EP2465397B1 - Vacuum cleaner bag and method for manufacturing same - Google Patents

Vacuum cleaner bag and method for manufacturing same Download PDFInfo

- Publication number

- EP2465397B1 EP2465397B1 EP20100195704 EP10195704A EP2465397B1 EP 2465397 B1 EP2465397 B1 EP 2465397B1 EP 20100195704 EP20100195704 EP 20100195704 EP 10195704 A EP10195704 A EP 10195704A EP 2465397 B1 EP2465397 B1 EP 2465397B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- vacuum cleaner

- holding means

- cleaner bag

- inwardly folded

- bag according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Not-in-force

Links

- 238000004519 manufacturing process Methods 0.000 title description 7

- 238000000034 method Methods 0.000 title description 3

- 239000000463 material Substances 0.000 description 20

- 239000010410 layer Substances 0.000 description 10

- 238000003466 welding Methods 0.000 description 5

- 238000004026 adhesive bonding Methods 0.000 description 4

- 239000000123 paper Substances 0.000 description 4

- 125000006850 spacer group Chemical group 0.000 description 4

- 239000004745 nonwoven fabric Substances 0.000 description 3

- 238000005192 partition Methods 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- 238000004080 punching Methods 0.000 description 3

- 230000007704 transition Effects 0.000 description 3

- 239000002131 composite material Substances 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 239000010408 film Substances 0.000 description 2

- 239000011888 foil Substances 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- 230000008961 swelling Effects 0.000 description 2

- 238000012549 training Methods 0.000 description 2

- 230000002411 adverse Effects 0.000 description 1

- 239000011111 cardboard Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000005112 continuous flow technique Methods 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 239000000428 dust Substances 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000006260 foam Substances 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 239000002356 single layer Substances 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L9/00—Details or accessories of suction cleaners, e.g. mechanical means for controlling the suction or for effecting pulsating action; Storing devices specially adapted to suction cleaners or parts thereof; Carrying-vehicles specially adapted for suction cleaners

- A47L9/10—Filters; Dust separators; Dust removal; Automatic exchange of filters

- A47L9/14—Bags or the like; Rigid filtering receptacles; Attachment of, or closures for, bags or receptacles

Definitions

- the present invention relates to a vacuum cleaner bag having at least one inwardly folded wall portion which is held in at least one holding means in the inwardly folded position.

- the DE 20 2008 016 300 discloses a vacuum cleaner bag in which an inwardly directed fold is arranged on one side. In operation, this fold may inflate outwardly, thus significantly increasing the internal volume of the vacuum cleaner bag.

- a disadvantage of such inwardly folded wall sections that they inflate during operation and press outwards, so that the filter material presses against the inner wall of the dust chamber of the vacuum cleaner and in large areas, a flow of air is difficult to be prevented. This deteriorates the suction power. If the inwardly folded wall section remains folded in, the suction performance is likewise impaired since the filter material is not or only insignificantly flows through in the region of the fold.

- the EP 2 198 765 discloses a vacuum cleaner bag in the form of a block bottom bag, in which a spacer is provided in an interior, which limits the distance between two side walls to each other, to avoid uncontrolled inflation of the vacuum cleaner bag.

- the inwardly folded wall section is held in the inwardly folded position via at least one retaining means.

- the inwardly folded wall portion is available as a filter surface and thus the filter area in relation to the internal volume of the vacuum cleaner bag is significantly higher than without inwardly folded wall portion.

- the holding means has at least one recess or is formed from a net or grid. This ensures that the holding agent can be flowed through and does not adversely affect the suction power.

- the recess in the holding means is preferably arranged laterally offset from an inflow opening in the upper part or the lower part, so that the holding means also acts as an impact protection and deflects an incoming air flow.

- the size of the recess is preferably greater than 2 cm 2 , in particular larger than the inflow opening.

- the geometry of the recess is freely selectable and also several recesses may be incorporated into the retaining means.

- the holding means is fixed at least in a central region of the wall portion.

- the inwardly folded wall portion may be fixed over the entire length by the holding means, but for the function of holding the inwardly folded portion to prevent inflation, however, it suffices if the inwardly folded wall portion at one or more points on the Hattestoff is fixed.

- a fixation on the holding means is particularly useful in the central region, since the inwardly folded wall portion is preferably also fixed to a seam of the vacuum cleaner bag edge.

- the vacuum cleaner bag on at least two sides on an inwardly folded wall portion.

- the two inwardly folded wall portions may be connected to each other via the holding means, so that in operation the holding means is loaded to train through the wall sections.

- the inwardly folded wall portions may be formed symmetrically in order to avoid a displacement of the holding means to a direction by unilaterally acting tensile forces.

- the holding means is preferably connected via a seam with the inwardly folded wall portion.

- the seam is preferably directed outwards, so that the seam does not restrict the effective filter volume of the vacuum cleaner bag.

- the vacuum cleaner bag preferably comprises a top and a bottom as a sheet.

- the holding means may be formed as an air-permeable sheet.

- the materials used are preferably single-layer or multi-layer nonwoven materials, paper, composite materials, films or other materials.

- fabrics such as meshes, scrims, yarn, paper, cardboard or foil. To form a seam, these materials can preferably be welded or glued.

- At least one seam is provided, which connects the upper part, the lower part and the holding means with each other.

- the holding means is formed integrally with the upper part and / or the lower part. It is possible to manufacture upper part, lower part and holding means separately, but also an integral design of the holding means is possible.

