EP2303524B1 - Untermesser für den scherkopf eines trockenrasierapparates - Google Patents

Untermesser für den scherkopf eines trockenrasierapparates Download PDFInfo

- Publication number

- EP2303524B1 EP2303524B1 EP09757181.4A EP09757181A EP2303524B1 EP 2303524 B1 EP2303524 B1 EP 2303524B1 EP 09757181 A EP09757181 A EP 09757181A EP 2303524 B1 EP2303524 B1 EP 2303524B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- blades

- blade

- lower cutter

- dry shaver

- width

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B26—HAND CUTTING TOOLS; CUTTING; SEVERING

- B26B—HAND-HELD CUTTING TOOLS NOT OTHERWISE PROVIDED FOR

- B26B19/00—Clippers or shavers operating with a plurality of cutting edges, e.g. hair clippers, dry shavers

- B26B19/02—Clippers or shavers operating with a plurality of cutting edges, e.g. hair clippers, dry shavers of the reciprocating-cutter type

- B26B19/04—Cutting heads therefor; Cutters therefor; Securing equipment thereof

- B26B19/044—Manufacture and assembly of cutter blocks

Definitions

- the invention relates to a lower blade for a dry shaver, according to the preamble of claim 1.

- Such a lower blade is for example from the DE-A 10 2005 009 264 A1 known.

- the strip-shaped blades of this lower blade taper monotonously towards the middle.

- a lower knife is also from the US 7,022,195 B2 known, this lower blade is composed of a plurality of strip-shaped blade elements which have a constant width or a width increasing towards the center.

- Such lower blades are driven oscillating within the shaving head of a dry shaver and pressed against the perforated foil and are exposed to a complex load during shaving.

- the lower blade designs according to the known type have the disadvantage that they generate very high friction losses due to viscous friction between the perforated foil and the involved friction surfaces of the lower blade. This leads to a high energy consumption and also to a user unpleasant heating of the shaving parts as well as premature wear. Due to the non-uniform mechanical stress distribution over the course of the individual blades, these bulge unevenly over the blade length due to the forces which occur when the shaving head is pressed against the skin of the user. This leads to partial loss of direct contact between lower blade and perforated film, which cut into the hole already threaded hair is not cut, but only fed, resulting in a painful scribing of the Hair may result from the skin. In addition, the perforated foil can be damaged by the uneven bulging of the blades.

- the inventive solution a uniform material loading over the entire course of the individual blades is achieved, whereby the permanent uniform contact between the perforated film and the bottom blade is ensured even under heavy loads.

- This also makes it possible that in the actual cutting area, the blades can be kept narrow without loss of stability, which can reduce the viscous friction between the perforated film and lower blade. As a result, the material used is better utilized.

- the invention provides that the tapering of the strip width of the blades takes place continuously, which promotes a uniform load distribution along the blade.

- the taper of the strip width is preferably designed arcuate.

- the blades are preferably formed symmetrically to the centerline of the strips and preferably have acute-angled cutting edges to reduce the cutting forces encountered during shaving.

- the in Fig. 1 shown dry shaver consists of a housing 1, which serves, inter alia, the inclusion of a drawing not shown electric motor and, where appropriate, also not graphically illustrated accumulators for energy storage and is provided with an on / off switch 2.

- a housing 1 which serves, inter alia, the inclusion of a drawing not shown electric motor and, where appropriate, also not graphically illustrated accumulators for energy storage and is provided with an on / off switch 2.

- an oscillating driven drive element 3 is led out of the housing 1.

- the lower blade 4 are locked by appropriate / suitable per se known coupling means with the drive element 3.

- the two lower blades 4 arranged parallel to one another can then be driven in an oscillating manner along their longitudinal extent, that is to say in accordance with the double arrow 5.

- the lower blades 4 are at least partially surrounded in each case by one of the two outer blades, which are each formed as a perforated foil 6. They are mounted in a removable frame 7, which is latched to the housing 1.

- the perforated foils 6 are perforated flat with passage openings which can be embodied as holes and / or slots and through which the hair to be shaved enters the shaving head during the shaving process. Due to the cutting edges formed on both the film passage holes and the lower blades 4 and the movement of the lower blades 4 relative to the hole foils 6, the hairs entering the shaving head are sheared between the respective shearing edges.

