JP2010005986A - 生タイヤの成型方法 - Google Patents

生タイヤの成型方法 Download PDFInfo

- Publication number

- JP2010005986A JP2010005986A JP2008170148A JP2008170148A JP2010005986A JP 2010005986 A JP2010005986 A JP 2010005986A JP 2008170148 A JP2008170148 A JP 2008170148A JP 2008170148 A JP2008170148 A JP 2008170148A JP 2010005986 A JP2010005986 A JP 2010005986A

- Authority

- JP

- Japan

- Prior art keywords

- mold

- inner liner

- rubber sheet

- winding

- laminate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/08—Building tyres

- B29D30/20—Building tyres by the flat-tyre method, i.e. building on cylindrical drums

- B29D30/30—Applying the layers; Guiding or stretching the layers during application

- B29D30/3007—Applying the layers; Guiding or stretching the layers during application by feeding a sheet perpendicular to the drum axis and joining the ends to form an annular element

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/0681—Parts of pneumatic tyres; accessories, auxiliary operations

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B1/00—Layered products having a non-planar shape

- B32B1/08—Tubular products

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B25/00—Layered products comprising a layer of natural or synthetic rubber

- B32B25/04—Layered products comprising a layer of natural or synthetic rubber comprising rubber as the main or only constituent of a layer, which is next to another layer of the same or of a different material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B25/00—Layered products comprising a layer of natural or synthetic rubber

- B32B25/04—Layered products comprising a layer of natural or synthetic rubber comprising rubber as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B25/08—Layered products comprising a layer of natural or synthetic rubber comprising rubber as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/04—Interconnection of layers

- B32B7/12—Interconnection of layers using interposed adhesives or interposed materials with bonding properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C1/00—Tyres characterised by the chemical composition or the physical arrangement or mixture of the composition

- B60C1/0008—Compositions of the inner liner

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C5/00—Inflatable pneumatic tyres or inner tubes

- B60C5/12—Inflatable pneumatic tyres or inner tubes without separate inflatable inserts, e.g. tubeless tyres with transverse section open to the rim

- B60C5/14—Inflatable pneumatic tyres or inner tubes without separate inflatable inserts, e.g. tubeless tyres with transverse section open to the rim with impervious liner or coating on the inner wall of the tyre

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/0681—Parts of pneumatic tyres; accessories, auxiliary operations

- B29D2030/0682—Inner liners

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/724—Permeability to gases, adsorption

- B32B2307/7242—Non-permeable

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C5/00—Inflatable pneumatic tyres or inner tubes

- B60C5/12—Inflatable pneumatic tyres or inner tubes without separate inflatable inserts, e.g. tubeless tyres with transverse section open to the rim

- B60C5/14—Inflatable pneumatic tyres or inner tubes without separate inflatable inserts, e.g. tubeless tyres with transverse section open to the rim with impervious liner or coating on the inner wall of the tyre

- B60C2005/145—Inflatable pneumatic tyres or inner tubes without separate inflatable inserts, e.g. tubeless tyres with transverse section open to the rim with impervious liner or coating on the inner wall of the tyre made of laminated layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C5/00—Inflatable pneumatic tyres or inner tubes

- B60C5/12—Inflatable pneumatic tyres or inner tubes without separate inflatable inserts, e.g. tubeless tyres with transverse section open to the rim

- B60C5/14—Inflatable pneumatic tyres or inner tubes without separate inflatable inserts, e.g. tubeless tyres with transverse section open to the rim with impervious liner or coating on the inner wall of the tyre

- B60C2005/147—Inflatable pneumatic tyres or inner tubes without separate inflatable inserts, e.g. tubeless tyres with transverse section open to the rim with impervious liner or coating on the inner wall of the tyre characterised by the joint or splice

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Tyre Moulding (AREA)

- Tires In General (AREA)

Abstract

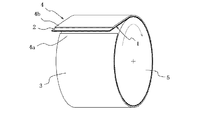

【解決手段】幅を揃えたガスバリア性の薄膜状フィルムインナーライナ1と未加硫隣接ゴムシート3とを成型型の全周にわたって巻付けるに当り、端縁がそのフィルムインナーライナ1から突出する未加硫隣接ゴムシート3の突出部分を、成型型への巻付け始端部分4aの一部とし、その突出部分を成型型の表面に粘着させた状態で積層体4の巻付けを開始し、成型型に対する巻付け終端部分4bを、巻付け始端部分4aの内周側に入れ込んで接合させる。

【選択図】図1

Description

なおこの成型方法は、薄膜状フィルムインナーライナと未加硫ゴムシートとの幅が揃わない場合をも可とするものである。

なお、ここにおいてもまた、フィルムインナーライナの端部分どうしの直接的な接合は、そのインナーライナの、巻付け終端部分側の接着剤層上に、巻付け始端部分側を重ね合わせることによって行うことができる。

