JP2006509975A - 複合された潤滑材料を有する転がり軸受 - Google Patents

複合された潤滑材料を有する転がり軸受 Download PDFInfo

- Publication number

- JP2006509975A JP2006509975A JP2004559608A JP2004559608A JP2006509975A JP 2006509975 A JP2006509975 A JP 2006509975A JP 2004559608 A JP2004559608 A JP 2004559608A JP 2004559608 A JP2004559608 A JP 2004559608A JP 2006509975 A JP2006509975 A JP 2006509975A

- Authority

- JP

- Japan

- Prior art keywords

- rolling bearing

- lubricant

- bearing according

- coating

- coated

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000005096 rolling process Methods 0.000 title claims abstract description 46

- 239000002131 composite material Substances 0.000 title claims abstract 3

- 239000000463 material Substances 0.000 title claims description 22

- 230000001050 lubricating effect Effects 0.000 title claims description 19

- 239000000314 lubricant Substances 0.000 claims abstract description 78

- 238000000576 coating method Methods 0.000 claims description 71

- 239000011248 coating agent Substances 0.000 claims description 68

- 239000010410 layer Substances 0.000 claims description 60

- 239000002346 layers by function Substances 0.000 claims description 16

- 229920000642 polymer Polymers 0.000 claims description 16

- 230000008859 change Effects 0.000 claims description 6

- 239000007787 solid Substances 0.000 claims description 4

- 229910052751 metal Inorganic materials 0.000 claims description 3

- 239000002184 metal Substances 0.000 claims description 3

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims description 2

- 229910052799 carbon Inorganic materials 0.000 claims description 2

- 239000007788 liquid Substances 0.000 claims description 2

- 230000000007 visual effect Effects 0.000 claims description 2

- 238000013016 damping Methods 0.000 claims 1

- 239000000203 mixture Substances 0.000 claims 1

- 238000005461 lubrication Methods 0.000 description 16

- 230000008901 benefit Effects 0.000 description 13

- 239000003921 oil Substances 0.000 description 13

- 238000000034 method Methods 0.000 description 7

- 230000008569 process Effects 0.000 description 7

- 230000000694 effects Effects 0.000 description 6

- 239000000758 substrate Substances 0.000 description 6

- 239000000853 adhesive Substances 0.000 description 4

- 230000001070 adhesive effect Effects 0.000 description 4

- 238000005516 engineering process Methods 0.000 description 4

- UHOVQNZJYSORNB-UHFFFAOYSA-N Benzene Chemical compound C1=CC=CC=C1 UHOVQNZJYSORNB-UHFFFAOYSA-N 0.000 description 3

- 230000002411 adverse Effects 0.000 description 3

- 239000004519 grease Substances 0.000 description 3

- 238000012423 maintenance Methods 0.000 description 3

- 238000011109 contamination Methods 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 230000001066 destructive effect Effects 0.000 description 2

- 230000006870 function Effects 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 230000003993 interaction Effects 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 230000013011 mating Effects 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 238000002161 passivation Methods 0.000 description 2

- 239000011241 protective layer Substances 0.000 description 2

- 230000002829 reductive effect Effects 0.000 description 2

- 230000006641 stabilisation Effects 0.000 description 2

- 238000011105 stabilization Methods 0.000 description 2

- 230000000087 stabilizing effect Effects 0.000 description 2

- 230000007704 transition Effects 0.000 description 2

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000000996 additive effect Effects 0.000 description 1

- 150000001298 alcohols Chemical class 0.000 description 1

- 238000000889 atomisation Methods 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 239000012876 carrier material Substances 0.000 description 1

- 229910052804 chromium Inorganic materials 0.000 description 1

- 239000011651 chromium Substances 0.000 description 1

- 238000012937 correction Methods 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 239000003814 drug Substances 0.000 description 1

- 229940079593 drug Drugs 0.000 description 1

- 230000003628 erosive effect Effects 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 238000011049 filling Methods 0.000 description 1

- -1 greases Substances 0.000 description 1

- 230000020169 heat generation Effects 0.000 description 1

- 230000036512 infertility Effects 0.000 description 1

- 230000001788 irregular Effects 0.000 description 1

- 239000010687 lubricating oil Substances 0.000 description 1

- 238000011089 mechanical engineering Methods 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

- 238000005272 metallurgy Methods 0.000 description 1

- 230000005012 migration Effects 0.000 description 1

- 238000013508 migration Methods 0.000 description 1

- 239000003595 mist Substances 0.000 description 1

- 150000002894 organic compounds Chemical class 0.000 description 1

- 230000036961 partial effect Effects 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 239000004810 polytetrafluoroethylene Substances 0.000 description 1