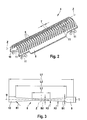

- FIG. 2 shown lower blade 4 has a plurality of U-shaped mutually parallel blades 8, which extend in the form of strips between the two edge regions 10 and 9.

- Each of the two edge regions 9 and 10 has at its front or rear end in each case a fastening portion 11 for connection to a carrier element not shown in detail, which ultimately serves to connect the lower blade 4 with the drive element 3 of the dry shaver.

- the longitudinal extent of each edge region 9 or 10 between its two attachment portions 11 corresponds to the direction of oscillation according to the double arrow 5.

- the blades 8 according to the embodiment shown here are perpendicular to the longitudinal extent of the edge regions 9, 10.

- the width of the blades 8 and the pitch T of Blades of the lower blade 4 are measured parallel to the longitudinal extent of the edge regions.

- the width of the strip-shaped blades 8 is not constant over the length L1, but tapers, starting from the edge portion 9 to the zenith Z of the bow to increase from there to the edge portion 10 out again. This becomes particularly apparent from the illustration Fig. 3 clear.

- Fig. 3 shows the development of a single blade 8, which is formed symmetrically both with respect to the center line M and with respect to the zenith Z.

- the edge regions 9, 10 are in Fig. 3 represented by the width of the pitch T, which is about 1 mm.

- the total length L1 of the blade 8 is approximately 11.5 mm.

- the entire tapered region of the blade 8 bounded on both sides by the approach of the inner radii R1 at the end regions 9, 10 extends over a length L2 of about 8.9 mm.

- the blade 8 tapers by means of a concave inner radius R1, which is about 0.2 mm, to the width B1, which is about 0.58 mm. This is followed by a convex outer radius R2 of about 33 mm. This gives the blade in this area a convex outer contour along its longitudinal extent. At the inside end of the radius R2, the blade merges with a concave inner radius R3 of about 3.5 mm into the parallel middle part. This part has a width B2 of 0.32 mm and a length L3 of about 3.1 mm.

- the notch effect is eliminated, which is due to the bending load due to the cutting forces occurring to blade fractures could occur in the connecting region between the edge regions 9, 10 and the blades 8 itself. Due to the outer radius R2, the stress distribution is evened out in the region of the greatest bending / torsional load and stress peaks are avoided. By the inner radius R3, the notch effect between R2 and the parallel middle part L3 is eliminated.

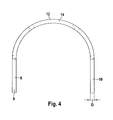

- Fig. 4 shows a view of a curved blade member 8, which was generated by corresponding U-shaped bending of an originally flat output lower blade 4.

- Der Blade 8 ist in der Figur 1 classroom.

- the flat starting lower blade 4 is produced in particular by an etching-technical process from a strip-shaped starting body made of metal, into which the slots lying between the individual blades 8 are etched. This starting body is then then bent in a U-shape, so that a lower blade, as it Fig. 2 shows, arises. Due to the etching technology production arises in the region of the two opposite cutting edges 12, 13 of each blade 8, an undercut, as in the FIGS. 5 and 6 is clearly shown. This undercut 14 is located after the U-shaped bending on the inside of the sheet. Again Fig. 4 can be removed, the material thickness of the starting sheet D is about 0.3 mm.

- Fig. 6 clearly shown undercut under each of the two cutting edges 12, 13 extends along a radius R4 of about 0.3 mm and generates at the cutting edges 12, 13 a cutting edge angle W of about 50 °.

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Life Sciences & Earth Sciences (AREA)

- Forests & Forestry (AREA)

- Mechanical Engineering (AREA)

