EP1528998B1 - Weichenantrieb für bewegliche herze - Google Patents

Weichenantrieb für bewegliche herze Download PDFInfo

- Publication number

- EP1528998B1 EP1528998B1 EP03735142A EP03735142A EP1528998B1 EP 1528998 B1 EP1528998 B1 EP 1528998B1 EP 03735142 A EP03735142 A EP 03735142A EP 03735142 A EP03735142 A EP 03735142A EP 1528998 B1 EP1528998 B1 EP 1528998B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- driver

- stroke

- cylinder piston

- piston unit

- switch actuator

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61L—GUIDING RAILWAY TRAFFIC; ENSURING THE SAFETY OF RAILWAY TRAFFIC

- B61L5/00—Local operating mechanisms for points or track-mounted scotch-blocks; Visible or audible signals; Local operating mechanisms for visible or audible signals

- B61L5/04—Fluid-pressure devices for operating points or scotch-blocks

Definitions

- the invention relates to a point machine for movable core pieces with at least one cylinder piston unit with a defined preset piston stroke.

- a point drive is known from WO 02/055361 A1.

- the invention now aims to provide a point machine of the type mentioned, in which prefabricated cylinder piston units with defined preset piston stroke can be used, which is subsequently guaranteed after installation in the laid switch also an exact adjustment of the actually required adjustment path.

- the inventive design the point drive of the type mentioned essentially in that the cylinder piston unit is connected with adjustable in the axial direction of the piston stroke camps, which is connected to a stationary substructure for setting a defined center position of the piston stroke and the driver for the movable core and that the driver for the movable centerpiece is coupled with the interposition of adjustable in the axial direction stops with the cylinder piston unit.

- the cylinder piston unit is connected to adjustable in the direction of the piston bearings, the possibility is created, a factory-designed with a defined piston stroke cylinder piston unit, in which the factory preset stroke must be greater than the actual stroke of the movable switch part or center piece so anyway to arrange in a threshold, in particular in a trough threshold, that an exact positioning in the sense of a defined center position of the adjustment of the cylinder piston unit succeeds.

- the adjustable bearings must be adjusted accordingly, so that the cylinder piston unit as a whole is oriented so that the center position of the movable frog point or the movable core coincides with the center position of the preset stroke of the cylinder piston unit.

- the training is advantageously such that the driver has a sliding block and a relative movement of the centerpiece in two intersecting, different from the axis of Verstellhubes Axles allows.

- Such a quasi gimbal suspension allows to record relative movement of switch parts under the rolling load accordingly, without the high-precision aligned drivers and attacks or the coupling parts are overloaded to the cylinder piston unit.

- the exact stroke adjustment or the exact setting of the idle stroke can be done in a particularly simple manner so that the driver is interspersed by a spindle with on both sides of the driver different thread direction in the direction of Verstellhubes and cooperates with non-rotatably guided nuts with an adjustable idle stroke. Since, as mentioned in the beginning, the cylinder piston unit was initially set exactly on the center position, the adjustment stroke can be changed to both sides of the center with such a spindle at the same time and thus adjusted to the exact required adjustment of the centerpiece, with the center position on both sides in each case an identical idle stroke is formed.

- the movable centerpiece is guided and moved, in particular near the centerpiece tip during its pivoting movement about a circular arc and moved, so due to the linear orientation of Verstellhubes a number of additional forces and in particular pivot forces must be absorbed without risk of overloading.

- the corresponding compliance in the rail longitudinal direction can be ensured in a simple manner by conventional means, such as elongated holes or the like.

- a relative panning the heart piece and in particular the frog tip over the driver and in particular to ensure the sliding block of the driver, and to avoid picking up vertical movements when crossing the switch under rolling load, or when switching the apex in cooperation with a rolling device is the training Advantageously made such that the driver is pivotally mounted about the axis of the cylinder piston unit and the sliding block of the driver carries or has a journal or cylinder portion which is pivotally mounted about an axis extending substantially normal to the direction of Verstellhubes.

- a structurally particularly simple and in a simple manner operable from the outside setting device for adjusting the center position of the cylinder piston unit in a trough threshold be designed so that the adjustable in the axial direction of the piston stroke bearing are designed as a clevis whose Fork rotatably and slidably supported in the axial direction and is connected via a bearing pin with the hydraulic cylinder piston unit and that with the clevis a clevis screw is connected, which passes through a stop and carries an adjusting nut whose rotation causes an axial displacement of the clevis.

- the corresponding adjustment is achieved by operating lock nuts on both sides of the trough threshold.

