JP2008235010A - 表示装置の製造方法 - Google Patents

表示装置の製造方法 Download PDFInfo

- Publication number

- JP2008235010A JP2008235010A JP2007072965A JP2007072965A JP2008235010A JP 2008235010 A JP2008235010 A JP 2008235010A JP 2007072965 A JP2007072965 A JP 2007072965A JP 2007072965 A JP2007072965 A JP 2007072965A JP 2008235010 A JP2008235010 A JP 2008235010A

- Authority

- JP

- Japan

- Prior art keywords

- transfer layer

- substrate

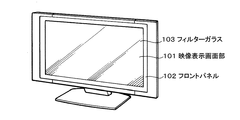

- display device

- layer

- manufacturing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05B—ELECTRIC HEATING; ELECTRIC LIGHT SOURCES NOT OTHERWISE PROVIDED FOR; CIRCUIT ARRANGEMENTS FOR ELECTRIC LIGHT SOURCES, IN GENERAL

- H05B33/00—Electroluminescent light sources

- H05B33/10—Apparatus or processes specially adapted to the manufacture of electroluminescent light sources

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/04—Coating on selected surface areas, e.g. using masks

- C23C14/048—Coating on selected surface areas, e.g. using masks using irradiation by energy or particles

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K71/00—Manufacture or treatment specially adapted for the organic devices covered by this subclass

- H10K71/10—Deposition of organic active material

- H10K71/16—Deposition of organic active material using physical vapour deposition [PVD], e.g. vacuum deposition or sputtering

- H10K71/164—Deposition of organic active material using physical vapour deposition [PVD], e.g. vacuum deposition or sputtering using vacuum deposition

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K71/00—Manufacture or treatment specially adapted for the organic devices covered by this subclass

- H10K71/10—Deposition of organic active material

- H10K71/18—Deposition of organic active material using non-liquid printing techniques, e.g. thermal transfer printing from a donor sheet

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K71/00—Manufacture or treatment specially adapted for the organic devices covered by this subclass

-

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10K—ORGANIC ELECTRIC SOLID-STATE DEVICES

- H10K71/00—Manufacture or treatment specially adapted for the organic devices covered by this subclass

- H10K71/40—Thermal treatment, e.g. annealing in the presence of a solvent vapour

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/50—Photovoltaic [PV] energy

- Y02E10/549—Organic PV cells

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/50—Manufacturing or production processes characterised by the final manufactured product

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- Toxicology (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Electroluminescent Light Sources (AREA)

- Devices For Indicating Variable Information By Combining Individual Elements (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007072965A JP2008235010A (ja) | 2007-03-20 | 2007-03-20 | 表示装置の製造方法 |

| TW97107223A TW200904240A (en) | 2007-03-20 | 2008-02-29 | Method for manufacturing display device |

| KR20080023271A KR20080085705A (ko) | 2007-03-20 | 2008-03-13 | 표시 장치의 제조 방법 |

| CN2008100875012A CN101272643B (zh) | 2007-03-20 | 2008-03-19 | 用于制造显示装置的方法 |

| US12/051,603 US20080233827A1 (en) | 2007-03-20 | 2008-03-19 | Method for manufacturing display device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2007072965A JP2008235010A (ja) | 2007-03-20 | 2007-03-20 | 表示装置の製造方法 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2008235010A true JP2008235010A (ja) | 2008-10-02 |

| JP2008235010A5 JP2008235010A5 (enExample) | 2008-11-13 |

Family

ID=39775224

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2007072965A Pending JP2008235010A (ja) | 2007-03-20 | 2007-03-20 | 表示装置の製造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20080233827A1 (enExample) |

| JP (1) | JP2008235010A (enExample) |

| KR (1) | KR20080085705A (enExample) |

| CN (1) | CN101272643B (enExample) |

| TW (1) | TW200904240A (enExample) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011114873A1 (ja) * | 2010-03-18 | 2011-09-22 | 株式会社半導体エネルギー研究所 | 成膜方法及び成膜用基板の作製方法 |