従ってここでは、フィルムインナーライナの端部分どうしの接合域と、隣接ゴムシートの端部分どうしの接合域とが、成型型の周方向に間隔をおいて位置することになる。

この一方で、未加硫隣接ゴムシートの接合域が20mmを越えると、重ね合わせ接合域でのゴムシート厚みが厚くなるため、製品タイヤのユニフォミティ、バランス等の低下が否めなくなり、また、薄膜状フィルムインナーライナの接合域が60mmを超えると、性能上は特に問題はないものの、不必要にフィルム材料を使用することになり、材料歩留りの低下、経済性の低下等が否めなくなる。

なお、フィルムインナーライナ1とゴムシート3との幅は揃わない場合もある。

すなわち、60mmを越えると貼損じたり精度が低下するおそれが高まることになる。

2 接着剤層

3 未加硫隣接ゴムシート

4 積層体

4a 巻付け始端部分

4b 巻付け終端部分

5 成型型

a,b 接合部

c 離隔距離

Claims (5)

- ガスバリア性の薄膜状フィルムインナーライナと、未加硫隣接ゴムシートとを、それらのそれぞれの、長さ方向の各端縁位置を、それらの延在方向に相互にずらした状態で、接着剤層の介在下で貼着させてなる積層体の一本以上を、成型型の周りに、薄膜状フィルムインナーライナが内側となる姿勢で、成型型の全周にわたって巻付けるに当り、端縁がそのフィルムインナーライナから突出して位置する未加硫隣接ゴムシートのその突出部分を、積層体の、成型型への巻付け始端部分の一部とし、その突出部分を成型型の表面に粘着させた状態で積層体の巻付けを開始し、積層体の、成型型に対する巻付け終端部分を、同一のまたは、他の積層体の巻付け始端部分の内周側に入れ込んで、薄膜状フィルムインナーライナの端部分どうし、および、未加硫隣接ゴムシートの端部分どうしのそれぞれを、成型型の周方向に間隔をおいた位置で直接的に、重ね合わせもしくは突き合わせ接合させる生タイヤの成型方法。

- 複数本の積層体を、成型型の周りに、それの全周にわたって巻付けるに当り、一本の積層体の巻付け始端部分の一部としての前記突出部分を成型型の表面に直接的に粘着させる一方、他の積層体の巻付け始端部分の一部としての前記突出部分を、先に巻付けた積層体の巻付け終端部分を介して成型型の表面に間接的に粘着させて、一本の積層体の巻付け終端部分の薄膜状フィルムインナーライナおよび未加硫隣接ゴムシートのそれぞれの端部分に対し、他の積層体の巻付け始端部分の薄膜状フィムルムインナーライナおよび未加硫隣接ゴムシートのそれぞれの端部分を、成型型の周方向に間隔をおいた位置で直接的に、重ね合わせもしくは突き合わせ接合させる請求項1に記載の生タイヤの成型方法。

- 未加硫隣接ゴムシートを、インナーライナ用ゴムシート、スキージゴム用ゴムシートもしくは、カーカスプライ用コードを埋設したゴムシートとする請求項1もしくは2に記載の生タイヤの成型方法。

- 同一の積層体内での、または、異なった積層体間での、未加硫ゴムシートの端部分どうしの重ね合わせもしくは突き合わせ接合域および、薄膜状フィルムインナーライナの端部分どうしの重ね合わせもしくは突き合わせ接合域のそれぞれの、成型型の周方向の長さを0〜20mmおよび、0mmを越えて60mm以下の範囲とする請求項1〜3のいずれかに記載の生タイヤの成型方法。

- 未加硫隣接ゴムシートの端部分どうしの接合域と、薄膜状フィルムインナーライナの端部分どうしの接合域との、成型型の周方向の離隔距離を0〜60mmの範囲とする請求項1〜4のいずれかに記載の生タイヤの成型方法。

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008170148A JP5140503B2 (ja) | 2008-06-30 | 2008-06-30 | 生タイヤの成型方法 |

| PCT/JP2009/061979 WO2010001901A1 (ja) | 2008-06-30 | 2009-06-30 | 生タイヤの成型方法 |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2008170148A JP5140503B2 (ja) | 2008-06-30 | 2008-06-30 | 生タイヤの成型方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2010005986A true JP2010005986A (ja) | 2010-01-14 |

| JP5140503B2 JP5140503B2 (ja) | 2013-02-06 |

Family

ID=41465993

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008170148A Expired - Fee Related JP5140503B2 (ja) | 2008-06-30 | 2008-06-30 | 生タイヤの成型方法 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP5140503B2 (ja) |

