JP2005281010A - 誘電体セラミック材料及び積層セラミック基板 - Google Patents

誘電体セラミック材料及び積層セラミック基板 Download PDFInfo

- Publication number

- JP2005281010A JP2005281010A JP2004093425A JP2004093425A JP2005281010A JP 2005281010 A JP2005281010 A JP 2005281010A JP 2004093425 A JP2004093425 A JP 2004093425A JP 2004093425 A JP2004093425 A JP 2004093425A JP 2005281010 A JP2005281010 A JP 2005281010A

- Authority

- JP

- Japan

- Prior art keywords

- crystal phase

- ceramic material

- dielectric

- ceramic substrate

- firing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 239000000919 ceramic Substances 0.000 title claims abstract description 27

- 239000000758 substrate Substances 0.000 title claims abstract description 22

- 229910010293 ceramic material Inorganic materials 0.000 title claims abstract description 21

- 239000013078 crystal Substances 0.000 claims abstract description 23

- 239000000843 powder Substances 0.000 claims abstract description 23

- 239000011521 glass Substances 0.000 claims abstract description 22

- 238000010304 firing Methods 0.000 claims abstract description 18

- 229910020068 MgAl Inorganic materials 0.000 claims abstract description 16

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 claims abstract description 11

- 238000002441 X-ray diffraction Methods 0.000 claims abstract description 9

- 239000002994 raw material Substances 0.000 claims abstract description 5

- 229910018072 Al 2 O 3 Inorganic materials 0.000 claims description 8

- 229910004298 SiO 2 Inorganic materials 0.000 claims description 7

- 238000010030 laminating Methods 0.000 claims description 4

- 238000005452 bending Methods 0.000 description 9

- KFZMGEQAYNKOFK-UHFFFAOYSA-N Isopropanol Chemical compound CC(C)O KFZMGEQAYNKOFK-UHFFFAOYSA-N 0.000 description 4

- 239000003990 capacitor Substances 0.000 description 4

- 239000000463 material Substances 0.000 description 4

- 239000002002 slurry Substances 0.000 description 4

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 description 3

- 238000005259 measurement Methods 0.000 description 3

- 229910052709 silver Inorganic materials 0.000 description 3

- 239000004332 silver Substances 0.000 description 3

- 238000002425 crystallisation Methods 0.000 description 2

- 230000008025 crystallization Effects 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 238000010295 mobile communication Methods 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- DKPFZGUDAPQIHT-UHFFFAOYSA-N Butyl acetate Natural products CCCCOC(C)=O DKPFZGUDAPQIHT-UHFFFAOYSA-N 0.000 description 1

- OFOBLEOULBTSOW-UHFFFAOYSA-N Propanedioic acid Natural products OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 description 1

- 229920005822 acrylic binder Polymers 0.000 description 1

- 150000001336 alkenes Chemical class 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 229920001577 copolymer Polymers 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 239000000945 filler Substances 0.000 description 1

- 239000006112 glass ceramic composition Substances 0.000 description 1

- 239000002241 glass-ceramic Substances 0.000 description 1

- FUZZWVXGSFPDMH-UHFFFAOYSA-N hexanoic acid Chemical compound CCCCCC(O)=O FUZZWVXGSFPDMH-UHFFFAOYSA-N 0.000 description 1

- 239000011976 maleic acid Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- JRZJOMJEPLMPRA-UHFFFAOYSA-N olefin Natural products CCCCCCCC=C JRZJOMJEPLMPRA-UHFFFAOYSA-N 0.000 description 1

- 238000013001 point bending Methods 0.000 description 1

- 229920002689 polyvinyl acetate Polymers 0.000 description 1

- 239000011118 polyvinyl acetate Substances 0.000 description 1

- 230000001376 precipitating effect Effects 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 238000007650 screen-printing Methods 0.000 description 1

- 229910052596 spinel Inorganic materials 0.000 description 1

- 239000011029 spinel Substances 0.000 description 1

- 238000010998 test method Methods 0.000 description 1

- VZCYOOQTPOCHFL-UHFFFAOYSA-N trans-butenedioic acid Natural products OC(=O)C=CC(O)=O VZCYOOQTPOCHFL-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B35/00—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products

- C04B35/01—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics

- C04B35/10—Shaped ceramic products characterised by their composition; Ceramics compositions; Processing powders of inorganic compounds preparatory to the manufacturing of ceramic products based on oxide ceramics based on aluminium oxide

- C04B35/111—Fine ceramics

- C04B35/117—Composites

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C10/00—Devitrified glass ceramics, i.e. glass ceramics having a crystalline phase dispersed in a glassy phase and constituting at least 50% by weight of the total composition

