EP1536900B2 - Procede pour debuter un procedure de coulee - Google Patents

Procede pour debuter un procedure de coulee Download PDFInfo

- Publication number

- EP1536900B2 EP1536900B2 EP03798105A EP03798105A EP1536900B2 EP 1536900 B2 EP1536900 B2 EP 1536900B2 EP 03798105 A EP03798105 A EP 03798105A EP 03798105 A EP03798105 A EP 03798105A EP 1536900 B2 EP1536900 B2 EP 1536900B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- casting

- strip

- velocity

- speed

- starting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000005266 casting Methods 0.000 title claims abstract description 322

- 238000000034 method Methods 0.000 title claims abstract description 56

- 229910052751 metal Inorganic materials 0.000 claims abstract description 80

- 239000002184 metal Substances 0.000 claims abstract description 80

- 238000007711 solidification Methods 0.000 claims abstract description 18

- 230000008023 solidification Effects 0.000 claims abstract description 17

- 239000000155 melt Substances 0.000 claims description 21

- 230000015572 biosynthetic process Effects 0.000 claims description 12

- 238000013178 mathematical model Methods 0.000 claims description 9

- 238000004519 manufacturing process Methods 0.000 claims description 7

- 230000009471 action Effects 0.000 claims description 6

- 230000001105 regulatory effect Effects 0.000 claims description 3

- 238000004364 calculation method Methods 0.000 claims 1

- 230000002093 peripheral effect Effects 0.000 abstract description 7

- 238000000926 separation method Methods 0.000 description 33

- 230000008569 process Effects 0.000 description 13

- 238000005259 measurement Methods 0.000 description 11

- 238000002844 melting Methods 0.000 description 11

- 230000008018 melting Effects 0.000 description 11

- 229910000831 Steel Inorganic materials 0.000 description 9

- 239000010959 steel Substances 0.000 description 9

- 230000004044 response Effects 0.000 description 4

- 239000007787 solid Substances 0.000 description 4

- 230000007704 transition Effects 0.000 description 4

- 238000001816 cooling Methods 0.000 description 3

- 238000012545 processing Methods 0.000 description 3

- 230000008901 benefit Effects 0.000 description 2

- 230000002349 favourable effect Effects 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 230000000630 rising effect Effects 0.000 description 2

- 241001494479 Pecora Species 0.000 description 1

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000005094 computer simulation Methods 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 229910001338 liquidmetal Inorganic materials 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000005058 metal casting Methods 0.000 description 1

- 229910001092 metal group alloy Inorganic materials 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000002156 mixing Methods 0.000 description 1

- 238000012544 monitoring process Methods 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 230000003071 parasitic effect Effects 0.000 description 1

- 238000007712 rapid solidification Methods 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000007858 starting material Substances 0.000 description 1

- 238000009628 steelmaking Methods 0.000 description 1

- 238000004381 surface treatment Methods 0.000 description 1

- 238000007669 thermal treatment Methods 0.000 description 1

- 230000008719 thickening Effects 0.000 description 1

- 238000012546 transfer Methods 0.000 description 1

- 238000009966 trimming Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/06—Continuous casting of metals, i.e. casting in indefinite lengths into moulds with travelling walls, e.g. with rolls, plates, belts, caterpillars

- B22D11/0622—Continuous casting of metals, i.e. casting in indefinite lengths into moulds with travelling walls, e.g. with rolls, plates, belts, caterpillars formed by two casting wheels

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/16—Controlling or regulating processes or operations

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D11/00—Continuous casting of metals, i.e. casting in indefinite lengths

- B22D11/16—Controlling or regulating processes or operations

- B22D11/161—Controlling or regulating processes or operations for automatic starting the casting process

Definitions

- the invention relates to a method for starting a casting process in a Zweiwalzeng screen thanks without the application of a Anfahrstranges.

- essentially cooled molds with a continuous mold cavity are used, in which the molten metal introduced on the input side solidifies, at least in the area of contact with the mold cavity walls.

- a substantially solidified metal strand is withdrawn from the mold.

- a first filling of the mold cavity is carried out with molten metal, in particular a predominantly vertical orientation of the mold cavity a completely solidified initial piece must be achieved so that the molten metal does not flow through the mold uncontrollably and exits from it.

- the casting thickness of the metal strand to be produced, the solidification conditions and the amount of heat which can be dissipated through the Ferm cavity walls during the short residence time in the mold are of considerable importance.

- a starting strand is usually introduced into the mold before the start of casting, which largely but not necessarily completely closes the outlet cross section of the mold cavity and only after the formation of a solid compound of the introduced melt with the Anfahrstrangkopf and a pronounced strand shell with sufficient thickness along the mold cavity walls with a pair of driving rollers from the mold is discharged.

- This start-up requires at least a new Anfahrstrangkopf coupled to the Anfahrstrang at each restart of the caster.

- Such a Anfahrstrang as it is used in formed by Breitseitanofficen and narrow side walls strip steel casting molds, for example, from US-A 4,719,960 known.

- a starter line for the special application in a two-roll lapping plant is in EP-A 208 642 described.

- This Anfahrstrang contains a dummy head with two flanges formed by thin metal strips, which abut the lateral surfaces of the casting rolls and thus form a space for receiving the inflowing molten metal.

- the Aus disciplinen the Anfahrstranges and the cast strip from the casting gap formed by the casting rolls takes place.

- a dummy bar is not absolutely necessary because the open casting gap is bridged within a very short time due to the rapid solidification of the molten metal at the mold walls. Start-up procedures in which no start-up train is required are also already known several times.

- a starting method is known, in which the two cooperating casting rolls are brought to a start position before pouring, in which no casting gap is present and the casting rolls stand still. Immediately after the start of the melt supply and a first strand shell formation on the two lateral surfaces of the casting rolls they are moved apart on the Railg fauxspalt (strip thickness) and brought the Gleß Ober along a start-up curve on operating casting speed.

- a starting process with stationary casting rolls is very unreliable because the is-pouring in the melt space can not be measured with the necessary accuracy to the narrowest cross section between the casting rolls. Therefore, neither an increase in force between the two casting rolls nor the degree of filling of the mold is reasonably controllable.

- a different degree of solidification of the melt along the bandwidth and in particular near the side plate can cause significant Kell Struktur by solidified metal above the narrowest cross-section and subsequently lead to side plate damage. Furthermore, in such a starting method with standing casting rolls, there is an increased risk for sectional strand-shell adhesives in sections on the lateral surface of the casting rolls.

- a casting method for a two-roll caster is known in which, before the start of the supply of melt, the casting gap between the two casting rolls is set to a value reduced with respect to the operating casting nip.

- the supply of melt occurs in rotating casting rolls, wherein the casting speed is adjusted so that the thickness of the produced strip is greater than the previously set casting gap.

- the tendency to drip metal melt is reduced by a reduced casting gap.

- the ones described above with regard to the JP-A 61-266159 described disadvantages to an increasing extent, in particular the tendency to side plate damage.

- Object of the present invention is therefore, To avoid the disadvantages of the prior art described above and to propose a method for starting a casting in a two-roll casting device and a device for carrying out the method, wherein the passage of molten metal through the casting gap can be kept low and at the same time the tendency to form wedge and Thickening at the beginning of the cast strip is avoided as possible. At the same time a separation of a first piece of the cast strip, which does not meet the quality requirements of a continuous production to be achieved by the subsequently produced under largely stationary operating conditions band without the need for mechanical separation devices are required.

- the casting speed is always determined by the casting roll peripheral speed since the strand shells formed and adhered to the casting roll shells are transported at this velocity through the narrowest cross section between the casting rolls and bonded together.

- the start casting speed is a low casting speed at which, due to the extended residence time of the forming strand shells in the melt space, an increased strand shell growth occurs and therefore the downwardly open casting gap can be bridged particularly quickly.

- the banding casting speed is a casting speed which depends in particular on the current liquid metal casting level and also on the solidification conditions and the casting roll separation force required due to the steel analysis, in which strip formation and removal of the formed strip take place downwards and are maintained at the largely constant strip forming conditions can be.

- the molten metal is continuously filled up to the level of the operating casting level, with the belt forming speed continuously increasing with increasing casting level.

- the casting gap is kept in the claimed process during the entire starting process on the value of the operating casting thickness, there are additional benefits: By a reduced start-casting speed, a low band throughput is achieved until complete achievement of the target Radiog informLites and kept such a small amount of rejects , Furthermore, the operating casting thickness, which is not reduced in the starting phase, causes less interference, which, as a result of solidification on the narrow side walls, leads to widening of the casting gap when passing through the casting cross section and possibly uncontrolled tearing of the cast strand.

- the starting casting speed is chosen smaller than half the operating casting speed, the casting rolls usually rotate.

- the starting phase can also be initiated with standing casting rolls, so that the start casting speed at the beginning of the feeding of molten metal is still 0 m / min and the casting rolls are then rapidly accelerated.

- a start casting speed in this range allows a good timing between the melt feed to the attainment of the operating pouring level and the ramp-up of the start casting speed to a belting casting speed that approximates the operating casting speed. This is accomplished by a moderate, steady increase in casting roll peripheral speed to a belting casting speed that matches a measurable target casting level To ensure reliable banding (strand shell formation on the casting roll surfaces in the molten pool). Accordingly, the belt-forming casting speed is adjusted or regulated in accordance with a measurable target casting level.

- Another way of optimally adjusting the banding casting speed is to control the banding casting speed in response to the release force occurring between the casting rolls.

- the separating force acting between the two casting rolls is, for a given casting gap, a measure of the strand shell thickness and the current solidification state in the narrowest cross section between the casting rolls. It is higher as the solidification process in this area progresses.

- the predominantly rising metal bath level in the start phase which has a significant influence on strand shell formation, is also taken into account here.

- the measured values of a bath level measurement and a separation force measurement can also be used in combination.

- the band-separating casting speed is to be understood as the casting speed at which the first part of the cast metal strip, which was produced under unsteady casting conditions in the starting phase of the casting process and is thus to be regarded as scrap material, is separated from the continuously following metal strip produced under largely stationary casting conditions.

- This separation takes place according to a possible embodiment exclusively under the action of the dead weight of the narrowest cross section between the casting rollers leaving down hanging starting piece of the cast metal strip by tearing it in the casting gap by increasing the casting speed on the belt separation casting speed, the solidification conditions and thus the mechanical properties of the cast strip in G confusequerites, especially by reducing the tensile strength, so changed that the strip in this cross-section tears off without additional mechanical measures.

- the separation of the cast metal strip at tape release casting speed can be accomplished by the action of a gravitational action increased tape tension applied by a driver assembly located downstream of the casting nip of the two-roll caster.

- An improvement in the separation conditions can be achieved by superposing a short-term increase in casting thickness by 5 to 40% on the increase in casting speed to the strip-separation casting speed.

- the belt separation casting speed is higher than the operation casting speed, preferably 5% to 40% higher than the operation casting speed.

- This belt separation casting speed is set briefly as soon as approximately stationary casting conditions are reached. It is preferred that even a consistent strip quality is ensured.

- the strip separation casting speed is expediently set in the starting phase when the molten metal in the melting chamber has essentially reached the desired operating casting level.

- the casting speed is increased to approximately the operating casting speed before reaching the desired operating pouring mirror in the melting chamber.

- the proposed method allows the steady state casting operation to be achieved within 5 to 60 seconds after the start of metal melt feed into the melt space.

- At least reference data of the instantaneous casting speed and the current G foolador let the molten metal in the melting space and / or the instantaneous separation force between the casting rolls and / or the gap width between the casting rolls and / or the strip thickness of the cast metal strip determined continuously during the casting start and fed to a computing unit and generated from these reference data including a mathematical model for the starting process manipulated variables for the casting speed, for the position of a Bandleit stimulate and for the transport speed of the cast metal strip in a belt conveyor and transmitted to the drive units of these devices become.

- the separation conditions for the separation of the first piece of the cast metal strip in the casting cross-section are improved when using the mathematical model based on current input data such as steel grade, operating casting thickness, temperature ratios, quality related Solidification conditions, etc., in addition a manipulated variable for the distance positioning of the two casting rolls to each other, in particular an increased starting casting thickness, is generated.

- the quality of the metal strip produced can be continually optimized and adapted to changing operating conditions in general and during the casting process if the mathematical model comprises a metallurgical model for forming a specific microstructure in the cast metal strip and / or for influencing the geometry of the cast metal strip.

- a two-roll caster equipped in this way enables the acquisition of current production data from the steelmaking process and their joint processing with measurement data at the caster in a computer model for optimizing the starting process.

- a separating force measuring device for determining the instantaneous, caused essentially by the banding separating force between the two casting rolls or a position-measuring device for determining the instantaneous gap width between the casting rolls or a measuring device for determining the instantaneous strip thickness is used.

- Each of these measurements provides reference data which at least indirectly produce a mathematically describable relationship with the strand shell formation in the melt pool and thus with the metal strand formation in the narrowest cross section between the casting rolls and which can therefore be used in a mathematical model to calculate manipulated variables in order to minimize or minimize the starting process Optimized in terms of shape and trackability of the strip breaking edge.

- a further improvement of the starting method can be achieved by combining at least two of these measuring methods, wherein the measurements are carried out simultaneously and processed in a correspondingly expanded mathematical model.

- a further optimization of the method results when at least one of the two casting rolls is coupled to a casting roll adjusting device and the computing unit is additionally connected by a signal line to a casting roll adjusting device for setting a starting casting thickness.

- the casting format preferably the operating casting thickness

- the steel production taken characteristic data such as the superheating temperature of the melt, and measured data on the system in the process model

- the present method and the associated two-roll caster is suitable for casting molten metals, preferably Fe-containing metal alloys, in particular for steels.

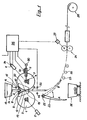

- a two-roll caster with the necessary for carrying out the method according to the invention Facilities is in Fig.1 shown schematically. It consists of two in a horizontal plane at a distance from each other and equipped with an internal cooling, not shown, casting rolls 1, 2. These are rotatably supported in shaft bearings 3, 4 and coupled with rotary actuators 5, 6, the opposing rotation of the casting rolls 1, 2 to G confusewalzenachsen 1 ', 2' with a controllable peripheral speed, which corresponds to the casting speed allow. To determine the instantaneous casting speed, at least one of the casting rolls 1, 2 or the associated rotary drives 5, 6 or the cast metal strip itself is assigned a speed measuring device 34.

- One of the two casting rolls 2 is slidably supported in the horizontal plane transversely to the casting roll axis 2 'and coupled to a casting roll adjusting device 7, whereby the distance between the two casting rolls 1, 2 is adjustable adjustable to each other.

- side plates 8 are pressed against the front side, which together with a portion of the lateral surfaces 9, 10 of the rotating casting rolls form a melting chamber 11 for receiving molten metal 12.

- the molten metal 12 is continuously and regulated introduced from an intermediate vessel 13 through a dip tube 14 in the melt space 11, so that during the stationary casting operation, the melt supply through the Tauchrohrauslässe in submerged form, ie always below a held at a constant level casting mirror 15.

- a level measuring device 16 arranged above the melting space 11, a continuous monitoring of the level of the casting mirror takes place.

- the solid shell shells 19, 20 formed on the lateral surfaces 9, 10 of the casting rolls in the melting chamber 11 are connected in the casting gap 18 to a substantially solidified metal strip 21, which is conveyed downwardly from the casting gap 18 by the rotational movement of the casting rolls 1, 2, by a downstream one pivotable Bandleit recognized 22 and tape guide rollers 23 is deflected in a substantially horizontal transport direction and one of a pair of drive rollers belt conveyor 24 is discharged from the Zweiwalzengit listening.

- the arc-shaped Bandleit Vietnamese 22 is connected to a drive unit 25, which makes it possible to pivot the Bandleit Vietnamese 22 from a retreat position A to an operating position B and back.

- the tape guide is in the retraction position A and is pivoted after the separation of a first piece of the cast metal strip in the operating position B and can remain there during the entire stationary production process.

- a scrap receiving carriage 26 is arranged, in which at most initially dripping metal melt and the first portion of the cast strip can be collected and transported away if necessary.

- the scrap receiving trolley can also be designed without wheels. It may be positioned within a chamber wall enclosing the path of the cast metal strip from the casting rolls to the first driver. Also, this first portion of the cast strip does not necessarily fall directly into the scrap receiving trolley, but can also be fed indirectly thereto.

- the cast metal strip After the cast metal strip emerges from the belt transport device 24 equipped with a drive unit 27, it is finished in further processing devices 28 (not illustrated in detail) and finally wound into bundles 29 and / or cut into sheets.

- the further treatment devices 28 may be formed, for example, by rolling stands, trimming devices, surface treatment devices, thermal treatment devices of various kinds, such as heating devices, holding ovens, temperature compensation furnaces, and cooling sections.

- the Zweiwalzengitinnate is equipped with a computing unit 36, which makes it possible to automatically perform the starting process in response to predetermined input variables and determined on the device current metrics.

- a computing unit 36 which makes it possible to automatically perform the starting process in response to predetermined input variables and determined on the device current metrics.

- optimal manipulated variables such as the start casting speed v gSt , the position of the belt guide , the drive speed of the belt conveyor and possibly the starting casting thickness D St and other control variables are generated in the arithmetic unit and the starting process continuously controlled and supervised.

- Manipulated variables which are generated from the arithmetic unit 36 for carrying out the starting process, are based on measurement data from the casting plant that are currently collected and that directly or indirectly have a connection with the strand shell growth.

- Predestined for this purpose are the instantaneous level of the casting mirror 15, ie the level of the casting mirror in the melting space 11, which can be determined continuously by means of a level-measuring device 16.

- the release force F Tr between the two casting rolls 1, 2 represents a reaction force on the passed strand shells and also provides a reference value for the degree of solidification in the narrowest cross section between the casting rolls. It is to be determined with a separating force measuring device 30, which is associated with the casting roll bearings 3, 4 or incorporated in the G confusewalzenverstell issued 7.

- Another way to determine a reference size provides the instantaneous gap width G between the casting rolls, which is closely related to the release force F Tr , since a higher separation force increased radial deflection of the casting rolls 1, 2 causes each other or their deformation.

- This can be measured directly by a position measuring device 31 on the casting rolls or indirectly via a strip thickness measuring device 32.

- the simultaneous measurement and processing of the measurement data of several of the measuring systems described minimizes the time required for the start of the system and in particular increases the quality of the strip breaking edge of the subsequent metal strip with regard to their geometry and their ability to be guided through the plant, as well as the quality of the product produced from the start of production.

- the solidification conditions on the lateral surfaces 9, 10 of the two casting rolls and in the casting gap 18 at steady-state casting speed and at belt separation casting speed are in the FIGS. 2a and 2b compared.

- the two casting rolls 1, 2 are set to a casting gap 18, which corresponds in particular to the stationary casting level and the operating casting thickness D of the desired cast metal strip.

- the two strand shells 19, 20 are joined together and it forms at stationary casting conditions a solidified metal strip.

- the V-shaped lines 37 illustrate the transition from 100% melt to a mixing area with an increasing solids content and the V-shaped line 38 illustrates the transition to 100% solids, thus the solidified strand part.

- Fig. 2b Figure 12 shows the changed solidification conditions at a belt-separation casting speed which is increased over the operation-casting speed. This means that the peripheral speed of the casting rolls is increased. The cooling conditions were not changed. As a result, the available strand shell formation time in the melt space and thus the strand shell growth is reduced, so that the fürerstarrungspraxis 39 shifts in the casting direction and in G confusequerites either an increased proportion of liquid content is present and / or the average strip temperature is at least higher than at operating casting speed. In both cases, the tensile strength of the hanging down metal strip piece at the strip separation casting speed is reduced so far that the metal strip breaks off under the action of its weight in G confusequerites.

- the casting speed is increased to such a high belt separation casting speed and then immediately lowered again so that no separation force is temporarily measured.

- molten metal flows because of the lack of connection between the two strand shells and under the effect of ferrostatic pressure in the space below the narrowest cross section between the casting rolls after. This leads to a bulging of the metal strip and a considerable rewarming of the near-surface strip layers and to the demolition under the influence of the downside band weight.

- the G confusetikpractic h Gsp can be measured only after reaching a certain degree of filling, since the melt space is constricted due to the casting roll arrangement to G confusequerites toward funnel-shaped and in this very narrow range a level measurement is not technically feasible. After a period of about 5 to 15 seconds, which can be variably selected, the operating pouring level h Betr is reached and maintained at this level.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Continuous Casting (AREA)

Abstract

Claims (19)

- Procédé de démarrage d'un processus de coulée dans un dispositif de coulée à deux cylindres sans barre d'amorce, caractérisé par les étapes suivantes :• réglage d'une épaisseur de coulée de fonctionnement (D) et mise en rotation des cylindres de coulée (1, 2) à une vitesse circonférentielle de cylindres de coulée qui équivaut à une vitesse de coulée de départ (VgSt) réduite par rapport à une vitesse stationnaire de coulée de fonctionnement (VgBetr),• acheminement de coulée métallique (12) dans une chambre de coulée (11) formée par les cylindres de coulée en rotation (1, 2) et les plaques latérales (8) les touchant et formation d'une bande métallique coulée (21) ayant un format de section transversale prédéfini sensiblement constant avec augmentation simultanée de la vitesse de coulée (vg) jusqu'à une vitesse de coulée de formation de bande (VgBb),• augmentation consécutive de la vitesse de coulée (vg) jusqu'à une vitesse de coulée de sectionnement de bande (vgTr) qui est significativement plus élevée qu'une vitesse de coulée (vg) suffisante pour les conditions momentanées de solidification et sectionnement de la bande métallique (21) coulée jusqu'à ce moment,• réglage d'une vitesse stationnaire de coulée de fonctionnement (VgBetr),• réorientation de la bande métallique coulée suivante (21) vers un dispositif de transport de bande (24) et début du fonctionnement en coulée stationnaire.

- Procédé selon la revendication 1, caractérisé en ce que la vitesse de coulée de démarrage (VgSt) est inférieure à la moitié de la vitesse de coulée de fonctionnement (vgBetr).

- Procédé selon la revendication 1 ou 2, caractérisé en ce que la vitesse de coulée de démarrage (VgSt) s'élève à moins d'environ 12 m/min.

- Procédé selon l'une quelconque des revendications 1 à 3, caractérisé en ce que la vitesse de coulée de démarrage (vgSt) s'élève encore à 0 m/min. au début de l'acheminement de coulée métallique et s'accélère ensuite.

- Procédé selon l'une quelconque des revendications précédentes, caractérisé en ce que la vitesse de coulée de formation de bande (vgBb) se règle en fonction d'un niveau théorique mesurable de coulée (hGsp).

- Procédé selon l'une quelconque des revendications précédentes, caractérisé en ce que la vitesse de coulée de formation de bande (vgBb) équivaut sensiblement à la vitesse stationnaire de coulée de fonctionnement (vgBetr).

- Procédé selon l'une quelconque des revendications précédentes, caractérisé en ce que la vitesse de coulée de formation de bande (vgBb) se règle en fonction de la force de sectionnement (FTr) apparaissant entre les cylindres de coulée.

- Procédé selon l'une quelconque des revendications précédentes, caractérisé en ce que la vitesse de coulée de sectionnement de bande (vgTr) est supérieure à la vitesse de coulée de formation de bande (vgBb) et/ou la vitesse de coulée de fonctionnement (vgBetr).

- Procédé selon l'une quelconque des revendications 1 à 7, caractérisé en ce que la vitesse de coulée de sectionnement de bande (vgTr) est de 5 % à 40 % supérieure à la vitesse de coulée de formation de bande (vgBb) et/ou la vitesse de coulée de fonctionnement (vgBetr).

- Procédé selon l'une quelconque des revendications précédentes, caractérisé en ce qu'à l'augmentation de la vitesse de coulée jusqu'à la vitesse de coulée de sectionnement de bande (vgTr) se superpose une augmentation de brève durée de l'épaisseur de coulée (D) à raison de 5 à 40 %.

- Procédé selon l'une quelconque des revendications précédentes, caractérisé en ce que la vitesse de coulée de sectionnement de bande (vgTr) est réglée dès que la coulée métallique de la chambre de coulée (11) a atteint sensiblement le niveau théorique de coulée de fonctionnement (hGsp).

- Procédé selon l'une quelconque des revendications précédentes, caractérisé en ce que le sectionnement de la bande métallique coulée se fait à la vitesse de coulée de sectionnement de bande (vgTr) par cassure de la bande coulée sous l'effet du poids propre de la bande métallique dans le canal de coulée (18) entre les cylindres de coulée (1, 2).

- Procédé selon l'une quelconque des revendications précédentes, caractérisé en ce que le sectionnement de la bande métallique coulée se fait à la vitesse de coulée de sectionnement de bande (vgTr) sous l'effet d'une traction accrue de la bande.

- Procédé selon l'une quelconque des revendication précédentes, caractérisé en ce que la vitesse de coulée (vg) augmente jusqu'à atteindre approximativement la vitesse de coulée de fonctionnement (vgBetr) au moins pendant un laps de temps avant d'atteindre le niveau théorique de coulée de fonctionnement (hgsp) dans la chambre de coulée (11).

- Procédé selon l'une quelconque des revendications précédentes, caractérisé en ce que le fonctionnement en coulée stationnaire est atteint dans les 5 à 60 secondes après le premier acheminement de coulée métallique dans la chambre de coulée (11).

- Procédé selon l'une quelconque des revendications précédentes, caractérisé en ce qu'au démarrage d'un processus de coulée pour la fabrication d'une bande métallique très mince, une épaisseur de coulée de démarrage (DSt) accrue par rapport à l'épaisseur de coulée de fonctionnement (D) est réglée et que cette épaisseur de coulée de démarrage est ramenée au plus tôt après formation d'une bande métallique coulée d'un format de section transversale prédéfini sensiblement constant à l'épaisseur de coulée de fonctionnement (D).

- Procédé selon l'une quelconque des revendications précédentes, caractérisé en ce qu'au moins des données de référence de vitesse de coulée (vg) et de hauteur momentanée de niveau de coulée momentanée et/ou de force momentanée de sectionnement (FTr) entre les cylindres de coulée et/ou de largeur de canal (G) entre les cylindres de coulée et/ou d'épaisseur de bande de la bande métallique coulée sont déterminées en continu pendant le démarrage de la coulée et acheminées à une unité de calcul (36) et qu'à partir de ces données de référence, en faisant intervenir un modèle mathématique pour le processus de démarrage, des grandeurs de réglage pour la vitesse de coulée, pour la position d'un dispositif de guidage de bande (22) et pour la vitesse de transport de la bande métallique coulée dans un dispositif de transport de bande (24) sont générées et communiquées aux unités de commande (5, 6, 25, 27) de ces dispositifs.

- Procédé selon la revendication 15, caractérisé en ce qu'à partir du modèle mathématique, on génère en plus une grandeur de réglage pour le positionnement en espacement des cylindres de coulée (1, 2) l'un par rapport à l'autre, notamment une épaisseur de coulée de démarrage (DSt).

- Procédé selon la revendication 15 ou 16, caractérisé en ce que le modèle mathématique est un modèle métallurgique servant à constituer une certaine structure dans la bande métallique coulée et/ou à influer sur la géométrie de la bande métallique coulée.

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT03798105T ATE312676T1 (de) | 2002-09-12 | 2003-08-18 | Verfahren und vorrichtung zum starten eines giessvorganges |

| SI200330195T SI1536900T1 (sl) | 2002-09-12 | 2003-08-18 | Postopek in naprava za zacetek postopka litja |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT13672002 | 2002-09-12 | ||

| AT0136702A AT411822B (de) | 2002-09-12 | 2002-09-12 | Verfahren und vorrichtung zum starten eines giessvorganges |

| PCT/EP2003/009110 WO2004028725A1 (fr) | 2002-09-12 | 2003-08-18 | Procede et dispositif pour debuter un processus de coulee |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP1536900A1 EP1536900A1 (fr) | 2005-06-08 |

| EP1536900B1 EP1536900B1 (fr) | 2005-12-14 |

| EP1536900B2 true EP1536900B2 (fr) | 2012-08-15 |

Family

ID=29274633

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03798105A Expired - Lifetime EP1536900B2 (fr) | 2002-09-12 | 2003-08-18 | Procede pour debuter un procedure de coulee |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US7156153B2 (fr) |

| EP (1) | EP1536900B2 (fr) |

| KR (1) | KR101143384B1 (fr) |

| CN (1) | CN100577326C (fr) |

| AT (1) | AT411822B (fr) |

| AU (1) | AU2003258624B2 (fr) |

| DE (1) | DE50301955D1 (fr) |

| MX (1) | MXPA05002697A (fr) |

| WO (1) | WO2004028725A1 (fr) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT412539B (de) | 2003-05-06 | 2005-04-25 | Voest Alpine Ind Anlagen | Zweiwalzengiesseinrichtung |

| AT501044B8 (de) * | 2004-10-29 | 2007-02-15 | Voest Alpine Ind Anlagen | Verfahren zum herstellen eines gegossenen stahlbandes |

| WO2007048250A1 (fr) * | 2005-10-28 | 2007-05-03 | Novelis Inc. | Homogénéisation et traitement thermique de métaux coulés |

| US7562540B2 (en) * | 2006-06-16 | 2009-07-21 | Green Material Corporation | Fiberizing device for producing fibers from molten waste |

| JP5103916B2 (ja) * | 2007-02-01 | 2012-12-19 | 株式会社Ihi | 双ロール鋳造機の操業方法及びサイド堰支持装置 |

| EP2581150A1 (fr) | 2011-10-12 | 2013-04-17 | Siemens Aktiengesellschaft | Dispositif de laminage par coulée avec refroidissement cryogène des laminoirs par coulée |

| JP6511968B2 (ja) * | 2015-06-03 | 2019-05-15 | 日産自動車株式会社 | 双ロール式縦型鋳造装置及び双ロール式縦型鋳造方法 |

| CN104942251B (zh) * | 2015-07-01 | 2017-01-11 | 重庆大学 | 炼钢厂连铸机的开浇时间确定方法 |

| EP3202502A1 (fr) * | 2016-02-04 | 2017-08-09 | Primetals Technologies Germany GmbH | Reglage de position de bande |

| US10618107B2 (en) | 2016-04-14 | 2020-04-14 | GM Global Technology Operations LLC | Variable thickness continuous casting for tailor rolling |

| CN108145112B (zh) * | 2016-12-05 | 2020-01-21 | 上海梅山钢铁股份有限公司 | 基于液位自动控制的板坯连铸塞棒控流自动开浇工艺 |

Citations (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5956950A (ja) † | 1982-09-28 | 1984-04-02 | Nippon Kokan Kk <Nkk> | 金属板の連続鋳造方法 |

| JPS59215257A (ja) † | 1983-05-20 | 1984-12-05 | Ishikawajima Harima Heavy Ind Co Ltd | 双ロール式連鋳方法 |

| JPS6064754A (ja) † | 1983-09-19 | 1985-04-13 | Hitachi Ltd | 薄帯板の連続鋳造方法及び装置 |

| JPS6064753A (ja) † | 1983-09-19 | 1985-04-13 | Hitachi Ltd | 双ロ−ル式鋳造機の鋳造方法及びその装置 |

| JPS61232044A (ja) † | 1985-04-05 | 1986-10-16 | Mitsubishi Heavy Ind Ltd | 薄板連続鋳造方法 |

| JPS61232045A (ja) † | 1985-04-05 | 1986-10-16 | Mitsubishi Heavy Ind Ltd | 薄板連続鋳造方法 |

| JPS61266159A (ja) † | 1985-05-21 | 1986-11-25 | Mitsubishi Heavy Ind Ltd | 薄板連続鋳造装置の運転方法 |

| JPS6297749A (ja) † | 1985-10-24 | 1987-05-07 | Mitsubishi Heavy Ind Ltd | 薄板連続鋳造方法 |

| US4702300A (en) † | 1985-03-15 | 1987-10-27 | Hitachi, Ltd. | Double drum type continuous casting machine |

| JPS6349347A (ja) † | 1986-08-13 | 1988-03-02 | Ishikawajima Harima Heavy Ind Co Ltd | 双ロ−ル回転数制御方法 |

| JPS63290654A (ja) † | 1987-05-22 | 1988-11-28 | Nisshin Steel Co Ltd | 薄板連続鋳造方法 |

| JPS6434553A (en) † | 1987-07-31 | 1989-02-06 | Mitsubishi Heavy Ind Ltd | Method for controlling molten steel level in continuous casting machine |

| JPH01154850A (ja) † | 1987-12-10 | 1989-06-16 | Ishikawajima Harima Heavy Ind Co Ltd | 双ロール式連鋳機の板厚制御方法 |

| US5031688A (en) † | 1989-12-11 | 1991-07-16 | Bethlehem Steel Corporation | Method and apparatus for controlling the thickness of metal strip cast in a twin roll continuous casting machine |

| US5052467A (en) † | 1989-08-03 | 1991-10-01 | Nippon Steel Corporation | Control device and a control method for twin-roll continuous caster |

| EP0450775A2 (fr) † | 1990-04-04 | 1991-10-09 | Ishikawajima-Harima Heavy Industries Co., Ltd. | Procédé et dispositif de coulage d'une bande |

| WO1992002321A1 (fr) † | 1990-08-03 | 1992-02-20 | Davy Mckee (Poole) Limited | Dispositif de coulee de metal a double cylindre |

| JPH04167950A (ja) † | 1990-11-01 | 1992-06-16 | Toshiba Corp | 双ロール式連続鋳造機の制御方法および装置 |

| US5191927A (en) † | 1990-11-22 | 1993-03-09 | Mitsubishi Jukogyo Kabushiki Kaisha | Method and apparatus for detecting a sheet thickness in a continuous casting machine |

| JPH05169205A (ja) † | 1991-10-25 | 1993-07-09 | Kobe Steel Ltd | 双ロール式連続鋳造機の鋳造速度制御方法 |

| KR930006638B1 (ko) † | 1991-12-28 | 1993-07-22 | 포항제철 주식회사 | 강의 연속주조 자동 제어방법 |

| US5287912A (en) † | 1991-11-21 | 1994-02-22 | Ishikawajima-Harima Heavy Industries Company Limited | Strip casting |

| JPH06114504A (ja) † | 1992-10-09 | 1994-04-26 | Nippon Steel Corp | 双ドラム薄板連続鋳造法 |

| WO1995009708A1 (fr) † | 1993-10-07 | 1995-04-13 | Fata Hunter, Inc. | Procede de coulee a cylindres a calibrage fin |

| WO1997034718A1 (fr) † | 1996-03-19 | 1997-09-25 | Ishikawajima-Harima Heavy Industries Company Limited | Absorbeurs de chaleur sans contact pour la coulee en bandes |

| US5706882A (en) † | 1994-12-29 | 1998-01-13 | Usinor-Sacilor | Control process for twin-roll continuous casting |

| EP0903191A2 (fr) † | 1997-09-18 | 1999-03-24 | Ishikawajima-Harima Heavy Industries Co., Ltd. | Installation de coulée de bandes |

| KR19990051823A (ko) † | 1997-12-20 | 1999-07-05 | 이구택 | 쌍롤형 박판주조장치에서의 주조롤 속도 조정방법 및 장치 |

| US5927375A (en) † | 1996-11-07 | 1999-07-27 | Usinor Of Puteaux | Continuous casting process between rolls |

| WO1999048636A1 (fr) † | 1998-03-25 | 1999-09-30 | Voest-Alpine Industrieanlagenbau Gmbh | Installation et procede de coulee en continu d'un ruban mince |

| US5988258A (en) † | 1997-03-27 | 1999-11-23 | Ishikawajima-Harima Heavy Industries Company Limited | Casting metal strip |

| US6085183A (en) † | 1995-03-09 | 2000-07-04 | Siemens Aktiengesellschaft | Intelligent computerized control system |

| EP1025934A2 (fr) † | 1999-02-05 | 2000-08-09 | Ishikawajima-Harima Heavy Industries Co., Ltd. | Procédé de coulage à deux cylindres de tôle en ruban |

| WO2001039914A1 (fr) † | 1999-12-01 | 2001-06-07 | Ishikawajima-Harima Heavy Industries Company Limited | Bande en acier de moulage |

| KR20020017028A (ko) † | 2000-08-28 | 2002-03-07 | 이구택 | 쌍롤형 박판주조 제어장치 및 방법 |

| EP1372890A1 (fr) † | 2001-03-26 | 2004-01-02 | Danieli & C. Officine Meccaniche SpA | Procede de cisaillage d'une bande metallique pendant la phase de coulee |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0138059A1 (fr) * | 1983-09-19 | 1985-04-24 | Hitachi, Ltd. | Procédé et dispositif pour couler une bande métallique entre deux cylindres |

| FR2582971B1 (fr) | 1985-06-07 | 1987-09-25 | Siderurgie Fse Inst Rech | Procede et mannequin d'extraction d'un produit de coulee continue entre cylindres |

| DE3603190A1 (de) | 1986-02-03 | 1987-08-06 | Schloemann Siemag Ag | Anfahrkopf fuer eine stahlbandgiessanlage |

| DE3608503C2 (de) * | 1986-03-14 | 1994-09-01 | Stopinc Ag | Verfahren zum automatischen Angießen eines Stranges einer Stranggießanlage |

| JPH01133644A (ja) * | 1987-11-20 | 1989-05-25 | Ishikawajima Harima Heavy Ind Co Ltd | 双ロール式連鋳機における鋳造開始方法 |

| JPH01166865A (ja) * | 1987-12-24 | 1989-06-30 | Ishikawajima Harima Heavy Ind Co Ltd | 双ロール連鋳法 |

| CN1010776B (zh) * | 1989-04-20 | 1990-12-12 | 北京市海淀区农业科学研究所 | 有机-无机复合肥料 |

| GB9512561D0 (en) * | 1995-06-21 | 1995-08-23 | Davy Distington Ltd | A method of casting metal strip |

| EP0903190B1 (fr) * | 1997-09-18 | 2003-04-16 | Castrip, LLC | Installation de coulée de bandes |

| AUPQ291199A0 (en) | 1999-09-17 | 1999-10-07 | Bhp Steel (Jla) Pty Limited | Strip casting |

| KR100406380B1 (ko) * | 1999-12-23 | 2003-11-19 | 주식회사 포스코 | 쌍롤식 박판주조기를 이용한 박판제조방법 |

-

2002

- 2002-09-12 AT AT0136702A patent/AT411822B/de not_active IP Right Cessation

-

2003

- 2003-08-18 MX MXPA05002697A patent/MXPA05002697A/es active IP Right Grant

- 2003-08-18 EP EP03798105A patent/EP1536900B2/fr not_active Expired - Lifetime

- 2003-08-18 DE DE50301955T patent/DE50301955D1/de not_active Expired - Lifetime

- 2003-08-18 US US10/527,533 patent/US7156153B2/en not_active Expired - Lifetime

- 2003-08-18 KR KR1020057004324A patent/KR101143384B1/ko active IP Right Grant

- 2003-08-18 WO PCT/EP2003/009110 patent/WO2004028725A1/fr not_active Application Discontinuation

- 2003-08-18 AU AU2003258624A patent/AU2003258624B2/en not_active Ceased

- 2003-08-18 CN CN03821789A patent/CN100577326C/zh not_active Expired - Fee Related

Patent Citations (36)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5956950A (ja) † | 1982-09-28 | 1984-04-02 | Nippon Kokan Kk <Nkk> | 金属板の連続鋳造方法 |

| JPS59215257A (ja) † | 1983-05-20 | 1984-12-05 | Ishikawajima Harima Heavy Ind Co Ltd | 双ロール式連鋳方法 |

| JPS6064754A (ja) † | 1983-09-19 | 1985-04-13 | Hitachi Ltd | 薄帯板の連続鋳造方法及び装置 |

| JPS6064753A (ja) † | 1983-09-19 | 1985-04-13 | Hitachi Ltd | 双ロ−ル式鋳造機の鋳造方法及びその装置 |

| US4702300A (en) † | 1985-03-15 | 1987-10-27 | Hitachi, Ltd. | Double drum type continuous casting machine |

| JPS61232044A (ja) † | 1985-04-05 | 1986-10-16 | Mitsubishi Heavy Ind Ltd | 薄板連続鋳造方法 |

| JPS61232045A (ja) † | 1985-04-05 | 1986-10-16 | Mitsubishi Heavy Ind Ltd | 薄板連続鋳造方法 |

| JPS61266159A (ja) † | 1985-05-21 | 1986-11-25 | Mitsubishi Heavy Ind Ltd | 薄板連続鋳造装置の運転方法 |

| JPS6297749A (ja) † | 1985-10-24 | 1987-05-07 | Mitsubishi Heavy Ind Ltd | 薄板連続鋳造方法 |

| JPS6349347A (ja) † | 1986-08-13 | 1988-03-02 | Ishikawajima Harima Heavy Ind Co Ltd | 双ロ−ル回転数制御方法 |

| JPS63290654A (ja) † | 1987-05-22 | 1988-11-28 | Nisshin Steel Co Ltd | 薄板連続鋳造方法 |

| JPS6434553A (en) † | 1987-07-31 | 1989-02-06 | Mitsubishi Heavy Ind Ltd | Method for controlling molten steel level in continuous casting machine |

| JPH01154850A (ja) † | 1987-12-10 | 1989-06-16 | Ishikawajima Harima Heavy Ind Co Ltd | 双ロール式連鋳機の板厚制御方法 |

| US5052467A (en) † | 1989-08-03 | 1991-10-01 | Nippon Steel Corporation | Control device and a control method for twin-roll continuous caster |

| US5031688A (en) † | 1989-12-11 | 1991-07-16 | Bethlehem Steel Corporation | Method and apparatus for controlling the thickness of metal strip cast in a twin roll continuous casting machine |

| EP0450775A2 (fr) † | 1990-04-04 | 1991-10-09 | Ishikawajima-Harima Heavy Industries Co., Ltd. | Procédé et dispositif de coulage d'une bande |

| WO1992002321A1 (fr) † | 1990-08-03 | 1992-02-20 | Davy Mckee (Poole) Limited | Dispositif de coulee de metal a double cylindre |

| JPH04167950A (ja) † | 1990-11-01 | 1992-06-16 | Toshiba Corp | 双ロール式連続鋳造機の制御方法および装置 |

| US5191927A (en) † | 1990-11-22 | 1993-03-09 | Mitsubishi Jukogyo Kabushiki Kaisha | Method and apparatus for detecting a sheet thickness in a continuous casting machine |

| JPH05169205A (ja) † | 1991-10-25 | 1993-07-09 | Kobe Steel Ltd | 双ロール式連続鋳造機の鋳造速度制御方法 |

| US5287912A (en) † | 1991-11-21 | 1994-02-22 | Ishikawajima-Harima Heavy Industries Company Limited | Strip casting |

| KR930006638B1 (ko) † | 1991-12-28 | 1993-07-22 | 포항제철 주식회사 | 강의 연속주조 자동 제어방법 |

| JPH06114504A (ja) † | 1992-10-09 | 1994-04-26 | Nippon Steel Corp | 双ドラム薄板連続鋳造法 |

| WO1995009708A1 (fr) † | 1993-10-07 | 1995-04-13 | Fata Hunter, Inc. | Procede de coulee a cylindres a calibrage fin |

| US5706882A (en) † | 1994-12-29 | 1998-01-13 | Usinor-Sacilor | Control process for twin-roll continuous casting |

| US6085183A (en) † | 1995-03-09 | 2000-07-04 | Siemens Aktiengesellschaft | Intelligent computerized control system |

| WO1997034718A1 (fr) † | 1996-03-19 | 1997-09-25 | Ishikawajima-Harima Heavy Industries Company Limited | Absorbeurs de chaleur sans contact pour la coulee en bandes |

| US5927375A (en) † | 1996-11-07 | 1999-07-27 | Usinor Of Puteaux | Continuous casting process between rolls |

| US5988258A (en) † | 1997-03-27 | 1999-11-23 | Ishikawajima-Harima Heavy Industries Company Limited | Casting metal strip |

| EP0903191A2 (fr) † | 1997-09-18 | 1999-03-24 | Ishikawajima-Harima Heavy Industries Co., Ltd. | Installation de coulée de bandes |

| KR19990051823A (ko) † | 1997-12-20 | 1999-07-05 | 이구택 | 쌍롤형 박판주조장치에서의 주조롤 속도 조정방법 및 장치 |

| WO1999048636A1 (fr) † | 1998-03-25 | 1999-09-30 | Voest-Alpine Industrieanlagenbau Gmbh | Installation et procede de coulee en continu d'un ruban mince |

| EP1025934A2 (fr) † | 1999-02-05 | 2000-08-09 | Ishikawajima-Harima Heavy Industries Co., Ltd. | Procédé de coulage à deux cylindres de tôle en ruban |

| WO2001039914A1 (fr) † | 1999-12-01 | 2001-06-07 | Ishikawajima-Harima Heavy Industries Company Limited | Bande en acier de moulage |

| KR20020017028A (ko) † | 2000-08-28 | 2002-03-07 | 이구택 | 쌍롤형 박판주조 제어장치 및 방법 |

| EP1372890A1 (fr) † | 2001-03-26 | 2004-01-02 | Danieli & C. Officine Meccaniche SpA | Procede de cisaillage d'une bande metallique pendant la phase de coulee |

Non-Patent Citations (1)

| Title |

|---|

| Wechsler, R. et al., "The Castrip Process for Twin-Roll Casting of Steel Strip", September 2002, pages 69-74 † |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20050057316A (ko) | 2005-06-16 |

| MXPA05002697A (es) | 2005-05-27 |

| US7156153B2 (en) | 2007-01-02 |

| AU2003258624A1 (en) | 2004-04-19 |

| US20050224210A1 (en) | 2005-10-13 |

| EP1536900B1 (fr) | 2005-12-14 |

| AT411822B (de) | 2004-06-25 |

| AU2003258624B2 (en) | 2008-11-20 |

| CN1681613A (zh) | 2005-10-12 |

| WO2004028725A1 (fr) | 2004-04-08 |

| DE50301955D1 (de) | 2006-01-19 |

| ATA13672002A (de) | 2003-11-15 |

| EP1536900A1 (fr) | 2005-06-08 |

| KR101143384B1 (ko) | 2012-05-23 |

| CN100577326C (zh) | 2010-01-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1812185B1 (fr) | Procede de production d'une bande d'acier coule | |

| EP2627464B1 (fr) | Procédé et installation de production à efficacité énergétique pour une bande d'acier laminée à chaud | |

| EP1536900B2 (fr) | Procede pour debuter un procedure de coulee | |

| EP3558563B1 (fr) | Procede de fabrication de bandes bobinees sans fin laminees a chaud dans une installation combinee de coulee et de laminage, et installation combinee de coulee et de laminage | |

| EP2441539A1 (fr) | Procédé à sortie d'énergie optimisée et installation de production d'une bande chaude en acier | |

| EP2441538A1 (fr) | Dispositif de coulée continue doté d'une réduction de barre dynamique | |

| DE10042078A1 (de) | Verfahren und Vorrichtung zum kontinuierlichen Gießen von Stahlband aus Stahlschmelze | |

| EP2217394B1 (fr) | Procédé et dispositif destinés à la fabrication d'une bande de métal | |

| EP3554744B1 (fr) | Procédé et dispositif de régulation d'une installation de coulée continue | |

| EP3495086A1 (fr) | Procédé et dispositif de fabrication d'un matériau composite en forme de bande | |

| EP1077782B1 (fr) | Dispositif et procede de coulee de metal, proche des cotes finales | |

| DE3440236C2 (fr) | ||

| WO2016165933A1 (fr) | Installation de coulée et de laminage et procédé servant à faire fonctionner ladite installation | |

| DE69323922T2 (de) | Verfahren und Vorrichtung zum kontinuierlichen Giessen eines metallischen Bandes | |

| EP3993921A1 (fr) | Acheminement de matière fondue pour installations de coulée en bande | |

| EP1289687B1 (fr) | Procede et installation pour fabriquer une bande de metal | |

| EP3173166B1 (fr) | Procédé et dispositif de réglage de la largeur d'une barre métallique coulée en continu | |

| DE2853868C2 (de) | Verfahren zum Stranggießen von Stahl sowie dementsprechend hergestellter Stahlstrang | |

| EP0832990B1 (fr) | Procédé pour fabriquer des barres metalliques revêtues, en particulier de bandes en acier | |

| DE19814988A1 (de) | Gießverfahren für ein dünnes Metallband | |

| DE69000282T2 (de) | Verfahren und vorrichtung zur herstellung von duennen metallprodukten mittels strangguss. | |

| DE1292793C2 (de) | Vorrichtung zum Abziehen eines Stahlstranges aus einer Strangkokille | |

| EP1243362A2 (fr) | Procédé et dispositif de fabrication de feuillard à chaud dans une machine de coulée continue de type à deux rouleaux | |

| DE4404858A1 (de) | Verfahren und Vorrichtung zum Gießen von Blechen und Bändern |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050309 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051214 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051214 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051214 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051214 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| DAX | Request for extension of the european patent (deleted) | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50301955 Country of ref document: DE Date of ref document: 20060119 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060314 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060314 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060314 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20060301 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060325 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060515 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060615 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060831 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: DANIELI & C. OFFICINE MECCANICHE SPA Effective date: 20060913 Opponent name: CASTRIP, LLC Effective date: 20060913 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: DANIELI & C. OFFICINE MECCANICHE SPA Opponent name: CASTRIP, LLC |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060818 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070831 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051214 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: SIEMENS VAI METALS TECHNOLOGIES GMBH & CO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20051214 |

|

| NLT2 | Nl: modifications (of names), taken from the european patent patent bulletin |

Owner name: SIEMENS VAI METALS TECHNOLOGIES GMBH & CO Effective date: 20081105 |

|

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: SIEMENS VAI METALS TECHNOLOGIES GMBH |

|

| RTI2 | Title (correction) |

Free format text: METHOD FOR COMMENCING A CASTING PROCESS |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20110914 Year of fee payment: 9 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20120815 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20120824 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R102 Ref document number: 50301955 Country of ref document: DE Effective date: 20120815 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20120809 Year of fee payment: 10 Ref country code: SE Payment date: 20120809 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SI Payment date: 20120725 Year of fee payment: 10 Ref country code: TR Payment date: 20120725 Year of fee payment: 10 Ref country code: SK Payment date: 20120817 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20120815 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20120823 Year of fee payment: 10 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: NAV |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20120806 Year of fee payment: 10 |

|

| BERE | Be: lapsed |

Owner name: *VOEST-ALPINE INDUSTRIEANLAGENBAU G.M.B.H. & CO. Effective date: 20120831 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20120815 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120831 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20130827 Year of fee payment: 11 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20130818 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130818 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: MM4A Ref document number: E 478 Country of ref document: SK Effective date: 20130818 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20140430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130819 |

|

| REG | Reference to a national code |

Ref country code: SI Ref legal event code: KO00 Effective date: 20140401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130818 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130902 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20140818 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130818 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130819 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130818 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref country code: DE Ref legal event code: R082 Ref document number: 50301955 Country of ref document: DE Representative=s name: HEYERHOFF GEIGER & PARTNER PATENTANWAELTE PART, DE Ref country code: DE Ref legal event code: R081 Ref document number: 50301955 Country of ref document: DE Owner name: PRIMETALS TECHNOLOGIES AUSTRIA GMBH, AT Free format text: FORMER OWNER: VOEST-ALPINE INDUSTRIEANLAGENBAU GMBH & CO., LINZ, AT |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20210819 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 50301955 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50301955 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230301 |