- the holding means may be formed in one or two layers, wherein it is possible in a two-ply training to connect an upper layer to the upper part and a lower layer with the lower part, so that the retaining means with the two layers edge forms the inwardly folded wall portion ,

- the holding means is held by at least one holder on the upper part and / or lower part.

- a predetermined distance of the holding means to the upper part and / or lower part can be specified, in particular it can be prevented that the holding means rests on the upper part or lower part and thus the available filter surface is reduced.

- the at least one holder is formed integrally with the holding means, for example as a material strip, which is then fixed to the upper part or lower part.

- the strip of material can be provided by punching out the passage opening if the material strip remains at least partially connected to the holding means during punching.

- an upper part and a lower part are first provided from a sheet of air-permeable material, the upper part and lower part are preferably formed separately, but can also be made integrally from one piece.

- a holding means is arranged on a marginal first edge of the upper part and a first edge or fold of the lower part. Then, the first edge of the upper part is connected to the holding means and a first edge or fold of the lower part.

- a second edge or fold of the upper part is then connected to the holding means and a second edge or fold of the lower part, which connects the holding means to the lower part.

- upper part and lower part of sheet material are substantially tubular and promoted to form a vacuum cleaner bag then upper part and lower part perpendicular to the conveying direction and connected to each other, preferably welded.

- the production of the vacuum cleaner bag can be done in a continuous flow process with high efficiency.

- upper part, lower part and retaining means of weldable materials such as a single or multi-layer nonwoven fabric, which are then welded together.

- one, two or three webs of a filter material can be supplied to a processing station.

- a vacuum cleaner bag 1 comprises an upper part and a lower part 3 made of an air-permeable material, in particular a nonwoven fabric, paper, film or composite material.

- the vacuum cleaner bag 1 has on two opposite sides of an inwardly folded wall portion 4 on.

- Each inwardly folded wall portion 4 comprises an upper pleat leg 5, which is formed integrally with the upper part 2, and a lower pleat leg 6, which is formed integrally with the lower part 3.

- a holding means 8 is arranged in the form of a sheet, which is at least partially connected to the inwardly folded wall portion 4.

- the holding means 8 is formed from a sheet of air-permeable material, in particular a nonwoven fabric, paper, foil, a scrim, mesh or other material. A training as a strip, yarn or other connection means between the opposite wall sections 4 is possible.

- the holding means 8 can be loaded in tension and can also have a certain elasticity.

- the holding means 8 prevents that the two inwardly folded wall sections 4 inflate during operation of the vacuum cleaner bag to the outside.

- the holding means 8 can be fixed only in a central region on the inwardly folded wall portion 4. It is also possible that the holding means 8 is fixed over the entire length of the folding edge 7.

- the holding means 8 is intended to prevent at least a swelling of the inwardly folded wall portion 4 to the outside.

- a seam 9 is provided, which is formed by welding or gluing, and on the pleat legs 5 of the upper part 2, the pleat legs 6 of the lower part 3 and an edge portion of the holding means are fixed to each other, preferably by welding or gluing.

- a seam 10 is provided, which also connects the pleat leg 5 and the pleat leg 6 and the retaining means 8. The seams 9 and 10 are each directed outwards and thus are outside the internal volume of the vacuum cleaner bag.

- FIG. 2 the items of the vacuum cleaner bag 1 are shown before the assembly.

- an inflow opening 12 is recessed, which is surrounded by a holding plate 11.

- a recess 13 is provided, which is formed larger than the inflow opening 12 and after the preparation of the vacuum cleaner bag 1 of the inflow opening 12 is opposite. It is also possible for the recess 13 to be arranged offset to the inflow opening 12, so that an incoming air flow is at least partially deflected by the holding means 8, so that the holding means 8 acts as impact protection.

- the upper part 2, the lower part 3 and the holding means 8 are each shown as a rectangular sheet, wherein it is expedient for the production when upper part 2, lower part 3 and holding means 8 are fed as web material to a processing station.

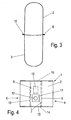

- FIG. 3 an intermediate stage of the production of the vacuum cleaner bag 1 is shown.

- the upper part 2 and the lower part 3 are formed substantially tubular and are separated on the mutually facing side by the holding means 8 from each other. In the region of the free edges of the upper part 2 and the lower part 3 and the edges of the holding means 8, these have been connected to seams 9 and 10 with each other.

- the intermediate stage of the vacuum cleaner bag 1 has an upper hose and a lower hose, which are separated from one another via the holding means 8. In the holding means 8 only recesses 13 are introduced, which allow a flow through.

- the now flat superimposed track section is formed on four opposite sides of four layers, while in the central region, only the upper part 2, the holding means 8 and the lower part 3 are present.

- This web is now guided to a cutting and welding station, cut perpendicular to the conveying direction of the vacuum cleaner bag 1 and welded.

- the finished vacuum cleaner bag is in the plan view in FIG. 4 shown.

- the inwardly folded wall sections 4 are arranged with a folding edge 7.

- the wall sections 4 have a width which is between 10% and 40% of the width of the vacuum cleaner bag, preferably in a range between 1 cm and 8 cm, in particular 2 cm to 5 cm.

- cutting edges 14 are provided, which are arranged adjacent to a seam 15, for example by welding or gluing.

- the recess 13 is laterally offset from the inflow opening 12. It is of course also possible to arrange the recess 13 in alignment with the inflow opening 12.

- a plurality of recesses 13 may be provided, for example, on both sides of the inflow opening 12 at least one recess 13th be provided.

- the holding means 8 may also consist of a net or scrim, so that the introduction of recesses 13 is not necessary.