| JP2011195870A (ja) * | 2010-03-18 | 2011-10-06 | Semiconductor Energy Lab Co Ltd | 成膜方法 |

| US8900675B2 (en) | 2010-03-18 | 2014-12-02 | Semiconductor Energy Laboratory Co., Ltd. | Deposition method and method for manufacturing deposition substrate |

| US8951816B2 (en) | 2010-03-18 | 2015-02-10 | Semiconductor Energy Laboratory Co., Ltd. | Film forming method |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2012091243A1 (ko) * | 2010-12-27 | 2012-07-05 | 제일모직 주식회사 | 열전사 필름 |

| JP5695535B2 (ja) | 2011-09-27 | 2015-04-08 | 株式会社東芝 | 表示装置の製造方法 |

| TW201321871A (zh) * | 2011-11-29 | 2013-06-01 | Au Optronics Corp | 顯示面板及其製作方法 |

| KR20150012530A (ko) * | 2013-07-25 | 2015-02-04 | 삼성디스플레이 주식회사 | 전사용 도너 기판 및 유기 발광 표시 장치의 제조 방법 |

| CN111490185A (zh) * | 2013-12-26 | 2020-08-04 | 科迪华公司 | 电子装置的热加工 |

| KR102303994B1 (ko) * | 2014-10-20 | 2021-09-23 | 삼성디스플레이 주식회사 | 유기발광 표시기판의 제조방법 |

| CN107221548A (zh) * | 2016-03-22 | 2017-09-29 | 上海和辉光电有限公司 | Oled显示面板、智能显示玻璃装置及制备方法 |

| US10615345B2 (en) * | 2016-06-03 | 2020-04-07 | The Trustees Of Princeton University | Method and device for using an organic underlayer to enable crystallization of disordered organic thin films |

| KR20250038812A (ko) * | 2018-05-11 | 2025-03-19 | 가부시키가이샤 한도오따이 에네루기 켄큐쇼 | 표시 장치, 표시 모듈, 및 전자 기기 |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002216957A (ja) * | 2001-01-19 | 2002-08-02 | Sharp Corp | 転写法を用いた有機led表示パネルの製造方法およびそれにより製造された有機led表示パネル |

| JP2003077657A (ja) * | 2001-09-05 | 2003-03-14 | Sharp Corp | 有機led層形成用塗液、有機led用ドナーフィルム、それを用いた有機led表示パネルの製造方法および有機led表示パネル |

| JP2003187972A (ja) * | 2001-12-20 | 2003-07-04 | Dainippon Printing Co Ltd | 有機el素子の製造方法および有機el転写体と被転写体 |

| JP2003347054A (ja) * | 2002-05-29 | 2003-12-05 | Sharp Corp | 薄膜転写用フィルムとその製造方法およびそれを用いた有機el素子 |

| JP2004193018A (ja) * | 2002-12-12 | 2004-07-08 | Fuji Photo Film Co Ltd | 有機電界発光素子の製造方法及び有機電界発光素子 |

| JP2005116238A (ja) * | 2003-10-03 | 2005-04-28 | Tdk Corp | 有機el素子及び有機elディスプレイ |

| WO2005059951A2 (en) * | 2003-12-19 | 2005-06-30 | Cambridge Display Technology Limited | Optical device comprising a charge transport layer of insoluble organic material and method for the production thereof |

| JP2006086069A (ja) * | 2004-09-17 | 2006-03-30 | Three M Innovative Properties Co | 有機エレクトロルミネッセンス素子及びその製造方法 |

| JP2006108098A (ja) * | 2004-10-05 | 2006-04-20 | Samsung Sdi Co Ltd | ドナー基板の製造方法,およびドナー基板を用いた有機電界発光表示装置の製造方法 |