- 229920001343 polytetrafluoroethylene Polymers 0.000 description 1

- 238000010298 pulverizing process Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 239000002904 solvent Substances 0.000 description 1

- 239000004071 soot Substances 0.000 description 1

- 230000003068 static effect Effects 0.000 description 1

- 230000001954 sterilising effect Effects 0.000 description 1

- 238000004659 sterilization and disinfection Methods 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 231100000331 toxic Toxicity 0.000 description 1

- 230000002588 toxic effect Effects 0.000 description 1

- ITRNXVSDJBHYNJ-UHFFFAOYSA-N tungsten disulfide Chemical compound S=[W]=S ITRNXVSDJBHYNJ-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61C—DENTISTRY; APPARATUS OR METHODS FOR ORAL OR DENTAL HYGIENE

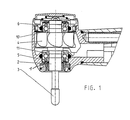

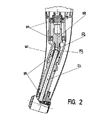

- A61C1/00—Dental machines for boring or cutting ; General features of dental machines or apparatus, e.g. hand-piece design

- A61C1/08—Machine parts specially adapted for dentistry

- A61C1/18—Flexible shafts; Clutches or the like; Bearings or lubricating arrangements; Drives or transmissions

- A61C1/181—Bearings or lubricating arrangements, e.g. air-cushion bearings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/32—Balls

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/58—Raceways; Race rings

- F16C33/62—Selection of substances

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C33/00—Parts of bearings; Special methods for making bearings or parts thereof

- F16C33/30—Parts of ball or roller bearings

- F16C33/66—Special parts or details in view of lubrication

- F16C33/6696—Special parts or details in view of lubrication with solids as lubricant, e.g. dry coatings, powder

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/02—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows

- F16C19/14—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load

- F16C19/16—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with a single row of balls

- F16C19/163—Bearings with rolling contact, for exclusively rotary movement with bearing balls essentially of the same size in one or more circular rows for both radial and axial load with a single row of balls with angular contact

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C19/00—Bearings with rolling contact, for exclusively rotary movement

- F16C19/54—Systems consisting of a plurality of bearings with rolling friction

- F16C19/546—Systems with spaced apart rolling bearings including at least one angular contact bearing

- F16C19/547—Systems with spaced apart rolling bearings including at least one angular contact bearing with two angular contact rolling bearings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16C—SHAFTS; FLEXIBLE SHAFTS; ELEMENTS OR CRANKSHAFT MECHANISMS; ROTARY BODIES OTHER THAN GEARING ELEMENTS; BEARINGS

- F16C2316/00—Apparatus in health or amusement

- F16C2316/10—Apparatus in health or amusement in medical appliances, e.g. in diagnosis, dentistry, instruments, prostheses, medical imaging appliances

- F16C2316/13—Dental machines

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Mechanical Engineering (AREA)

- Oral & Maxillofacial Surgery (AREA)

- Epidemiology (AREA)

- Dentistry (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Rolling Contact Bearings (AREA)

- Sliding-Contact Bearings (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10259003A DE10259003A1 (de) | 2002-12-16 | 2002-12-16 | Wälzlager mit integriertem Schmiermaterial |

| PCT/DE2003/004125 WO2004055402A1 (de) | 2002-12-16 | 2003-12-12 | Wälzlager mit integriertem schmiermaterial |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006509975A true JP2006509975A (ja) | 2006-03-23 |

| JP2006509975A5 JP2006509975A5 (cg-RX-API-DMAC7.html) | 2007-02-01 |

Family

ID=32336404

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004559608A Pending JP2006509975A (ja) | 2002-12-16 | 2003-12-12 | 複合された潤滑材料を有する転がり軸受 |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1573215A1 (cg-RX-API-DMAC7.html) |

| JP (1) | JP2006509975A (cg-RX-API-DMAC7.html) |

| AU (1) | AU2003294656A1 (cg-RX-API-DMAC7.html) |

| BR (1) | BR0317378A (cg-RX-API-DMAC7.html) |

| DE (1) | DE10259003A1 (cg-RX-API-DMAC7.html) |

| WO (1) | WO2004055402A1 (cg-RX-API-DMAC7.html) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2025027818A1 (ja) * | 2023-08-02 | 2025-02-06 | 三菱電機株式会社 | 転がり軸受、転がり軸受の異常診断装置および転がり軸受の異常診断方法 |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102006057484B4 (de) * | 2006-12-06 | 2010-05-12 | Schaeffler Kg | Wälzlager mit einer Oberflächenbeschichtung |

