EP1671001B1 - Serrure - Google Patents

Serrure Download PDFInfo

- Publication number

- EP1671001B1 EP1671001B1 EP04763924A EP04763924A EP1671001B1 EP 1671001 B1 EP1671001 B1 EP 1671001B1 EP 04763924 A EP04763924 A EP 04763924A EP 04763924 A EP04763924 A EP 04763924A EP 1671001 B1 EP1671001 B1 EP 1671001B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- lock

- toothed wheel

- shaft

- disposed

- lock cylinder

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000033001 locomotion Effects 0.000 claims abstract description 43

- 230000008878 coupling Effects 0.000 claims description 3

- 238000010168 coupling process Methods 0.000 claims description 3

- 238000005859 coupling reaction Methods 0.000 claims description 3

- 239000002184 metal Substances 0.000 claims description 3

- 229920002994 synthetic fiber Polymers 0.000 claims 1

- 230000005540 biological transmission Effects 0.000 abstract description 24

- 238000004519 manufacturing process Methods 0.000 description 2

- 210000001520 comb Anatomy 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B17/00—Accessories in connection with locks

- E05B17/04—Devices for coupling the turning cylinder of a single or a double cylinder lock with the bolt operating member

- E05B17/042—Devices for coupling the turning cylinder of a single or a double cylinder lock with the bolt operating member using toothed wheels or geared sectors

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B53/00—Operation or control of locks by mechanical transmissions, e.g. from a distance

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05B—LOCKS; ACCESSORIES THEREFOR; HANDCUFFS

- E05B63/00—Locks or fastenings with special structural characteristics

- E05B63/0017—Locks with sliding bolt without provision for latching

Definitions

- the invention relates to a lock with a lock cylinder which can be actuated with a key and has a driving tongue, with a push movement exporting element and with a transmission device for transmitting the movement of the driving tongue on the element to this by means of first and second means in the closed position or to move the open position, wherein the transmission means comprises a first gear rotatably disposed about the lock cylinder and rotatable with the driver tongue.

- Such locks are eg from the document EP 7395 A1 known. They are used, inter alia, to lock window or door leaf with the frame. However, these locks or the transmission devices of these locks on a variety of gears. In most cases, there are up to seven gears, which are necessary for the movement of the bolt and are used. In addition, this lock often has too large backset. Although it is quite possible that the first gear is a fully closed gear. However, the assembly is relatively expensive.

- the invention is therefore an object of the invention to provide a lock of the type mentioned, which ensures technically simple means always safe operation and at the same time has small dimensions and is inexpensive to produce.

- the essence of the invention is that, in the simplest embodiment, only three elements can be used to transmit the motion of the driver tongue to the element.

- the rotational movement induced by the driver tongue is transmitted to the first gear, which meshes with the at least second gear. Due to the movement of the first gear and the second gear and thus the shaft is set in rotation, which in turn leads to a movement of the device. Since the at least one shaft is arranged transversely to the lock cylinder axis, very small backset dimensions can also be realized for the first time.

- this second gear has a position such that a re-immerse or come into meshing engagement at least made difficult, since the corresponding teeth of the first and second gears are no longer in the designated position.

- the shaft is provided with a third gear or spindle device which has a greater distance from the second gear than the recess in the region of the free end of the driving tongue and also with the first gear combs. Since the distance between the second and third gear is greater than the recess in the region of the outer edge, meshes always one of the second and third gears with the first gear.

- the device for converting the rotational movement of the first shaft into a pushing movement of the element.

- An advantageous embodiment is given by the fact that the device has a spindle arranged on the shaft, which is in engagement with a transmission member of the element. Due to the rotation of the spindle, the transmission member, which is connected to the element, forcibly guided and also forcibly moved, so that results in a linear movement of the element.

- the transmission member insertable in an opening of the thrust movements element insertable or one of the element or latch projecting and integrally formed with this nose is.

- this nose can be arranged on almost all areas of the bolt.

- a particularly compact design results, however, when the nose is arranged at the inner end of the element or bolt.

- the device has an outer thread arranged on the shaft, which is in engagement with a threaded element arranged on the element.

- the threaded element consists of externally on the element angeodneten grooves or of an internal thread arranged in the element.

- the device consists of a shaft arranged on the thread, which is able to engage in corresponding, arranged on the element recesses.

- the device has a disk arranged on the shaft, which engages with a second spindle arranged on the element.

- the spindle is arranged on the thrust movement exporting element, and this spindle is rotated by the disc in rotation.