- C03C10/0036—Devitrified glass ceramics, i.e. glass ceramics having a crystalline phase dispersed in a glassy phase and constituting at least 50% by weight of the total composition containing SiO2, Al2O3 and a divalent metal oxide as main constituents

- C03C10/0045—Devitrified glass ceramics, i.e. glass ceramics having a crystalline phase dispersed in a glassy phase and constituting at least 50% by weight of the total composition containing SiO2, Al2O3 and a divalent metal oxide as main constituents containing SiO2, Al2O3 and MgO as main constituents

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C14/00—Glass compositions containing a non-glass component, e.g. compositions containing fibres, filaments, whiskers, platelets, or the like, dispersed in a glass matrix

- C03C14/004—Glass compositions containing a non-glass component, e.g. compositions containing fibres, filaments, whiskers, platelets, or the like, dispersed in a glass matrix the non-glass component being in the form of particles or flakes

-

- C—CHEMISTRY; METALLURGY

- C03—GLASS; MINERAL OR SLAG WOOL

- C03C—CHEMICAL COMPOSITION OF GLASSES, GLAZES OR VITREOUS ENAMELS; SURFACE TREATMENT OF GLASS; SURFACE TREATMENT OF FIBRES OR FILAMENTS MADE FROM GLASS, MINERALS OR SLAGS; JOINING GLASS TO GLASS OR OTHER MATERIALS

- C03C2214/00—Nature of the non-vitreous component

- C03C2214/04—Particles; Flakes

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3205—Alkaline earth oxides or oxide forming salts thereof, e.g. beryllium oxide

- C04B2235/3206—Magnesium oxides or oxide-forming salts thereof

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3217—Aluminum oxide or oxide forming salts thereof, e.g. bauxite, alpha-alumina

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/32—Metal oxides, mixed metal oxides, or oxide-forming salts thereof, e.g. carbonates, nitrates, (oxy)hydroxides, chlorides

- C04B2235/3217—Aluminum oxide or oxide forming salts thereof, e.g. bauxite, alpha-alumina

- C04B2235/3222—Aluminates other than alumino-silicates, e.g. spinel (MgAl2O4)

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/30—Constituents and secondary phases not being of a fibrous nature

- C04B2235/36—Glass starting materials for making ceramics, e.g. silica glass

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/02—Composition of constituents of the starting material or of secondary phases of the final product

- C04B2235/50—Constituents or additives of the starting mixture chosen for their shape or used because of their shape or their physical appearance

- C04B2235/54—Particle size related information

- C04B2235/5418—Particle size related information expressed by the size of the particles or aggregates thereof

- C04B2235/5436—Particle size related information expressed by the size of the particles or aggregates thereof micrometer sized, i.e. from 1 to 100 micron

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/60—Aspects relating to the preparation, properties or mechanical treatment of green bodies or pre-forms

- C04B2235/602—Making the green bodies or pre-forms by moulding

- C04B2235/6025—Tape casting, e.g. with a doctor blade

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

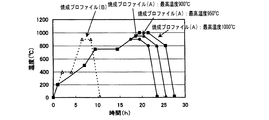

- C04B2235/65—Aspects relating to heat treatments of ceramic bodies such as green ceramics or pre-sintered ceramics, e.g. burning, sintering or melting processes

- C04B2235/656—Aspects relating to heat treatments of ceramic bodies such as green ceramics or pre-sintered ceramics, e.g. burning, sintering or melting processes characterised by specific heating conditions during heat treatment

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/65—Aspects relating to heat treatments of ceramic bodies such as green ceramics or pre-sintered ceramics, e.g. burning, sintering or melting processes

- C04B2235/656—Aspects relating to heat treatments of ceramic bodies such as green ceramics or pre-sintered ceramics, e.g. burning, sintering or melting processes characterised by specific heating conditions during heat treatment

- C04B2235/6562—Heating rate

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/70—Aspects relating to sintered or melt-casted ceramic products

- C04B2235/80—Phases present in the sintered or melt-cast ceramic products other than the main phase

-

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B2235/00—Aspects relating to ceramic starting mixtures or sintered ceramic products

- C04B2235/70—Aspects relating to sintered or melt-casted ceramic products

- C04B2235/96—Properties of ceramic products, e.g. mechanical properties such as strength, toughness, wear resistance

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K1/00—Printed circuits

- H05K1/02—Details

- H05K1/03—Use of materials for the substrate

- H05K1/0306—Inorganic insulating substrates, e.g. ceramic, glass

-

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K3/00—Apparatus or processes for manufacturing printed circuits

- H05K3/46—Manufacturing multilayer circuits

- H05K3/4611—Manufacturing multilayer circuits by laminating two or more circuit boards

