JP2006120870A - 配線形成方法及び装置 - Google Patents

配線形成方法及び装置 Download PDFInfo

- Publication number

- JP2006120870A JP2006120870A JP2004307354A JP2004307354A JP2006120870A JP 2006120870 A JP2006120870 A JP 2006120870A JP 2004307354 A JP2004307354 A JP 2004307354A JP 2004307354 A JP2004307354 A JP 2004307354A JP 2006120870 A JP2006120870 A JP 2006120870A

- Authority

- JP

- Japan

- Prior art keywords

- wiring

- film

- conductive film

- forming

- substrate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000034 method Methods 0.000 title claims description 73

- 230000015572 biosynthetic process Effects 0.000 title claims description 28

- 239000000758 substrate Substances 0.000 claims abstract description 166

- 239000000463 material Substances 0.000 claims abstract description 86

- 238000009713 electroplating Methods 0.000 claims abstract description 55

- 239000007788 liquid Substances 0.000 claims abstract description 26

- 238000007747 plating Methods 0.000 claims description 86

- 238000005498 polishing Methods 0.000 claims description 61

- 229910052802 copper Inorganic materials 0.000 claims description 60

- 239000010949 copper Substances 0.000 claims description 60

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 59

- 229910052751 metal Inorganic materials 0.000 claims description 26

- 239000002184 metal Substances 0.000 claims description 26

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 claims description 17

- NBIIXXVUZAFLBC-UHFFFAOYSA-N Phosphoric acid Chemical compound OP(O)(O)=O NBIIXXVUZAFLBC-UHFFFAOYSA-N 0.000 claims description 14

- 239000006061 abrasive grain Substances 0.000 claims description 13

- KJTLSVCANCCWHF-UHFFFAOYSA-N Ruthenium Chemical compound [Ru] KJTLSVCANCCWHF-UHFFFAOYSA-N 0.000 claims description 10

- 229910052707 ruthenium Inorganic materials 0.000 claims description 10

- 239000010936 titanium Substances 0.000 claims description 9

- 229910052719 titanium Inorganic materials 0.000 claims description 9

- 229910052763 palladium Inorganic materials 0.000 claims description 8

- 229910052703 rhodium Inorganic materials 0.000 claims description 8

- 239000010948 rhodium Substances 0.000 claims description 8

- MHOVAHRLVXNVSD-UHFFFAOYSA-N rhodium atom Chemical compound [Rh] MHOVAHRLVXNVSD-UHFFFAOYSA-N 0.000 claims description 8

- 229910000147 aluminium phosphate Inorganic materials 0.000 claims description 7

- 229910052715 tantalum Inorganic materials 0.000 claims description 7

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 claims description 6

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 claims description 6

- 229910052709 silver Inorganic materials 0.000 claims description 6

- 239000004332 silver Substances 0.000 claims description 6

- GUVRBAGPIYLISA-UHFFFAOYSA-N tantalum atom Chemical compound [Ta] GUVRBAGPIYLISA-UHFFFAOYSA-N 0.000 claims description 6

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 claims description 6

- 229910052721 tungsten Inorganic materials 0.000 claims description 6

- 239000010937 tungsten Substances 0.000 claims description 6

- VPTUPAVOBUEXMZ-UHFFFAOYSA-N (1-hydroxy-2-phosphonoethyl)phosphonic acid Chemical compound OP(=O)(O)C(O)CP(O)(O)=O VPTUPAVOBUEXMZ-UHFFFAOYSA-N 0.000 claims description 4