- the first wave is arranged virtually next to the lock cylinder.

- a second shaft is present, which is arranged transversely to both the first shaft and the lock cylinder axis and has at least the further fourth gear, that meshes with the second gear. This second shaft can then be arranged above the lock cylinder such that the second shaft then extends above the lock cylinder.

- the element is an approach, a coupling piece of a push rod or a bolt.

- the teeth of the gears There are many ways to shape the teeth of the gears. But it is advantageous if the first gear has a helical toothing and the second or third gear is formed in a helical shape.

- the shaft can be arranged in almost all areas around the lock cylinder with any but suitable orientations.

- a particularly simple arrangement but is given when the shaft is approximately perpendicular to the axis of the lock cylinder.

- the device In order to be able to induce two opposing linear movements either selectively or simultaneously with one transmission device, it is advantageous if the device is designed to transmit two counter-rotating linear movements. But this can be done e.g. be made possible by the fact that the spindle has two opposite slopes. But it is also possible that the external thread has two opposing slopes. At these components with the opposite slopes then two elements can be articulated to perform the thrust movement and thus moved.

- a further device is arranged on the shaft. This can be done simultaneously two pushing movements transmitting elements or bars are set in a linear movement.

- lock cylinder is a commercially available cylinder.

- other lock cylinders can be used as long as they have the corresponding Mit videzunge.

- the lock is made of metal or plastic or a combination thereof.

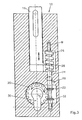

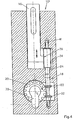

- the lock 10, 10 I , 10 II , 10 III , 10 IV and 10 V includes a lock cylinder 12 which is operable with a key.

- a Mit Economicszunge 14 is moved on a circular path to effect with a transmission device 18 is a linear movement of a thrusting motion transmitting element 16 in its closed position or its open position.

- this push-motion transmitting element is a bolt 16.

- this element 16 may also be the approach or coupling piece of a push rod or a similar movement-transmitting element.

- the transmission device 18 consists in all embodiments of a rotatable about the lock cylinder 12 and rotatable with the Mit supportivezunge 14 first gear 20.

- This first gear 20 meshes with at least one second gear 22 which is disposed on a shaft 24.

- the shaft 24 is provided with means 26, 28; 34, 36; 38, 40; 42, 44; 46, 48 provided, which puts the latch 16 in a linear or pushing movement.

- the device consists of a shaft 24 arranged on the spindle 26, in which a transmission member 28 of the bolt 16 engages.

- the spindle 26 may have two mutually opposite slopes. This is on the one hand advantageous if the linear movement or the exit of the element or bolt 16 should be designed freely selectable. On the other hand, it is also possible to move simultaneously two elements or bars 16 opposite each other linear.

- the transmission member is a projection 28 projecting from the latch 28, which is arranged at the inner end of the bolt 16.

- the nose 28 is formed integrally with the latch 16.

- the first gear 20 has a recess 30 in which the Mit Sprintunge 14 is received.

- the recess 30 has such a dimension on, the lock cylinder 12 can be pushed through this recess 30 during its assembly.

- the lock cylinder is a commercial profile cylinder 12

- the recess 30 has approximately the shape of the outer contour of the profile cylinder 12.

- all commercial cylinders and even special forms thereof can be used.

- FIGS. 1 to 4 . 6 and 8th A simpler solution is in the FIGS. 1 to 4 . 6 and 8th shown.

- This consists of a third gear 32 or according to FIG. 8 from a spindle device 32 ', which is arranged on the shaft 24 to the second gear 22 with a distance which is greater than the recess 30 in the region of the free Mit Sprintunge 14.

- the third gear 32 is arranged so that it the first gear 20 meshes. Since this distance between the second and third gears 22 and 32 or between the second gear 32 and the spindle device 32 'is greater than this clear width of the recess 30, there is at least one of the two gears 22 or 32 and the second gear 22 or the spindle device 32 'in mesh with the first gear 20.

- first to third gears 20,22 and 32 may have any suitable shapes.

- a helical toothing was selected for the first gear 20.

- the second and third gears 22 and 32 each have a bevel gear shape, with the second and third gears 22 and 32 being disposed on the shaft 24 so that their respective smaller end surfaces are aligned with each other.

- the arrangement of the shaft 24 with respect to the lock cylinder can of course be arranged depending on the desired location of engagement of the bolt 16 with the frame.

- the shaft 24 is arranged approximately perpendicular to the axis of the lock cylinder 12, approximately parallel to the vertical axis of the lock cylinder 12th

- the bolt 16 is moved in the embodiment shown in the direction of the vertical axis of the lock cylinder 12 in the desired position.

- the nose 28 is in engagement with the spindle groove of the spindle 26 and is forcibly guided with the movement of the spindle 26 in the embodiment shown depending on the direction of rotation of the shaft 24 upwards or downwards. Since the nose 28 is in this case made in one piece with the latch 16, therefore, the bolt 16 also performs a linear movement upwards or downwards.

- FIGS. 4 to 7 illustrated second to fourth embodiments will now be described essentially with respect to their differences from the first embodiment.

- the Figure 4 shows a lock 10 I , in which the means for implementing the rotational movement of the first shaft 24 in a pushing movement of the element 16 from an arranged on the shaft 24 external thread 34 which is in engagement with a member 16 arranged on the threaded element 36.

- this threaded element 36 consists of grooves 38 which mesh with the external thread 34.

- the remaining parts of this castle 10 I are identical to those of the first embodiment, so that a detailed re-description is omitted.

- the first gear 20 is set in rotation, the shaft 24 and thus also the external thread 34 rotates. Due to this rotation of the external thread 34, the grooves 38 engaged with the external thread 34 become depending on the direction of rotation of the shaft 24 forcibly guided upward or downward according to the drawing.

- This in Figure 5 illustrated third embodiment differs not only in the nature of the device, but also with respect to the transmission device 18.

- This third embodiment has a second shaft 50 which is arranged transversely to both the first shaft 24 and the lock cylinder axis S.

- This second shaft 50 has at least one fourth gear 52, which meshes with the second and third gear 22 and 32, respectively.

- the second shaft 50, a fifth gear 54, which also meshes with the first gear 20 and the fourth gear 52 has a greater distance than the inside diameter of the recess 30 is.

- the third embodiment according to Figure 5 an external thread 34.

- the element 16 is provided with an inner thread 40 arranged in a bore into which the external thread 34 engages.

- the generation of the linear or pushing movement of the element 16 follows in a similar manner as in the second embodiment.

- the fourth embodiment is in Figure 6 shown.

- This fourth embodiment has certain similarities with respect to the means for implementing the rotational movement of the shaft 24 in the linear or pushing movement of the element 16.

- the peculiarity here is that in the shaft 24 only a single thread 42 is formed, which is able to engage in corresponding arranged on the element 16 recesses 44.

- the device consists of a shaft 24 arranged on the disc 46, which is in engagement with a member 16 arranged on the second spindle 48. Due to the high frictional force between the disk 46 and the second spindle 48 to be ensured in this embodiment, rotating the disk 46 also rotates the second spindle 48, forcing it into linear motion.

- the extending portion of the element 16 can be made in one piece with the second spindle 48 or as an extra part.

- FIG. 8 a sixth embodiment of a lock 10 V is shown, which differs from the first embodiment only in that instead of the third gear 32, the spindle device 32 'is present. For the rest, reference is made to the description of the first embodiment.

- the material for the lock 10 metal or plastic or a combination thereof can be selected.

Landscapes

- Lock And Its Accessories (AREA)

- Pharmaceuticals Containing Other Organic And Inorganic Compounds (AREA)

- Hydrogenated Pyridines (AREA)

Claims (19)

- Serrure (10) avec un cylindre de fermeture (12) qui est apte à être actionné avec une clé et qui présente une patte d'entraînement (14), avec un élément (16) qui décrit un mouvement coulissant, et avec un dispositif de transmission (18) pour transmettre le mouvement de la patte d'entraînement (14) à l'élément (16) pour amener celui-ci, à l'aide d'un premier et d'un second dispositif (26, 28 ; 34, 36 ; 42, 44 ; 46, 48) dans la position de fermeture ou dans la position d'ouverture, étant précisé que le dispositif de transmission (18) présente une première roue dentée (20) disposée pour pouvoir tourner sur le cylindre (12) et apte à tourner avec la patte d'entraînement (14), et que la première roue dentée (20) présente un évidement (30) dans lequel est logée la patte d'entraînement (14), et des dimensions telles que le cylindre (12) peut passer à travers lors du montage, caractérisée en ce que le dispositif de transmission (18) présente au moins une deuxième roue dentée (22), étant précisé que soit la deuxième roue dentée (22) s'engrène avec la première roue dentée (20), soit une autre roue dentée (52) s'engrène avec les première et deuxième roues dentées, et que la deuxième roue dentée (22) est disposée sur au moins un premier arbre (24) dont l'axe (W) s'étend transversalement par rapport à l'axe (S) du cylindre de fermeture, et en ce que les premiers dispositifs (26 ; 34 ; 42 ; 46) sont disposés, fixes en rotation, sur le premier arbre (24) et sont en prise avec les seconds dispositifs (28 ; 36 ; 44 ; 48) disposés sur l'élément (16), de manière à transformer le mouvement rotatif du premier arbre (24) en mouvement coulissant de l'élément (16).

- Serrure selon la revendication 1, caractérisée en ce que le premier axe (24) est pourvu d'une troisième roue dentée (32) ou d'un dispositif à filetage (32') dont l'écartement par rapport à la deuxième roue dentée (22) est supérieur à la taille de l'évidement (30) dans la zone de l'extrémité libre de la patte d'entraînement (14), et qui s'engrène lui aussi avec la première roue dentée (20).

- Serrure selon la revendication 1, caractérisée en ce que le dispositif présente un filetage (26) qui est disposé sur l'arbre (24) et qui est en prise avec un organe de transmission (28) de l'élément (16).

- Serrure selon la revendication 3, caractérisée en ce que l'organe de transmission est constitué par une pièce d'introduction apte à être introduite dans une ouverture de l'élément qui transmet les mouvements coulissants, ou par une saillie (28) qui dépasse de l'élément ou du pêne (16) et qui est réalisée d'une seule pièce avec celui-ci.

- Serrure selon la revendication 4, caractérisée en ce que la pièce d'introduction ou la saillie (28) est disposée sur l'extrémité intérieure de l'élément ou du pêne (16).

- Serrure selon la revendication 1, caractérisée en ce que le dispositif présente un filetage extérieur (34) qui est disposé sur l'arbre (24) et qui est en prise avec un élément fileté (36) disposé sur l'élément (16).

- Serrure selon la revendication 6, caractérisée en ce que l'élément fileté se compose de rainures (38) disposées sur l'extérieur de l'élément (16) ou d'un filetage intérieur (40) disposé dans l'élément (16).

- Serrure selon la revendication 6 ou 7, caractérisée en ce que le dispositif se compose d'une spire (42) qui est disposée sur l'arbre (24) et qui peut pénétrer dans des évidements correspondants (44) disposés sur l'élément (16).

- Serrure selon la revendication 1, caractérisée en ce que le dispositif présente une plaque (26) qui est disposée sur l'arbre (24) et qui est en prise avec un deuxième filetage (48) disposée sur l'élément (16).

- Serrure selon l'une des revendications 1 à 9, caractérisée en ce qu'il est prévu un deuxième arbre (50) qui est disposé transversalement par rapport au premier arbre (24) et à l'axe (S) du cylindre de fermeture et qui présente au moins l'autre roue dentée, la quatrième roue dentée (52), qui s'engrène avec la deuxième roue dentée (22).

- Serrure selon l'une des revendications 1 à 10, caractérisée en ce que l'élément est constitué par une pièce rapportée, un élément d'accouplement d'une tige de poussée ou un pêne (16).

- Serrure selon l'une des revendications 1 à 11, caractérisée en ce que la première roue dentée (20) présente une denture hélicoïdale et les deuxième, troisième et quatrième roues dentées (22, 32, 52) sont conçues comme des roues coniques.

- Serrure selon l'une des revendications 1 à 12, caractérisée en ce que les premier et deuxième arbres (24, 50') sont à peu près perpendiculaires à l'axe du cylindre de fermeture (12).

- Serrure selon l'une des revendications 1 à 13, caractérisée en ce que le dispositif (26, 28 ; 34, 36 ; 38, 40 ; 42, 44 ; 46, 48) est conçu pour transmettre deux mouvements linéaires contraires.

- Serrure selon l'une des revendications 1 à 14, caractérisée en ce qu'un autre dispositif (26) est disposé sur l'arbre (24).

- Serrure selon l'une des revendications 1 à 15, caractérisée en ce qu'il est prévu au moins un autre dispositif de transmission (18).

- Serrure selon l'une des revendications 1 à 16, caractérisée en ce que le cylindre de fermeture est un cylindre (12) du commerce.

- Serrure selon l'une des revendications 1 à 17, caractérisée en ce que la surface de la patte d'entraînement (14) dirigée vers l'extérieur est pourvue d'une denture correspondant à la première roue dentée (20).

- Serrure selon l'une des revendications 1 à 18, caractérisée en ce qu'elle se compose de métal ou de matière plastique ou d'une combinaison des deux.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| SI200431504T SI1671001T1 (sl) | 2003-08-09 | 2004-08-09 | Ključavnica |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE20312319U DE20312319U1 (de) | 2003-08-09 | 2003-08-09 | Schloß |

| DE20313066U DE20313066U1 (de) | 2003-08-20 | 2003-08-20 | Schloß |

| PCT/EP2004/008900 WO2005014958A1 (fr) | 2003-08-09 | 2004-08-09 | Serrure |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1671001A1 EP1671001A1 (fr) | 2006-06-21 |

| EP1671001B1 true EP1671001B1 (fr) | 2010-06-16 |

Family

ID=34137348

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04763924A Expired - Lifetime EP1671001B1 (fr) | 2003-08-09 | 2004-08-09 | Serrure |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1671001B1 (fr) |

| AT (1) | ATE471422T1 (fr) |

| DE (1) | DE502004011286D1 (fr) |

| RU (1) | RU2352744C2 (fr) |

| SI (1) | SI1671001T1 (fr) |

| WO (1) | WO2005014958A1 (fr) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202010011700U1 (de) | 2010-02-17 | 2010-11-04 | Ginzel, Lothar, Dipl.-Ing. | Sicherungsvorrichtung |

| CN111963042A (zh) * | 2020-08-07 | 2020-11-20 | 马国庆 | 一种儿童金刚网防护窗 |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008052183A1 (de) * | 2008-10-17 | 2010-04-22 | Wincor Nixdorf International Gmbh | Verriegelungsvorrichtung für Wertbehälter |

| ITVI20120073A1 (it) * | 2012-03-28 | 2013-09-29 | Giancarlo Brun | Dispositivo di chiusura per serramenti e serramento comprendente tale dispositivo. |

| ITVI20120072A1 (it) * | 2012-03-28 | 2013-09-29 | Giancarlo Brun | Dispositivo di chiusura per serramenti e serramento comprendente tale dispositivo. |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US338505A (en) * | 1886-03-23 | Safe-lock | ||

| US4163375A (en) * | 1978-01-16 | 1979-08-07 | Vsi Corporation | Right angle lock |

| DE2831896C2 (de) * | 1978-07-20 | 1985-02-14 | Gretsch-Unitas Gmbh Baubeschlagfabrik, 7257 Ditzingen | Zahnradantrieb in einem schließzylinderbetätigbaren Treibstangenschloß |

| DE9212975U1 (de) * | 1992-09-27 | 1993-02-11 | Reelitz, Sigrid, 2862 Worpswede | Schubriegel mit/ohne Alarm |

| IT1303013B1 (it) * | 1998-04-16 | 2000-10-20 | Elvox Costruzioni Elettroniche | Dispositivo di blocco particolarmente studiato per essere applicato acancelli |

| DE10126909A1 (de) * | 2001-06-01 | 2002-12-12 | Huf Huelsbeck & Fuerst Gmbh | Schließvorrichtung |

-

2004

- 2004-08-09 RU RU2006106844/12A patent/RU2352744C2/ru not_active IP Right Cessation

- 2004-08-09 SI SI200431504T patent/SI1671001T1/sl unknown

- 2004-08-09 EP EP04763924A patent/EP1671001B1/fr not_active Expired - Lifetime

- 2004-08-09 DE DE502004011286T patent/DE502004011286D1/de not_active Expired - Lifetime

- 2004-08-09 WO PCT/EP2004/008900 patent/WO2005014958A1/fr active Application Filing

- 2004-08-09 AT AT04763924T patent/ATE471422T1/de active

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE202010011700U1 (de) | 2010-02-17 | 2010-11-04 | Ginzel, Lothar, Dipl.-Ing. | Sicherungsvorrichtung |

| DE202010011701U1 (de) | 2010-02-17 | 2010-11-04 | Ginzel, Lothar, Dipl.-Ing. | Sicherungsvorrichtung |

| CN111963042A (zh) * | 2020-08-07 | 2020-11-20 | 马国庆 | 一种儿童金刚网防护窗 |

Also Published As

| Publication number | Publication date |

|---|---|

| RU2352744C2 (ru) | 2009-04-20 |

| EP1671001A1 (fr) | 2006-06-21 |

| DE502004011286D1 (de) | 2010-07-29 |

| WO2005014958A1 (fr) | 2005-02-17 |

| SI1671001T1 (sl) | 2010-10-29 |

| ATE471422T1 (de) | 2010-07-15 |

| RU2006106844A (ru) | 2006-09-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1290303B1 (fr) | Serrure a barres pour systeme de fermeture | |

| AT392818B (de) | Schliesssystem | |

| EP1428959A1 (fr) | Serrure de porte de véhicule automobile | |

| AT11207U1 (de) | Kupplungsvorrichtung mit panikfunktion für elektromechanische feststellvorrichtungen | |

| CH653083A5 (de) | Tuerverschluss. | |

| EP0924369B1 (fr) | Ferrure de porte | |

| EP2133494A2 (fr) | Dispositif de verrouillage de sécurité doté d'un dispositif de déverrouillage de secours | |

| DE3833758A1 (de) | Beschlag mit einer handhabe zur betaetigung der schlossnuss eines in eine tuer od. dgl. eingesetzten schlosses | |

| EP3800315B1 (fr) | Module d'entrainement pour le deplacement d'un element de fermeture par rapport a un cadre dans une ouverture de batiment | |

| EP1671001B1 (fr) | Serrure | |

| DE9104260U1 (de) | Stangenschloß | |

| EP0598927B1 (fr) | Mécanisme d'actionnement d'une ferrure de fenêtre, porte et ouvrants similaires | |

| EP0036141B1 (fr) | Dispositif d'arrêt actionné par une clé | |

| DE4407912C2 (de) | Elektromechanisches Schloß | |

| EP2752537A2 (fr) | Agencement de ferrure | |

| EP2093356B1 (fr) | Serrure à mécanisme de verrouillage amélioré | |

| DE19526660B4 (de) | Elektromechanisches Schloß | |

| DE202016007457U1 (de) | Drehriegelschloss | |

| DE9408501U1 (de) | Schloß für Türen oder Fenster | |

| DE2917793A1 (de) | Tuerbeschlag | |

| EP0606877B1 (fr) | Ferrure pour une serrure avec un pêne demi-tour et un pêne dormant | |

| DE20312319U1 (de) | Schloß | |

| DE69807801T2 (de) | Verriegelungsvorrichtung, insbesondere Einsteckschloss für den Flügel einer Tür oder eines Fensters | |

| DE20313066U1 (de) | Schloß | |

| EP1024240B1 (fr) | Dispositif de verrouillage |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20060224 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| DAX | Request for extension of the european patent (deleted) | ||

| 17Q | First examination report despatched |

Effective date: 20070329 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP Ref country code: CH Ref legal event code: NV Representative=s name: E. BLUM & CO. AG PATENT- UND MARKENANWAELTE VSP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502004011286 Country of ref document: DE Date of ref document: 20100729 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20100616 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100616 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100616 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100616 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100917 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100616 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100616 Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100616 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100616 |

|

| BERE | Be: lapsed |

Owner name: NIEMANN, HANS DIETER Effective date: 20100831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100616 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100616 Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20101018 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100616 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20101028 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100831 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100616 |

|

| 26N | No opposition filed |

Effective date: 20110317 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R097 Ref document number: 502004011286 Country of ref document: DE Effective date: 20110316 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100831 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502004011286 Country of ref document: DE Owner name: ROTO GLUSKE-BKV GMBH, DE Free format text: FORMER OWNER: HANS DIETER NIEMANN, 50169 KERPEN, DE Effective date: 20110705 Ref country code: DE Ref legal event code: R081 Ref document number: 502004011286 Country of ref document: DE Owner name: ROTO GLUSKE-BKV GMBH, DE Free format text: FORMER OWNER: NIEMANN, HANS DIETER, 50169 KERPEN, DE Effective date: 20110705 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20110824 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20110812 Year of fee payment: 8 Ref country code: GB Payment date: 20110819 Year of fee payment: 8 Ref country code: FR Payment date: 20110901 Year of fee payment: 8 Ref country code: SI Payment date: 20110727 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20110823 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100809 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100616 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20101217 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100616 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 471422 Country of ref document: AT Kind code of ref document: T Effective date: 20120809 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120809 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120831 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120831 |

|

| REG | Reference to a national code |

Ref country code: SI Ref legal event code: KO00 Effective date: 20130313 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20130430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120810 Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120809 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120809 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130301 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120809 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120831 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 502004011286 Country of ref document: DE Effective date: 20130301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100916 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20100927 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502004011286 Country of ref document: DE Representative=s name: DRAUDT, AXEL, DIPL.-ING., DE |