JP2008228564A - 自動車の駆動系の熱的過負荷保護のための方法及び装置 - Google Patents

自動車の駆動系の熱的過負荷保護のための方法及び装置 Download PDFInfo

- Publication number

- JP2008228564A JP2008228564A JP2008058129A JP2008058129A JP2008228564A JP 2008228564 A JP2008228564 A JP 2008228564A JP 2008058129 A JP2008058129 A JP 2008058129A JP 2008058129 A JP2008058129 A JP 2008058129A JP 2008228564 A JP2008228564 A JP 2008228564A

- Authority

- JP

- Japan

- Prior art keywords

- drive system

- temperature

- thermal

- limit value

- protection

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 title claims abstract description 12

- 239000000779 smoke Substances 0.000 claims description 8

- 230000008878 coupling Effects 0.000 claims description 3

- 238000010168 coupling process Methods 0.000 claims description 3

- 238000005859 coupling reaction Methods 0.000 claims description 3

- 230000001419 dependent effect Effects 0.000 claims description 3

- 238000004364 calculation method Methods 0.000 claims description 2

- 230000001143 conditioned effect Effects 0.000 claims 1

- 230000004913 activation Effects 0.000 abstract 1

- 239000005357 flat glass Substances 0.000 abstract 1

- 238000005219 brazing Methods 0.000 description 8

- 230000007246 mechanism Effects 0.000 description 4

- 230000001105 regulatory effect Effects 0.000 description 3

- 230000002441 reversible effect Effects 0.000 description 3

- 239000004020 conductor Substances 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000020169 heat generation Effects 0.000 description 2

- 239000000155 melt Substances 0.000 description 2

- 238000013021 overheating Methods 0.000 description 2

- 238000004804 winding Methods 0.000 description 2

- 230000009471 action Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 230000009849 deactivation Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000002427 irreversible effect Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 239000004065 semiconductor Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02H—EMERGENCY PROTECTIVE CIRCUIT ARRANGEMENTS

- H02H7/00—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions

- H02H7/08—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for dynamo-electric motors

- H02H7/085—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for dynamo-electric motors against excessive load

- H02H7/0851—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for dynamo-electric motors against excessive load for motors actuating a movable member between two end positions, e.g. detecting an end position or obstruction by overload signal

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02H—EMERGENCY PROTECTIVE CIRCUIT ARRANGEMENTS

- H02H7/00—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions

- H02H7/08—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for dynamo-electric motors

- H02H7/085—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for dynamo-electric motors against excessive load

- H02H7/0852—Emergency protective circuit arrangements specially adapted for specific types of electric machines or apparatus or for sectionalised protection of cable or line systems, and effecting automatic switching in the event of an undesired change from normal working conditions for dynamo-electric motors against excessive load directly responsive to abnormal temperature by using a temperature sensor

Landscapes

- Control Of Direct Current Motors (AREA)

- Protection Of Generators And Motors (AREA)

- Stopping Of Electric Motors (AREA)

- Control Of Electric Motors In General (AREA)

Abstract

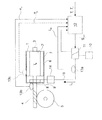

【解決手段】電子式の挟み込み保護を備えた調整装置の駆動系、特に自動車の窓開閉駆動部、の熱的過負荷保護のための装置及び方法を提供する。駆動系1の運転温度(TB)が決定され、温度限界値(T1)に達したとき駆動系1が非能動化され、一方電子式の挟み込み保護は能動化状態にとどまり、また温度限界値(T1)を越えたときは駆動系1へのエネルギー供給は伸長線又はヒューズの様式の安全要素14を用いて遮断される。

