EP3121904B1 - Klemmenbauelement - Google Patents

Klemmenbauelement Download PDFInfo

- Publication number

- EP3121904B1 EP3121904B1 EP16186605.8A EP16186605A EP3121904B1 EP 3121904 B1 EP3121904 B1 EP 3121904B1 EP 16186605 A EP16186605 A EP 16186605A EP 3121904 B1 EP3121904 B1 EP 3121904B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- clamping

- spring

- actuating

- clamping spring

- terminal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/28—Clamped connections, spring connections

- H01R4/48—Clamped connections, spring connections utilising a spring, clip, or other resilient member

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/02—Contact members

- H01R13/22—Contacts for co-operating by abutting

- H01R13/24—Contacts for co-operating by abutting resilient; resiliently-mounted

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/62—Means for facilitating engagement or disengagement of coupling parts or for holding them in engagement

- H01R13/629—Additional means for facilitating engagement or disengagement of coupling parts, e.g. aligning or guiding means, levers, gas pressure electrical locking indicators, manufacturing tolerances

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R25/00—Coupling parts adapted for simultaneous co-operation with two or more identical counterparts, e.g. for distributing energy to two or more circuits

- H01R25/14—Rails or bus-bars constructed so that the counterparts can be connected thereto at any point along their length

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/28—Clamped connections, spring connections

- H01R4/48—Clamped connections, spring connections utilising a spring, clip, or other resilient member

- H01R4/4809—Clamped connections, spring connections utilising a spring, clip, or other resilient member using a leaf spring to bias the conductor toward the busbar

- H01R4/48185—Clamped connections, spring connections utilising a spring, clip, or other resilient member using a leaf spring to bias the conductor toward the busbar adapted for axial insertion of a wire end

- H01R4/4819—Clamped connections, spring connections utilising a spring, clip, or other resilient member using a leaf spring to bias the conductor toward the busbar adapted for axial insertion of a wire end the spring shape allowing insertion of the conductor end when the spring is unbiased

- H01R4/4821—Single-blade spring

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R9/00—Structural associations of a plurality of mutually-insulated electrical connecting elements, e.g. terminal strips or terminal blocks; Terminals or binding posts mounted upon a base or in a case; Bases therefor

- H01R9/22—Bases, e.g. strip, block, panel

- H01R9/24—Terminal blocks

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/28—Clamped connections, spring connections

- H01R4/48—Clamped connections, spring connections utilising a spring, clip, or other resilient member

- H01R4/4809—Clamped connections, spring connections utilising a spring, clip, or other resilient member using a leaf spring to bias the conductor toward the busbar

- H01R4/484—Spring housing details

- H01R4/4842—Spring housing details the spring housing being provided with a single opening for insertion of a spring-activating tool

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/28—Clamped connections, spring connections

- H01R4/48—Clamped connections, spring connections utilising a spring, clip, or other resilient member

- H01R4/4809—Clamped connections, spring connections utilising a spring, clip, or other resilient member using a leaf spring to bias the conductor toward the busbar

- H01R4/4846—Busbar details

- H01R4/4852—Means for improving the contact with the conductor, e.g. uneven wire-receiving surface

Definitions

- the invention relates to a terminal device with a Isolierstoffgepuruse and at least one spring clip for clamping an electrical conductor, wherein the spring clamp a busbar piece and extending in the longitudinal direction with a free terminal end in the direction of the busbar piece and forming a nip for the electrical conductor against the busbar piece has resilient clamping spring, and wherein in the insulating housing at least one leading to an associated terminal point conductor insertion opening and each one arranged next to a conductor insertion opening and provided for insertion of an actuating tool and opening the associated clamping spring with the actuating tool actuating channel.

- Such terminal components are sufficiently well known, for example, as modular terminal blocks or as input / output modules of a fieldbus system which can be connected to field devices via the spring terminals and are used in particular in automation technology.

- the spring terminals with their clamping spring provide a long-term stable, vibration-proof contact for an electrical conductor. To open the nip, however, an actuation of the clamping spring against the spring restoring force is necessary.

- clamping springs are for example off DE 299 15 515 U1 . EP 0 335 093 B1 . GB 1 593 321 . AT 376 524 B and DE 28 26 978 C2 in the insulating material integrated operating lever known to press in the direction of the width of the clamping springs in addition to the terminal point for the electrical conductor to the clamping spring.

- the actuating direction of the actuating lever differs from the conductor insertion direction, so that the spring terminals occupy a relatively large width.

- Terminal elements are known in which obliquely to the conductor insertion opening actuating channels are provided to actuate a clamping spring.

- the clamped by the main axes of the conductor insertion openings and the actuating channel in each case and the clamping spring in the region of the clamping point transverse to the longitudinal direction over the width of the clamping spring intersecting planes are at an angle to each other.

- the actuating channels assigned to the conductor insertion openings occupy a relatively large space.

- DE 195 04 092 B4 discloses a spring clip for an electrical conductor in which a Portereinfiihrungsö réelle is arranged in the deflection of a tension spring parallel to an actuating channel. While the conductor insertion opening opens into a clamping portion at the free end of the tension spring, the actuating channel is aligned on an opposite, adjoining the one spring bow actuating portion of the tension spring to open the tension spring from there with a pressure pin.

- Such a rearward actuation is also for a U-shaped bent clamping spring from the DE 299 15 512 U1 known.

- a generic terminal device is from the US 6,056,585 known.

- the DE 10 2005 048 972 A1 discloses a spring-loaded terminal with clamping spring and current bar.

- the actuating channel terminates in a direction transverse to the longitudinal direction of the clamping point for the electrical conductor adjacent the actuating portion of the clamping spring, so that the clamping point and actuating portion lie on the width of the clamping spring next to each other.

- the conductor insertion opening is spatially separated from the actuating channel by an intermediate wall of insulating material of the insulating housing.

- the actuating channel runs in cross section in the direction of the width of the clamping spring seen in alignment with the conductor insertion opening.

- the main axis of the actuating channel is tilted in longitudinal section at an angle of 5 to 25 degrees to the main axis of the conductor insertion opening.

- the actuating channel is tapered from the upper opening down to the spring clamp in longitudinal section.

- At least one clamping spring starting from a substantially parallel to the main axis of the conductor insertion opening extending and bearing against the insulating housing plant leg is bent with a spring bow. Then a clamping leg extends in the direction of the busbar, which adjoins the spring bow.

- a cage tension spring essentially simply U-shaped bent clamping spring is with the plant leg, or the clamping leg opposite, set in the insulating housing and possibly on or in the busbar.

- the free end of the abutment leg can be inserted, for example, in an opening in the busbar.

- the clamping leg of the at least one clamping spring may be bent back in the mouth region of the actuating channel in the direction of the abutment leg, while extending in the direction of the width of the clamping spring adjacent clamping portion of the clamping spring for the electrical conductor from the plant leg away.

- the clamping spring Seen over the width of the clamping spring in the region of the clamping point, the clamping spring is thus divided into two parts and has a clamping section optimized for clamping the electrical conductor and an actuating section optimized for actuation with an actuating tool via the actuating channel.

- abutment leg By bending back the abutment leg in the region of the actuating portion, the deflection of the spring can be limited.

- the bent-back portion of the abutment leg thus forms an overload protection by this abuts in the actuated state of the clamping spring to the plant leg or the insulating material.

- an improved guidance of an actuating tool is achieved by the bending back of the clamping leg, so that the risk of jamming of the actuating tool is reduced by the clamping spring.

- an overload stop is provided on the insulating housing or a busbar section, which is adapted to the clamping point forming free terminal end of the clamping spring such that in an attempt to excessive deflection of the clamping spring by an electrical conductor, the free terminal end abuts the overload stop.

- the terminal device may be an active or passive device.

- two or more spring terminals may be simply connected together by the one common bus bar to thereby electrically connect conductors clamped to the spring terminals.

- electrically conductive electrically and / or electronically (active and / or passive) components are arranged in the insulating material housing with at least one spring clip.

- a terminal component may be, for example, an input / output module for clamping field devices, wherein on the side surfaces of the insulating housing terminal contacts for establishing a data bus and / or a power supply are arranged when two or more terminal components are snapped directly adjacent to each other on a top hat rail , It is advantageous in this case if the insulating housing has latching hooks for latching the terminal component onto a DIN rail.

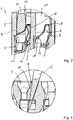

- FIGS. 1a ) to d) can be seen a partial section through a terminal device 1 in cross section with an actuating sequence.

- FIG. 1a shows the partial section of the terminal component 1 in the unactuated state. It can be seen that in a Isolierstoffgeophuse 2, a conductor insertion opening 3 is introduced, which leads to a spring clip 4, which is formed in a conventional manner from a busbar piece 5 and a substantially U-shaped clamping spring 6.

- the clamping spring 6 has a fixed in Isolierstoffgeophuse 2 and / or the busbar section 5 contact section 7, an adjoining spring bow 8 and adjoining the spring bow 8 clamping leg 9, the free end 10 in the rebound (relaxed) state at a projection 11 of Busbar piece 5 is applied and forms a terminal point for an electrical conductor in this area.

- clamping leg 9 over the width of the clamping spring 6, d. H. in the cross-sectional view in the direction transverse to the longitudinal direction L of the clamping leg 9 and transversely to the spring direction F of the clamping spring 6 is divided into two parts such that an adjoining the terminal point and abutting the busbar piece clamping portion of the free end 10 extends in the direction of busbar piece 5, while an over the width of the clamping spring 6 adjacent operating portion 12 is slightly bent back in the direction of the plant leg 6. It can be seen that the deflection takes place at an angle of approximately 15 to 45 degrees from the longitudinal extension direction of the free end 10 forming the nip. The free end of the actuating portion need not point to the plant leg 7 in the relaxed state of the clamping spring 6, but is still bent back in the direction of plant leg compared to the free end.

- an overload stop Ü provided, which is adapted to the nip forming free terminal end 10 of the clamping spring 6 such that in an attempt to excessive deflection of the clamping spring 6 by an electrical conductor, the free terminal end 10 abuts the overload stop Ü.

- This also provides protection against overloading by the electrical conductor, for example due to an impermissibly bent conductor end or an excessively large conductor cross-section.

- FIG. 1b can detect the state of the terminal device 1 when actuated by a screwdriver 13, which is arranged in a arranged adjacent to the conductor insertion opening 3 and based on the illustrated cross section in the same alignment extending actuating channel 14.

- the actuating channel 14 extends so far that the free end of the screwdriver 13 can reach the actuating portion 12 and pushes the clamping leg 9 with the narrow side edge of the screwdriver 13 in the direction of plant leg 7.

- the operating section 12 opposite narrow side edge of the screwdriver 13 rests against the insulating housing 2.

- Figure 1c can detect the operating state of the clamping device 1, wherein the clamping spring 6 by the screwdriver 13 as in the FIG. 1b ) is open and now an electrical conductor 15 is inserted with a stripped at the end of the free conductor end in the conductor insertion channel 3.

- the clamping point forming free end 10 of the clamping leg 9 sprung so far from the conductor insertion area that the electrical conductor 15 can be easily inserted into the insulating 2 and the spring clip 4.

- Figure 1d reveals the final clamping state in which the screwdriver 13 is now pulled out of the actuating channel 14 and the operating portion 12 is released in this way.

- the clamping spring 6 can thereby spring back with its clamping leg 9 in the direction of busbar piece, so that the free, forming a nip end 10 abuts the stripped free end of the electrical conductor 15 and this against the busbar 5 and in particular against the projection 11 of the bus bar 5 presses.

- the projection 11 of the busbar 5 By the projection 11 of the busbar 5, a defined contact point with the smallest possible contact surface is ensured, so that the available spring force can be concentrated on this smallest possible contact surface, as is known.

- the terminal component 1 offers by running in the transverse direction parallel to the conductor insertion direction operating channel 14 and the provision of the actuating portion in the width direction of the clamping spring 6, the possibility of a very space-saving design.

- the same opening can be used in principle for the actuating channel 14 and the conductor insertion opening 3. It is also conceivable that between actuation channel 14 and conductor insertion opening 3, a (thin) wall of insulating material is provided, which is made integral with the insulating material 2.

- FIG. 2 shows a cross-sectional view of a terminal component 1 in partial section with the spring leg 9 rebounded in the rest position and in the actuating position in the direction of the plant leg 7 bent-back clamping leg 7. From the operating position shown in the left half is clear that the bent in the direction of plant leg 7 actuating portion 12 abuts with its free end of the clamping leg 9 on the plant leg 7 when the screwdriver 13 is inserted into the actuating channel 14. A further deflection and overloading of the clamping spring 6 is thereby prevented.

- the contact leg 7 of the clamping spring 6 with its free end dips into an opening of the busbar piece 5 in order to fix the clamping spring 6 to the busbar piece 5.

- the busbar piece 5 itself is bent approximately U-shaped to provide at its bottom a stop surface for the electrical conductor 15 and with its upwardly bent free end a nip.

- FIG. 3 leaves a longitudinal section through the clamp component 1 FIG. 2 recognize in partial section.

- the conductor insertion opening 3 is spatially separated by an intermediate wall 16 of insulating material of the insulating housing 2 of the actuating channel 14.

- the actuating channel extends in cross-section, ie in the direction of the width of the clamping spring 6, in alignment with the conductor insertion opening 3, while the main axis of the actuating channel 16 is in longitudinal section (FIG. FIG. 3 ) is slightly tilted (5 to 25 degrees) to the main axis of the conductor insertion opening 3 is tilted.

- the actuating channel from the upper opening down to the spring clip 4 in tapered longitudinal section and thus adapted to the tapered contour of conventional screwdriver 13 accordingly.

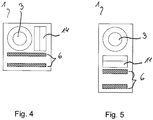

- FIG. 4 shows a plan view of the terminal components 1 from FIGS. 1 to 3 in the area of a nip. It is clear that by the operation of the spring clip with a screwdriver and the thus arranged arrangement of the actuating channel 14 in the width direction of the clamping spring 6 in addition to the conductor insertion opening 3 a balanced in length and width, approximately square space distribution results. On the other hand results in the in FIG. 5 illustrated conventional terminal components 1 a unequal in width and length space.

- the terminal device 1 according to the invention allows the balanced distribution of clamping spring 6, actuating channel 14 and conductor insertion opening 3 placement of the spring terminals in a uniform grid. Due to the greater width of the clamping spring 6 in comparison to the in FIG. 5 As shown in the conventional variant, it is possible to reduce the thickness of the spring plate, whereby the radius of the spring bow can also be reduced without sacrificing spring force. This leads to a reduction in size.

- the terminal component 1 can be, for example, a terminal block in which two or more terminal points are connected to one another via the busbars 5.

- Such terminal blocks are known per se. They may also be equipped with electrical and / or electronic components, such as relays, fuses, etc., to form so-called functional terminals, such as isolating and measuring terminals, fuse terminals, initiator and actuator terminals, diode terminals, LED terminals,

- functional terminals such as isolating and measuring terminals, fuse terminals, initiator and actuator terminals, diode terminals, LED terminals

- terminal components are modules for automation technology, such as fieldbus couplers and connected input / output modules, which are connected via the spring terminals with fieldbus devices.

- connection contacts for establishing a data bus and / or a power power supply protrude on the side walls of the insulating material, when terminal components adjacent to each other are placed side by side on a DIN rail (see. DE 44 02 002 B4 ).

Landscapes

- Connections Arranged To Contact A Plurality Of Conductors (AREA)

- Clamps And Clips (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102008039864A DE102008039864B4 (de) | 2008-08-27 | 2008-08-27 | Klemmenbauelement |

| EP09777637.1A EP2319127B1 (de) | 2008-08-27 | 2009-08-04 | Klemmenbauelement |

Related Parent Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09777637.1A Division-Into EP2319127B1 (de) | 2008-08-27 | 2009-08-04 | Klemmenbauelement |

| EP09777637.1A Division EP2319127B1 (de) | 2008-08-27 | 2009-08-04 | Klemmenbauelement |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP3121904A1 EP3121904A1 (de) | 2017-01-25 |

| EP3121904B1 true EP3121904B1 (de) | 2018-06-20 |

Family

ID=41202395

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP16186605.8A Active EP3121904B1 (de) | 2008-08-27 | 2009-08-04 | Klemmenbauelement |

| EP09777637.1A Active EP2319127B1 (de) | 2008-08-27 | 2009-08-04 | Klemmenbauelement |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09777637.1A Active EP2319127B1 (de) | 2008-08-27 | 2009-08-04 | Klemmenbauelement |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US8535084B2 (enExample) |

| EP (2) | EP3121904B1 (enExample) |

| JP (1) | JP5746030B2 (enExample) |

| KR (2) | KR101740065B1 (enExample) |

| CN (1) | CN102197539B (enExample) |

| DE (1) | DE102008039864B4 (enExample) |

| RU (1) | RU2500058C2 (enExample) |

| WO (1) | WO2010022846A1 (enExample) |

Families Citing this family (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107069274B (zh) * | 2010-05-07 | 2020-08-18 | 安费诺有限公司 | 高性能线缆连接器 |

| DE102010047170B4 (de) * | 2010-09-30 | 2019-10-10 | Abb Ag | Installationsschaltgerät mit einer Steckklemmvorrichtung |

| US8608519B1 (en) | 2012-05-24 | 2013-12-17 | Cooper Technologies Company | Quick lock conductor receiver |

| US8968022B2 (en) * | 2013-02-25 | 2015-03-03 | Tyco Electronics Corporation | Electrical connector having poke-in wire contact |

| DE202014101915U1 (de) * | 2014-04-23 | 2015-07-24 | Wago Verwaltungsgesellschaft Mbh | Leiteranschlussklemme |

| DE102014111832A1 (de) * | 2014-08-19 | 2016-02-25 | Phoenix Contact Gmbh & Co. Kg | Elektrische Anschlussklemme |

| LU93137B1 (de) * | 2016-07-01 | 2018-01-09 | Phoenix Contact Gmbh & Co Kg Intellectual Property Licenses & Standards | Aufnahmeelement, Anordnung und Verfahren |

| CN110431716B (zh) | 2017-01-06 | 2021-08-06 | 哈勃股份有限公司 | 具有免螺丝连接端子的电气布线装置 |

| DE102017109694B4 (de) * | 2017-05-05 | 2022-10-06 | Wago Verwaltungsgesellschaft Mbh | Anschlussklemme |

| KR101928382B1 (ko) | 2017-06-27 | 2018-12-12 | 주식회사 크래비스 | 이형 재질 접합 구조의 접속 단자를 가진 산업용 제어기의 입출력 모듈 |

| EP3460917A1 (en) | 2017-09-20 | 2019-03-27 | Delphi Technologies, Inc. | Electrical connector |

| EP3537543A4 (en) * | 2018-01-15 | 2019-10-23 | Fuji Electric FA Components & Systems Co. Ltd. | CONNECTING BRACKET AND ELECTRICAL MACHINE |

| DE102019101880B4 (de) * | 2019-01-25 | 2023-09-14 | Wago Verwaltungsgesellschaft Mbh | Klemmfeder und Leiteranschlussklemme |

| US11495895B2 (en) | 2019-05-01 | 2022-11-08 | Hubbell Incorporated | Terminations for electrical wiring devices |

| CN114930643B (zh) * | 2020-01-09 | 2025-10-14 | 菲尼克斯电气公司 | 具有用于能分开地连接总线区段的接触装置的电气设备 |

| WO2023049455A1 (en) | 2021-09-27 | 2023-03-30 | Hubbell Incorporated | Screwless connection terminals with wire manager |

Family Cites Families (35)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2205086A1 (de) * | 1972-02-03 | 1973-08-16 | Controlmatic Ges Fuer Ind Auto | Klemmenbaustein-system |

| DE2724354C2 (de) | 1977-05-28 | 1982-09-30 | C.A. Weidmüller KG, 4930 Detmold | Schraubenlose Klemme für elektrische Leiter |

| CH619324A5 (en) | 1977-08-10 | 1980-09-15 | Feller Ag | Screwless electrical connecting terminal |

| DE2737594C2 (de) * | 1977-08-20 | 1983-11-10 | Phönix Elektrizitätsgesellschaft H. Knümann GmbH & Co KG, 4933 Blomberg | Schraubenlose Anschlußklemme |

| GB1593321A (en) | 1978-01-14 | 1981-07-15 | Crabtree Electrical Ind Ltd | Electrical fittings |

| AT376524B (de) | 1978-06-05 | 1984-11-26 | Siemens Ag Oesterreich | Reihenklemme zur loesbaren elektrisch leitenden verbindung |

| DE2838734C2 (de) * | 1978-09-06 | 1985-01-17 | Phönix Elektrizitätsgesellschaft H. Knümann GmbH & Co KG, 4933 Blomberg | Schraubenlose Anschlußklemme |

| DE7911182U1 (de) | 1979-04-17 | 1979-08-16 | C. A. Weidmueller Kg, 4930 Detmold | Schraubenlose Klemme für elektrische Leiter |

| DE2922447C2 (de) | 1979-06-01 | 1985-08-01 | Gerhard Dr. 7900 Ulm Hudelmaier | Transportbetonmischer |

| JPH044371Y2 (enExample) * | 1986-01-10 | 1992-02-07 | ||

| CH674282A5 (enExample) | 1988-03-28 | 1990-05-15 | Feller Ag | |

| JPH0310475U (enExample) * | 1989-06-16 | 1991-01-31 | ||

| JPH0635376Y2 (ja) * | 1989-11-20 | 1994-09-14 | 東京電気株式会社 | 自己鎖錠形端子装置 |

| US5348496A (en) * | 1993-04-29 | 1994-09-20 | Eagle Electric Manufacturing Co., Inc. | Break-off key for releasing push-wire connection in wiring device |

| DE4402002B4 (de) | 1994-01-18 | 2005-10-27 | Wago Verwaltungsgesellschaft Mbh | E/A-Module/ für einen Datenbus |

| DE9403137U1 (de) | 1994-02-25 | 1995-06-22 | F. Wieland Elektrische Industrie Gmbh, 96052 Bamberg | Federklemme für einen elektrischen Leiter |

| US5453028A (en) * | 1994-05-11 | 1995-09-26 | Molex Incorporated | Electrical connector |

| JPH0955238A (ja) * | 1995-08-10 | 1997-02-25 | Shinko Seisakusho:Kk | 端子装置 |

| JP3010475B2 (ja) | 1995-12-28 | 2000-02-21 | 日本航空電子工業株式会社 | 表面実装コネクタ |

| JPH11204175A (ja) * | 1998-01-16 | 1999-07-30 | Kyoshin Kogyo Kk | ワンタッチコネクタおよびワンタッチコネクタ組合せ体 |

| US6074242A (en) * | 1998-12-31 | 2000-06-13 | Methode Electronics, Inc. | Wire-trap connector for solderless compression connection |

| DE29915512U1 (de) | 1999-09-03 | 2001-01-18 | Weidmüller Interface GmbH & Co., 32760 Detmold | Federklemme zum Anschließen elektrischer Leiter |

| DE29915515U1 (de) | 1999-09-03 | 2001-02-01 | Weidmüller Interface GmbH & Co., 32760 Detmold | Federklemme zum Anschließen elektricher Leiter |

| DE29920231U1 (de) * | 1999-11-17 | 2001-04-05 | Weidmüller Interface GmbH & Co, 32760 Detmold | Schraubenlose Anschlußklemme |

| EP1353407B1 (de) | 2002-04-12 | 2011-01-19 | Weidmüller Interface GmbH & Co. KG | Anschlussvorrichtung für Leiter |

| JP3855833B2 (ja) * | 2002-04-23 | 2006-12-13 | オムロン株式会社 | 電線接続コネクタ |

| JP4079680B2 (ja) * | 2002-04-26 | 2008-04-23 | 独立行政法人産業技術総合研究所 | 画像合成装置及び方法 |

| DE10239273A1 (de) * | 2002-08-22 | 2004-03-04 | Wago Verwaltungsgesellschaft Mbh | Federkraftklemmanschluß für einen elektrischen Leiter |

| DE102004008447A1 (de) * | 2004-02-19 | 2005-09-08 | Abb Patent Gmbh | Federkraftklemme |

| US20060286839A1 (en) * | 2005-06-21 | 2006-12-21 | Bethurum Gary C | Electrical Disconnect With Push-In Connectors |

| DE102005045596B3 (de) | 2005-09-23 | 2007-06-21 | Siemens Ag | Feder-Steckklemme |

| DE102005048972B4 (de) * | 2005-10-13 | 2010-08-12 | Phoenix Contact Gmbh & Co. Kg | Federkraftklemme mit Klemmfeder und Strombalken |

| DE202006009460U1 (de) * | 2005-10-29 | 2007-03-15 | Weidmüller Interface GmbH & Co. KG | Anschlussvorrichtung für Leiter |

| DE102006005260A1 (de) * | 2006-02-02 | 2007-08-16 | Phoenix Contact Gmbh & Co. Kg | Elektrische Anschlußklemme |

| DE202006020822U1 (de) * | 2006-04-19 | 2010-08-05 | Phoenix Contact Gmbh & Co. Kg | Federkraftklemme |

-

2008

- 2008-08-27 DE DE102008039864A patent/DE102008039864B4/de not_active Withdrawn - After Issue

-

2009

- 2009-08-04 EP EP16186605.8A patent/EP3121904B1/de active Active

- 2009-08-04 US US13/060,497 patent/US8535084B2/en active Active

- 2009-08-04 EP EP09777637.1A patent/EP2319127B1/de active Active

- 2009-08-04 KR KR1020117006889A patent/KR101740065B1/ko active Active

- 2009-08-04 RU RU2011111569/07A patent/RU2500058C2/ru active

- 2009-08-04 WO PCT/EP2009/005633 patent/WO2010022846A1/de not_active Ceased

- 2009-08-04 JP JP2011524218A patent/JP5746030B2/ja active Active

- 2009-08-04 CN CN200980141971.5A patent/CN102197539B/zh active Active

- 2009-08-04 KR KR1020177013370A patent/KR101769273B1/ko active Active

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| RU2500058C2 (ru) | 2013-11-27 |

| KR20110076897A (ko) | 2011-07-06 |

| CN102197539A (zh) | 2011-09-21 |

| DE102008039864B4 (de) | 2011-01-05 |

| US20110212653A1 (en) | 2011-09-01 |

| JP5746030B2 (ja) | 2015-07-08 |

| RU2011111569A (ru) | 2012-10-10 |

| KR20170059483A (ko) | 2017-05-30 |

| KR101740065B1 (ko) | 2017-05-25 |

| KR101769273B1 (ko) | 2017-08-17 |

| WO2010022846A1 (de) | 2010-03-04 |

| DE102008039864A1 (de) | 2010-04-08 |

| CN102197539B (zh) | 2015-04-08 |

| EP2319127B1 (de) | 2016-12-07 |

| JP2012501054A (ja) | 2012-01-12 |

| US8535084B2 (en) | 2013-09-17 |

| EP2319127A1 (de) | 2011-05-11 |

| EP3121904A1 (de) | 2017-01-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP3121904B1 (de) | Klemmenbauelement | |