| JP2006123546A (ja) * | 2004-10-19 | 2006-05-18 | Samsung Sdi Co Ltd | ドナー基板,有機電界発光表示装置の製造方法 |

| JP2006231407A (ja) * | 2005-02-22 | 2006-09-07 | Samsung Sdi Co Ltd | レーザ照射装置及びレーザ熱転写法 |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7005166B2 (en) * | 2001-06-19 | 2006-02-28 | Dai Nippon Printing Co., Ltd. | Method for fluorescent image formation, print produced thereby and thermal transfer sheet thereof |

| US6699597B2 (en) * | 2001-08-16 | 2004-03-02 | 3M Innovative Properties Company | Method and materials for patterning of an amorphous, non-polymeric, organic matrix with electrically active material disposed therein |

| KR100490539B1 (ko) * | 2002-09-19 | 2005-05-17 | 삼성에스디아이 주식회사 | 유기 전계 발광소자 및 그 제조방법 |

| US7052355B2 (en) * | 2003-10-30 | 2006-05-30 | General Electric Company | Organic electro-optic device and method for making the same |

| US20050123850A1 (en) * | 2003-12-09 | 2005-06-09 | 3M Innovative Properties Company | Thermal transfer of light-emitting dendrimers |

| KR100731728B1 (ko) * | 2004-08-27 | 2007-06-22 | 삼성에스디아이 주식회사 | 레이저 전사용 도너 기판 및 이를 이용한 유기 전계 발광소자의 제조 방법 |

| KR20060020030A (ko) * | 2004-08-30 | 2006-03-06 | 삼성에스디아이 주식회사 | 도너 기판의 제조방법 |

| KR100611767B1 (ko) * | 2004-08-30 | 2006-08-10 | 삼성에스디아이 주식회사 | 레이저 전사용 도너 기판 및 그 필름을 사용하여 제조되는유기 전계 발광 소자의 제조 방법 |

-

2007

- 2007-03-20 JP JP2007072965A patent/JP2008235010A/ja active Pending

-

2008

- 2008-02-29 TW TW97107223A patent/TW200904240A/zh unknown

- 2008-03-13 KR KR20080023271A patent/KR20080085705A/ko not_active Withdrawn

- 2008-03-19 US US12/051,603 patent/US20080233827A1/en not_active Abandoned

- 2008-03-19 CN CN2008100875012A patent/CN101272643B/zh not_active Expired - Fee Related

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002216957A (ja) * | 2001-01-19 | 2002-08-02 | Sharp Corp | 転写法を用いた有機led表示パネルの製造方法およびそれにより製造された有機led表示パネル |

| JP2003077657A (ja) * | 2001-09-05 | 2003-03-14 | Sharp Corp | 有機led層形成用塗液、有機led用ドナーフィルム、それを用いた有機led表示パネルの製造方法および有機led表示パネル |

| JP2003187972A (ja) * | 2001-12-20 | 2003-07-04 | Dainippon Printing Co Ltd | 有機el素子の製造方法および有機el転写体と被転写体 |

| JP2003347054A (ja) * | 2002-05-29 | 2003-12-05 | Sharp Corp | 薄膜転写用フィルムとその製造方法およびそれを用いた有機el素子 |

| JP2004193018A (ja) * | 2002-12-12 | 2004-07-08 | Fuji Photo Film Co Ltd | 有機電界発光素子の製造方法及び有機電界発光素子 |

| JP2005116238A (ja) * | 2003-10-03 | 2005-04-28 | Tdk Corp | 有機el素子及び有機elディスプレイ |

| WO2005059951A2 (en) * | 2003-12-19 | 2005-06-30 | Cambridge Display Technology Limited | Optical device comprising a charge transport layer of insoluble organic material and method for the production thereof |

| JP2007520858A (ja) * | 2003-12-19 | 2007-07-26 | ケンブリッジ ディスプレイ テクノロジー リミテッド | 光学装置 |

| JP2006086069A (ja) * | 2004-09-17 | 2006-03-30 | Three M Innovative Properties Co | 有機エレクトロルミネッセンス素子及びその製造方法 |

| JP2006108098A (ja) * | 2004-10-05 | 2006-04-20 | Samsung Sdi Co Ltd | ドナー基板の製造方法,およびドナー基板を用いた有機電界発光表示装置の製造方法 |

| JP2006123546A (ja) * | 2004-10-19 | 2006-05-18 | Samsung Sdi Co Ltd | ドナー基板,有機電界発光表示装置の製造方法 |

| JP2006231407A (ja) * | 2005-02-22 | 2006-09-07 | Samsung Sdi Co Ltd | レーザ照射装置及びレーザ熱転写法 |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011114873A1 (ja) * | 2010-03-18 | 2011-09-22 | 株式会社半導体エネルギー研究所 | 成膜方法及び成膜用基板の作製方法 |

| JP2011195870A (ja) * | 2010-03-18 | 2011-10-06 | Semiconductor Energy Lab Co Ltd | 成膜方法 |

| US8815352B2 (en) | 2010-03-18 | 2014-08-26 | Semiconductor Energy Laboratory Co., Ltd. | Film forming method and method for manufacturing film-formation substrate |

| US8900675B2 (en) | 2010-03-18 | 2014-12-02 | Semiconductor Energy Laboratory Co., Ltd. | Deposition method and method for manufacturing deposition substrate |

| US8951816B2 (en) | 2010-03-18 | 2015-02-10 | Semiconductor Energy Laboratory Co., Ltd. | Film forming method |

| JP5666556B2 (ja) * | 2010-03-18 | 2015-02-12 | 株式会社半導体エネルギー研究所 | 成膜方法及び成膜用基板の作製方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20080085705A (ko) | 2008-09-24 |

| CN101272643A (zh) | 2008-09-24 |

| US20080233827A1 (en) | 2008-09-25 |

| TW200904240A (en) | 2009-01-16 |

| CN101272643B (zh) | 2010-10-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2008235010A (ja) | 表示装置の製造方法 | |

| US9209233B2 (en) | Method for manufacturing display and display | |

| CN101916824B (zh) | 转印基板和制造显示设备的方法 | |

| CN100527436C (zh) | 显示装置的制造方法 | |

| CN101615658B (zh) | 供体基板和显示器制造方法 | |

| CN101363113B (zh) | 蒸发源及其制造方法和有机电致发光显示装置的制造方法 | |

| JP2006309995A (ja) | 転写用基板および表示装置の製造方法ならびに表示装置 | |

| CN101156244A (zh) | 显示器的制造方法 | |

| US7993806B2 (en) | Transfer substrate, and fabrication process of organic electroluminescent devices | |

| JP4396864B2 (ja) | 表示装置およびその製造方法 | |

| CN100483619C (zh) | 转移衬底、转移方法和有机电发光器件制造方法 | |

| JP2009146715A (ja) | ドナー基板および表示装置の製造方法 | |

| JP4793071B2 (ja) | 表示装置および表示装置の製造方法 | |

| JP2009146716A (ja) | 表示装置およびドナー基板 | |

| JP2008235011A (ja) | 表示装置の製造方法 | |

| JP2008311103A (ja) | 表示装置の製造方法および表示装置 | |

| JP2009266451A (ja) | 表示装置の製造方法および転写基板 | |

| JP2006309955A (ja) | 有機電界発光素子の製造方法および有機電界発光素子 | |

| JP2010192826A (ja) | ドナー基板および表示装置の製造方法 | |

| JP2011034852A (ja) | ドナー基板の製造方法およびドナー基板、並びに表示装置の製造方法 | |

| JP2011108421A (ja) | 表示装置の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20080916 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20080916 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090806 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090811 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20090917 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20091020 |

|

| RD02 | Notification of acceptance of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7422 Effective date: 20091021 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20091026 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20091109 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20091214 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20101019 |