| DE102007015103A1 (de) | 2007-03-29 | 2008-10-02 | Schaeffler Kg | Wälzlager |

| DE102009038410A1 (de) | 2009-08-21 | 2011-02-24 | Schaeffler Technologies Gmbh & Co. Kg | Bauteil mit tribologisch belasteten Komponenten |

| DE102010013630A1 (de) * | 2010-04-01 | 2011-10-06 | Aktiebolaget Skf | Lagerring eines Gleit- oder Wälzlagers |

| DE102014104599B8 (de) | 2014-04-01 | 2019-01-17 | Thyssenkrupp Ag | Wälzlager |

| DE102015211125B4 (de) * | 2015-06-17 | 2019-04-18 | Schaeffler Technologies AG & Co. KG | Käfig für ein Wälzlager sowie Verfahren zur Herstellung eines solchen Käfigs |

| DE102017204355B4 (de) * | 2017-03-16 | 2025-11-06 | Ensinger Sintimid GmbH | Wälzlagerkäfig für ein Dentaltechniklager und Verfahren zum Herstellen eines solchen Wälzlagerkäfigs |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0788853B2 (ja) * | 1990-07-16 | 1995-09-27 | 株式会社安川電機 | ころがり軸受 |

| JP2002349577A (ja) * | 2001-05-29 | 2002-12-04 | Nsk Ltd | 転がり摺動部材 |

Family Cites Families (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5557717A (en) * | 1978-10-25 | 1980-04-28 | Koyo Seiko Co Ltd | Rolling bearing |

| US5207513A (en) * | 1990-11-30 | 1993-05-04 | Ntn Corporation | Rolling bearing with solid lubricant |

| JP3021923B2 (ja) * | 1992-02-27 | 2000-03-15 | エヌティエヌ株式会社 | 半導体製造設備用転がり軸受 |

| JPH06193637A (ja) * | 1992-12-25 | 1994-07-15 | Ntn Corp | 転がり軸受 |

| JP3535558B2 (ja) * | 1994-03-07 | 2004-06-07 | 株式会社東芝 | 摺動部材、転がり軸受および回転陽極x線管 |

| JPH0874862A (ja) * | 1994-09-06 | 1996-03-19 | Hitachi Ltd | 固体潤滑軸受 |

| JPH0893774A (ja) * | 1994-09-21 | 1996-04-09 | Ntn Corp | 固体潤滑転がり軸受 |

| JP3002957B2 (ja) * | 1995-09-11 | 2000-01-24 | 光洋精工株式会社 | 転がり軸受および転がり軸受の潤滑膜形成方法 |

| RU2095653C1 (ru) * | 1996-09-25 | 1997-11-10 | Константин Дмитриевич Семкин | Подшипник с постоянным смазочным слоем и способ его изготовления |

| JPH1151066A (ja) * | 1997-07-30 | 1999-02-23 | Nippon Seiko Kk | 潤滑剤含有ポリマ充填転がり軸受及びその製造方法 |

| NL1007046C2 (nl) * | 1997-09-16 | 1999-03-17 | Skf Ind Trading & Dev | Bekleed wentellager. |

| JPH11201175A (ja) * | 1998-01-07 | 1999-07-27 | Koyo Seiko Co Ltd | 転がり軸受 |

| NL1009170C2 (nl) * | 1998-05-14 | 1999-11-16 | Skf Eng & Res Centre Bv | Bekleed wentellager. |

| JP2000136828A (ja) * | 1998-11-04 | 2000-05-16 | Koyo Seiko Co Ltd | 転がり軸受 |

| JP3772944B2 (ja) * | 1998-12-17 | 2006-05-10 | 日本精工株式会社 | 潤滑剤含有ポリマ充填転がり軸受 |

| US6296393B1 (en) * | 1998-12-17 | 2001-10-02 | Nsk Ltd. | Lubricant-containing polymer-filled rolling bearing and process for the production thereof |

| AU1440401A (en) * | 1999-10-29 | 2001-05-14 | Timken Company, The | Antifriction bearing for use in a corrosive environment |

| JP3961739B2 (ja) * | 2000-04-19 | 2007-08-22 | 株式会社ジェイテクト | 転がり軸受 |

| JP3811596B2 (ja) * | 2000-06-15 | 2006-08-23 | 株式会社ジェイテクト | 転がり運動部品 |

| JP2002122152A (ja) * | 2000-10-13 | 2002-04-26 | Nsk Ltd | 転動部材 |

| JP2002195276A (ja) * | 2000-12-27 | 2002-07-10 | Nsk Ltd | 転がり軸受 |

| US6764307B2 (en) * | 2001-03-28 | 2004-07-20 | Minebea Company, Ltd. | Polymer-metal composition retainer for self-lubricating bearing |