- the training with Advantage made such that the stop as an upwardly open slot a transverse to the threshold longitudinal direction extending wall of a trough threshold or a stationary part of a switch is formed.

- a lock cylinder with the functions of moving, locking and monitoring the locking of the movable switch member with factory set to a specific stroke type used, the factory-set stroke is in any case greater than the stroke of the movable switch member.

- the actual Hubanpassung to the special switch is made by adjusting the idle stroke between the driver on UmstellverBankzylinder and the movable switch part, which can be changed by adjusting the idle stroke, the stroke of the switch part with constant cylinder stroke and thus continuously.

- At the left or right-hand thread in the middle region of the symmetrical spindle rod of the spindle drive sit two drive nuts, which are positively but slidably guided on the housing of the driver, wherein the spindle rod itself is passed through a sliding block.

- the nuts can interact with the interposition of a plate spring with the sliding block or Gleitsteinarna the driver, the sliding block itself in turn interacts with the directly connected to the movable core components.

- the sliding block which itself is part of the driver, thus absorbs those components which are to ensure the transmission of the displacement to the core, which in turn slide into the slider dipping parts in the sliding block pivotally engage to prevent a corresponding overload.

- the entire closure device is fixed to frame parts of a trough threshold, wherein the spindle provided with clevises cooperate with the corresponding adjusting nuts to allow the adjustment of the center position.

- the steps required for the exact setting thus consist in that firstly the idle stroke is set to maximum stroke on one side, the frog is adjusted to an end position which Distance between the heart and wing rail is measured and the core is moved to the other end position with renewed measuring of the distance, whereupon a center adjustment is made until the same distance between the heart and wing rail is on both sides. Based on this center adjustment, the idle stroke is reduced by the distance dimension as a result, whereby the exact Einjust ist was achieved.

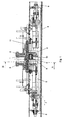

- the movable core is designated 1 and slidable in contact with the wing rails 2 and 3 respectively. All components of the Umstell-, closure and testing facilities are located below the track level in a trough threshold 4.

- the switching device 5 is in this case formed by a cylinder piston unit and is articulated by means of bearings 6 at the stationary trough threshold. As will be explained below, the bearings 6 are such that an adjustment of the switching device 5 in the threshold longitudinal direction can be made according to the double arrow 7 for adjusting the center position of the cylinder piston unit.

- the changeover device 5 is coupled to a driver part 8, which forwards the changeover movement to the movable center piece 1.

- the entrainment takes place here via adjustable stops 9, which cooperate with a sliding block 10, which in turn is connected to the base plate 11 of the movable core piece 1.

- a Leerhubes between the stops 9 and the sliding block 10 the effective stroke of the movable core 1 can be set exactly.

- the driver now further includes a sliding block 10, which is penetrated by the spindle 13 and is slidably mounted on this between the stops 9.

- the idle stroke a between the stops 9 and the sliding block 10 can now be adjusted to reduce the Umstellhub the Zylinderkolbenaggregates 5 to the respectively required Verstellhub the movable core 1.

- the sliding block 10 furthermore has an inner part 18 with a cylinder section with the cylinder axis 19, so that a pivoting of the cylinder part 18 about the rotation axis 19 relative to the outer part 20 of the sliding block 10 and thus relative to the driver 8 can take place.

- the cylinder part 18 engages in a driver bracket 21, which in turn is welded to the base plate 11 of the movable core 1, so that a total compensation movement during the necessary during the Umstellieri of the center piece 1 pivoting of the core 1 relative to the switching device 5 is possible.

- the bow-like shape of the driver part 21 can be seen, it can be seen that the sliding block 10 according to the double arrow 22 is slidably movable in the bow-shaped driving part 21, so that longitudinal displacements of the movable core 1, which caused for example by thermal expansions can not be passed on to the changeover mechanism. Furthermore, it can be seen that the stops 9, i. the driving nut, are rotatably supported on the sleeves 34 of the driver. As a result, an anti-rotation of the stops 9 is achieved relative to the spindle rotation and the axial displacement of the stops 9 ensured.

- a positioning of the driver 8 to the axis 23 is set to the central angle ⁇ , so that no forces are introduced into the cylinder piston unit from these movements.

- the bearing 6 is in this case provided with a fork head 25, the fork rotatably supported and slidably supported in the direction of the axis 23 of the cylinder piston unit 5 and is connected via a bearing pin 26 with the hydraulic cylinder piston unit 5.

- the fixation of the rotational position of the fork head 5 takes place in this case in that the clevis 25 is supported on a web 27 extending from the trough-side wall.