- 229910001316 Ag alloy Inorganic materials 0.000 claims description 4

- 229910000881 Cu alloy Inorganic materials 0.000 claims description 4

- 238000013461 design Methods 0.000 abstract description 3

- 238000009413 insulation Methods 0.000 abstract 1

- 239000010408 film Substances 0.000 description 289

- 230000008569 process Effects 0.000 description 26

- 230000004888 barrier function Effects 0.000 description 20

- 239000011261 inert gas Substances 0.000 description 20

- 239000011229 interlayer Substances 0.000 description 19

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 15

- 239000012298 atmosphere Substances 0.000 description 14

- 239000002313 adhesive film Substances 0.000 description 12

- 239000007789 gas Substances 0.000 description 12

- 230000002093 peripheral effect Effects 0.000 description 11

- 229910045601 alloy Inorganic materials 0.000 description 10

- 239000000956 alloy Substances 0.000 description 10

- 238000010586 diagram Methods 0.000 description 9

- 238000012545 processing Methods 0.000 description 9

- 230000001681 protective effect Effects 0.000 description 9

- 238000010438 heat treatment Methods 0.000 description 8

- 238000005240 physical vapour deposition Methods 0.000 description 8

- 239000000126 substance Substances 0.000 description 8

- 239000010410 layer Substances 0.000 description 7

- 238000011282 treatment Methods 0.000 description 7

- 239000000919 ceramic Substances 0.000 description 6

- 238000004140 cleaning Methods 0.000 description 6

- 230000000694 effects Effects 0.000 description 6

- 238000007772 electroless plating Methods 0.000 description 6

- 238000001020 plasma etching Methods 0.000 description 6

- 238000000137 annealing Methods 0.000 description 5

- 238000011068 loading method Methods 0.000 description 5

- 238000011084 recovery Methods 0.000 description 5

- 239000004065 semiconductor Substances 0.000 description 5

- 239000002253 acid Substances 0.000 description 4

- 238000003486 chemical etching Methods 0.000 description 4

- 238000005516 engineering process Methods 0.000 description 4

- 238000012546 transfer Methods 0.000 description 4

- UVKTVGIDMKVNQD-UHFFFAOYSA-N CCO.OP(O)=O.OP(O)=O Chemical compound CCO.OP(O)=O.OP(O)=O UVKTVGIDMKVNQD-UHFFFAOYSA-N 0.000 description 3

- JPVYNHNXODAKFH-UHFFFAOYSA-N Cu2+ Chemical compound [Cu+2] JPVYNHNXODAKFH-UHFFFAOYSA-N 0.000 description 3

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 3

- 239000004020 conductor Substances 0.000 description 3

- 229910001431 copper ion Inorganic materials 0.000 description 3

- 239000012528 membrane Substances 0.000 description 3

- 239000011148 porous material Substances 0.000 description 3

- 238000007789 sealing Methods 0.000 description 3

- 238000005406 washing Methods 0.000 description 3

- 229910000531 Co alloy Inorganic materials 0.000 description 2

- 229910000990 Ni alloy Inorganic materials 0.000 description 2

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 2

- MCMNRKCIXSYSNV-UHFFFAOYSA-N Zirconium dioxide Chemical compound O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 description 2

- 239000003054 catalyst Substances 0.000 description 2

- 239000003795 chemical substances by application Substances 0.000 description 2

- 238000005229 chemical vapour deposition Methods 0.000 description 2

- 239000012141 concentrate Substances 0.000 description 2

- 230000007423 decrease Effects 0.000 description 2

- 238000007726 management method Methods 0.000 description 2

- 230000007246 mechanism Effects 0.000 description 2

- 239000004745 nonwoven fabric Substances 0.000 description 2

- 230000003647 oxidation Effects 0.000 description 2

- 238000007254 oxidation reaction Methods 0.000 description 2

- -1 polypropylene Polymers 0.000 description 2

- 239000004094 surface-active agent Substances 0.000 description 2

- 239000010409 thin film Substances 0.000 description 2

- MYMOFIZGZYHOMD-UHFFFAOYSA-N Dioxygen Chemical compound O=O MYMOFIZGZYHOMD-UHFFFAOYSA-N 0.000 description 1

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 1

- 239000004698 Polyethylene Substances 0.000 description 1

- 239000004743 Polypropylene Substances 0.000 description 1

- 229910052581 Si3N4 Inorganic materials 0.000 description 1

- 229910004298 SiO 2 Inorganic materials 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 230000002378 acidificating effect Effects 0.000 description 1