| US6994474B2 (en) * | 2001-05-29 | 2006-02-07 | Nsk Ltd. | Rolling sliding member and rolling apparatus |

| JP2003013960A (ja) * | 2001-06-27 | 2003-01-15 | Nsk Ltd | 高速回転用転がり軸受 |

| JP2002357225A (ja) * | 2001-05-31 | 2002-12-13 | Nsk Ltd | 転がり軸受 |

| DE10145405A1 (de) * | 2001-09-14 | 2003-04-03 | Fraunhofer Ges Forschung | Wälzlager mit einem inneren und einem äußeren Laufring |

| NL1019860C2 (nl) * | 2002-01-30 | 2003-08-05 | Skf Ab | Wentellager met een keramisch wentelelement en stalen binnen- of buitenring. |

-

2002

- 2002-12-16 DE DE10259003A patent/DE10259003A1/de not_active Withdrawn

-

2003

- 2003-12-12 EP EP03785573A patent/EP1573215A1/de not_active Withdrawn

- 2003-12-12 JP JP2004559608A patent/JP2006509975A/ja active Pending

- 2003-12-12 WO PCT/DE2003/004125 patent/WO2004055402A1/de not_active Ceased

- 2003-12-12 AU AU2003294656A patent/AU2003294656A1/en not_active Abandoned

- 2003-12-12 BR BR0317378-0A patent/BR0317378A/pt not_active Application Discontinuation

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0788853B2 (ja) * | 1990-07-16 | 1995-09-27 | 株式会社安川電機 | ころがり軸受 |

| JP2002349577A (ja) * | 2001-05-29 | 2002-12-04 | Nsk Ltd | 転がり摺動部材 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2025027818A1 (ja) * | 2023-08-02 | 2025-02-06 | 三菱電機株式会社 | 転がり軸受、転がり軸受の異常診断装置および転がり軸受の異常診断方法 |

| JPWO2025027818A1 (cg-RX-API-DMAC7.html) * | 2023-08-02 | 2025-02-06 | ||

| JP7790627B2 (ja) | 2023-08-02 | 2025-12-23 | 三菱電機株式会社 | 転がり軸受、転がり軸受の異常診断装置および転がり軸受の異常診断方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| BR0317378A (pt) | 2005-11-16 |

| DE10259003A1 (de) | 2004-06-24 |

| AU2003294656A1 (en) | 2004-07-09 |

| EP1573215A1 (de) | 2005-09-14 |

| WO2004055402A1 (de) | 2004-07-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4244106B2 (ja) | コーティングされているころがり軸受 | |

| JP4897343B2 (ja) | 軸受部材 | |

| DellaCorte | The evaluation of a modified chrome oxide based high temperature solid lubricant coating for foil gas bearings | |

| EP2957784A1 (en) | Sliding member | |

| JP2006509975A (ja) | 複合された潤滑材料を有する転がり軸受 | |

| JPH02271106A (ja) | すべり軸受装置 | |

| JPH102338A (ja) | 潤滑ころがり接触装置、潤滑法、潤滑組成物及びセラミック転動要素 | |

| KR20100092026A (ko) | 스러스트 베어링용 슬라이딩 부재 | |

| JP6481798B2 (ja) | 転がり軸受 | |

| JP3121701B2 (ja) | 半導体製造設備用転がり軸受 | |

| CN100497977C (zh) | 滑动轴承用润滑脂 | |

| KR20030074648A (ko) | 분말 야금 부품을 포함하는 구름 베어링 | |

| US20140234064A1 (en) | Sealing System, An Industrial Robot With A Sealing System, And Method For Providing A Sealing Surface | |

| JP3770221B2 (ja) | 摺動部材 | |

| US20060274985A1 (en) | Antifriction bearing comprising integrated lubricating material | |

| JP2010255682A (ja) | 転がり摺動部材のdlc膜剥離防止方法、転がり支持装置の使用方法 | |

| US20060115788A1 (en) | Dental hand instrument comprising components which can be displaced in relation to each other | |

| JP2503966Y2 (ja) | 転がり軸受 | |

| JP6855974B2 (ja) | 転がり軸受及びその製造方法 | |

| JP2013087894A (ja) | 転がり軸受の製造方法及び転がり軸受 | |

| JPS63167125A (ja) | ころがり軸受 | |

| JP2007085363A (ja) | 軸受およびその製造方法 | |

| JP2012031989A (ja) | 転がり軸受及びそれを備えたダンパー付きプーリー | |

| JPH03172611A (ja) | 固体潤滑転がり軸受 | |

| JP2004138194A (ja) | 気体軸受及びその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20061211 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20061211 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20091020 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20100119 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20100126 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100420 |