- H05K3/4626—Manufacturing multilayer circuits by laminating two or more circuit boards characterised by the insulating layers or materials

- H05K3/4629—Manufacturing multilayer circuits by laminating two or more circuit boards characterised by the insulating layers or materials laminating inorganic sheets comprising printed circuits, e.g. green ceramic sheets

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Ceramic Engineering (AREA)

- Organic Chemistry (AREA)

- Materials Engineering (AREA)

- Geochemistry & Mineralogy (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Dispersion Chemistry (AREA)

- Crystallography & Structural Chemistry (AREA)

- Composite Materials (AREA)

- Manufacturing & Machinery (AREA)

- Structural Engineering (AREA)

- Compositions Of Oxide Ceramics (AREA)

- Production Of Multi-Layered Print Wiring Board (AREA)

- Inorganic Insulating Materials (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004093425A JP2005281010A (ja) | 2004-03-26 | 2004-03-26 | 誘電体セラミック材料及び積層セラミック基板 |

| CNA2005100067642A CN1673143A (zh) | 2004-03-26 | 2005-02-04 | 电介质陶瓷材料及层叠陶瓷基板 |

| US11/057,218 US7189669B2 (en) | 2004-03-26 | 2005-02-15 | Dielectric ceramic material and multilayer ceramic substrate |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2004093425A JP2005281010A (ja) | 2004-03-26 | 2004-03-26 | 誘電体セラミック材料及び積層セラミック基板 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2005281010A true JP2005281010A (ja) | 2005-10-13 |

| JP2005281010A5 JP2005281010A5 (enExample) | 2006-09-21 |

Family

ID=34990781

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2004093425A Withdrawn JP2005281010A (ja) | 2004-03-26 | 2004-03-26 | 誘電体セラミック材料及び積層セラミック基板 |

Country Status (3)

| Country | Link |

|---|---|

| US (1) | US7189669B2 (enExample) |

| JP (1) | JP2005281010A (enExample) |

| CN (1) | CN1673143A (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012243845A (ja) * | 2011-05-17 | 2012-12-10 | Tcst Tech Co Ltd | 電子部品を封止するために用いる高密度ltccパッケージ構造及びその高密度ltcc材料 |

| WO2013099944A1 (ja) * | 2011-12-27 | 2013-07-04 | 株式会社村田製作所 | 多層セラミック基板およびそれを用いた電子部品 |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TW200704270A (en) * | 2005-02-17 | 2007-01-16 | Tdk Corp | Spacer for flat panel display and flat panel display |

| CN101786866B (zh) | 2009-12-22 | 2012-12-05 | 广东风华高新科技股份有限公司 | 一种抗还原性铜内电极高频低温烧结陶瓷介质材料 |

| CN106103667B (zh) | 2013-11-18 | 2019-12-10 | 雅富顿化学公司 | 用于进气阀沉积物控制的混合的清洁剂组合物 |

| JP6201190B2 (ja) * | 2014-04-25 | 2017-09-27 | 住友金属鉱山株式会社 | 厚膜導体形成用組成物及びそれを用いて得られる厚膜導体 |

| FR3033555A1 (fr) * | 2015-03-09 | 2016-09-16 | Saint-Gobain Centre De Rech Et D'Etudes Europeen | Produit non faconne pour reparation de fours de fusion de verre |

| US10273425B2 (en) | 2017-03-13 | 2019-04-30 | Afton Chemical Corporation | Polyol carrier fluids and fuel compositions including polyol carrier fluids |

| US12024686B2 (en) | 2022-09-30 | 2024-07-02 | Afton Chemical Corporation | Gasoline additive composition for improved engine performance |

| US12169192B2 (en) | 2020-11-02 | 2024-12-17 | Afton Chemical Corporation | Methods of identifying a hydrocarbon fuel |

| CN113643840B (zh) * | 2021-10-13 | 2022-03-11 | 西安宏星电子浆料科技股份有限公司 | 同时适用于氧化铝陶瓷基板和隔离介质层的厚膜电阻浆料 |

| US11873461B1 (en) | 2022-09-22 | 2024-01-16 | Afton Chemical Corporation | Extreme pressure additives with improved copper corrosion |

| US12134742B2 (en) | 2022-09-30 | 2024-11-05 | Afton Chemical Corporation | Fuel composition |

| US11884890B1 (en) | 2023-02-07 | 2024-01-30 | Afton Chemical Corporation | Gasoline additive composition for improved engine performance |

| US11795412B1 (en) | 2023-03-03 | 2023-10-24 | Afton Chemical Corporation | Lubricating composition for industrial gear fluids |