| EP1777720B1 (de) | Elektrisches Bauteil, insbesondere Relaisfassung, mit Federklemmen und Verfahren zu seiner Herstellung | |

| DE102007022806B3 (de) | Klemmenbauteil | |

| DE102006016364B4 (de) | Klemmenblock zum Anschließen von elektrischen Leitern | |

| EP3507866B1 (de) | Leiteranschlussklemme | |

| EP3298659B1 (de) | Leiteranschlussklemme | |

| EP1515397B1 (de) | Anschlussvorrichtung zum Direktsteckanschluss von Leiterenden | |

| EP3042419B1 (de) | Federkraftanschlussklemme | |

| WO2015128407A1 (de) | Verbindungsklemme und federkraftklemmkontakt hierzu | |

| EP3595090B1 (de) | Leiteranschlussklemme | |

| DE102010010260C9 (de) | Steckverbinder | |

| DE102015100257A1 (de) | Leiteranschlussklemme zum Anklemmen wenigstens eines elektrischen Leiters | |

| DE102013104394A1 (de) | Leiteranschlussklemme | |

| EP3000153A1 (de) | Steckbrücke mit übereinanderliegenden blechelementen | |

| DE102009030645B4 (de) | Brückerelement und Set aus zumindest einem Klemmelement und Brückerelement | |

| DE102020128775B4 (de) | Leiteranschlussklemme in Form eines Verteilerklemmenblocks | |

| EP3038213B1 (de) | Leiteranschlussklemme zum anklemmen wenigstens eines elektrischen leiters | |

| DE10134417C1 (de) | Elektrische Anschluß- oder Verbindungseinrichtung | |

| DE102008047526B4 (de) | Kontakteinsatz und Leiteranschlussklemme | |

| EP1916741B1 (de) | Installationsschaltgerät und Anschlussklemme für ein Installationsschaltgerät | |

| DE102017117300A1 (de) | Querbrücker und Reihenklemmenanordnung | |

| DE202006012799U1 (de) | Anschlussleiste für elektrische Geräte, insbesondere für Stecker | |

| EP0123040B1 (de) | Klemmbrett für elektrische oder elektronische Geräte, z.B. Überstrom-Schutzschalter | |

| EP3855572A1 (de) | Verbindungsklemme | |

| EP0141086B1 (de) | Anschlussklemme für Niederspannungsanlage, insbesondere Schaltgeräte |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20160831 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 2319127 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: H01R 4/48 20060101AFI20180129BHEP Ipc: H01R 9/24 20060101ALN20180129BHEP |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: H01R 9/24 20060101ALN20180205BHEP Ipc: H01R 4/48 20060101AFI20180205BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20180219 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 2319127 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 1011221 Country of ref document: AT Kind code of ref document: T Effective date: 20180715 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502009015046 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MP Effective date: 20180620 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180920 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180920 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180921 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20181020 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502009015046 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180831 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180804 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180831 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: MM Effective date: 20180831 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20180920 |

|

| 26N | No opposition filed |

Effective date: 20190321 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180804 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180820 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180831 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 1011221 Country of ref document: AT Kind code of ref document: T Effective date: 20180804 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180920 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180804 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20090804 Ref country code: MK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20180620 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20180620 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502009015046 Country of ref document: DE Representative=s name: MEISSNER BOLTE PATENTANWAELTE RECHTSANWAELTE P, DE |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230516 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250827 Year of fee payment: 17 |