- FIG. 5 a modified embodiment for a vacuum cleaner bag 1 is shown, which corresponds in shape substantially to the previous embodiment. Only the holding means 8 'is formed integrally with the lower part 3, so that instead of the three individual parts ( FIG. 2 ) only two items are available.

- the upper part 2 corresponds to the previous embodiment.

- a seam 9 is now produced on one side, in which an edge of the upper part 2 with an edge of the holding means 8 'and an edge of the lower part 3 are interconnected.

- a modified seam 10 ' On the opposite side is a modified seam 10 ', in which an edge of the upper part 2 is connected to a fold, a strip or a transition region 10' between the holding means 8 'and the lower part 3. In this respect, only one edge and one fold or strip are connected to each other.

- the vacuum cleaner bag 1 from a single web, so that upper part 2, holding means 8 'and lower part 3 are formed integrally. Then, at the seams 9 and 10, only one edge of the upper part 2 or of the lower part 3 is fixed to one another with a transition section 10 'between holding means and lower part 3 or holding means and upper part 2.

- vacuum bags 1 extend the seams 9 and 10 over the entire length of the vacuum cleaner bag 1. It is of course possible to provide the fixation of the holding means 8 only in a central region, so shorter form.

- the inwardly folded wall sections 4 could also be held together only in a central region, while in the peripheral region, the seams 15 prevent outward swelling.

- the holding means 8 need not extend over the entire length of the vacuum cleaner bag 1. It is possible to form the retaining means 8 only as a transverse strip, which is arranged in the region of the inflow opening 12 and is connected at opposite end faces with the inwardly folded wall sections 4.

- FIG. 6 shows a perspective view of another embodiment of a vacuum cleaner bag, in which compared to the in FIG. 1 embodiment shown still a holder 20 is provided and otherwise the same components are denoted by the same reference numerals.

- the holder 20 is formed by a strip of material which is formed during the punching of the passage opening 13 when at least a part of the material strip remains connected to the holding means 8, as shown at an edge 22.

- the holder 20 is fixed at the free end to the upper part 2 adjacent to the inflow opening 12, so that an incoming air flow initially strikes the holder 20, which acts as a deflection device and impact protection.

- the holder 20 also ensures that the holding means 8 does not rest on the lower part 3 but spaced from the lower part 3 is held.

- FIG. 7 is one opposite FIG. 6 modified embodiment shown in which a holder 30 is formed integrally with a holding means 8.

- the holder 30 is connected at a transition to the holding means 8 and fixed on the opposite side 32 on the lower part 3 in a central region opposite to the inflow opening 12.

- the holder 30 can also form an impact protection and also ensures that the incoming air flow pulls the lower part 3 away from the upper part 2 and the retaining means 8 is also pulled away from the upper part 2 by the holder 30. This ensures that the holding means 8 is spaced from the upper part 2 and held by the lower part 3 and the corresponding filter surfaces can be flowed through.

- a holder 40 is provided, which is arranged in a loop shape and unlike the holder 20 in FIG. 6 is fixed at the free end 41 on the opposite side of the inflow opening 12.

- an air flow entering through the inflow opening 12 can flow through the through-opening 13 onto the lower part 3, then being pulled away from the holding means 8 and the upper part 2, so that a secure unfolding of the vacuum cleaner bag after insertion into a vacuum cleaner is ensured.

- FIGS. 6 to 8 shown holders 20, 30 and 40 may be combined with each other, for example, a plurality of holders may be fixed to the holding means 8 in order to ensure a predetermined spacing between the upper part 2, holding means 8 and lower part 3.

- FIG. 9 a vacuum cleaner bag is shown in which a dividing wall 50 is arranged in an upper chamber between upper part 2 and a holding means 8 "', the dividing wall 50 being adjacent to an edge 52 Inflow opening 12 fixed to the upper part 2 and on the opposite side to a seam 51 between the upper part 2 and a pleat leg 5.

- the partition may be formed as a rectangular piece of material, preferably made of a non-woven, and at the edges, not shown, at the seams 15 of the vacuum cleaner bag ( FIG. 4 ).

- the holding means 8 is formed in two layers, with an upper layer forming the upper pleat leg 5 and a lower layer forming the lower pleat leg 6.

- the pleat legs 5 and 6 are connected to one another at at least one connection point 18, preferably a weld includes a frame-shaped portion surrounding a through-hole 13.

- the partition 50 omitted and arranged on opposite sides an additional spacer 60 between the upper pleat leg 5 and the lower pleat leg 6.

- the spacer 60 is formed from a shaped body, for example made of foam, and has upper ribs 61 for abutment with the upper fold leg 5 and lower ribs 62 for engagement with the lower fold leg 6.

- partition 50 and the spacer 60 can also in the embodiments of FIGS. 1 to 8 be provided.

Description

Die vorliegende Erfindung betrifft einen Staubsaugerbeutel mit mindestens einem nach innen gefalteten Wandabschnitt, der über mindestens ein Haltemittel in der nach innen gefalteten Position gehalten ist.The present invention relates to a vacuum cleaner bag having at least one inwardly folded wall portion which is held in at least one holding means in the inwardly folded position.

Die

Die

Es ist daher Aufgabe der vorliegenden Erfindung, einen Staubsaugerbeutel zu schaffen, bei dem die wirksame Filteroberfläche besser genutzt wird und der eine lange Standzeit besitzt.It is therefore an object of the present invention to provide a vacuum cleaner bag, in which the effective filter surface is better used and has a long life.