【選択図】図1

Description

2 ロータ

3 モータ軸

4 ウオーム

5 ウオーム歯車

6 モータハウジング/極ヘッド

7 ステータ

8 コミュテータ

9 ブラシ保持器

10 バッテリ

11 電力段

12 操作電子回路

13a 電流センサ

13b ホールセンサ

13c 温度センサ

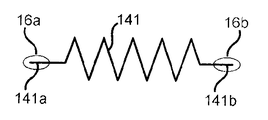

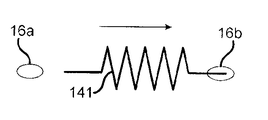

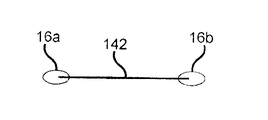

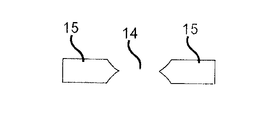

14 安全要素

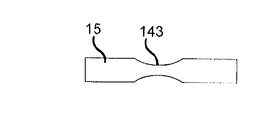

15 電流路

16 ろうパッド

17 導電路部分

141 ばね要素

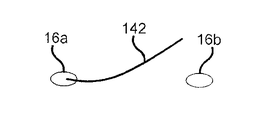

142 板/たわみばね

143 所定破断箇所

Iist 実際/負荷電流

nist モータ回転速度

IM 負荷/モータ電流

TA 周囲/外部温度

TB 運転温度

T1 第1の温度限界値

T2 第2の温度限界値

Claims (7)

- 電子式の挟み込み保護を備えた調整装置の駆動系、特に自動車の窓開閉駆動部、の熱的過負荷保護のための装置において、電動機(1)と、計算機ユニット(12)と、熱的安全要素(14)とを有し、

・計算機ユニット(12)は、運転に条件付けられるパラメータ(Iist、TA)を考慮したアルゴリズムを用いて、駆動系又は駆動系の構成部分の運転温度(TB)を決定し、第1の温度限界値(T1)に達したとき駆動系を非能動化し、その際電子式の挟み込み保護は能動化状態にとどまるように設けられ、

・熱的安全要素(14)は、第2の温度限界値(T2)に達したとき駆動系へのエネルギー供給を遮断し、その際第2の温度限界値(T2)は第1の温度限界値(T1)より高い位置にある

ことを特徴とする駆動系の熱的過負荷保護装置。 - 計算ユニット(12)は、挟み込み事故が検出され第1の温度限界値(T1)に達したとき、挟み込まれた対象を解放する方向に駆動系を操作するように設けられていることを特徴とする請求項1記載の装置。

- 熱的安全要素(14)が電動機(1)の負荷電流(IM)を導く電流担体(15、16)中に組み込まれており、この電流担体は導電路状の結合部として電動機(1)のコミュテータブラシ(9)に通じていることを特徴とする請求項1又は2記載の装置。

- 調整装置の駆動系、特に自動車の窓開閉駆動部、の熱的過負荷保護のための方法において、

・駆動系の運転の間対象の挟み込みが監視され、挟み込み事故の際には駆動系を非能動化ないし逆駆動させる電子式の挟み込み保護が能動化され、

・駆動系又はその構成部分、特に電動機、の運転温度(TB)が確定され、

・確定された運転温度(TB)が(第1の)温度限界値(T1)と比較され、現下の運転温度(TB)が温度限界値(T1)に達するとき駆動系が非能動化され、その際電子式の挟み込み保護は能動化状態にとどまっており、

・駆動系が能動化されており、同時に運転温度(TB)が温度限界値(T1)を特定の温度値(ΔT12)だけ越えたとき、熱的安全要素(14)が引き外され、駆動系へのエネルギー供給が遮断される

ことを特徴とする駆動系の熱的過負荷保護方法。 - 運転温度(TB)が第1の温度限界値(T1)の上でかつ駆動系(1)ないし構成部分の火災の危険又は煙発生に対し置かれた第2の温度限界値(T2)の下方に達したとき、熱的安全要素(14)が引き外されることを特徴とする請求項4記載の方法。

- 現下の負荷電流(Iist、TB)、モータ回転速度(nist)及び駆動系の周囲温度(TA)の少なくともいずれかが運転パラメータとして検出されることを特徴とする請求項4又は5記載の方法。