- the clevis 25 is connected to a clevis screw 28, which carries an adjusting nut 29.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Actuator (AREA)

- Transmission Devices (AREA)

- Railway Tracks (AREA)

- Percussive Tools And Related Accessories (AREA)

- Die Bonding (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT03735142T ATE335643T1 (de) | 2002-08-13 | 2003-06-16 | Weichenantrieb für bewegliche herze |

| SI200330521T SI1528998T1 (sl) | 2002-08-13 | 2003-06-16 | Kretnicni pogon za premicna srca |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT12282002 | 2002-08-13 | ||

| AT0122802A AT411350B (de) | 2002-08-13 | 2002-08-13 | Weichenantrieb für bewegliche herze |

| PCT/AT2003/000169 WO2004014709A1 (de) | 2002-08-13 | 2003-06-16 | Weichenantrieb für bewegliche herze |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1528998A1 EP1528998A1 (de) | 2005-05-11 |

| EP1528998B1 true EP1528998B1 (de) | 2006-08-09 |

Family

ID=3687511

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03735142A Expired - Lifetime EP1528998B1 (de) | 2002-08-13 | 2003-06-16 | Weichenantrieb für bewegliche herze |

Country Status (16)

| Country | Link |

|---|---|

| US (1) | US7168663B2 (pl) |

| EP (1) | EP1528998B1 (pl) |

| CN (1) | CN100465037C (pl) |

| AT (1) | AT411350B (pl) |

| AU (1) | AU2003237561B2 (pl) |

| BR (1) | BR0313463A (pl) |

| CA (1) | CA2493999A1 (pl) |

| DE (1) | DE50304598D1 (pl) |

| DK (1) | DK1528998T3 (pl) |

| ES (1) | ES2270048T3 (pl) |

| HR (1) | HRP20050236A2 (pl) |

| NO (1) | NO20051252L (pl) |

| PL (1) | PL201243B1 (pl) |

| PT (1) | PT1528998E (pl) |

| WO (1) | WO2004014709A1 (pl) |

| ZA (1) | ZA200500892B (pl) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10340784B4 (de) * | 2003-09-02 | 2007-04-12 | Thyssenkrupp Gft Gleistechnik Gmbh | Kreuzung oder Weiche |

| ITFI20030296A1 (it) * | 2003-11-19 | 2005-05-20 | Ge Transp Systems S P A | Cassa di manovra per scambi ferroviari |

| US7341226B2 (en) * | 2004-11-17 | 2008-03-11 | General Electric Company | Movable point frog switching assembly |

| ES1072245Y (es) | 2010-04-09 | 2010-09-09 | Amurrio Ferrocarril Y Equipos | Dispositivo de encerrojamiento para corazon de punta movil |

| DE102012017982A1 (de) * | 2012-09-12 | 2014-03-13 | Schwihag Ag | Herzstückrollvorrichtung |

| CZ24854U1 (cs) * | 2012-12-13 | 2013-01-21 | DT-VÝHYBKÁRNA A STROJÍRNA, a.s. | Dotlacovací zarízení |

| RU2539619C2 (ru) * | 2013-02-14 | 2015-01-20 | Открытое Акционерное Общество "Российские Железные Дороги" | Комплект устройств для закрепления и контроля положения остряков и подвижных сердечников крестовин стрелок |

| US9290192B2 (en) | 2013-12-11 | 2016-03-22 | Voestalpine Nortrak Inc. | Spring wing controller |

| US9932054B2 (en) * | 2016-02-19 | 2018-04-03 | Progress Rail Services Corporation | Double point derail switch |

| CN107601271B (zh) * | 2017-11-02 | 2024-04-09 | 扬州市神力吊具制造有限公司 | 一种辙叉吊具 |

| CN110396875B (zh) * | 2018-04-25 | 2021-02-23 | 比亚迪股份有限公司 | 一种道岔梁驱动装置、道岔和轨道 |

| CN114108401A (zh) * | 2020-08-31 | 2022-03-01 | 董军军 | 一种道岔转辙部分及护轨部分专用改道器 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1446743A (en) * | 1923-02-27 | Switch-locking mechanism | ||

| US1253439A (en) * | 1915-10-09 | 1918-01-15 | Thomas George Stiles | Switch mechanism. |

| US1744604A (en) * | 1928-06-09 | 1930-01-21 | Thomas J Arledge | Automatic switch-latch mechanism |

| DE2002025C3 (de) * | 1970-01-17 | 1975-06-12 | Butzbacher Weichenbau Gmbh, 6308 Butzbach | Herzstück mit beweglicher Spitze |

| US3521053A (en) * | 1968-06-10 | 1970-07-21 | Pintsch Bamag Ag | Crossing frogs for rails of railroad track and the like |

| IT1213950B (it) * | 1987-12-16 | 1990-01-05 | Sasib Spa | Dispositivo universale di fermascambiatura esterna per deviatoi ferroviari |

| DK0467865T3 (da) * | 1990-07-19 | 1994-10-31 | Siliani Angiolo Spa | Apparat til betjening af skiftetunger i jernbanesporskifter |

| IT1242226B (it) * | 1990-10-10 | 1994-03-03 | Sasib Spa | Dispositivo di manovra per deviatoi ferroviari, in particolare per linee ad alta velocita' |

| DE4305228A1 (de) * | 1993-02-19 | 1994-08-25 | Butzbacher Weichenbau Gmbh | Herzstück |

| AT403462B (de) * | 1995-05-03 | 1998-02-25 | Vae Ag | Einrichtung zum umstellen von weichen |

| CN1151951A (zh) * | 1995-12-13 | 1997-06-18 | 西门子公司 | 转辙器传动装置 |

| IT1298019B1 (it) * | 1997-10-22 | 1999-12-20 | Sasib Railway Spa | Cassa di manovra per scambi ferroviari, ferrotranviari, o simili. |

| CN2401422Y (zh) * | 1999-12-10 | 2000-10-18 | 北京铁路局太原电务器材厂 | 轨枕式道岔转辙机 |

| AT411047B (de) * | 2001-01-11 | 2003-09-25 | Vae Eisenbahnsysteme Gmbh | Einrichtung zum verriegeln der endlagen von beweglichen weichenteilen |

-

2002

- 2002-08-13 AT AT0122802A patent/AT411350B/de not_active IP Right Cessation

-

2003

- 2003-06-16 CN CNB038193817A patent/CN100465037C/zh not_active Expired - Fee Related

- 2003-06-16 BR BR0313463-6A patent/BR0313463A/pt not_active IP Right Cessation

- 2003-06-16 PT PT03735142T patent/PT1528998E/pt unknown

- 2003-06-16 PL PL373579A patent/PL201243B1/pl not_active IP Right Cessation

- 2003-06-16 HR HR20050236A patent/HRP20050236A2/hr not_active Application Discontinuation

- 2003-06-16 DK DK03735142T patent/DK1528998T3/da active

- 2003-06-16 DE DE50304598T patent/DE50304598D1/de not_active Expired - Lifetime

- 2003-06-16 WO PCT/AT2003/000169 patent/WO2004014709A1/de not_active Ceased

- 2003-06-16 US US10/523,564 patent/US7168663B2/en not_active Expired - Fee Related

- 2003-06-16 ES ES03735142T patent/ES2270048T3/es not_active Expired - Lifetime

- 2003-06-16 EP EP03735142A patent/EP1528998B1/de not_active Expired - Lifetime

- 2003-06-16 AU AU2003237561A patent/AU2003237561B2/en not_active Ceased

- 2003-06-16 CA CA002493999A patent/CA2493999A1/en not_active Abandoned

-

2005

- 2005-01-31 ZA ZA200500892A patent/ZA200500892B/xx unknown

- 2005-03-10 NO NO20051252A patent/NO20051252L/no not_active Application Discontinuation

Also Published As

| Publication number | Publication date |

|---|---|

| ZA200500892B (en) | 2006-07-26 |

| AU2003237561A1 (en) | 2004-02-25 |

| PL373579A1 (pl) | 2005-09-05 |

| CN1675097A (zh) | 2005-09-28 |

| DE50304598D1 (de) | 2006-09-21 |

| ES2270048T3 (es) | 2007-04-01 |

| PL201243B1 (pl) | 2009-03-31 |

| US20050269459A1 (en) | 2005-12-08 |

| PT1528998E (pt) | 2006-12-29 |

| DK1528998T3 (da) | 2006-12-11 |

| US7168663B2 (en) | 2007-01-30 |

| NO20051252L (no) | 2005-03-10 |

| WO2004014709A1 (de) | 2004-02-19 |

| CN100465037C (zh) | 2009-03-04 |

| AU2003237561B2 (en) | 2009-10-01 |

| ATA12282002A (de) | 2003-05-15 |

| CA2493999A1 (en) | 2004-02-19 |

| AT411350B (de) | 2003-12-29 |

| HRP20050236A2 (en) | 2005-10-31 |

| BR0313463A (pt) | 2005-07-05 |

| EP1528998A1 (de) | 2005-05-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69129704T2 (de) | Betätigungsvorrichtung für Eisenbahnweichen, insbesondere für Hochgeschwindigkeitsbahnen | |

