造物及びその製造方法 |

| JPH08279134A (ja) * | 1995-04-04 | 1996-10-22 | Kao Corp | 磁気記録媒体 |

| US5674621A (en) * | 1996-01-29 | 1997-10-07 | Eastman Kodak Company | Fuser members with an outermost layer of a fluorinated diamond like carbon |

| WO2015112540A1 (en) * | 2014-01-24 | 2015-07-30 | 3M Innovative Properties Company | Abrasive material having a structured surface |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3478779B1 (en) | 2021-10-06 |

| US10967399B2 (en) | 2021-04-06 |

| CN109415584B (zh) | 2022-06-03 |

| CN109415584A (zh) | 2019-03-01 |

| WO2018005109A1 (en) | 2018-01-04 |

| US20190184422A1 (en) | 2019-06-20 |

| EP3478779A1 (en) | 2019-05-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10967399B2 (en) | Fluorocarbon release coating | |

| US20210347135A1 (en) | Materials and methods for forming nano-structures on substrates | |

| TWI546198B (zh) | 阻氣性薄膜 | |

| TWI449058B (zh) | 透明導電性膜及觸控面板 | |

| TWI567219B (zh) | 氣體阻隔膜及氣體阻隔膜的製造方法 | |

| JP4917943B2 (ja) | ガスバリアフィルムの製造方法 | |

| JP4059480B2 (ja) | 積層体およびその製造方法 | |

| Loh et al. | Surface modifications of polymers with fluorine‐containing plasmas: Deposition versus replacement reactions | |

| TW201408483A (zh) | 具有封裝阻隔膜之光伏打裝置 | |

| De Giglio et al. | Polymer surface chemistry: characterization by XPS | |

| CN111025434A (zh) | 防反射玻璃 | |

| WO2015115510A1 (ja) | ガスバリアー性フィルム及びその製造方法 | |

| JP2013111874A (ja) | ガスバリア基材およびガスバリア積層体 | |

| JP4260907B2 (ja) | フィルム積層体 | |

| CN112435776A (zh) | 一种柔性导电薄膜及其制备方法 | |

| JP2003341003A (ja) | 積層体およびその製造方法 | |

| US20240043989A1 (en) | Metallic Nanohole Arrays on Nanowells with Controlled Depth and Methods of Making the Same | |

| JP6720980B2 (ja) | ガスバリアー性フィルム | |

| Yang et al. | Plasma polymerization of allylpentafluorobenzene on copper surfaces | |

| JPS59179632A (ja) | 記録フイルムの製造方法 | |

| Zuri et al. | Film formation and crack development in plasma polymerized hexamethyldisiloxane | |

| Senda et al. | Ion-assisted vapor deposition of acryl polymer thin films | |

| JP5332403B2 (ja) | ガスバリア性積層フィルム | |

| Wang | Ultrathin fluoropolymer films deposited on a polyimide (kapton®) surface by RF magnetron sputtering of poly (tetrafluoroethylene) | |

| US20230174564A1 (en) | Fluorinated photoinitiators and fluorinated (co)polymer layers made using the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| RD03 | Notification of appointment of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7423 Effective date: 20200326 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20200612 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20200612 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20200602 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20210430 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20210518 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20211214 |