Diese Aufgabe wird durch einen Staubsaugerbeutel mit den Merkmalen des Anspruches 1 gelöst.This object is achieved by a vacuum cleaner bag with the features of

Bei dem erfindungsgemäßen Staubsaugerbeutel ist der nach innen gefaltete Wandabschnitt über mindestens ein Halternittel in der nach innen gefalteten Position gehalten. Dadurch wird vermieden, dass der nach innen gefaltete Wandabschnitt sich nach außen aufbläht und sich gegen die Innenwand einer Kammer eines Staubsaugerbeutels anlegt, so dass der an der Wand anliegende Bereich nicht mit Luft durchströmt wird. Vielmehr wird der nach innen gefaltete Wandabschnitt im Wesentlichen in einer durchströmbaren Position gehalten, wobei zumindest ein Aufblähen nach außen verhindert wird. Eine gewisse Elastizität des Haltemittels beeinträchtigt diese Funktion nicht. Zudem wird gewährleistet, dass der nach innen gefaltete Wandabschnitt als Filteroberfläche zur Verfügung steht und somit die Filterfläche im Verhältnis zum Innenvolumen des Staubsaugerbeutels signifikant höher ist als ohne nach innen gefalteten Wandabschnitt.In the vacuum cleaner bag according to the invention, the inwardly folded wall section is held in the inwardly folded position via at least one retaining means. This avoids that the inwardly folded wall portion inflates outwardly and applies against the inner wall of a chamber of a vacuum cleaner bag, so that the voltage applied to the wall area is not traversed with air. Rather, the inwardly folded wall portion is held substantially in a permeable position, wherein at least inflation to the outside is prevented. A certain elasticity of the holding means does not impair this function. In addition, it is ensured that the inwardly folded wall portion is available as a filter surface and thus the filter area in relation to the internal volume of the vacuum cleaner bag is significantly higher than without inwardly folded wall portion.

Das Haltemittel weist mindestens eine Aussparung auf oder ist aus einem Netz oder Gitter gebildet. Dadurch ist gewährleistet, dass das Halternittel durchströmbar ist und die Saugleistung nicht nachteilig beeinflusst. Die Aussparung in dem Haltemittel ist vorzugsweise seitlich versetzt zu einer Einströmöffnung in dem Oberteil oder dem Unterteil angeordnet, so dass das Haltemittel auch als Pralischutz wirkt und einen eintretenden Luftstrom ablenkt. Die Größe der Aussparung ist vorzugsweise größer als 2 cm2, insbesondere größer als die Einströmöffnung. Die Geometrie der Aussparung ist frei wählbar und zudem können auch mehrere Aussparungen in das Haltemittel eingebracht sein.The holding means has at least one recess or is formed from a net or grid. This ensures that the holding agent can be flowed through and does not adversely affect the suction power. The recess in the holding means is preferably arranged laterally offset from an inflow opening in the upper part or the lower part, so that the holding means also acts as an impact protection and deflects an incoming air flow. The size of the recess is preferably greater than 2 cm 2 , in particular larger than the inflow opening. The geometry of the recess is freely selectable and also several recesses may be incorporated into the retaining means.

Vorzugsweise ist das Haltemittel zumindest in einem mittleren Bereich des Wandabschnittes fixiert. Der nach innen gefaltete Wandabschnitt kann über die gesamte Länge durch das Haltemittel fixiert sein, aber für die Funktion des Haltens des nach innen gefalteten Abschnittes zur Vermeidung eines Aufblähens reicht es jedoch aus, wenn der nach innen gefaltete Wandabschnitt an ein oder mehreren Punkten an dem Hattemittel fixiert ist. Insbesondere im mittleren Bereich ist jedoch eine Fixierung am Haltemittel sinnvoll, da der nach innen gefaltete Wandabschnitt randseitig vorzugsweise ebenfalls an einer Naht des Staubsaugerbeutels fixiert ist.Preferably, the holding means is fixed at least in a central region of the wall portion. The inwardly folded wall portion may be fixed over the entire length by the holding means, but for the function of holding the inwardly folded portion to prevent inflation, however, it suffices if the inwardly folded wall portion at one or more points on the Hattemittel is fixed. However, a fixation on the holding means is particularly useful in the central region, since the inwardly folded wall portion is preferably also fixed to a seam of the vacuum cleaner bag edge.

Gemäß einer bevorzugten Ausgestaltung weist der Staubsaugerbeutel an mindestens zwei Seiten einen nach innen gefalteten Wandabschnitt auf. Die zwei nach innen gefalteten Wandabschnitte können dabei über das Haltemittel miteinander verbunden sein, so dass im Betrieb das Haltemittel auf Zug durch die Wandabschnitte belastet wird. Die nach innen gefalteten Wandabschnitte können dabei symmetrisch ausgebildet sein, um ein Verschieben des Haltemittels zu einer Richtung durch einseitig wirkende Zugkräfte zu vermeiden.According to a preferred embodiment, the vacuum cleaner bag on at least two sides on an inwardly folded wall portion. The two inwardly folded wall portions may be connected to each other via the holding means, so that in operation the holding means is loaded to train through the wall sections. The inwardly folded wall portions may be formed symmetrically in order to avoid a displacement of the holding means to a direction by unilaterally acting tensile forces.

Das Haltemittel ist vorzugsweise über eine Naht mit dem nach innen gefalteten Wandabschnitt verbunden. Die Naht ist dabei vorzugsweise nach außen gerichtet, so dass die Naht das wirksame Filtervolumen des Staubsaugerbeutels nicht einschränkt.The holding means is preferably connected via a seam with the inwardly folded wall portion. The seam is preferably directed outwards, so that the seam does not restrict the effective filter volume of the vacuum cleaner bag.

Der Staubsaugerbeutel umfasst vorzugsweise ein Oberteil und ein Unterteil als Flächengebilde. Auch das Haltemittel kann als luftdurchlässiges Flächengebilde gebildet sein. Als Materialien werden vorzugsweise ein- oder mehrlagige Vliesmaterialien, Papier, Verbundwerkstoffe, Folien oder andere Materialien eingesetzt. Für das Haltemittel können zudem Stoffe wie Netzstoffe, Gitterstoffe, Garn, Papier, Pappe oder Folie eingesetzt werden. Zur Ausbildung einer Naht können diese Materialien vorzugsweise verschweißt oder verklebt werden.The vacuum cleaner bag preferably comprises a top and a bottom as a sheet. Also, the holding means may be formed as an air-permeable sheet. The materials used are preferably single-layer or multi-layer nonwoven materials, paper, composite materials, films or other materials. For the holding means can also be used fabrics such as meshes, scrims, yarn, paper, cardboard or foil. To form a seam, these materials can preferably be welded or glued.

Gemäß einer Ausgestaltung der Erfindung ist mindestens eine Naht vorgesehen, die das Oberteil, das Unterteil und das Haltemittel miteinander verbindet. Dadurch können mittels eines Verfahrensschrittes, wie Verkleben oder Verschweißen, die Einzelteile miteinander verbunden werden, was eine effektive Herstellung ermöglicht.According to one embodiment of the invention, at least one seam is provided, which connects the upper part, the lower part and the holding means with each other. As a result, by means of a method step, such as gluing or welding, the individual parts can be connected to one another, which enables effective production.

Gemäß einer weiteren Ausgestaltung der Erfindung ist das Haltemittel integral mit dem Oberteil und/oder dem Unterteil ausgebildet. Es ist möglich, Oberteil, Unterteil und Haltemittel separat herzustellen, aber auch eine integrale Ausbildung des Haltemittels ist möglich. Das Haltemittel kann dabei einlagig oder zweilagig ausgebildet sein, wobei es bei einer zweilagigen Ausbildung möglich ist, eine obere Lage mit dem Oberteil zu verbinden und eine untere Lage mit dem Unterteil, so dass das Haltmittel mit den beiden Lagen randseitig den nach innen gefalteten Wandabschnitt ausbildet.According to a further embodiment of the invention, the holding means is formed integrally with the upper part and / or the lower part. It is possible to manufacture upper part, lower part and holding means separately, but also an integral design of the holding means is possible. The holding means may be formed in one or two layers, wherein it is possible in a two-ply training to connect an upper layer to the upper part and a lower layer with the lower part, so that the retaining means with the two layers edge forms the inwardly folded wall portion ,

Nach einer weiteren Ausgestaltung ist das Haltemittel über mindestens einen Halter am Oberteil und/oder Unterteil gehalten. Dadurch kann ein vorbestimmter Abstand des Haltemittels zum Oberteil und/oder Unterteil vorgegeben werden, insbesondere kann verhindert werden, dass das Haltemittel am Oberteil oder Unterteil anliegt und somit die zur Verfügung stehende Filterfläche reduziert wird. Vorzugsweise ist der mindestens eine Halter integral mit dem Haltemittel ausgebildet, beispielsweise als Materialstreifen, der dann am Oberteil oder Unterteil fixiert ist. Der Materialstreifen kann durch Ausstanzen der Durchgangsöffnung bereitgestellt werden, wenn beim Ausstanzen der Materialstreifen zumindest teilweise mit dem Haltemittel verbunden bleibt.According to a further embodiment, the holding means is held by at least one holder on the upper part and / or lower part. Thereby, a predetermined distance of the holding means to the upper part and / or lower part can be specified, in particular it can be prevented that the holding means rests on the upper part or lower part and thus the available filter surface is reduced. Preferably, the at least one holder is formed integrally with the holding means, for example as a material strip, which is then fixed to the upper part or lower part. The strip of material can be provided by punching out the passage opening if the material strip remains at least partially connected to the holding means during punching.

Bei dem erfindungsgemäßen Verfahren zum Herstellen eines Staubsaugerbeutels wird zunächst ein Oberteil und ein Unterteil aus einem Flächengebilde aus luftdurchlässigem Material bereitgestellt, wobei Oberteil und Unterteil vorzugsweise getrennt ausgebildet sind, aber auch integral aus einem Stück gefertigt sein können. Anschließend wird ein Haltemittel an einer randseitigen ersten Kante des Oberteils und einer ersten Kante oder Falte des Unterteils angeordnet. Dann wird die erste Kante des Oberteils mit dem Haltemittel und einer ersten Kante oder Falte des Unterteils verbunden. In einem weiteren Schritt wird dann eine zweite Kante oder Falte des Oberteils mit dem Haltemittel und einer zweiten Kante oder Falte des Unterteils verbunden, die das Haltemittel mit dem Unterteil verbindet. Dadurch wird mit nur wenigen Schritten ein gefalteter Wandabschnitt bereitgestellt, der über ein Haltemittel in einer nach innen gefalteten Position fixiert werden kann.In the method according to the invention for producing a vacuum cleaner bag, an upper part and a lower part are first provided from a sheet of air-permeable material, the upper part and lower part are preferably formed separately, but can also be made integrally from one piece. Subsequently, a holding means is arranged on a marginal first edge of the upper part and a first edge or fold of the lower part. Then, the first edge of the upper part is connected to the holding means and a first edge or fold of the lower part. In a further step, a second edge or fold of the upper part is then connected to the holding means and a second edge or fold of the lower part, which connects the holding means to the lower part. As a result, a folded wall section is provided with only a few steps, which can be fixed in a folded-in position via a holding means.

Vorzugsweise werden Oberteil und Unterteil aus Bahnmaterial im Wesentlichen schlauchförmig gefördert und zur Ausbildung eines Staubsaugerbeutels werden dann Oberteil und Unterteil senkrecht zur Förderrichtung geschnitten und miteinander verbunden, vorzugsweise verschweißt. Dadurch kann die Herstellung der Staubsaugerbeutel in einem kontinuierlichen Durchlaufverfahren mit hoher Effizienz erfolgen.Preferably, upper part and lower part of sheet material are substantially tubular and promoted to form a vacuum cleaner bag then upper part and lower part perpendicular to the conveying direction and connected to each other, preferably welded. Thus, the production of the vacuum cleaner bag can be done in a continuous flow process with high efficiency.

Vorzugsweise bestehen Oberteil, Unterteil und Haltemittel aus schweißfähigen Materialien, beispielsweise einem ein- oder mehrlagigen Vliesstoff, die dann miteinander verschweißt werden.Preferably upper part, lower part and retaining means of weldable materials, such as a single or multi-layer nonwoven fabric, which are then welded together.

Zur Ausbildung von Oberteil, Unterteil und Haltemittel und zur Herstellung eines Staubsaugerbeutels können optional ein, zwei oder drei Bahnen eines Filtermaterials zu einer Verarbeitungsstation zugeführt werden. Vorzugsweise werden zwei oder drei Bahnen parallel zueinander zu der Verarbeitungsstation zugeführt, um den erfindungsgemäßen Staubsaugerbeutel herzustellen.To form the upper part, lower part and holding means and for producing a vacuum cleaner bag, optionally one, two or three webs of a filter material can be supplied to a processing station. Preferably two or three webs fed parallel to each other to the processing station to produce the vacuum cleaner bag according to the invention.

Die Erfindung wird nachfolgend anhand mehrerer Ausführungsbeispiele mit Bezug auf die beigefügten Zeichnungen näher erläutert. Es zeigen:

Figur 1- eine perspektivische Ansicht eines erfindungsgemäßen Staubsaugerbeutels;

Figur 2- eine Draufsicht auf die Einzelteile des Staubsaugerbeutels der

Figur 1 Figur 3- eine Seitenansicht des Staubsaugerbeutels der

Figur 1 Figur 4- eine Draufsicht auf den Staubsaugerbeutel der

Figur 1 Figur 5- eine Draufsicht auf Einzelteile eines modifizierten Staubsaugerbeutels;

Figur 6- eine perspektivische Ansicht eines weiteren Ausführungsbeispiels eines Staubsaugerbeutels;

Figur 7- eine perspektivische Ansicht eines weiteren Ausführungsbeispiels eines Staubsaugerbeutels;

Figur 8- eine perspektivische Ansicht eines weiteren Ausführungsbeispiels eines Staubsaugerbeutels;

Figur 9- eine Seitenansicht eines weiteren Ausführungsbeispiels eines Staubsaugerbeutels mit modifiziertem Haltemittel; und

Figur 10- eine Seitenansicht eines zu

Figur 9 abgewandelten Ausführungsbeispiels eines Staubsaugerbeutels.

- FIG. 1

- a perspective view of a vacuum cleaner bag according to the invention;

- FIG. 2

- a plan view of the items of the vacuum cleaner bag

FIG. 1 ; - FIG. 3

- a side view of the vacuum cleaner bag the

FIG. 1 in the preparation of; - FIG. 4

- a plan view of the vacuum cleaner bag the

FIG. 1 ; - FIG. 5

- a plan view of items of a modified vacuum cleaner bag;

- FIG. 6

- a perspective view of another embodiment of a vacuum cleaner bag;

- FIG. 7

- a perspective view of another embodiment of a vacuum cleaner bag;

- FIG. 8

- a perspective view of another embodiment of a vacuum cleaner bag;

- FIG. 9

- a side view of another embodiment of a vacuum cleaner bag with modified holding means; and

- FIG. 10

- a side view of an

FIG. 9 modified embodiment of a vacuum cleaner bag.

Ein Staubsaugerbeutel 1 umfasst ein Oberteil und ein Unterteil 3 aus einem luftdurchlässigen Material, insbesondere einem Flächengebilde aus einem Vliesstoff, Papier, Folie oder einem Verbundwerkstoff. Der Staubsaugerbeutel 1 weist an zwei gegenüberliegenden Seiten einen nach innen gefalteten Wandabschnitt 4 auf. Jeder nach innen gefaltete Wandabschnitt 4 umfasst einen oberen Faltenschenkel 5, der integral mit dem Oberteil 2 ausgebildet ist, sowie einen unteren Faltenschenkel 6, der integral mit dem Unterteil 3 ausgebildet ist.A vacuum

An einer Faltkante 7 des nach innen gefalteten Wandabschnittes 4 ist ein Haltemittel 8 in Form eines Flächengebildes angeordnet, der zumindest bereichsweise mit dem nach innen gefalteten Wandabschnitt 4 verbunden ist. Das Haltemittel 8 ist aus einem Flächengebilde aus luftdurchlässigem Material, insbesondere einem Vliesstoff, Papier, Folie, einem Gitterstoff, Netz oder einen anderen Material gebildet. Auch eine Ausbildung als Streifen, Garn oder anderes Verbindungsmittel zwischen den gegenüberliegenden Wandabschnitten 4 ist möglich. Das Haltemittel 8 ist auf Zug belastbar und kann auch eine gewisse Elastizität besitzen. Das Haltemittel 8 verhindert dabei, dass die beiden nach innen gefalteten Wandabschnitte 4 sich im Betrieb des Staubsaugerbeutels nach außen aufblähen. Das Haltemittel 8 kann dabei nur in einem mittleren Bereich an dem nach innen gefalteten Wandabschnitt 4 fixiert sein. Es ist auch möglich, dass das Haltemittel 8 über die gesamte Länge der Faltkante 7 fixiert wird. Das Haltemittel 8 soll zumindest ein Aufblähen des nach innen gefalteten Wandabschnittes 4 nach außen verhindern.At a folded

Um das Haltemittel 8 mit dem nach innen gefalteten Wandabschnitt 4 zu verbinden, ist eine Naht 9 vorgesehen, die durch Schweißen oder Kleben gebildet ist, und an der der Faltenschenkel 5 des Oberteils 2, der Faltenschenkel 6 des Unterteils 3 sowie ein Randabschnitt des Haltemittels 8 aneinander fixiert sind, vorzugsweise durch Schweißen oder Kleben. Auf der gegenüberliegenden Seite ist eine Naht 10 vorgesehen, die ebenfalls den Faltenschenkel 5 und den Faltenschenkel 6 sowie das Haltemittel 8 verbindet. Die Nähte 9 und 10 sind jeweils nach außen gerichtet und befinden sich somit außerhalb des Innenvolumens des Staubsaugerbeutels.In order to connect the holding means 8 with the inwardly folded

In

In

In

Ausgehend von

Der nun flach aufeinander liegende Bahnabschnitt ist an gegenüberliegenden Randseiten vierlagig ausgebildet, während im mittleren Bereich nur das Oberteil 2, das Haltemittel 8 und das Unterteil 3 vorhanden sind. Diese Bahn wird nun zu einer Schneid- und Schweißstation geführt, bei der senkrecht zur Förderrichtung der Staubsaugerbeutel 1 geschnitten und verschweißt wird.The now flat superimposed track section is formed on four opposite sides of four layers, while in the central region, only the

Der fertige Staubsaugerbeutel ist in der Draufsicht in

In

Es ist auch möglich, den Staubsaugerbeutel 1 aus einer einzigen Bahn herzustellen, so dass Oberteil 2, Haltemittel 8' sowie Unterteil 3 integral ausgebildet sind. Dann werden an den Nähten 9 und 10 jeweils nur eine Kante des Oberteils 2 bzw. des Unterteils 3 mit einem Übergangsabschnitt 10' zwischen Haltemittel und Unterteil 3 bzw. Haltemittel und Oberteil 2 aneinander fixiert.It is also possible to produce the vacuum

Bei dem in

In

Bei dem in

Die in den

Zudem ist es möglich, weitere Elemente in dem Staubsaugerbeutel vorzusehen. In

Bei dem in

Bei dem in

Die in

Claims (12)

- Vacuum cleaner bag (1), with at least one inwardly folded wall section (4), which is held in the inwardly folded position by way of at least one holding means (8, 8'), characterised in that the holding means (8, 8') is formed by an air-permeable areal structure and the areal structure has at least one cut-out (13) or is formed from a net or mesh.

- Vacuum cleaner bag according to claim 1, characterised in that the holding means (8, 8') is fixed at least in a centre region of the inwardly folded wall section (4).

- Vacuum cleaner bag according to claim 1 or 2, characterised in that an inwardly folded wall section (4) is provided at at least two sides.

- Vacuum cleaner bag according to any one of the preceding claims, characterised in that two inwardly folded wall sections (4) are connected together by way of the holding means (8, 8').

- Vacuum cleaner bag according to any one of the preceding claims, characterised in that the holding means (8, 8') are connected with the inwardly folded wall section (4) by way of a seam (9, 10).

- Vacuum cleaner bag according to claim 5, characterised in that the seam (9, 10) is oriented outwardly.

- Vacuum cleaner bag according to any one of the preceding claims, characterised in that the vacuum cleaner bag (1) comprises an upper part (2) and a lower part (3) as areal structure.

- Vacuum cleaner bag according to claim 7, characterised in that at least one seam (9, 10) connecting the upper part (2), the lower part (3) and the holding means (8, 8') together is provided.

- Vacuum cleaner bag according to any one of claims 1 to 8, characterised in that the cut-out (13) is arranged to be laterally offset with respect to an inflow opening (12) in the upper part (2) or the lower part (3).

- Vacuum cleaner bag according to any one of the preceding claims, characterised in that the holding means (8') is constructed integrally with the upper part (2) and/or the lower part (3).

- Vacuum cleaner bag according to any one of the preceding claims, characterised in that the vacuum cleaner bag (1) is constructed as a flat bag and has at opposite sides a four-layered edge section with an inwardly folded wall section (4).

- Vacuum cleaner bag according to any one of the preceding claims, characterised in that the holding means (8, 8') is held at the upper part (2) and/or lower part (3) by way of at least one holder (20, 30, 40).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP20100195704 EP2465397B1 (en) | 2010-12-17 | 2010-12-17 | Vacuum cleaner bag and method for manufacturing same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP20100195704 EP2465397B1 (en) | 2010-12-17 | 2010-12-17 | Vacuum cleaner bag and method for manufacturing same |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2465397A1 EP2465397A1 (en) | 2012-06-20 |

| EP2465397B1 true EP2465397B1 (en) | 2014-06-11 |

Family

ID=44025252

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP20100195704 Not-in-force EP2465397B1 (en) | 2010-12-17 | 2010-12-17 | Vacuum cleaner bag and method for manufacturing same |

Country Status (1)

| Country | Link |

|---|---|

| EP (1) | EP2465397B1 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102012219341A1 (en) * | 2012-10-23 | 2014-04-24 | BSH Bosch und Siemens Hausgeräte GmbH | Dust collector bag for vacuum cleaner, has inlet opening that is provided to intake the duct-acted upon suction air, and air-permeable foam layer that is arranged on the exhaust side of filter layer |

| DE102015114330A1 (en) * | 2015-08-28 | 2017-03-02 | Branofilter Gmbh | Vacuum Cleaner Bags |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE129156C (en) * | ||||

| US2014118A (en) * | 1933-11-27 | 1935-09-10 | Hoover Co | Suction cleaner |

| US2268352A (en) * | 1940-09-07 | 1941-12-30 | Hoover Co | Suction cleaner dirt bag |

| GB694415A (en) * | 1951-03-02 | 1953-07-22 | British Thomson Houston Co Ltd | Improvements in and relating to vacuum cleaner dust bags |

| US2620045A (en) * | 1951-09-06 | 1952-12-02 | Hoover Co | Suction cleaner bag |

| BE528940A (en) * | 1953-05-18 | |||

| CA1007578A (en) * | 1973-09-17 | 1977-03-29 | Edward G. Lutz | Filter bag structure for a suction cleaner |

| DE8815619U1 (en) * | 1988-12-16 | 1989-01-26 | Branofilter Gmbh, 8501 Dietenhofen, De | |

| DE102008061250C5 (en) * | 2008-12-10 | 2018-12-20 | Wolf Pvg Gmbh & Co. Kg | Vacuum cleaner bag and method of making a vacuum cleaner bag |

| DE202008016300U1 (en) | 2008-12-10 | 2009-02-26 | Wolf Pvg Gmbh & Co. Kg | Dust bags |

-

2010

- 2010-12-17 EP EP20100195704 patent/EP2465397B1/en not_active Not-in-force

Also Published As

| Publication number | Publication date |

|---|---|

| EP2465397A1 (en) | 2012-06-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE10348375B4 (en) | Filter bag and method for its production | |

| DE202008016300U1 (en) | Dust bags | |

| WO2007134734A1 (en) | Dust filter bag | |

| WO2007073889A1 (en) | Filter bag for a vacuum cleaner and method for producing the same | |

| EP2489292B1 (en) | Bag for a vacuum cleaner | |

| DE102008045683A1 (en) | Dust filter bag device for vacuum cleaner, has filter walls with wall sections forming positions, where glued connection joint or welded connection joint of positions counteracts and/or limits extension of filter bag in operating condition | |

| EP2929823B1 (en) | Vacuum cleaner filter bag for an upright vacuum cleaner | |

| EP2445382B1 (en) | Block bottom filter bag for vacuum cleaners | |

| EP2359730B1 (en) | Vacuum cleaner filter bag with side fold | |

| EP2198765B1 (en) | Vacuum cleaner bag and method for manufacturing vacuum cleaner bag | |

| EP2465397B1 (en) | Vacuum cleaner bag and method for manufacturing same | |

| EP2067427A2 (en) | Dust filter bag for a vacuum cleaner | |

| EP2452603B1 (en) | Folded vacuum cleaner filter bag | |

| DE102011120688B4 (en) | Dust filter bag with a dust collector insert | |

| DE202010013156U1 (en) | Dust bags | |

| DE102008031989A1 (en) | Dust filter bag for household vacuum cleaner, has impact device comprising impact surface, where wall section exhibiting impact surface has higher impact effect than wall section of bag wall that surrounds wall section exhibiting surface | |

| DE202011108953U1 (en) | Dust filter bag with a dust collector insert | |

| EP2465398A1 (en) | Vacuum cleaner bag and method for manufacturing same | |

| DE202009012839U1 (en) | Vacuum Cleaner Bags | |

| DE102015101316A1 (en) | Method and device for producing a vacuum cleaner bag and vacuum cleaner bag | |

| DE202010013158U1 (en) | Dust bags |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| AX | Request for extension of the european patent |

Extension state: BA ME |

|

| 17P | Request for examination filed |

Effective date: 20121217 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| RIC1 | Information provided on ipc code assigned before grant |

Ipc: A47L 9/14 20060101AFI20131209BHEP |

|

| INTG | Intention to grant announced |

Effective date: 20140103 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 671793 Country of ref document: AT Kind code of ref document: T Effective date: 20140715 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502010007176 Country of ref document: DE Effective date: 20140724 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140912 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140911 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20140611 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: RS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141013 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141011 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502010007176 Country of ref document: DE |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 |

|

| 26N | No opposition filed |

Effective date: 20150312 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502010007176 Country of ref document: DE Effective date: 20150312 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141217 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20141217 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141217 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141231 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141217 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20141231 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SM Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20101217 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 7 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 671793 Country of ref document: AT Kind code of ref document: T Effective date: 20151217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20151217 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140611 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20211224 Year of fee payment: 12 Ref country code: DE Payment date: 20211231 Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502010007176 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230701 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20221231 |