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 238000013459 approach Methods 0.000 description 1

- 230000000740 bleeding effect Effects 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 150000001879 copper Chemical class 0.000 description 1

- 229910000365 copper sulfate Inorganic materials 0.000 description 1

- ARUVKPQLZAKDPS-UHFFFAOYSA-L copper(II) sulfate Chemical compound [Cu+2].[O-][S+2]([O-])([O-])[O-] ARUVKPQLZAKDPS-UHFFFAOYSA-L 0.000 description 1

- 229910052878 cordierite Inorganic materials 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- JSKIRARMQDRGJZ-UHFFFAOYSA-N dimagnesium dioxido-bis[(1-oxido-3-oxo-2,4,6,8,9-pentaoxa-1,3-disila-5,7-dialuminabicyclo[3.3.1]nonan-7-yl)oxy]silane Chemical compound [Mg++].[Mg++].[O-][Si]([O-])(O[Al]1O[Al]2O[Si](=O)O[Si]([O-])(O1)O2)O[Al]1O[Al]2O[Si](=O)O[Si]([O-])(O1)O2 JSKIRARMQDRGJZ-UHFFFAOYSA-N 0.000 description 1

- KZHJGOXRZJKJNY-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Si]=O.O=[Al]O[Al]=O.O=[Al]O[Al]=O.O=[Al]O[Al]=O KZHJGOXRZJKJNY-UHFFFAOYSA-N 0.000 description 1

- 229910001882 dioxygen Inorganic materials 0.000 description 1

- 238000007599 discharging Methods 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000005530 etching Methods 0.000 description 1

- 239000006260 foam Substances 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 238000007654 immersion Methods 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- 229910052741 iridium Inorganic materials 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 229910003465 moissanite Inorganic materials 0.000 description 1

- 229910052863 mullite Inorganic materials 0.000 description 1

- 229910052758 niobium Inorganic materials 0.000 description 1

- 230000000149 penetrating effect Effects 0.000 description 1

- 238000009832 plasma treatment Methods 0.000 description 1

- 229920000573 polyethylene Polymers 0.000 description 1

- 229920001155 polypropylene Polymers 0.000 description 1

- 238000012805 post-processing Methods 0.000 description 1

- 238000007781 pre-processing Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 1

- 229910010271 silicon carbide Inorganic materials 0.000 description 1

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 1

- 238000001179 sorption measurement Methods 0.000 description 1

- 238000004544 sputter deposition Methods 0.000 description 1

- 238000000992 sputter etching Methods 0.000 description 1

- 150000003682 vanadium compounds Chemical class 0.000 description 1

- 238000001039 wet etching Methods 0.000 description 1

- 239000002759 woven fabric Substances 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

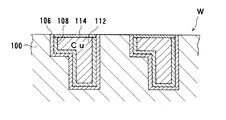

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76838—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the conductors

- H01L21/76841—Barrier, adhesion or liner layers

- H01L21/76871—Layers specifically deposited to enhance or enable the nucleation of further layers, i.e. seed layers

- H01L21/76873—Layers specifically deposited to enhance or enable the nucleation of further layers, i.e. seed layers for electroplating

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D17/00—Constructional parts, or assemblies thereof, of cells for electrolytic coating

- C25D17/001—Apparatus specially adapted for electrolytic coating of wafers, e.g. semiconductors or solar cells

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D7/00—Electroplating characterised by the article coated

- C25D7/12—Semiconductors

- C25D7/123—Semiconductors first coated with a seed layer or a conductive layer

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/28—Manufacture of electrodes on semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/268

- H01L21/283—Deposition of conductive or insulating materials for electrodes conducting electric current

- H01L21/288—Deposition of conductive or insulating materials for electrodes conducting electric current from a liquid, e.g. electrolytic deposition

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/3205—Deposition of non-insulating-, e.g. conductive- or resistive-, layers on insulating layers; After-treatment of these layers

- H01L21/321—After treatment

- H01L21/32115—Planarisation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/31—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to form insulating layers thereon, e.g. for masking or by using photolithographic techniques; After treatment of these layers; Selection of materials for these layers

- H01L21/3205—Deposition of non-insulating-, e.g. conductive- or resistive-, layers on insulating layers; After-treatment of these layers

- H01L21/321—After treatment

- H01L21/32115—Planarisation

- H01L21/3212—Planarisation by chemical mechanical polishing [CMP]

- H01L21/32125—Planarisation by chemical mechanical polishing [CMP] by simultaneously passing an electrical current, i.e. electrochemical mechanical polishing, e.g. ECMP

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76838—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the conductors

- H01L21/76841—Barrier, adhesion or liner layers

- H01L21/76843—Barrier, adhesion or liner layers formed in openings in a dielectric

- H01L21/76849—Barrier, adhesion or liner layers formed in openings in a dielectric the layer being positioned on top of the main fill metal

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/70—Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; Manufacture of integrated circuit devices or of parts thereof

- H01L21/71—Manufacture of specific parts of devices defined in group H01L21/70

- H01L21/768—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics

- H01L21/76838—Applying interconnections to be used for carrying current between separate components within a device comprising conductors and dielectrics characterised by the formation and the after-treatment of the conductors

- H01L21/76877—Filling of holes, grooves or trenches, e.g. vias, with conductive material

Landscapes

- Engineering & Computer Science (AREA)

- Computer Hardware Design (AREA)

- Power Engineering (AREA)

- Physics & Mathematics (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Electrochemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Internal Circuitry In Semiconductor Integrated Circuit Devices (AREA)

- Electroplating Methods And Accessories (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004307354A JP2006120870A (ja) | 2004-10-21 | 2004-10-21 | 配線形成方法及び装置 |

| US11/254,789 US20060086618A1 (en) | 2004-10-21 | 2005-10-21 | Method and apparatus for forming interconnects |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004307354A JP2006120870A (ja) | 2004-10-21 | 2004-10-21 | 配線形成方法及び装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2006120870A true JP2006120870A (ja) | 2006-05-11 |

| JP2006120870A5 JP2006120870A5 (enExample) | 2007-07-19 |

Family

ID=36205204

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004307354A Pending JP2006120870A (ja) | 2004-10-21 | 2004-10-21 | 配線形成方法及び装置 |

Country Status (2)

| Country | Link |

|---|---|

| US (1) | US20060086618A1 (enExample) |

| JP (1) | JP2006120870A (enExample) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2009064803A (ja) * | 2007-09-04 | 2009-03-26 | Renesas Technology Corp | 半導体装置 |

| JP2010512002A (ja) * | 2006-11-30 | 2010-04-15 | アドバンスト・マイクロ・ディバイシズ・インコーポレイテッド | 銀を含む配線を有する半導体構造及びその形成方法 |

| JP2011523780A (ja) * | 2008-05-21 | 2011-08-18 | インターナショナル・ビジネス・マシーンズ・コーポレーション | 導電性コンタクトの組み込みのための構造体及びプロセス |

| US8198730B2 (en) | 2007-01-10 | 2012-06-12 | Nec Corporation | Semiconductor device and method of manufacturing the same |

| KR101458038B1 (ko) * | 2006-11-30 | 2014-11-03 | 글로벌파운드리즈 인크. | 은을 포함한 배선을 구비한 반도체 구조체와 그 형성 방법 |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1894900A3 (en) * | 2006-08-28 | 2010-02-24 | Osaka University | Catalyst-aided chemical processing method and apparatus |

| JP2008141088A (ja) * | 2006-12-05 | 2008-06-19 | Nec Electronics Corp | 半導体装置の製造方法 |

| US20130052368A1 (en) * | 2010-03-19 | 2013-02-28 | Sigma-Aldrich Co. Llc | Methods for preparing thin films by atomic layer deposition using hydrazines |

| TW202138115A (zh) * | 2019-12-24 | 2021-10-16 | 日商荏原製作所股份有限公司 | 基板處理裝置、基板處理方法及基板處理系統 |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4067307B2 (ja) * | 2000-04-27 | 2008-03-26 | 株式会社荏原製作所 | 回転保持装置 |