| US12454653B2 (en) | 2023-12-11 | 2025-10-28 | Afton Chemical Corporation | Gasoline additive composition for improved engine performance |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08188446A (ja) * | 1995-01-11 | 1996-07-23 | Sumitomo Metal Mining Co Ltd | ガラスセラミック基板 |

| JP3721570B2 (ja) | 1996-10-22 | 2005-11-30 | 日本電気硝子株式会社 | ガラスセラミック誘電体材料 |

| JP3441924B2 (ja) | 1997-06-20 | 2003-09-02 | 京セラ株式会社 | 配線基板およびその実装構造 |

| JP3680713B2 (ja) * | 2000-07-21 | 2005-08-10 | 株式会社村田製作所 | 絶縁体磁器、セラミック多層基板、セラミック電子部品及び積層セラミック電子部品 |

| JPWO2002079114A1 (ja) * | 2001-03-28 | 2004-07-22 | 株式会社村田製作所 | 絶縁体セラミック組成物およびそれを用いた絶縁体セラミック |

-

2004

- 2004-03-26 JP JP2004093425A patent/JP2005281010A/ja not_active Withdrawn

-

2005

- 2005-02-04 CN CNA2005100067642A patent/CN1673143A/zh active Pending

- 2005-02-15 US US11/057,218 patent/US7189669B2/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012243845A (ja) * | 2011-05-17 | 2012-12-10 | Tcst Tech Co Ltd | 電子部品を封止するために用いる高密度ltccパッケージ構造及びその高密度ltcc材料 |

| WO2013099944A1 (ja) * | 2011-12-27 | 2013-07-04 | 株式会社村田製作所 | 多層セラミック基板およびそれを用いた電子部品 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20050215411A1 (en) | 2005-09-29 |

| CN1673143A (zh) | 2005-09-28 |

| US7189669B2 (en) | 2007-03-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2005281010A (ja) | 誘電体セラミック材料及び積層セラミック基板 | |

| EP2168928A1 (en) | Glass Ceramic Substrate | |

| JP2009007209A (ja) | 誘電体磁器及びそれを用いた積層セラミックコンデンサ | |

| CN101754938A (zh) | 陶瓷基板及其制造方法以及电介质瓷器组合物 | |

| JP2006124201A (ja) | 無鉛ガラス、ガラスセラミックス組成物および誘電体 | |

| TWI245750B (en) | Method for producing raw material powder for dielectric ceramic, dielectric ceramic, and multiplayer ceramic capacitor | |

| JP2006290728A (ja) | 誘電体磁器組成物及びその製造方法 | |

| JP2009120477A (ja) | ガラス組成物、これを含む誘電体組成物及びこれを用いた積層セラミックキャパシタ内蔵型低温同時焼成セラミック基板 | |

| JP2007137747A (ja) | 誘電体磁器及びその製造方法 | |

| JP2007238376A (ja) | 圧電セラミックス用焼結助剤、bnt−bt系圧電セラミックス、積層型圧電デバイスおよびbnt−bt系圧電セラミックスの製造方法 | |

| JP4637017B2 (ja) | セラミックス組成物及びセラミックス配線基板 | |

| JP3741556B2 (ja) | 低温焼成磁器およびこれを備えた電子部品 | |

| JP2006016215A (ja) | 誘電体セラミック及び積層セラミック基板 | |

| JP2020164380A (ja) | 黒色マーク組成物およびこれを用いた電子部品 | |

| JP2010037126A (ja) | セラミック組成物及びセラミック焼結体 | |

| JP5977088B2 (ja) | 低温焼成基板用無鉛ガラスセラミックス組成物 | |

| JP4412266B2 (ja) | 誘電体磁器組成物及びその製造方法 | |

| JP4704836B2 (ja) | 低温焼成磁器組成物及びその製造方法並びにこれを用いた電子部品 | |

| JP4802490B2 (ja) | 電子部品、誘電体磁器組成物およびその製造方法 | |

| JP4619173B2 (ja) | 複合電子部品材料 | |

| JP3940419B2 (ja) | 誘電体磁器組成物及びその製造方法 | |

| JPWO2006109465A1 (ja) | 誘電体磁器組成物およびそれを用いた高周波デバイス | |

| JP4253652B2 (ja) | 誘電体磁器組成物及びそれを用いて作製される電子部品並びに積層セラミックコンデンサの製造方法 | |

| JP2006169005A (ja) | 電子部品、誘電体磁器組成物およびその製造方法 | |

| JP2006256956A (ja) | ガラスセラミックス焼結体及びマイクロ波用回路部材 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20060822 |

|

| A761 | Written withdrawal of application |

Free format text: JAPANESE INTERMEDIATE CODE: A761 Effective date: 20090604 |