| WO (1) | WO2010001901A1 (ja) |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010167829A (ja) * | 2009-01-20 | 2010-08-05 | Yokohama Rubber Co Ltd:The | 空気入りタイヤ及びその製造方法 |

| WO2012066816A1 (ja) * | 2010-11-17 | 2012-05-24 | 住友ゴム工業株式会社 | 空気入りタイヤの製造方法 |

| WO2012086276A1 (ja) * | 2010-12-22 | 2012-06-28 | 横浜ゴム株式会社 | 空気入りタイヤ |

| WO2012165512A1 (ja) | 2011-05-31 | 2012-12-06 | 株式会社ブリヂストン | 積層体、タイヤ、及び該タイヤの製造方法 |

| JP2012240658A (ja) * | 2011-05-24 | 2012-12-10 | Yokohama Rubber Co Ltd:The | 空気入りタイヤ |

| WO2013051325A1 (ja) * | 2011-10-04 | 2013-04-11 | 住友ゴム工業株式会社 | 空気入りタイヤの製造方法 |

| WO2013054602A1 (ja) * | 2011-10-11 | 2013-04-18 | 住友ゴム工業株式会社 | 空気入りタイヤの製造方法 |

| JP2013078883A (ja) * | 2011-10-04 | 2013-05-02 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| JP2013086460A (ja) * | 2011-10-21 | 2013-05-13 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| JP2013091249A (ja) * | 2011-10-26 | 2013-05-16 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| JP2013099898A (ja) * | 2011-11-09 | 2013-05-23 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| JP2013107332A (ja) * | 2011-11-22 | 2013-06-06 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| JP2013136224A (ja) * | 2011-11-29 | 2013-07-11 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| JP2016052789A (ja) * | 2015-11-02 | 2016-04-14 | 横浜ゴム株式会社 | 空気入りタイヤの製造方法 |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ITTO20120778A1 (it) * | 2012-09-10 | 2014-03-11 | Bridgestone Europ Nv | Metodo e stazione di costruzione di un pneumatico |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2000272023A (ja) * | 1999-03-26 | 2000-10-03 | Yokohama Rubber Co Ltd:The | 空気入りタイヤの製造方法 |

| JP4122031B2 (ja) * | 2006-03-29 | 2008-07-23 | 横浜ゴム株式会社 | 空気入りタイヤの製造方法 |

| JP5016248B2 (ja) * | 2006-04-06 | 2012-09-05 | 株式会社ブリヂストン | タイヤ |

| JP2008221638A (ja) * | 2007-03-13 | 2008-09-25 | Bridgestone Corp | シート状タイヤ構成部材の製造方法及び製造装置 |

-

2008

- 2008-06-30 JP JP2008170148A patent/JP5140503B2/ja not_active Expired - Fee Related

-

2009

- 2009-06-30 WO PCT/JP2009/061979 patent/WO2010001901A1/ja not_active Ceased

Cited By (30)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010167829A (ja) * | 2009-01-20 | 2010-08-05 | Yokohama Rubber Co Ltd:The | 空気入りタイヤ及びその製造方法 |

| EP2623304A4 (en) * | 2010-11-17 | 2016-11-23 | Sumitomo Rubber Ind | METHOD FOR PRODUCING AIR TIRES |

| WO2012066816A1 (ja) * | 2010-11-17 | 2012-05-24 | 住友ゴム工業株式会社 | 空気入りタイヤの製造方法 |

| JP2012106403A (ja) * | 2010-11-17 | 2012-06-07 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| US10046532B2 (en) | 2010-11-17 | 2018-08-14 | Sumitomo Rubber Industries, Ltd. | Method for manufacturing pneumatic tire |

| WO2012086276A1 (ja) * | 2010-12-22 | 2012-06-28 | 横浜ゴム株式会社 | 空気入りタイヤ |

| JP2012144238A (ja) * | 2010-12-22 | 2012-08-02 | Yokohama Rubber Co Ltd:The | 空気入りタイヤ |

| US10293644B2 (en) | 2010-12-22 | 2019-05-21 | The Yokohama Rubber Co., Ltd. | Pneumatic tire |

| JP2012240658A (ja) * | 2011-05-24 | 2012-12-10 | Yokohama Rubber Co Ltd:The | 空気入りタイヤ |

| WO2012165512A1 (ja) | 2011-05-31 | 2012-12-06 | 株式会社ブリヂストン | 積層体、タイヤ、及び該タイヤの製造方法 |

| US9815330B2 (en) | 2011-05-31 | 2017-11-14 | Bridgestone Corporation | Laminate, tire, and method for producing tire |