| JP4644926B2 (ja) * | 2000-10-13 | 2011-03-09 | ソニー株式会社 | 半導体製造装置および半導体装置の製造方法 |

| JP3664669B2 (ja) * | 2001-06-27 | 2005-06-29 | 株式会社荏原製作所 | 電解めっき装置 |

| AU2003217197A1 (en) * | 2002-01-10 | 2003-07-30 | Semitool, Inc. | Method for applying metal features onto barrier layers using electrochemical deposition |

| US7223685B2 (en) * | 2003-06-23 | 2007-05-29 | Intel Corporation | Damascene fabrication with electrochemical layer removal |

-

2004

- 2004-10-21 JP JP2004307354A patent/JP2006120870A/ja active Pending

-

2005

- 2005-10-21 US US11/254,789 patent/US20060086618A1/en not_active Abandoned

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010512002A (ja) * | 2006-11-30 | 2010-04-15 | アドバンスト・マイクロ・ディバイシズ・インコーポレイテッド | 銀を含む配線を有する半導体構造及びその形成方法 |

| KR101458038B1 (ko) * | 2006-11-30 | 2014-11-03 | 글로벌파운드리즈 인크. | 은을 포함한 배선을 구비한 반도체 구조체와 그 형성 방법 |

| US8198730B2 (en) | 2007-01-10 | 2012-06-12 | Nec Corporation | Semiconductor device and method of manufacturing the same |

| JP2009064803A (ja) * | 2007-09-04 | 2009-03-26 | Renesas Technology Corp | 半導体装置 |

| JP2011523780A (ja) * | 2008-05-21 | 2011-08-18 | インターナショナル・ビジネス・マシーンズ・コーポレーション | 導電性コンタクトの組み込みのための構造体及びプロセス |

Also Published As

| Publication number | Publication date |

|---|---|

| US20060086618A1 (en) | 2006-04-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TW567580B (en) | Semiconductor manufacturing device and manufacturing method for semiconductor device | |

| US6717189B2 (en) | Electroless plating liquid and semiconductor device | |

| JP3979464B2 (ja) | 無電解めっき前処理装置及び方法 | |

| US7141274B2 (en) | Substrate processing apparatus and method | |

| US6706422B2 (en) | Electroless Ni—B plating liquid, electronic device and method for manufacturing the same | |

| US20040234696A1 (en) | Plating device and method | |

| EP1430167A2 (en) | Plating apparatus and method | |

| US7947156B2 (en) | Substrate processing apparatus and substrate processing method | |

| US20040235237A1 (en) | Semiconductor device and method for manufacturing the same | |

| JP2006120870A (ja) | 配線形成方法及び装置 | |

| KR100891344B1 (ko) | 무전해 도금액 및 반도체 디바이스 | |

| US20040170766A1 (en) | Electroless plating method and device, and substrate processing method and apparatus | |

| JP4064132B2 (ja) | 基板処理装置及び基板処理方法 | |

| JP3812891B2 (ja) | 配線形成方法 | |

| JP2002285343A (ja) | 無電解めっき装置 | |

| JP4139124B2 (ja) | めっき装置及び方法 | |

| JP2004300576A (ja) | 基板処理方法及び基板処理装置 | |

| JP2010007153A (ja) | めっき装置及びめっき方法 | |

| JP4060700B2 (ja) | 基板処理装置及び基板処理方法 | |

| US20040186008A1 (en) | Catalyst-imparting treatment solution and electroless plating method | |

| JP2005116630A (ja) | 配線形成方法及び装置 | |

| JP2003183892A (ja) | めっき装置 | |

| JP3886383B2 (ja) | めっき装置及びめっき方法 | |

| JP2003034876A (ja) | 触媒処理液及び無電解めっき方法 | |

| JP2008150631A (ja) | めっき装置及びめっき方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070606 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070606 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20090810 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20090818 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20100105 |