- Dry Shavers And Clippers (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102008027224A DE102008027224A1 (de) | 2008-06-06 | 2008-06-06 | Untermesser für den Scherkopf eines Trockenrasierapparates |

| PCT/EP2009/003600 WO2009146798A1 (de) | 2008-06-06 | 2009-05-20 | Untermesser für den scherkopf eines trockenrasierapparates |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2303524A1 EP2303524A1 (de) | 2011-04-06 |

| EP2303524B1 true EP2303524B1 (de) | 2013-09-11 |

Family

ID=40957941

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09757181.4A Active EP2303524B1 (de) | 2008-06-06 | 2009-05-20 | Untermesser für den scherkopf eines trockenrasierapparates |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US8732961B2 (enExample) |

| EP (1) | EP2303524B1 (enExample) |

| JP (1) | JP5373068B2 (enExample) |

| CN (1) | CN102056716B (enExample) |

| DE (1) | DE102008027224A1 (enExample) |

| WO (1) | WO2009146798A1 (enExample) |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005036383A1 (de) * | 2005-07-29 | 2007-02-01 | Braun Gmbh | Scherkopf für einen elektrischen Rasierapparat |

| DE102008027224A1 (de) | 2008-06-06 | 2009-12-10 | Braun Gmbh | Untermesser für den Scherkopf eines Trockenrasierapparates |

| WO2015158571A1 (en) | 2014-04-18 | 2015-10-22 | Koninklijke Philips N.V. | Blade set, hair cutting appliance, and related manufacturing method |

| US10647010B2 (en) | 2014-07-04 | 2020-05-12 | Koninklijke Philips N.V. | Blade set, hair cutting appliance, and related manufacturing method |

| IT201900011250A1 (it) * | 2019-07-09 | 2021-01-09 | Gamma Piu S R L | Tagliacapelli elettrico |

| CN111390978B (zh) * | 2020-04-24 | 2024-06-18 | 中山市小石陶瓷刀片有限公司 | 一种往复式剃刀刀头及其制造方法 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2144525A (en) * | 1936-12-19 | 1939-01-17 | American Safety Razor Corp | Process of making dry shaver parts |

| US2223156A (en) * | 1937-12-07 | 1940-11-26 | Remington Rand Inc | Electric dry shaver |

| US2307471A (en) * | 1938-09-21 | 1943-01-05 | Remington Rand Inc | Shaving implement |

| US2325606A (en) * | 1940-07-26 | 1943-08-03 | Gillette Safety Rasor Company | Shaving implement |

| US2325605A (en) * | 1941-06-14 | 1943-08-03 | Nordberg Manufacturing Co | Impact member for impact crushers and securing means therefor |

| JP3237868B2 (ja) * | 1991-07-15 | 2001-12-10 | 松下電工株式会社 | 往復式電気かみそりの内刃の製法 |

| DE4423503C1 (de) * | 1994-07-05 | 1995-04-20 | Braun Ag | Untermesser für einen Trockenrasierapparat |

| KR100447912B1 (ko) * | 1996-04-26 | 2004-11-03 | 산요덴키가부시키가이샤 | 전기면도기와외부날의제조방법 |

| GB9614160D0 (en) * | 1996-07-05 | 1996-09-04 | Gillette Co | Dry shaving apparatus |

| EP1426148B1 (en) | 2001-09-10 | 2005-07-06 | Matsushita Electric Works, Ltd. | Method of manufacturing inner blade for electric razor |

| JP2005198795A (ja) * | 2004-01-15 | 2005-07-28 | Izumi Products Co | 往復式電気かみそりの内刃製造方法および内刃 |

| JP2006042899A (ja) * | 2004-07-30 | 2006-02-16 | Matsushita Electric Works Ltd | 往復式電気かみそりの内刃 |

| KR200391316Y1 (ko) | 2005-01-28 | 2005-08-02 | 오태준 | 전기면도기의 절삭날 어셈블리 |

| DE102005036383A1 (de) * | 2005-07-29 | 2007-02-01 | Braun Gmbh | Scherkopf für einen elektrischen Rasierapparat |

| JP4963020B2 (ja) * | 2005-08-23 | 2012-06-27 | 株式会社泉精器製作所 | 往復式電気かみそりの内刃 |

| DE102006023774A1 (de) * | 2006-05-20 | 2007-11-22 | Braun Gmbh | Untermesser für einen Trockenrasiererscherkopf |

| DE102008027224A1 (de) | 2008-06-06 | 2009-12-10 | Braun Gmbh | Untermesser für den Scherkopf eines Trockenrasierapparates |