| WO2013051325A1 (ja) * | 2011-10-04 | 2013-04-11 | 住友ゴム工業株式会社 | 空気入りタイヤの製造方法 |

| EP3330066A1 (en) * | 2011-10-04 | 2018-06-06 | Sumitomo Rubber Industries, Ltd. | Method for manufacturing pneumatic tires |

| US10464300B2 (en) | 2011-10-04 | 2019-11-05 | Sumitomo Rubber Industries, Ltd. | Method for manufacturing pneumatic tire |

| JP2013078883A (ja) * | 2011-10-04 | 2013-05-02 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| EP3351372A1 (en) * | 2011-10-04 | 2018-07-25 | Sumitomo Rubber Industries, Ltd. | Method for manufacturing pneumatic tires |

| CN103842165A (zh) * | 2011-10-04 | 2014-06-04 | 住友橡胶工业株式会社 | 充气轮胎的制造方法 |

| US20140261976A1 (en) * | 2011-10-04 | 2014-09-18 | Sumitomo Rubber Industries, Ltd. | Method for manufacturing pneumatic tire |

| EP2749403A4 (en) * | 2011-10-04 | 2016-01-06 | Sumitomo Rubber Ind | METHOD FOR PRODUCING AIR TIRES |

| EP3330065A1 (en) * | 2011-10-04 | 2018-06-06 | Sumitomo Rubber Industries, Ltd. | Method for manufacturing pneumatic tires |

| EP3330067A1 (en) * | 2011-10-04 | 2018-06-06 | Sumitomo Rubber Industries, Ltd. | Method for manufacturing pneumatic tires |

| EP3326793A1 (en) * | 2011-10-04 | 2018-05-30 | Sumitomo Rubber Industries, Ltd. | Method for manufacturing pneumatic tires |

| JP2013082139A (ja) * | 2011-10-11 | 2013-05-09 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| WO2013054602A1 (ja) * | 2011-10-11 | 2013-04-18 | 住友ゴム工業株式会社 | 空気入りタイヤの製造方法 |

| JP2013086460A (ja) * | 2011-10-21 | 2013-05-13 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| JP2013091249A (ja) * | 2011-10-26 | 2013-05-16 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| JP2013099898A (ja) * | 2011-11-09 | 2013-05-23 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| JP2013107332A (ja) * | 2011-11-22 | 2013-06-06 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| JP2013136224A (ja) * | 2011-11-29 | 2013-07-11 | Sumitomo Rubber Ind Ltd | 空気入りタイヤの製造方法 |

| JP2016052789A (ja) * | 2015-11-02 | 2016-04-14 | 横浜ゴム株式会社 | 空気入りタイヤの製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP5140503B2 (ja) | 2013-02-06 |

| WO2010001901A1 (ja) | 2010-01-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5140503B2 (ja) | 生タイヤの成型方法 | |

| CN101468522B (zh) | 充气轮胎的制造方法以及充气轮胎 | |

| CN102785533B (zh) | 充气轮胎及其制造方法 | |

| CN101410246B (zh) | 充气轮胎的制造方法 | |

| JP2011235635A5 (ja) | ||

| US20190143764A1 (en) | Pneumatic tire with noise damper | |

| CN103228430B (zh) | 充气轮胎的制造方法 | |

| US8926774B2 (en) | Method for manufacturing a pneumatic tire | |

| JP2012006499A (ja) | 空気入りタイヤ及びその製造方法 | |

| JP2009208444A (ja) | インナーライナーの成型方法 | |

| US8696846B2 (en) | Method of manufacturing a pneumatic tire | |

| CN104321204A (zh) | 轮胎内衬用片材和轮胎 | |

| JP2006198848A (ja) | 空気入りタイヤ及び空気入りタイヤの製造方法 | |

| WO2006106722A1 (ja) | 空気入りタイヤの内面部修理方法及び内面部修理材 | |

| KR101251424B1 (ko) | 공기입 타이어의 제조방법 및 그 방법에 의해 제조된 공기입 타이어 | |

| CN104838168B (zh) | 环带的制造方法及环带 | |

| JP2009083733A (ja) | 空気入りタイヤ | |

| JP3665038B2 (ja) | ゴム製袋体とその製造方法 | |

| JP2006272809A (ja) | 空気入りタイヤの内面部修理方法 | |

| JPH04101835A (ja) | 空気入りタイヤの成形方法 | |

| JP2011224907A (ja) | 空気入りタイヤの製造方法 | |

| CN217705381U (zh) | 轮胎 | |

| JPS6011336A (ja) | フアスナ−付きゴムシ−トの製造法 | |

| JP2007030312A (ja) | ゴムライニング方法 | |

| JP2007160833A (ja) | 円環状中空体の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20110421 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120807 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20120925 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20121023 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20121119 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5140503 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20151122 Year of fee payment: 3 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |