EP1559845B1 - Verfahren zur Herstellung eines Dämmstoffelementes und Dämmstoffelement - Google Patents

Verfahren zur Herstellung eines Dämmstoffelementes und Dämmstoffelement Download PDFInfo

- Publication number

- EP1559845B1 EP1559845B1 EP05001906A EP05001906A EP1559845B1 EP 1559845 B1 EP1559845 B1 EP 1559845B1 EP 05001906 A EP05001906 A EP 05001906A EP 05001906 A EP05001906 A EP 05001906A EP 1559845 B1 EP1559845 B1 EP 1559845B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- web

- mineral fibers

- supporting layer

- woven web

- major surface

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims description 22

- 238000004519 manufacturing process Methods 0.000 title claims description 19

- 229910052500 inorganic mineral Inorganic materials 0.000 title abstract 2

- 230000008569 process Effects 0.000 title description 4

- 239000011707 mineral Substances 0.000 title 1

- 239000002557 mineral fiber Substances 0.000 claims abstract description 85

- 239000011491 glass wool Substances 0.000 claims abstract description 10

- 239000011490 mineral wool Substances 0.000 claims abstract description 8

- 239000000203 mixture Substances 0.000 claims abstract description 7

- 239000000835 fiber Substances 0.000 claims description 39

- 239000011810 insulating material Substances 0.000 claims description 32

- 239000011230 binding agent Substances 0.000 claims description 28

- 239000002131 composite material Substances 0.000 claims description 10

- -1 polypropylene Polymers 0.000 claims description 7

- 238000003475 lamination Methods 0.000 claims description 6

- 239000000155 melt Substances 0.000 claims description 6

- 239000000126 substance Substances 0.000 claims description 6

- 238000000926 separation method Methods 0.000 claims description 5

- 229910052782 aluminium Inorganic materials 0.000 claims description 4

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 4

- 239000004744 fabric Substances 0.000 claims description 3

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 claims 2

- 239000004952 Polyamide Substances 0.000 claims 2

- 239000004698 Polyethylene Substances 0.000 claims 2

- 239000004743 Polypropylene Substances 0.000 claims 2

- 239000004411 aluminium Substances 0.000 claims 2

- 239000004760 aramid Substances 0.000 claims 2

- 229920003235 aromatic polyamide Polymers 0.000 claims 2

- 229910052799 carbon Inorganic materials 0.000 claims 2

- 239000011521 glass Substances 0.000 claims 2

- 229920002647 polyamide Polymers 0.000 claims 2

- 229920000573 polyethylene Polymers 0.000 claims 2

- 229920001155 polypropylene Polymers 0.000 claims 2

- KKEYFWRCBNTPAC-UHFFFAOYSA-L terephthalate(2-) Chemical compound [O-]C(=O)C1=CC=C(C([O-])=O)C=C1 KKEYFWRCBNTPAC-UHFFFAOYSA-L 0.000 claims 2

- 239000002759 woven fabric Substances 0.000 claims 2

- 238000005299 abrasion Methods 0.000 claims 1

- 238000009413 insulation Methods 0.000 abstract description 24

- WSFSSNUMVMOOMR-UHFFFAOYSA-N Formaldehyde Chemical compound O=C WSFSSNUMVMOOMR-UHFFFAOYSA-N 0.000 abstract description 6

- 229920001807 Urea-formaldehyde Polymers 0.000 abstract description 3

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 abstract description 2

- 239000007767 bonding agent Substances 0.000 abstract 2

- 239000000463 material Substances 0.000 description 13

- 241000446313 Lamella Species 0.000 description 8

- 230000006835 compression Effects 0.000 description 8

- 238000007906 compression Methods 0.000 description 8

- 230000001070 adhesive effect Effects 0.000 description 7

- 239000010408 film Substances 0.000 description 7

- 239000000853 adhesive Substances 0.000 description 6

- 238000005452 bending Methods 0.000 description 6

- 239000004745 nonwoven fabric Substances 0.000 description 5

- 239000004033 plastic Substances 0.000 description 5

- 229920003023 plastic Polymers 0.000 description 5

- 238000010030 laminating Methods 0.000 description 4

- 239000007787 solid Substances 0.000 description 4

- 238000009987 spinning Methods 0.000 description 4

- 239000000654 additive Substances 0.000 description 3

- 230000008901 benefit Effects 0.000 description 3

- 238000005520 cutting process Methods 0.000 description 3

- 239000011888 foil Substances 0.000 description 3

- BPQQTUXANYXVAA-UHFFFAOYSA-N Orthosilicate Chemical compound [O-][Si]([O-])([O-])[O-] BPQQTUXANYXVAA-UHFFFAOYSA-N 0.000 description 2

- 239000012876 carrier material Substances 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 239000006185 dispersion Substances 0.000 description 2

- 239000000428 dust Substances 0.000 description 2

- 238000000227 grinding Methods 0.000 description 2

- 239000012774 insulation material Substances 0.000 description 2

- 229910052751 metal Inorganic materials 0.000 description 2

- 239000002184 metal Substances 0.000 description 2

- 238000010327 methods by industry Methods 0.000 description 2

- 230000036961 partial effect Effects 0.000 description 2

- 230000002829 reductive effect Effects 0.000 description 2

- 238000004804 winding Methods 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000001133 acceleration Effects 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 239000002969 artificial stone Substances 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 229910052810 boron oxide Inorganic materials 0.000 description 1

- 239000004566 building material Substances 0.000 description 1

- 239000007795 chemical reaction product Substances 0.000 description 1

- 239000003795 chemical substances by application Substances 0.000 description 1

- 238000005253 cladding Methods 0.000 description 1

- 238000005056 compaction Methods 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 239000002826 coolant Substances 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000011143 downstream manufacturing Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000003628 erosive effect Effects 0.000 description 1

- 238000007667 floating Methods 0.000 description 1

- 230000004907 flux Effects 0.000 description 1

- SLGWESQGEUXWJQ-UHFFFAOYSA-N formaldehyde;phenol Chemical compound O=C.OC1=CC=CC=C1 SLGWESQGEUXWJQ-UHFFFAOYSA-N 0.000 description 1

- 239000012634 fragment Substances 0.000 description 1

- 239000003365 glass fiber Substances 0.000 description 1

- 150000004676 glycans Chemical group 0.000 description 1

- 229910052602 gypsum Inorganic materials 0.000 description 1

- 239000010440 gypsum Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000000265 homogenisation Methods 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000002955 isolation Methods 0.000 description 1

- 238000005304 joining Methods 0.000 description 1

- 238000003754 machining Methods 0.000 description 1

- 230000008018 melting Effects 0.000 description 1

- 238000002844 melting Methods 0.000 description 1

- 239000002480 mineral oil Substances 0.000 description 1

- 239000004570 mortar (masonry) Substances 0.000 description 1

- 239000003921 oil Substances 0.000 description 1

- MOWNZPNSYMGTMD-UHFFFAOYSA-N oxidoboron Chemical class O=[B] MOWNZPNSYMGTMD-UHFFFAOYSA-N 0.000 description 1

- 230000002093 peripheral effect Effects 0.000 description 1

- 229920001568 phenolic resin Polymers 0.000 description 1

- 239000011505 plaster Substances 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 229920006255 plastic film Polymers 0.000 description 1

- 229920000058 polyacrylate Polymers 0.000 description 1

- 229920001282 polysaccharide Polymers 0.000 description 1

- 239000005017 polysaccharide Substances 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 239000000047 product Substances 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 229920005989 resin Polymers 0.000 description 1

- 239000011347 resin Substances 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 239000003238 silicate melt Substances 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 239000004575 stone Substances 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 230000003746 surface roughness Effects 0.000 description 1

- 229920001169 thermoplastic Polymers 0.000 description 1

- 229920001187 thermosetting polymer Polymers 0.000 description 1

- 239000004416 thermosoftening plastic Substances 0.000 description 1

- 238000009827 uniform distribution Methods 0.000 description 1

- 238000009423 ventilation Methods 0.000 description 1

- 210000002268 wool Anatomy 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H13/00—Other non-woven fabrics

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4209—Inorganic fibres

- D04H1/4218—Glass fibres

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/42—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties characterised by the use of certain kinds of fibres insofar as this use has no preponderant influence on the consolidation of the fleece

- D04H1/4209—Inorganic fibres

- D04H1/4218—Glass fibres

- D04H1/4226—Glass fibres characterised by the apparatus for manufacturing the glass fleece

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/58—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by applying, incorporating or activating chemical or thermoplastic bonding agents, e.g. adhesives

- D04H1/64—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by applying, incorporating or activating chemical or thermoplastic bonding agents, e.g. adhesives the bonding agent being applied in wet state, e.g. chemical agents in dispersions or solutions

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/70—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres characterised by the method of forming fleeces or layers, e.g. reorientation of fibres

- D04H1/74—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres characterised by the method of forming fleeces or layers, e.g. reorientation of fibres the fibres being orientated, e.g. in parallel (anisotropic fleeces)

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/62—Insulation or other protection; Elements or use of specified material therefor

- E04B1/74—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls

- E04B1/76—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls specifically with respect to heat only

- E04B1/7654—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls specifically with respect to heat only comprising an insulating layer, disposed between two longitudinal supporting elements, e.g. to insulate ceilings

- E04B1/7658—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls specifically with respect to heat only comprising an insulating layer, disposed between two longitudinal supporting elements, e.g. to insulate ceilings comprising fiber insulation, e.g. as panels or loose filled fibres

- E04B1/7662—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls specifically with respect to heat only comprising an insulating layer, disposed between two longitudinal supporting elements, e.g. to insulate ceilings comprising fiber insulation, e.g. as panels or loose filled fibres comprising fiber blankets or batts

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

- E04B9/04—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation comprising slabs, panels, sheets or the like

- E04B9/045—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation comprising slabs, panels, sheets or the like being laminated

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B1/00—Constructions in general; Structures which are not restricted either to walls, e.g. partitions, or floors or ceilings or roofs

- E04B1/62—Insulation or other protection; Elements or use of specified material therefor

- E04B1/74—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls

- E04B1/76—Heat, sound or noise insulation, absorption, or reflection; Other building methods affording favourable thermal or acoustical conditions, e.g. accumulating of heat within walls specifically with respect to heat only

- E04B2001/7683—Fibrous blankets or panels characterised by the orientation of the fibres

Definitions

- the invention relates to a method for producing an insulating element made of binders bound mineral fibers, in particular rockwool and / or glass wool, wherein the mineral fibers are produced from a melt and deposited on a conveyor as a primary web, the primary web stabilized perpendicular to its longitudinal extent and as a secondary web with a core region having a course of mineral fibers substantially perpendicular or steep to the large surfaces, and at least one edge zone with a course of Mineralfasem substantially parallel to the large surfaces deposited on a second conveyor and fed to a curing oven for curing of the binder and subsequently dividing the secondary nonwoven by a separating cut parallel to the large surfaces of the secondary nonwoven into at least two insulating material webs and applying a carrier layer to at least one large surface becomes.

- the invention further relates to an insulation web made of mineral fibers bound with a binder, in particular of mineral wool and / or glass wool, prepared by the process consisting of a large surface having secondary nonwoven with a core region of a course of mineral fibers substantially at right angles or steeply to the large Having surfaces, with a large surface area and a resulting in dividing a secondary nonwoven web in two insulating material separating surface, wherein the Mineralfasem in the region of the separation surface perpendicular to the separation surface and in the region of the surface at an angle deviating from 90 ° to the large surface, in particular parallel to the large surface are arranged running, and with a lamination

- Insulating materials made of vitreous solidified mineral fibers are classified according to the chemical composition commercially available in glass wool and rock wool insulation materials. Both varieties differ in the chemical composition of the mineral fibers.

- the glass wool fibers are made from silicate melts that contain high levels of alkalis and boron oxides that act as fluxes. These melts have a wide processing range can be and with the help of rotating bowls whose walls have holes, take off to relatively smooth and long Mineralfasem, which are usually at least partially bound with mixtures of thermosetting phenol-formaldehyde and urea resins.

- the proportion of these binders in the glass wool insulating materials is for example about 5 to about 10% by mass and is also limited by the fact that the character of a non-combustible insulating material is to be preserved.

- the bond can also be made with thermoplastic binders such as polyacrylates.

- the pulp is added to other substances such as oils in amounts below about 0.4% by mass for hydrophobing and dust binding.

- the impregnated with binders and other additives mineral fibers are collected as fiber web on a slow-speed conveyor. In most cases, the mineral fibers of several fiberizing devices are deposited one after the other on this conveyor. The mineral fibers are oriented largely directionless in one plane. But they store very flat on top of each other. By slight vertical pressure, the fiber web is compressed to the desired thickness and the conveying speed of the conveyor simultaneously to the required density and the binder cured in a curing oven by means of hot air, so that the structure of the fiber web is fixed.

- the primary nonwoven consists of relatively coarse fiber flakes, in the core areas of which higher binder concentrations are present, while in the peripheral areas weaker or non-bonded mineral fibers predominate.

- the mineral fibers are aligned in the fiber flakes approximately in the transport direction.

- Stone wool insulation have contents of binders of about 2 to about 4.5% by mass. With this small amount of binders, only part of the mineral fibers are in contact with the binders.

- the binders used are predominantly mixtures of phenol, formaldehyde and urea resins. Some of the resins are already substituted by polysaccharides.

- Inorganic binders are used as for the glass wool insulating materials only for special applications of insulating materials, as they are much more brittle than the largely elastic to plastic plastic reacting organic binder, which meets the desired character of insulating materials from Mineralfasem as elastic-springy building materials.

- the additives used are mostly high-boiling mineral oils in proportions of 0.2% by mass, in exceptional cases also about 0.4% by mass.

- the primary nonwovens are deposited by means of a pendulum-suspended conveyor transversely across another conveyor, which allows the production of an endless fibrous web consisting of a plurality of obliquely superimposed individual layers.

- a pendulum-suspended conveyor transversely across another conveyor, which allows the production of an endless fibrous web consisting of a plurality of obliquely superimposed individual layers.

- the forces acting on the fiber web cause binder-rich core zones are compacted and unfolded into narrow lamellae, resulting in main folds with folds in flanks.

- the less bound or binder-free mineral fibers in the interstices of the folds and between the lamellae are slightly rolled and slightly compressed.

- the fine structure thus consists of relatively stiff slats, which have a certain flexibility due to their numerous folds, but are relatively stiff parallel to the folding axes and form spaces which are easily compressible.

- the compressive strength and the transverse tensile strength of the fibrous web clearly increase in comparison with a normal, in particular extremely flat, arrangement of the mineral fibers.

- the flexural strength of the fibrous web or of the sections separated from it in the form of plates or Dämmfilzen is therefore significantly higher in the transverse direction than in the production direction.

- the bending strength in the transverse direction on the order of three to four times as high as the bending strength in the production direction.

- Lamellae are usually 50 mm to 200 mm wide and 10 mm to 140 mm thick insulating material elements that are cut off in the direction of production by an at least correspondingly thick fiber web.

- the mineral fibers in the fiber web or in the particularly solid lamellae are oriented at right angles to the cut surfaces, which are now the large surfaces of the lamellae.

- Slats with densities of more than about 75 kg / m 3 are therefore suitable as tensile and pressure resistant insulating layer on the outer walls of buildings and can be glued on the outer wall and then plastered with a reinforced plaster layer.

- Such insulation is referred to as a thermal insulation composite system.

- the pressure-resistant lamella is sufficiently flexible in the longitudinal direction so that it can also be glued onto curved components.

- Slat plates in the bulk density range of about 30 to about 100 kg / m 3 , preferably ⁇ 60 kg / m 3 are separated in the desired thickness in the production direction as lamellae of between about 75 to 250 mm thick fiber web lying flat transverse be glued to a closed carrier material.

- the individual slats are pressed together only under slight pressure and usually form no closed insulation layer.

- the specific amounts of, for example, dispersion adhesives are very low.

- process engineering Bonding foils for example, can be even more easily connected to the surface of the lamellae by heating a foil layer, which in many cases is only about 0.03 to 0.06 mm thick.

- slat plates can also be made from glass wool fiber webs with mineral fibers extending at right angles to the large surfaces.

- the smooth Mineralfasem are directed in these lamellae pronounced parallel to each other and very easy to compress against lateral forces, especially since the bulk densities are generally lower than that of the lamella plates made of rock wool insulation materials.

- Lamellae can also be used to produce lamellar webs having widths of, for example, 500 mm or 1000 mm, thicknesses of approximately 20 mm to approximately 100 mm and lengths of several meters. Due to the orientation of the Mineralfasem perpendicular to the large surfaces can be flat surfaces, for example, provided by large ventilation ducts with a flat and relatively strong insulation layer.

- the lamella webs are compressible and can therefore in the direction of the width of the slats, i. in the longitudinal direction of the slat webs are easily performed around pipelines with small diameters and there give a uniform sheath. This behavior is favored by the joints between the individual lamellae, since here the transverse stiffening of the insulating material is interrupted.

- the lamellae of the lamellar webs are arranged on a carrier layer and connected to the carrier layer, in particular adhesively bonded.

- a carrier layer in particular metal, metal-plastic composite or metal-paper-plastic composite films are used, which may be supplemented by mesh scrims of different types of fibers.

- the slat webs that can be produced from individual slats are limited in terms of their material thickness by the weight of the slats and, among other things, by the weight of the slats, limited adhesive strength on the carrier layer and by the maximum material thickness of the secondary web.

- the lamellae are disc-wise of a mineral fiber web prepared in the usual way, in particular separated a secondary non-woven and adhered with one of the two cut surfaces on the support layer, so that the lamellae and thus the lamellae have a course of the individual Mineralfasem exactly right angles or at steep angles to the cut surfaces of the lamellae and thus the large surfaces of the lamella web.

- the lamellae Depending on the bulk density and the binder contents, the lamellae have a comparatively high transverse tensile strength and at the same time a high compressive strength, so that the lamellae are compressible and in particular compressible in the longitudinal direction of the lamella web.

- Laminated sheets with gross densities of up to approx. 60 kg / m 3 are therefore also used to insulate round components such as pipes, containers and other shaped surfaces. Due to their sufficiently high compressive strength, even roundness or flatness, lamellar sheets can also wear clothing, for example made of thin sheets, free of thermal bridges, without further support structures.

- the mineral fibers oriented at right angles or radially in the case of pipes to the insulated surfaces lead to an increase in the thermal conductivity of the insulating materials compared with insulating materials which have a laminar fiber structure or against pipe shells in which the mineral fibers are arranged concentrically around the central axis of the pipeline.

- lamellae The production of lamellae is complicated in terms of process engineering and leads to a low throughput speed of the production plants.

- the bonding technique is also substantially unsuitable for the partly heavy weight slats.

- An adhesive bond between adjacent lamellae can also be weakened by loose mineral fibers or mineral fiber fragments (dust) being present in the region of the adhesive surfaces.

- Laminated lanes are rolled up tightly for storage and transport and wrapped in a covering.

- the lamellae are stressed at the beginning and at the end of a role strong on shear. After unrolling these slats fall off easily.

- the lamellae are even thrown off when the lamella web is allowed to unroll itself after removal of the sheaths by the action of the large restoring forces.

- Austrollvorgang the end of the role whipping like a whip through the air, so that already partially detached lamellae are completely replaced by the acceleration or the strong impact of the end on the ground.

- carrier layers which are only partially glued to the lamellae are largely eliminated. These include, for example, mesh fabric made of glass fibers or similar planar structures.

- the lamella plates glued as individual elements have the processing technology advantage that necessary separating cuts can either be performed along the transverse joints between adjacent lamellae or at least serve as an auxiliary line for the guidance of a cutting tool.

- the transverse joints can also be marked as a kink on the carrier layer to adapt by folding the slats, the slats in size with respect to the installation conditions.

- a much more economical method for the production of insulating materials with the characteristic of lamellae, lamellar plates or lamellar sheets orientation of the mineral fibers is in the EP 0 741 827 B1 described.

- a thin primary nonwoven is unfolded by an up and down moving conveyor and placed endlessly and looped on a second conveyor. This creates individual layers which are pressed against each other in the horizontal direction and are compressed differently depending on the desired density of density.

- the primary fleece is guided between two pressure-resistant bands, which initially limit only the height of the primary fleece.

- the mineral fibers are aligned in the arcuately deflected tracks of the primary web parallel to boundary surfaces. To obtain largely flat surfaces, the primary nonwoven can also be actively compressed in the vertical direction.

- This orientation of the mineral fibers in the primary non-woven can be done in a separate device, but is suitably made in conjunction with a curing oven.

- the endless fibrous web between two pressure belts, of which at least one is movable in the vertical direction flows through hot air in the vertical direction.

- the printing tapes have pressure-resistant elements with holes in which surface areas of the fiber web press, whereby the surfaces are profiled. In the two surfaces of the fiber web may lead to a further alignment of the mineral fibers, a further compression compared to the underlying areas and possibly to a slight binder enrichment.

- the fibrous web with the binding and / or impregnating agents contained therein is heated, so that moisture present in the fibrous web is expelled and the binders cure, in which they form connecting films or solids.

- After fixation of the fibrous web by solidification of the binder is shown in longitudinal section a structure in which the mineral fibers are oriented in the core of the primary web predominantly perpendicular to the large surfaces of the endless fiber web.

- the mineral fibers are aligned parallel to the large surfaces. Because of the relatively high stiffness of the core of the primary web, the mineral fibers can also be compressed in a mushroom-like manner with correspondingly large vertical pressures and / or pressed downwards between the zones having mineral fibers running at right angles to the large surfaces. Between the arcuately deflected paths of the primary web generally remain small gussets that occur as different widths and different depths transverse grooves in the two major surfaces of the endless fiber web.

- the higher-density zones with the mineral fibers running at right angles to the large surfaces differ significantly from the intermediate zones with a flat arrangement of the mineral fibers.

- the structure In cross-section, the structure is less uniform than in insulation boards used to make fins. For example, the bending tensile strength is lower because of the inhomogeneity of the structure at a comparable density.

- the EP 0 867 572 A2 further describes an insulating element made of mineral fibers, consisting of a mineral fiber fleece and / or a plurality of interconnected lamellae and at least one applied on a main surface lamination in the form of a film.

- This insulating element thus consists of a thin uniform fiber web of flat superimposed and interconnected individual mineral fibers with a thickness of less than 15 mm and a lamination and several interconnected slats. The lamination can be applied both on the thin fiber web and on the lamellae.

- Strength increase may be in the in the EP 0 741 827 B1 as well as in the DD 248 934 A3 described method that the passing of the curing oven, the topmost, a few microns to millimeters thick zone of the fiber web is more compacted and enriched with binders, as the immediately underlying zones.

- a firmer contact with the lamination can be made, although the decisive for the use of transverse tensile strength of the fiber web is primarily influenced by the lower-lying zones.

- a device and a method for producing an insulating material from a strip-shaped nonwoven material in which the non-woven fibers are provided with a curable binder.

- the strip-shaped nonwoven material is first wave-compacted and then heated to cause the compound of the fibers of the non-woven material.

- the nonwoven material is divided centrally by means of a band saw arranged transversely to a conveying direction, so that two nonwoven strips are formed, each with adjacently arranged, U-shaped fiber arrangements.

- the insulating material can be preferably used for the isolation of pipes and other curved components with almost any diameter.

- the invention has the object of developing a method for producing an insulating element, and an insulating element such that, in a simple and inexpensive manner an insulating element can be manufactured which has improved strength characteristics as well as improved thermal conductivity so that the insulating element can be used both in the field of insulation of building facades as well as in the range of curved surfaces.

- the large surface to be joined to the carrier layer is made flat by removing protrusions and / or unevenness after passing through the curing oven before applying the carrier layer.

- an insulating element according to the invention is provided for solving the problem that a support layer is disposed on a smooth formed large surface of the secondary web and that the support layer is mounted on the large surface.

- insulating elements can be produced, which has a profile of a portion of Mineralfasem parallel to the large surfaces, whereby the heat transfer is reduced by the insulating material in the direction perpendicular to the large surfaces.

- mineral fibers aligned at right angles to these mineral fibers ie mineral fibers oriented in the main direction of the transmission heat losses, increase the thermal conductivity.

- These mineral fibers running at right angles to the large surfaces increase the transverse tensile and compressive strength of the insulating material and reduce the rigidity parallel to the large surfaces.

- the secondary web is machined after passing through the curing oven in the region of its with the support layer, for example, by the surface is abraded to eliminate protrusions and / or bumps.

- the surface is abraded to eliminate protrusions and / or bumps.

- mineral fibers whose orientation is not parallel or perpendicular to the large surface are removed.

- mineral fibers are cut away to a predetermined depth with at least one cut parallel to the large surfaces. Subsequently, a grinding process can be provided, with which the required surface roughness is set.

- the process according to the invention can be carried out immediately after the passage of the curing oven.

- both large surfaces of the secondary nonwoven fabric are processed and provided with a carrier layer before the secondary nonwoven fabric is subsequently divided into sections parallel and perpendicular to the large surfaces.

- the secondary nonwoven fabric can first be divided into sections by cuts made parallel to and at right angles to the large surfaces, in particular with saws or lasers, which sections are subsequently machined and adhesively bonded to carrier layers and then rolled up or stored flat on, for example, pallets.

- the region of the edge zone in which the mineral fibers are arranged flat or running at small angles to the large surface are partially or completely removed.

- the bending ability and compressibility of the secondary web or of the insulating element produced therefrom is increased in its longitudinal axis direction.

- An insulating element produced according to this invention is preferably suitable for insulating smooth curved surfaces, such as, for example, pipelines, due to the fact that, in the region of the large surface opposite the large surface area formed with the carrier layer, generally unclad large surface perpendicularly oriented mineral fibers.

- the compressibility of the insulating element in the region of the large surface with an orientation of the mineral fibers perpendicular to the large surface can be increased according to a further feature of the invention in that the secondary nonwoven or the insulating element is pre-compressed during rolling and thereby elasticized.

- the insulating element according to the invention can be covered with a lining, for example with a cover made of a thin sheet metal, wherein the cladding preferably on the large surfaces with the parallel thereto Mineral fibers is arranged so that the slightly compressible outer edge zone below the support layer can elastically resiliently adapt to the inner surface of the panel.

- the elasticity of the insulating element can be used to isolate for the arrangement of insulating elements in a small distance from each other arranged pipes.

- the elasticity of the insulation elements according to the invention is used in the contact areas.

- in at least one large surface in particular in the surface connected to the carrier layer are preferably introduced prior to winding, in particular at right angles to the longitudinal axis of the secondary web incisions and / or recesses.

- Such trained insulating elements have the advantage that their elasticity is improved, so that they are rollable or windable even with larger material thicknesses and associated greater rigidity. Also, this insulation elements could be used by this design for the insulation of objects with highly curved surfaces.

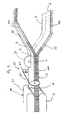

- FIG. 1 shows the first section of a plant 1 for producing a sheet-like insulating element 2 (FIG. 2) from mineral fibers 3.

- the mineral fibers 3 are produced from a silicate material, for example natural and / or artificial stones, by melting the silicate material in a cupola 4 and the melt 5 is fed to a fiberizing unit 6.

- the fiberizing unit 6 has a plurality of spinning wheels 7 driven in rotation, of which only one spinning wheel 7 is shown in FIG.

- the cupola 4 has on the output side a spout 8, via which the melt 5 flows from the cupola 4 onto the spinning wheels 7.

- the mineral fibers 3 are formed from the melt 5 and collected on a first conveyor belt 9.

- a primary nonwoven fabric 10 is formed in which the mineral fibers 3, which are mixed with binder in the fiberising aggregate 6, are aligned in substantially the same direction and arranged in a laminar manner.

- the primary nonwoven 10 is then transferred to a downstream processing station 12 via a second conveyor belt 11 which, in contrast to the first conveyor belt 9, is not a collecting conveyor belt but a transport conveyor belt.

- the general transport direction of the primary web 10 is changed. This change takes place from the original longitudinal direction into a transport in the original transverse direction of the primary web 10.

- the conveying direction is shown in FIG. 1 by an arrow 13.

- the primary web 10 is transported over a roller 14 whose purpose is to change the transport direction of the primary web 10 from a substantially horizontal direction in a substantially vertical direction to supply the primary web 10 to another processing station 15.

- This further processing station 15 has two parallel conveyor belts 16, 17 on, between which the primary web 10 is guided.

- the conveyor belts 16, 17 are arranged to oscillate and oscillate the primary web 10 at right angles to its longitudinal extent as a secondary web 18 on a further conveyor, not shown, which runs parallel to the conveyor belts 9 and 11.

- the thus suspended secondary web 18 is then fed to a compression station 19, in which the secondary web 18 is compressed.

- the compacting station 19 has an upper conveyor belt 20 and a lower conveyor belt 21, between which the secondary web 18 runs.

- the two conveyor belts 20 and 21 of the compression station 19 are arranged in a pendulous manner and, in addition to the function of compacting the secondary web 18, also function to lecturpreln the compacted secondary web 18 in the longitudinal direction meandering.

- This floating of the secondary web 18 causes the secondary web 18 in its central region has an orientation of the mineral fibers 3, which is aligned at right angles to the large surfaces 22, 23.

- the secondary web 18 has an orientation of the mineral fibers 3 which are at an angle other than the orthogonal to the large surfaces 22, 23 to a parallel orientation relative to these large surfaces 22, 23 varies. This arrangement and orientation of the mineral fibers 3 in the secondary web 18 results from the swaying of the secondary web 18 following the compression station 19.

- the suspended secondary web 18 is fed immediately after the swaying of a processing station 24, which has an upper conveyor belt 25 and a lower conveyor belt 26 and their conveying speeds compared to the conveying speed of the compression station 19 is lower, so that the suspended Sekundärvlies 18 compressed in its longitudinal direction and the individual meander of the suspended Sekundärvlieses 18 are pushed together.

- the processing station 24 is followed by a further processing station 27, which also has an upper conveyor belt 28 and a lower conveyor belt 29, between which the suspended secondary web 18 is conveyed.

- the processing station 27 has a further reduced conveying speed of the secondary web 18 in order to continue the compaction and the homogenization of the suspended secondary web 18.

- the thus prepared secondary web 18 forms an end product that can be further processed to form certain insulating elements 2 of mineral fibers 3, such as insulation boards or insulation panels, as will be described below with reference to Figure 2.

- the meandering unfolded and compressed secondary web 18 is fed to a curing oven 30 by two parallel conveyor belts 31 and 32 are arranged.

- hot air is conveyed through the conveyor belts 31, 32 and thus also through the secondary web 18, which hot air cures the binder contained in the secondary web 18 for connecting the individual mineral fibers 3.

- the secondary nonwoven 18 is fixed in its geometric shape, which it obtained in front of the curing oven through the processing stations 12, 15, 19 and 24 and 27.

- the secondary web 18 is compressed between the conveyor belts 31, 32 of the curing oven 30.

- the distance between the two conveyor belts 31, 32 in the curing oven 30 is set to the material thickness of the secondary web 18 and limited by the conveying speed of the conveyor belts 31, 32 in relation to the amount of hot air required to cure the binder.

- the secondary web 18 passes through a first sawing station 33, which has a band saw 34 with a band-shaped saw blade 35, with which saw blade 35 divides the secondary web 18 by a separating cut parallel to the large surfaces 22, 23 into two insulating elements 2 each having a large surface 22, 23 and a substantially coextensive, the respective large surface 22, 23 opposite separating surface.

- the secondary web 18 having a width of 2,400 mm is subsequently subdivided into four part webs by a circular saw with a circular saw blade 37 in the longitudinal direction, each sub web ultimately forming an insulating element 2 and having a width of 1,200 m.

- the insulation elements 22 separated in the longitudinal direction by the separating cut parallel to the large surfaces 22, 23 of the secondary nonwoven 18 are lifted apart and fed to a laminating station, in which a carrier layer 39 is applied to a large surface 22, 23 separating surfaces of the insulating elements 2.

- the carrier layers 39 are hereby stored for each insulating material web 2 in each case a laminating roll, wherein the carrier layers 39 withdrawn with the promotion of the insulating elements 2 of the Kasch michsrolle and the same surface is glued to the insulating elements 2.

- the insulating elements 2 are wound up and packed.

- the insulation elements 2 are cut to length in a predetermined length of the secondary web 18 by a section perpendicular to the longitudinal direction of the secondary web 18.

- the carrier layer 39 is formed as an aluminum-polyethylene composite film and forms an outer reinforcement, protective and / or decorative layer.

- the connection of the support layer 39 with the insulating element 2 in the laminating station is effected by a sprayed onto the insulating element 2 highly viscous dispersion adhesive which is sprayed over the entire surface, selectively or in strips depending on the required connection between the support layer 39 and the insulating element 2 and its adhesive effect.

- the carrier layer 39 is arranged on the large surface 22, 23 of the insulating element 2, in the region of which the mineral fibers 3 are arranged parallel to the large surface 22, 23.

- the insulation elements 2 according to FIG. 4 can be produced from a secondary nonwoven 18 according to FIG. 3, or the secondary nonwoven 18 can have an exclusively orthogonal course of the mineral fibers 2 to the large surfaces 22, 23 before the secondary nonwoven 18 is connected to the carrier layer 39.

- the insulating elements 2 according to FIG. 4 are thus characterized in that the edge zones 101 in the area of the large surfaces 22, 23 have been partially removed and that the cut surface 115 is designed to achieve a high transverse tensile strength in a core region 109 of the insulating element 1 according to FIG.

- the insulating elements 2 may be formed as insulating panels and produced in many different dimensions depending on the width of the production facilities.

- the insulating material elements 2 shown in Figure 4 are formed web-shaped, wherein the carrier layer 39 is disposed on a smooth-formed large surface 22, 23.

- the carrier layer 39 is arranged on the large surface 22, 23 in the region of the edge zone 101, which edge zone the mineral fibers 3 are arranged to extend substantially parallel to the large surface 22, 23.

- connection between the carrier layer 39 and the edge zone 101 takes place in the case of a carrier layer 39 made of an aluminum-polyethylene composite film in that the aluminum-polyethylene composite film is heated, so that the plastic content in the composite film softens and with the large surface 22, 23 bonded in the region of the edge zone 101.

- the insulating elements 2 according to Figure 4 are formed from a secondary web 18 by a division of the secondary web 18 according to the above description, wherein in the secondary web, the primary web 10 is arranged meandering. In the deflection areas between the meanders arise gussets, in which mineral fibers 3 are displaced.

- edge zone 101 can be removed starting from the large surface 22, 23 in different material thickness.

- material thickness of the edge zone is influenced in order to adapt the insulating element 2 to the application.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Architecture (AREA)

- Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- Civil Engineering (AREA)

- Electromagnetism (AREA)

- Inorganic Chemistry (AREA)

- Structural Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Dispersion Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Acoustics & Sound (AREA)

- Laminated Bodies (AREA)

- Nonwoven Fabrics (AREA)

- Thermistors And Varistors (AREA)

- Formation Of Insulating Films (AREA)

- Inorganic Insulating Materials (AREA)

- Glass Compositions (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PL05001906T PL1559845T3 (pl) | 2004-01-31 | 2005-01-31 | Sposób wytwarzania elementu izolacyjnego i element izolacyjny |

Applications Claiming Priority (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102004004954 | 2004-01-31 | ||

| DE102004004954 | 2004-01-31 | ||

| DE102004008627 | 2004-02-21 | ||

| DE102004008627 | 2004-02-21 | ||

| DE102004012359 | 2004-03-13 | ||

| DE102004012359 | 2004-03-13 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1559845A1 EP1559845A1 (de) | 2005-08-03 |

| EP1559845B1 true EP1559845B1 (de) | 2007-07-25 |

Family

ID=34657500

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP05001906A Expired - Lifetime EP1559845B1 (de) | 2004-01-31 | 2005-01-31 | Verfahren zur Herstellung eines Dämmstoffelementes und Dämmstoffelement |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1559845B1 (pt) |

| AT (1) | ATE368155T1 (pt) |

| DE (2) | DE502005001080D1 (pt) |

| ES (1) | ES2289606T3 (pt) |

| PL (1) | PL1559845T3 (pt) |

| PT (1) | PT1559845E (pt) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1997944A1 (en) * | 2007-05-11 | 2008-12-03 | Rockwool International A/S | Method of making mineral wool |

| DE102007046100A1 (de) * | 2007-09-27 | 2009-04-09 | Deutsche Rockwool Mineralwoll Gmbh + Co Ohg | Verfahren und Vorrichtung zur Herstellung von Dämmstoffelementen |

| DE202009017292U1 (de) * | 2009-12-19 | 2011-04-28 | Wolf, Michael | Flächenbauelement und seine Verwendung |

| PL412081A1 (pl) * | 2015-04-21 | 2016-10-24 | Tabor Aneta Tomisol | Mata izolacyjna lamelowa i linia produkcyjna do wytwarzania maty izolacyjnej lamelowej |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3012923A (en) * | 1957-09-30 | 1961-12-12 | Owens Corning Fiberglass Corp | Fibrous products and method and apparatus for producing same |

| CA1085282A (en) * | 1977-04-12 | 1980-09-09 | Paul E. Metcalfe | Heat insulating material and method of and apparatus for the manufacture thereof |

| DK155163B (da) * | 1986-06-30 | 1989-02-20 | Rockwool Int | Fremgangsmaade ved kontinuerlig fremstilling af mineraluldsplader |

| DK165926B (da) * | 1990-12-07 | 1993-02-08 | Rockwool Int | Fremgangsmaade til fremstilling af isoleringsplader sammensat af indbyrdes forbundne stavformede mineralfiberelementer |

| DK3593D0 (da) * | 1993-01-14 | 1993-01-14 | Rockwool Int | A method for producing a mineral fiber-insulating web, a plant for producing a mineral fiber-insulating web, and a mineral fiber-insulated plate |

| ES2197913T3 (es) * | 1994-01-28 | 2004-01-16 | Rockwool International A/S | Elemento aislante y procedimiento y planta para la fabricacion y embalaje. |

| DE10257977A1 (de) * | 2002-12-12 | 2004-07-01 | Rheinhold & Mahla Ag | Raumbegrenzungs-Paneel |

-

2005

- 2005-01-31 DE DE502005001080T patent/DE502005001080D1/de not_active Expired - Lifetime

- 2005-01-31 AT AT05001906T patent/ATE368155T1/de active

- 2005-01-31 PT PT05001906T patent/PT1559845E/pt unknown

- 2005-01-31 PL PL05001906T patent/PL1559845T3/pl unknown

- 2005-01-31 EP EP05001906A patent/EP1559845B1/de not_active Expired - Lifetime

- 2005-01-31 ES ES05001906T patent/ES2289606T3/es not_active Expired - Lifetime

- 2005-01-31 DE DE200510004504 patent/DE102005004504A1/de not_active Withdrawn

Non-Patent Citations (1)

| Title |

|---|

| None * |

Also Published As

| Publication number | Publication date |

|---|---|

| DE102005004504A1 (de) | 2005-09-15 |

| PL1559845T3 (pl) | 2007-12-31 |

| EP1559845A1 (de) | 2005-08-03 |

| DE502005001080D1 (de) | 2007-09-06 |

| ATE368155T1 (de) | 2007-08-15 |

| ES2289606T3 (es) | 2008-02-01 |

| PT1559845E (pt) | 2007-10-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0277500B1 (de) | Verfahren zur kontinuierlichen Herstellung einer Faserdämmstoffbahn und Vorrichtung zur Durchführung des Verfahrens | |

| DE69104730T2 (de) | Verfahren zur herstellung von isolierenden, aus untereinander verbundenen stabförmigen mineralfaserelementen bestehenden platten. | |

| EP1182177B2 (de) | Dämmstoffelement sowie Verfahren und Vorrichtung zur Herstellung eines Dämmstoffelements, insbesondere einer roll- und/oder wickelbaren Dämmstoffbahn aus Mineralfasern | |

| DE69500354T3 (de) | Dämmplatte aus Mineralwolle, ihre Anwendung und Verfahren zu ihrer Herstellung | |

| EP1708876B1 (de) | Verfahren zur herstellung einer dämmstoffbahn aus mineralfasern sowie dämmstoffbahn | |

| EP1559845B1 (de) | Verfahren zur Herstellung eines Dämmstoffelementes und Dämmstoffelement | |

| DE102004047193A1 (de) | Verfahren zur Herstellung einer Dämmstoffbahn aus Mineralfasern sowie Dämmstoffbahn | |

| DE102005026656A1 (de) | Herstellung einer Mineralfaserbahn mit weitgehend aufrecht stehenden Mineralfasern und Nutzung der dabei entstehenden Abfälle | |

| WO2006136389A1 (de) | Verfahren zur herstellung eines dämmstoffelementes aus mineralfasern und wärmedämmverbundsystem aus mehreren dämmstoffelementen | |

| EP1106743B1 (de) | Verfahren und Vorrichtung zur Herstellung einer Faserdämmstoffbahn | |

| EP1561847B1 (de) | Verfahren und Vorrichtung zur Herstellung von bahnen- oder plattenförmigen Dämmstoffen aus Mineralfasern | |

| EP1097335A1 (de) | Verfahren zur herstellung von rohrisolierungselementen und rohrisolierungselement | |

| DE19958973C2 (de) | Verfahren und Vorrichtung zur Herstellung einer Faserdämmstoffbahn | |

| DE102006028841B4 (de) | Dämmanordnung und Verfahren zur Herstellung eines Dämmstoffstreifens | |

| EP1559844B1 (de) | Dämmstoffelement und Wärmedämmverbundsystem | |

| EP1893825A2 (de) | Verfahren und vorrichtung zur herstellung von dämmstoffelementen aus mineralfasern | |

| DE10057431C2 (de) | Verwendung von Deckschichten einer Faserdämmstoffbahn | |

| DE102007046100A1 (de) | Verfahren und Vorrichtung zur Herstellung von Dämmstoffelementen | |

| DE20220257U1 (de) | Dämmstoffplatte zur Wärme- und Schalldämmung sowie Dämmschicht | |

| DE102005002649A1 (de) | Verfahren und Vorrichtung zur Herstellung von bahnen-oder plattenförmigen Dämmstoffen aus Mineralfasern | |

| EP1743970B1 (de) | Quaderförmiges Mineralfaserprodukt | |

| DE102006028838A1 (de) | Verfahren zur Herstellung eines Dämmstoffelementes aus Mineralfasern und Wärmedämmverbundsystem aus mehreren Dämmstoffelementen | |

| DE102006028835A1 (de) | Wärmedämmverbundsystem aus mehreren Dämmstoffelementen | |

| DE102006028842A1 (de) | Dämmstoffelement | |

| DE10057430A1 (de) | Verfahren zur Herstellung einer Faserdämmstoffbahn |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR LV MK YU |

|

| 17P | Request for examination filed |

Effective date: 20060202 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AXX | Extension fees paid |

Extension state: YU Payment date: 20060202 Extension state: LV Payment date: 20060202 Extension state: HR Payment date: 20060202 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: HR LV YU |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 502005001080 Country of ref document: DE Date of ref document: 20070906 Kind code of ref document: P |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20070912 |

|

| RIN2 | Information on inventor provided after grant (corrected) |

Inventor name: KLOSE, GERD-RUEDIGER, DR.-ING. Inventor name: PIEPER, HERBERT A. |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20071004 |

|

| RIN2 | Information on inventor provided after grant (corrected) |

Inventor name: PIEPER, HERBERT A. Inventor name: KLOSE, GERD-RUEDIGER, DR.-ING. |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071125 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070725 Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070725 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071025 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2289606 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071026 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070725 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070725 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070725 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20071025 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070725 |

|

| 26N | No opposition filed |

Effective date: 20080428 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070725 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: AU |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20090218 Year of fee payment: 5 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20090128 Year of fee payment: 5 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070725 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070725 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080131 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080126 |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20100802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070725 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100802 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080131 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20110224 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110223 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100201 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IE Payment date: 20130110 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502005001080 Country of ref document: DE Representative=s name: STENGER WATZKE RING INTELLECTUAL PROPERTY, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502005001080 Country of ref document: DE Owner name: ROCKWOOL INTERNATIONAL A/S, DK Free format text: FORMER OWNER: DEUTSCHE ROCKWOOL MINERALWOLL GMBH & CO. OHG, 45966 GLADBECK, DE Effective date: 20140801 Ref country code: DE Ref legal event code: R082 Ref document number: 502005001080 Country of ref document: DE Representative=s name: STENGER WATZKE RING INTELLECTUAL PROPERTY, DE Effective date: 20140801 Ref country code: DE Ref legal event code: R082 Ref document number: 502005001080 Country of ref document: DE Representative=s name: RAUSCH WANISCHECK-BERGMANN BRINKMANN PARTNERSC, DE Effective date: 20140801 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: MM4A |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140131 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20150122 AND 20150128 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: SD Effective date: 20150424 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 502005001080 Country of ref document: DE Representative=s name: BRINKMANN & PARTNER PATENTANWAELTE PARTNERSCHA, DE Ref country code: DE Ref legal event code: R082 Ref document number: 502005001080 Country of ref document: DE Representative=s name: RAUSCH WANISCHECK-BERGMANN BRINKMANN PARTNERSC, DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20190125 Year of fee payment: 15 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20200131 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20230103 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: HC Owner name: ROCKWOOL A/S; DK Free format text: DETAILS ASSIGNMENT: CHANGE OF OWNER(S), CHANGE OF OWNER(S) NAME; FORMER OWNER NAME: ROCKWOOL INTERNATIONAL A/S Effective date: 20230728 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 502005001080 Country of ref document: DE Owner name: ROCKWOOL A/S, DK Free format text: FORMER OWNER: ROCKWOOL INTERNATIONAL A/S, HEDEHUSENE, DK Ref country code: DE Ref legal event code: R082 Ref document number: 502005001080 Country of ref document: DE |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20240126 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20240104 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20240129 Year of fee payment: 20 Ref country code: GB Payment date: 20240129 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20240129 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 502005001080 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: MK Effective date: 20250130 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Expiry date: 20250130 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 368155 Country of ref document: AT Kind code of ref document: T Effective date: 20250131 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: PD Owner name: ROCKWOOL INTERNATIONAL A/S; DK Free format text: DETAILS ASSIGNMENT: CHANGE OF OWNER(S), OTHER; FORMER OWNER NAME: ROCKWOOL INTERNATIONAL A/S Effective date: 20241212 Ref country code: BE Ref legal event code: MK Effective date: 20250131 Ref country code: BE Ref legal event code: HC Owner name: ROCKWOOL A/S; DK Free format text: DETAILS ASSIGNMENT: CHANGE OF OWNER(S), CHANGE OF OWNER(S) NAME; FORMER OWNER NAME: ROCKWOOL INTERNATIONAL A/S Effective date: 20241212 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20240131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20250130 |