-

2008

- 2008-06-06 DE DE102008027224A patent/DE102008027224A1/de not_active Ceased

-

2009

- 2009-05-20 WO PCT/EP2009/003600 patent/WO2009146798A1/de not_active Ceased

- 2009-05-20 EP EP09757181.4A patent/EP2303524B1/de active Active

- 2009-05-20 JP JP2011511998A patent/JP5373068B2/ja active Active

- 2009-05-20 CN CN200980121069.7A patent/CN102056716B/zh active Active

-

2010

- 2010-12-03 US US12/959,683 patent/US8732961B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN102056716B (zh) | 2016-10-19 |

| WO2009146798A1 (de) | 2009-12-10 |

| DE102008027224A1 (de) | 2009-12-10 |

| JP2011521750A (ja) | 2011-07-28 |

| US20110067244A1 (en) | 2011-03-24 |

| US8732961B2 (en) | 2014-05-27 |

| JP5373068B2 (ja) | 2013-12-18 |

| EP2303524A1 (de) | 2011-04-06 |

| CN102056716A (zh) | 2011-05-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2303524B1 (de) | Untermesser für den scherkopf eines trockenrasierapparates | |

| EP2346651A1 (de) | Scherkopf für einen rasierapparat | |

| EP1497082B1 (de) | Scherkopf für ein haarschneidegerät | |

| WO2008141720A1 (de) | Schneideinrichtung zum schneiden von haaren | |

| EP2035194B1 (de) | Schereinheit für einen trockenrasierer | |

| DE3036453A1 (de) | Scherkopf eines trockenrasiergeraetes | |

| EP1257391B1 (de) | Schneidmesser | |

| DE102009035232B4 (de) | Schneidsatz für Haarschneidemaschinen | |

| WO2012162714A1 (de) | Schermesser mit messereinsatz | |

| DE2515183A1 (de) | Rasiermesser mit auswechselbarer klinge | |

| EP0008483B1 (de) | Langhaarscherteil, insbesondere für Trockenrasierapparate | |

| DE3408733A1 (de) | Schermesser fuer elektrorasierer | |

| WO2018077418A1 (de) | Schermesser und schneidgerät | |

| WO2002070212A1 (de) | Schersystem für einen trockenrasierer | |

| EP2110194A2 (de) | Sägeblatt und Handsäge | |

| EP2021153B1 (de) | Untermesser für einen trockenrasiererscherkopf | |

| DE69800963T2 (de) | Sicherheitsrasierer | |

| WO2018077419A1 (de) | Schermesser für ein schneidgerät | |

| EP1910042B1 (de) | Scherkopf für einen elektrischen rasierapparat | |

| DE8617670U1 (de) | Oszillierendes Trennmesser mit Verzahnung | |

| DE3028430A1 (de) | Rasiereinheit | |

| EP3581349B1 (de) | Verbandsstoffschere | |

| AT287997B (de) | Krallenplatte bestehend aus einer Metallblechplatte | |

| DE1503939C (de) | Sageblatt fur Stichsagemaschinen | |

| EP0994212A1 (de) | Scherwendel |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20101118 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA RS |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20120403 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20130415 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: KRAUSS, JOACHIM Inventor name: JUNK, PETER Inventor name: ODEMER, MICHAEL Inventor name: POHL, THORSTEN Inventor name: ZEGULA, CHRISTOPH Inventor name: SCHWARZ, TOBIAS Inventor name: WOLF, JUERGEN Inventor name: HARTMANN, ANDREAS Inventor name: VERSTEGE, THOMAS Inventor name: SABISCH, MARKUS Inventor name: EICHHORN, REINHOLD Inventor name: PETER, ANDREAS |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BOHEST AG, CH Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 631353 Country of ref document: AT Kind code of ref document: T Effective date: 20130915 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 502009007992 Country of ref document: DE Effective date: 20131107 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 Ref country code: HR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130710 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 Ref country code: NO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131211 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MG4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20131212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140111 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502009007992 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140113 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20140612 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502009007992 Country of ref document: DE Effective date: 20140612 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140520 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140520 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140531 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT; INVALID AB INITIO Effective date: 20090520 Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20130911 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20180516 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20180426 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 631353 Country of ref document: AT Kind code of ref document: T Effective date: 20190520 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190531 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190520 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20190531 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| P01 | Opt-out of the competence of the unified patent court (upc) registered |

Effective date: 20230430 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20250409 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20250402 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20250401 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20250401 Year of fee payment: 17 |