- 運転温度(Iist、TA)が、駆動系ないし構成部分の負荷又は負荷に依存する熱特性を写像するモデルに基いて及びアルゴリズムを用いての少なくとも一方により計算されることを特徴とする請求項4〜6のいずれか1つに記載の方法。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102007011548.4A DE102007011548B4 (de) | 2007-03-09 | 2007-03-09 | Verfahren und Vorrichtung zum thermischen Überlastschutz eines Antriebssystems eines Kraftfahrzeugs |

| DE102007011548.4 | 2007-03-09 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2008228564A true JP2008228564A (ja) | 2008-09-25 |

| JP2008228564A5 JP2008228564A5 (ja) | 2010-11-11 |

| JP5285930B2 JP5285930B2 (ja) | 2013-09-11 |

Family

ID=39677980

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2008058129A Active JP5285930B2 (ja) | 2007-03-09 | 2008-03-07 | 自動車の駆動系の熱的過負荷保護のための方法及び装置 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP5285930B2 (ja) |

| DE (1) | DE102007011548B4 (ja) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10873286B2 (en) | 2016-12-16 | 2020-12-22 | Siemens Aktiengesellschaft | Method and device for the computer-assisted operation of an electric motor |

| CN114530967A (zh) * | 2022-01-21 | 2022-05-24 | 东阳市联宜机电有限公司 | 有刷电机后端盖总成 |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2010112389A1 (de) | 2009-04-01 | 2010-10-07 | Continental Automotive Gmbh | Schaltung für einen bürstenlosen motor und verfahren zu deren betrieb |

| DE202010002664U1 (de) * | 2010-02-23 | 2011-07-12 | Brose Fahrzeugteile GmbH & Co. Kommanditgesellschaft, Würzburg | Elektromotor zum Antrieb einer Kraftfahrzeugkomponente |

| DE102010002993A1 (de) | 2010-03-18 | 2011-09-22 | Continental Automotive Gmbh | Schaltung für einen bürstenlosen Motor und Verfahren zu deren Betrieb |

| DE202010009326U1 (de) | 2010-06-21 | 2011-10-20 | Brose Fahrzeugteile GmbH & Co. Kommanditgesellschaft, Würzburg | Schmelzsicherung zur Unterbrechung einer gebrückten Unterbrechungsstelle im Stromkreis eines elektrischen Gerätes |

| DE202011001820U1 (de) | 2011-01-21 | 2012-04-27 | Brose Fahrzeugteile GmbH & Co. Kommanditgesellschaft, Würzburg | Schutzvorrichtung für die Steuerelektronik einer Kraftfahrzeugkomponente |

| FR2973603B1 (fr) * | 2011-03-31 | 2014-08-08 | Faurecia Bloc Avant | Porte-balais de moteur electrique et moteur electrique comportant un tel porte-balais |

| FR2989536B1 (fr) * | 2012-04-13 | 2018-01-05 | Faurecia Bloc Avant | Plaque porte-balai, destinee a equiper un moteur electrique, notamment pour un vehicule automobile |

| DE102012211861A1 (de) * | 2012-07-06 | 2014-01-09 | Brose Fahrzeugteile Gmbh & Co. Kg, Würzburg | Schutzvorrichtung und elektrische Antriebsanordnung |

| DE102012025110A1 (de) * | 2012-12-21 | 2014-06-26 | Brose Fahrzeugteile Gmbh & Co. Kommanditgesellschaft, Hallstadt | Thermischer Überlastschutz |

| DE102013222629A1 (de) * | 2013-11-07 | 2015-05-07 | Robert Bosch Gmbh | Kommutierungseinrichtung in einer elektrischen Maschine |

| DE102015211106B4 (de) * | 2015-06-17 | 2025-11-06 | Robert Bosch Gmbh | Verfahren zum Betreiben eines elektromotorischen Stellgebers für ein Schiebedachsystem in einem Kraftfahrzeug |

| DE102020211504B4 (de) | 2020-09-14 | 2022-07-07 | Fronius International Gmbh | Photovoltaik-Schutzvorrichtung |

| DE102020133376A1 (de) | 2020-12-14 | 2022-06-15 | Brose Fahrzeugteile Se & Co. Kommanditgesellschaft, Bamberg | Verfahren für den Betrieb einer motorischen Klappenanordnung eines Kraftfahrzeugs |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11289790A (ja) * | 1998-04-03 | 1999-10-19 | Lumitter Ind Corp Ltd | モータの過熱保護装置 |

| JP2007014057A (ja) * | 2005-06-28 | 2007-01-18 | Asmo Co Ltd | モータ制御装置 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5156636A (en) | 1990-11-26 | 1992-10-20 | Combustion Engineering, Inc. | Ultrasonic method and apparatus for measuring outside diameter and wall thickness of a tube and having temperature compensation |

| DE19635924C2 (de) * | 1996-09-04 | 2000-11-02 | Siemens Ag | Stellantrieb mit vor Überlastung geschütztem Elektromotor |

| DE202005010174U1 (de) * | 2005-06-29 | 2006-11-23 | Brose Fahrzeugteile Gmbh & Co. Kommanditgesellschaft, Coburg | Steuerungssystem für Fensterheber eines Kraftfahrzeugs |

| DE202005011235U1 (de) * | 2005-07-16 | 2006-12-07 | Brose Fahrzeugteile Gmbh & Co. Kommanditgesellschaft, Coburg | Vorrichtung zum Überlastschutz einer Versorgungsleitung für eine elektrische Last in einem Kraftfahrzeug |

-

2007

- 2007-03-09 DE DE102007011548.4A patent/DE102007011548B4/de not_active Expired - Fee Related

-

2008

- 2008-03-07 JP JP2008058129A patent/JP5285930B2/ja active Active

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11289790A (ja) * | 1998-04-03 | 1999-10-19 | Lumitter Ind Corp Ltd | モータの過熱保護装置 |

| JP2007014057A (ja) * | 2005-06-28 | 2007-01-18 | Asmo Co Ltd | モータ制御装置 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10873286B2 (en) | 2016-12-16 | 2020-12-22 | Siemens Aktiengesellschaft | Method and device for the computer-assisted operation of an electric motor |

| CN114530967A (zh) * | 2022-01-21 | 2022-05-24 | 东阳市联宜机电有限公司 | 有刷电机后端盖总成 |

| CN114530967B (zh) * | 2022-01-21 | 2023-08-22 | 浙江联宜电机有限公司 | 有刷电机后端盖总成 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE102007011548B4 (de) | 2015-08-27 |

| JP5285930B2 (ja) | 2013-09-11 |

| DE102007011548A1 (de) | 2008-09-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5285930B2 (ja) | 自動車の駆動系の熱的過負荷保護のための方法及び装置 | |

| JP5955502B2 (ja) | 負荷回路の断線検出装置 | |

| JP4185741B2 (ja) | 電子回路遮断器 | |

| ES2589308T3 (es) | Disyuntor electrónico | |

| JP5314695B2 (ja) | 平常時off型保護素子及びそれを備えた制御ユニット | |

| CN104332954B (zh) | 用于对电机进行热保护及功率调节的电路 | |

| JP4736006B2 (ja) | モータ始動制御装置およびモータ始動における保護方法 | |

| EP2842210B1 (en) | Switching circuit protector | |

| US10424914B2 (en) | Overtemperature protection | |

| JP2010158108A (ja) | 負荷回路の保護装置 | |

| JP2013229964A (ja) | 通電回路の保護装置 | |

| CN113644621A (zh) | 汽车电路保护装置、系统和方法 | |

| JP5269189B2 (ja) | 操作装置 | |

| US7705549B2 (en) | Series resistor assembly for an electric motor, circuit arrangement comprising a series resistor assembly for operating an electric motor and use of said assembly | |

| EP3202004B1 (en) | Compressor motor overload detection | |

| JP3715155B2 (ja) | 回路保護装置 | |

| US2166323A (en) | Control apparatus | |

| JP2003274683A (ja) | 電動機の保護装置 | |

| JP4324254B2 (ja) | 送風機 | |

| JP2010172049A (ja) | 電線保護回路および電線の保護方法 | |

| JP2013207854A (ja) | 過電流保護装置及びロボット制御装置 | |

| JP3813505B2 (ja) | 電動機の保護装置 | |

| GB2428311A (en) | Electronic power switching unit | |

| JPS6331476Y2 (ja) | ||

| JP2023059025A (ja) | 電源制御装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100929 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20100929 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120710 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20121204 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121213 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20121228 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A821 Effective date: 20121228 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20130301 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20130416 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20130418 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130514 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130603 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 5285930 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |