EP2051826B1 - Iron-based powder - Google Patents

Iron-based powder Download PDFInfo

- Publication number

- EP2051826B1 EP2051826B1 EP07748599A EP07748599A EP2051826B1 EP 2051826 B1 EP2051826 B1 EP 2051826B1 EP 07748599 A EP07748599 A EP 07748599A EP 07748599 A EP07748599 A EP 07748599A EP 2051826 B1 EP2051826 B1 EP 2051826B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- entry

- row

- powder

- max

- sintering

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000000843 powder Substances 0.000 title claims abstract description 72

- XEEYBQQBJWHFJM-UHFFFAOYSA-N Iron Chemical compound [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 title claims abstract description 48

- 229910052742 iron Inorganic materials 0.000 title claims abstract description 20

- 239000012535 impurity Substances 0.000 claims abstract description 4

- 238000005245 sintering Methods 0.000 claims description 29

- 239000000463 material Substances 0.000 claims description 20

- 238000005056 compaction Methods 0.000 claims description 14

- 238000000034 method Methods 0.000 claims description 12

- 239000000203 mixture Substances 0.000 claims description 12

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 8

- 239000011230 binding agent Substances 0.000 claims description 5

- 239000000314 lubricant Substances 0.000 claims description 4

- 230000007935 neutral effect Effects 0.000 claims description 2

- 239000010949 copper Substances 0.000 description 33

- 230000003647 oxidation Effects 0.000 description 27

- 238000007254 oxidation reaction Methods 0.000 description 27

- 229910052802 copper Inorganic materials 0.000 description 23

- 229910052782 aluminium Inorganic materials 0.000 description 21

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 19

- 239000011651 chromium Substances 0.000 description 18

- PNEYBMLMFCGWSK-UHFFFAOYSA-N Alumina Chemical compound [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 17

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 14

- 229910052804 chromium Inorganic materials 0.000 description 14

- 239000004411 aluminium Substances 0.000 description 13

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 11

- 229910052759 nickel Inorganic materials 0.000 description 11

- 229910045601 alloy Inorganic materials 0.000 description 8

- 239000000956 alloy Substances 0.000 description 8

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 7

- 238000005275 alloying Methods 0.000 description 7

- 229910052799 carbon Inorganic materials 0.000 description 7

- 239000000155 melt Substances 0.000 description 7

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 6

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 description 6

- 239000007791 liquid phase Substances 0.000 description 6

- 230000015572 biosynthetic process Effects 0.000 description 5

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 description 4

- 239000010410 layer Substances 0.000 description 4

- 229910052748 manganese Inorganic materials 0.000 description 4

- 239000011572 manganese Substances 0.000 description 4

- 238000009692 water atomization Methods 0.000 description 4

- 229910002549 Fe–Cu Inorganic materials 0.000 description 3

- UFHFLCQGNIYNRP-UHFFFAOYSA-N Hydrogen Chemical compound [H][H] UFHFLCQGNIYNRP-UHFFFAOYSA-N 0.000 description 3

- 229910000423 chromium oxide Inorganic materials 0.000 description 3

- 230000000694 effects Effects 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 238000004519 manufacturing process Methods 0.000 description 3

- 210000003739 neck Anatomy 0.000 description 3

- 229910052757 nitrogen Inorganic materials 0.000 description 3

- 239000013074 reference sample Substances 0.000 description 3

- 238000007711 solidification Methods 0.000 description 3

- 230000008023 solidification Effects 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- WGLPBDUCMAPZCE-UHFFFAOYSA-N Trioxochromium Chemical compound O=[Cr](=O)=O WGLPBDUCMAPZCE-UHFFFAOYSA-N 0.000 description 2

- 238000000889 atomisation Methods 0.000 description 2

- 229910001566 austenite Inorganic materials 0.000 description 2

- 150000001875 compounds Chemical class 0.000 description 2

- 238000009770 conventional sintering Methods 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 239000007789 gas Substances 0.000 description 2

- 238000009689 gas atomisation Methods 0.000 description 2

- 229910052735 hafnium Inorganic materials 0.000 description 2

- 239000001257 hydrogen Substances 0.000 description 2

- 229910052739 hydrogen Inorganic materials 0.000 description 2

- 229910052750 molybdenum Inorganic materials 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- 238000010587 phase diagram Methods 0.000 description 2

- 239000000523 sample Substances 0.000 description 2

- 229910052710 silicon Inorganic materials 0.000 description 2

- 239000010935 stainless steel Substances 0.000 description 2

- 229910001220 stainless steel Inorganic materials 0.000 description 2

- 238000009864 tensile test Methods 0.000 description 2

- 230000004584 weight gain Effects 0.000 description 2

- 235000019786 weight gain Nutrition 0.000 description 2

- 229910052727 yttrium Inorganic materials 0.000 description 2

- 229910052684 Cerium Inorganic materials 0.000 description 1

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 239000012876 carrier material Substances 0.000 description 1

- 239000003054 catalyst Substances 0.000 description 1

- 229910017052 cobalt Inorganic materials 0.000 description 1

- 239000010941 cobalt Substances 0.000 description 1

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 230000000994 depressogenic effect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000009792 diffusion process Methods 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 238000009499 grossing Methods 0.000 description 1

- VBJZVLUMGGDVMO-UHFFFAOYSA-N hafnium atom Chemical compound [Hf] VBJZVLUMGGDVMO-UHFFFAOYSA-N 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 238000010348 incorporation Methods 0.000 description 1

- 229910000953 kanthal Inorganic materials 0.000 description 1

- 229910052746 lanthanum Inorganic materials 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 239000011733 molybdenum Substances 0.000 description 1

- 229910052758 niobium Inorganic materials 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- 238000004663 powder metallurgy Methods 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 239000011241 protective layer Substances 0.000 description 1

- 229910052761 rare earth metal Inorganic materials 0.000 description 1

- 239000012925 reference material Substances 0.000 description 1

- 229910052706 scandium Inorganic materials 0.000 description 1

- VSZWPYCFIRKVQL-UHFFFAOYSA-N selanylidenegallium;selenium Chemical compound [Se].[Se]=[Ga].[Se]=[Ga] VSZWPYCFIRKVQL-UHFFFAOYSA-N 0.000 description 1

- 239000010703 silicon Substances 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- 229910052715 tantalum Inorganic materials 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

- 229910052720 vanadium Inorganic materials 0.000 description 1

- VWQVUPCCIRVNHF-UHFFFAOYSA-N yttrium atom Chemical compound [Y] VWQVUPCCIRVNHF-UHFFFAOYSA-N 0.000 description 1

- 229910052726 zirconium Inorganic materials 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/06—Ferrous alloys, e.g. steel alloys containing aluminium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/10—Sintering only

- B22F3/1003—Use of special medium during sintering, e.g. sintering aid

- B22F3/1007—Atmosphere

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F9/00—Making metallic powder or suspensions thereof

- B22F9/02—Making metallic powder or suspensions thereof using physical processes

- B22F9/06—Making metallic powder or suspensions thereof using physical processes starting from liquid material

- B22F9/08—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying

- B22F9/082—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying atomising using a fluid

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C33/00—Making ferrous alloys

- C22C33/02—Making ferrous alloys by powder metallurgy

- C22C33/0257—Making ferrous alloys by powder metallurgy characterised by the range of the alloying elements

- C22C33/0278—Making ferrous alloys by powder metallurgy characterised by the range of the alloying elements with at least one alloying element having a minimum content above 5%

- C22C33/0285—Making ferrous alloys by powder metallurgy characterised by the range of the alloying elements with at least one alloying element having a minimum content above 5% with Cr, Co, or Ni having a minimum content higher than 5%

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/20—Ferrous alloys, e.g. steel alloys containing chromium with copper

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/42—Ferrous alloys, e.g. steel alloys containing chromium with nickel with copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F9/00—Making metallic powder or suspensions thereof

- B22F9/02—Making metallic powder or suspensions thereof using physical processes

- B22F9/06—Making metallic powder or suspensions thereof using physical processes starting from liquid material

- B22F9/08—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying

- B22F9/082—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying atomising using a fluid

- B22F2009/0824—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying atomising using a fluid with a specific atomising fluid

- B22F2009/0828—Making metallic powder or suspensions thereof using physical processes starting from liquid material by casting, e.g. through sieves or in water, by atomising or spraying atomising using a fluid with a specific atomising fluid with water

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2998/00—Supplementary information concerning processes or compositions relating to powder metallurgy

- B22F2998/10—Processes characterised by the sequence of their steps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F2999/00—Aspects linked to processes or compositions used in powder metallurgy

Definitions

- the invention concerns atomised iron based powders having good high temperature oxidation resistance, more particular powders which are pre-alloyed with chromium and aluminium.

- FeCrAl-alloys Conventional iron based alloys containing typically Fe and 10-30% Cr and 1-10% A1, so-called FeCrAl-alloys, have been found highly useful in various high temperature applications, due to their good oxidation resistance and can be used at temperatures as high as 1200-1400 DEG C. Thus, such materials have been used in the production of electrical resistance elements and as carrier materials in motor vehicle catalysts. As a result of its aluminium content, the alloy is able to form at high temperatures and in the majority of atmospheres an impervious and adhesive surface oxide consisting substantially of A1203. This oxide protects the metal against further oxidation and also against many other forms of corrosion, such as carburization, sulphuration etc.

- US5970306 describes a method for manufacturing high temperature resistant shaped parts from a FeCrAl-powder by hot isostatically pressing (HIP).

- HIP hot isostatically pressing

- DE4235141 descibes a method of producing a part made from hot pressed powder based on a FeCrAl-alloy in which the powder is initially exposed to an oxygen-contg. atmos. to produce an chromium oxide protective layer around the particles.

- US6761751 describes a method of producing an FeCrAl material by gas atomization, wherein in addition to containing iron (Fe), chromium (Cr) and aluminium (Al) the material also contains minor fractions of one or more of the materials molybdenum (Mo), hafnium (Hf), zirconium (Zr), yttrium (Y), nitrogen (N), carbon (C) and oxygen (O).

- JP8120435 relates to a thermal spray material/powder comprising by weight 1 -15% of Cu, 4-10 % Al, 7-20 % of Cr and 0.02-2 % of at least one rare earth element and the balance Fe with inevitable impurities, for spraying the inner face of glass moulds for providing heat resistance.

- This object is to provide a method of producing a sintered component comprising providing an atomised iron based powder pre-alloyed with 10,5-30 wt% Cr, 3-15 wt% Al and 5-20 wt% Cu.

- pre-alloying the powder with Cu it is possible to sinter a component in conventional sintering processes and maintaining satisfactory material properties of the sintered component which component also have excellent high temperature oxidation resistance.

- an iron based powder pre-alloyed with 10,5-30 wt% Cr, 3-15 wt% All, 5-20 wt% Cu and 8-20 wt% Ni is proposed.

- the powders of the invention are preferably produced by providing a melt of iron and the alloying elements, water atomizing the melt whereby the powder forms from atomized droplets upon solidification.

- a sintered component can be produced from the powders of the invention by a) providing a sintering material comprising the powder of the invention; b) forming a green body from the sintering material; and c) sintering the green body in a reducing or neutral atmosphere, at an atmospheric pressure or below, and at a temperature above 1100°C.

- the sintering material could e.g. be loose sintered, cold compacted or warm compacted.

- the sintering material is a mixture between a binder and/or a lubricant with the powder of the invention.

- Cold compaction is performed at temperatures below 100°C, preferably at a compaction pressure within the range of 100 -1000 MPa.

- Warm compaction is performed at temperatures within the range of 100-200 °C, preferably at a compaction pressure within the range of 300 -1000 MPa.

- the sintering material could be a mixture between a binder and/or a lubricant with the powder of the invention, but also the powder it self i.e. without mixing the powder with a binder and/or a lubricant.

- the sintering material could be poured into a form where after the form containing the sintering material is inserted into the sintering furnace. For instance filters having excellent high temperature oxidation resistance can be produced by loose sintering the powder of the invention.

- a sintered component which exhibits excellent high temperature oxidation resistance may be produced from the powder of the invention which sintered component has a sintered density above 6,5 g/cm 3 , a tensile strength above 500 MPa and a yield strength above 400 MPa.

- the invention concerns pre-alloyed iron based powders comprising more than 10,5 wt% chromium, as well as certain amounts of aluminium and copper.

- FeCrAl-alloys have been shown to exhibit excellent oxidation resistance at high temperatures, but are unfortunately difficult to sinter under atmospheric pressure or below (vacuum). That is the reason why compounds based on FeCrAl powders are produced by the HIP- process (as described in e.g. US5970306 ).

- pre-alloying with copper was reduced with an improved sintered structure as the outcome - compared to a reference material without copper.

- the copper content is shown to facilitate the formation of sintering necks as can be seen from the accompanying metallographic pictures. We believe that this effect occurs due to a break-up of the aluminium oxide layer by iiquidised copper. Admixing copper and a FeCrAl-powder were also tested but sintering did not significantly improve in that case.

- the powders of the invention are made by making a melt of iron and the desired alloying elements.

- the melt is thereafter atomised whereby the powder is formed from the atomized droplets upon solidification.

- the atomization is performed according to conventional technology, e.g. gas or water atomization.

- the melt blend is water atomized, since a water atomised powder is easier to compact than a gas atomized powder.

- the powder forms due to the water atomization the powder is oxidized and thin chromium and aluminium oxide layers forms on the surface of the powder particles.

- the aluminium content should be above 3%, preferably the aluminium content should be above 5%, in order to obtain the desired oxidation resistance.

- the upper limit for the aluminium content is set to 15 wt%, and in fact it is preferred to have the aluminium content below 12 wt%.

- the boundaries for the copper content were derived from the tests described below. Accordingly it the copper content should be above 5 wt% to facilitate the formation of sintering necks and providing a sintered component having good high temperature oxidation resistance. Further the Cu-content should be below 20 wt%, powders having higher Cu-content may very well be useful for certain applications, but they are not within the scope of the present invention.

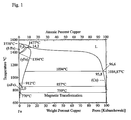

- Figure 1 shows the Fe-Cu phase diagram, but it is believed that that Cu will influence a system in a similar way.

- a certain amount of liquid phase must be formed, i.e. the area of ( ⁇ Fe +L) is of interest. Since the diagram is for the pure Fe-Cu system the information retrieved from it can only be used as a guideline.

- the amount of liquid phase formed during the sintering is required to break up the aluminium oxides but excess amounts of liquid phase collapses the structure during sintering.

- the amount of liquid phase formed is related to the chemical composition and the sintering temperature. The element having the strongest influence of the formation of liquid is copper. That is why different sintering temperatures depending of copper content of the samples were applied before the oxidation test.

- the powder can also be pre-alloyed with austenite-foming elements in particular nickel, but also the nickel equivalent manganese.

- austenite-foming elements in particular nickel, but also the nickel equivalent manganese.

- nickel is also known to have a beneficial effect on the oxidation resistance which of course is desirable in the applications intended for the powders of the invention.

- nickel is to be included in the powder it is preferred that the nickel content is in the interval of 8-20 wt%.

- Manganese can also be an additional austenite forming alloying element, preferably the manganese content is below 3 wt%.

- Cobalt is normally not used since it is comparably expensive.

- the carbon content is low, since carbon has a tendency to cause intergranular corrosion why preferably the carbon content should be less than 0,1 wt% carbon.

- the carbon content was about 0,02 wt% or lower.

- the nitrogen content is below 0,2 wt%.

- test samples and the reference sample were produced by filling a form (10mm diameter and 2mm thickness) with the powder of interest, followed by smoothing out the surface without compacting the powder. This procedure provides samples with high specific area (ca 45% porosity).

- test samples were sintered in a 100 % hydrogene atmosphere for 30 minutes at a temperature depending of the Cu content according to the following table: 5 % Cu 1150 °C 10 % Cu 1320 °C 15%Cu 1350 °C 20 % Cu 1320 °C

- the reference sample was sintered in a 100% hydrogen atmosphere for 30 minutes at 1320 °C.

- the oxidation tests were carried out in a laboratory furnace, a Lenton 12/50/300, at a temperature of 800 °C in air.

- Six samples could be tested at the same time by placing them on a sample holder and at each test run two of the samples were reference samples.

- Powder 2 and 3 were further tested at different oxidation temperatures.

- the following table shows the increase in weight relative to the reference 310B.

- Table 2 shows that difference in oxidation resistance between samples containing Cu and Al and reference samples is further pronounced at temperatures above 800 degree Celcius. Furthermore, the composition having a Al content of 5,5 % and a Cu content of 15 % seems to have better oxidation resistance compared to the composition having 10 Al and 10 % Cu.

- the table 3 shows that the density and the mechanical properties of Al- containing Cr or Cr-Ni stainless steel powders increases considerably if the powder are pre-alloyed with Cu. This indicates much improved sintering activity.

- FIG. 2A shows metallographic picture of a test bar comprising 22Cr + 5,5Al +10Cu+ bal.

- FIG 2B shows metallographic picture of a corresponding reference test bar comprising 22Cr + 5,5Al+ bal.

- FIG 3A shows metallographic picture of a test bar comprising 22Cr + 5,5Al + 18Ni + 8Cu+ bal.

- Fe and FIG 2B shows metallographic picture of a corresponding reference test bar comprising 22Cr + 5,5Al+ 18Ni + bal.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Powder Metallurgy (AREA)

- Manufacture Of Metal Powder And Suspensions Thereof (AREA)

- Electroplating And Plating Baths Therefor (AREA)

- Preventing Corrosion Or Incrustation Of Metals (AREA)

- Soft Magnetic Materials (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SE0601601 | 2006-07-21 | ||

| PCT/SE2007/050439 WO2008010767A1 (en) | 2006-07-21 | 2007-06-20 | Iron-based powder |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP2051826A1 EP2051826A1 (en) | 2009-04-29 |

| EP2051826B1 true EP2051826B1 (en) | 2011-09-21 |

Family

ID=38957027

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP07748599A Active EP2051826B1 (en) | 2006-07-21 | 2007-06-20 | Iron-based powder |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US20080019858A1 (enExample) |

| EP (1) | EP2051826B1 (enExample) |

| JP (1) | JP2009544841A (enExample) |

| CN (1) | CN101516549A (enExample) |

| AT (1) | ATE525156T1 (enExample) |

| DK (1) | DK2051826T3 (enExample) |

| ES (1) | ES2375159T3 (enExample) |

| TW (1) | TW200808982A (enExample) |

| WO (1) | WO2008010767A1 (enExample) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5384079B2 (ja) * | 2008-10-29 | 2014-01-08 | Ntn株式会社 | 焼結軸受 |

| TW201140139A (en) | 2010-03-11 | 2011-11-16 | Pacific Biosciences California | Micromirror arrays having self aligned features |

| CN102554216A (zh) * | 2012-02-07 | 2012-07-11 | 建德市易通金属粉材有限公司 | 一种水雾化铁铜合金粉末及制造方法 |

| JP6384752B2 (ja) * | 2014-07-15 | 2018-09-05 | 日立金属株式会社 | 磁心およびそれを用いたコイル部品 |

| DK3253512T3 (da) | 2015-02-03 | 2023-06-06 | Hoeganaes Ab Publ | Pulvermetalsammensætning til let maskinforarbejdning |

| CN106222566B (zh) * | 2016-08-23 | 2018-10-09 | 秦皇岛市雅豪新材料科技有限公司 | 一种超硬材料制品专用稀土调节水雾化Fe-Cu预合金粉末及其制备方法 |

| DE102018219686A1 (de) * | 2018-11-16 | 2020-05-20 | Mahle International Gmbh | Verfahren zum Herstellen eines mit Kupfer infiltrierten Ventilsitzrings |

| US20200216935A1 (en) * | 2019-01-04 | 2020-07-09 | Tenneco Inc. | Hard powder particles with improved compressibility and green strength |

| KR102352433B1 (ko) * | 2020-04-16 | 2022-01-19 | 김재곤 | 동 합금판 및 그의 제조방법 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4758272A (en) * | 1987-05-27 | 1988-07-19 | Corning Glass Works | Porous metal bodies |

| US4992233A (en) * | 1988-07-15 | 1991-02-12 | Corning Incorporated | Sintering metal powders into structures without sintering aids |

| US5292485A (en) * | 1990-04-03 | 1994-03-08 | Ngk Insulators, Ltd. | Heat-resistant metal monolith |

| JP3091246B2 (ja) * | 1990-04-03 | 2000-09-25 | 日本碍子株式会社 | 耐熱性金属質モノリス及びその製造方法 |

| JPH04116103A (ja) * | 1990-09-05 | 1992-04-16 | Daido Steel Co Ltd | 軟質磁性合金粉末 |

| US5427601A (en) * | 1990-11-29 | 1995-06-27 | Ngk Insulators, Ltd. | Sintered metal bodies and manufacturing method therefor |

| JPH08120435A (ja) | 1994-10-19 | 1996-05-14 | Nippon Steel Corp | ガラス成形金型用溶射材料およびその金型 |

| SE504208C2 (sv) * | 1995-04-26 | 1996-12-09 | Kanthal Ab | Sätt vid tillverkning av högtemperaturbeständigt formgods |

| SE513989C2 (sv) * | 2000-01-01 | 2000-12-11 | Sandvik Ab | Förfarande för tillverkning av ett FeCrAl-material och ett sådant marerial |

| PL200915B1 (pl) * | 2001-01-24 | 2009-02-27 | Federal Mogul Sintered Prod | Sposób wytwarzania wyrobu spiekanego na bazie żelaza zawierającego miedź |

| JP2005220438A (ja) * | 2004-01-06 | 2005-08-18 | Hitachi Metals Ltd | Fe−Cr−Al系磁性粉末と、Fe−Cr−Al系磁性粉末成形体およびその製造方法 |

-

2007

- 2007-06-20 ES ES07748599T patent/ES2375159T3/es active Active

- 2007-06-20 CN CNA2007800269533A patent/CN101516549A/zh active Pending

- 2007-06-20 WO PCT/SE2007/050439 patent/WO2008010767A1/en not_active Ceased

- 2007-06-20 JP JP2009520711A patent/JP2009544841A/ja active Pending

- 2007-06-20 EP EP07748599A patent/EP2051826B1/en active Active

- 2007-06-20 DK DK07748599.3T patent/DK2051826T3/da active

- 2007-06-20 AT AT07748599T patent/ATE525156T1/de not_active IP Right Cessation

- 2007-06-22 TW TW096122454A patent/TW200808982A/zh unknown

- 2007-06-25 US US11/767,643 patent/US20080019858A1/en not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| US20080019858A1 (en) | 2008-01-24 |

| EP2051826A1 (en) | 2009-04-29 |

| ATE525156T1 (de) | 2011-10-15 |

| DK2051826T3 (da) | 2012-01-09 |

| WO2008010767A1 (en) | 2008-01-24 |

| ES2375159T3 (es) | 2012-02-27 |

| TW200808982A (en) | 2008-02-16 |

| CN101516549A (zh) | 2009-08-26 |

| JP2009544841A (ja) | 2009-12-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP2051826B1 (en) | Iron-based powder | |

| US6761751B2 (en) | Method of making a FeCrAl material and such material | |

| EP1536027B1 (en) | Raw or granulated powder for sintering, and sintered compacts therefrom | |

| CA2059323C (en) | Steel powder admixture having distinct prealloyed powder of iron alloys | |

| EP2155921B1 (en) | Iron-based powder and composition thereof | |

| KR100249006B1 (ko) | 분말도금용 물분무철분및 그 제조방법 | |

| EP1077454B1 (en) | Composite magnetic material | |

| EP1042090A1 (en) | Method of manufacturing aluminide sheet by thermomechanical processing of aluminide powders | |

| EP2589450B1 (en) | Composite magnetic material and process for production thereof | |

| US20220025492A1 (en) | Metallurgical Compositions for Press-and-Sinter and Additive Manufacturing | |

| EP1522601B1 (en) | Sintered component made of stainless steel with high corrosion resistance and production method therefor | |

| EP0812925B1 (en) | Low alloy steel powders for sinterhardening | |

| JPH10102105A (ja) | 金属微粉末の製造方法 | |

| KR100768700B1 (ko) | 금속사출성형법을 이용한 합금 부품의 제조방법 및합금부품 | |

| US20090142219A1 (en) | Sinter-hardening powder and their sintered compacts | |

| WO1996005007A1 (en) | Iron-based powder containing chromium, molybdenum and manganese | |

| JPH0715121B2 (ja) | 射出成形用Fe―Co系合金微粉およびFe―Co系焼結磁性材料 | |

| JPH0257606A (ja) | ステンレス鋼微粉および焼結材料 | |

| JP2000064001A (ja) | 高強度焼結部品用混合粉 | |

| KR100978901B1 (ko) | 고인장강도 및 고경도를 가지는 철계 소결체 제조 방법 | |

| EP2045346B1 (en) | Method for producing a sintered composite sliding part | |

| EP1323840B1 (en) | Iron base mixed powder for high strength sintered parts | |

| RU2327547C1 (ru) | Способ получения порошка на железной основе (его варианты) | |

| JPH0459362B2 (enExample) | ||

| JPH026827B2 (enExample) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20090221 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK RS |

|

| 17Q | First examination report despatched |

Effective date: 20091209 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC MT NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: BA RS |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 602007017380 Country of ref document: DE Effective date: 20111124 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20110921 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 |

|

| LTIE | Lt: invalidation of european patent or patent extension |

Effective date: 20110921 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2375159 Country of ref document: ES Kind code of ref document: T3 Effective date: 20120227 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111222 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 Ref country code: AT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK05 Ref document number: 525156 Country of ref document: AT Kind code of ref document: T Effective date: 20110921 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120121 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120123 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20120622 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 602007017380 Country of ref document: DE Effective date: 20120622 |

|

| BERE | Be: lapsed |

Owner name: HOGANAS A.B. Effective date: 20120630 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120630 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120620 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120620 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20130228 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602007017380 Country of ref document: DE Effective date: 20130101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130101 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120630 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120630 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120620 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120630 Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120620 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120702 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20111221 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120702 Ref country code: MT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20110921 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20131022 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120620 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120620 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120621 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070620 |