| EP1528998B1 (de) | Weichenantrieb für bewegliche herze | |

| DE69813275T2 (de) | Schaltkasten für eisenbahn, strassenbahnweichen oder dergleichen vom sogenannten englischen typ | |

| DE19502105C2 (de) | Verschlußvorrichtung für Weichenzungen | |

| AT502042B1 (de) | Vorrichtung zur endlagenprüfung von beweglichen teilen einer schienenweiche | |

| AT391500B (de) | Umstellvorrichtung fuer bewegliche teile einer schienenweiche | |

| EP1159183A1 (de) | Weichenverschluss für weichenzungen | |

| AT411351B (de) | Endlagenprüfeinrichtung für bewegliche weichenteile | |

| DE19612091A1 (de) | Hubsäule | |

| EP1538264B1 (de) | Herzstück | |

| DE60123203T4 (de) | Weichenstellvorrichtung für Eisenbahnweichen oder dergleichen, mit einer auffahrbahren Widerstandsvorrichtung zum Entgegenwirken des Auffahrens der Weichen | |

| EP0315619B1 (de) | Umstellvorrichtung für schwenkbare Schienen oder bewegliche Herzstücke im Kreuzungsbereich einer Weiche | |

| EP1740771B1 (de) | Vorrichtung zur justierung eines gleisrostes und weichen | |

| EP2893081B1 (de) | Weiche für schienen | |

| EP0165229B1 (de) | Vorrichtung zur Sicherung der Lage der Zungenschienen von Gleisweichen | |

| EP0679789B1 (de) | Dreh-Beschlag oder Dreh-Kipp-Beschlag von Fenstern, Türen oder dergleichen | |

| EP0212484A2 (de) | Türschliesser | |

| EP0624506B1 (de) | Halterungsanordnung für querbewegliche Bremsklotzeinheiten an Schienenfahrzeuge | |

| EP1493645A1 (de) | Einrichtung zum Umstellen von Weichen | |

| DE10212979B4 (de) | Endlagenprüfvorrichtung für eine Weiche | |

| DE19732477C2 (de) | Vorrichtung für den Ausgleich von Längsbewegungen von Weichenzungen an Stell-oder Überwachungseinrichtungen | |

| DE4112928C2 (de) | Klammerverschluß für Weichen | |

| DE3334161C2 (pl) | ||

| DE20300816U1 (de) | Weiche für eine Förderanlage | |

| EP2812226B1 (de) | Einrichtung zum umstellen einer schienenweiche |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20050202 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| RAX | Requested extension states of the european patent have changed |

Extension state: LT Payment date: 20050202 Extension state: LV Payment date: 20050202 |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: LT LV |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060809 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060809 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50304598 Country of ref document: DE Date of ref document: 20060921 Kind code of ref document: P |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20061009 |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: PPS POLYVALENT PATENT SERVICE AG |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: EE Ref legal event code: FG4A Ref document number: E000646 Country of ref document: EE Effective date: 20061101 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20060403877 Country of ref document: GR |

|

| REG | Reference to a national code |

Ref country code: HU Ref legal event code: AG4A Ref document number: E000866 Country of ref document: HU |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20061103 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2270048 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070510 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070630 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20080610 Year of fee payment: 6 Ref country code: HU Payment date: 20080609 Year of fee payment: 6 Ref country code: LU Payment date: 20080613 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SK Payment date: 20080611 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FI Payment date: 20080613 Year of fee payment: 6 Ref country code: SI Payment date: 20080613 Year of fee payment: 6 Ref country code: BG Payment date: 20080618 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20080618 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20080728 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20080620 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060809 |

|

| BERE | Be: lapsed |

Owner name: *VAE G.M.B.H. Effective date: 20090630 Owner name: *VAE EISENBAHNSYSTEME G.M.B.H. Effective date: 20090630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090616 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20100101 |

|

| REG | Reference to a national code |

Ref country code: SK Ref legal event code: MM4A Ref document number: E 1146 Country of ref document: SK Effective date: 20090616 |

|

| REG | Reference to a national code |

Ref country code: SI Ref legal event code: KO00 Effective date: 20100205 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090617 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090617 Ref country code: SK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090616 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BG Free format text: FAILURE TO ELECT DOMICILE IN THE NATIONAL COUNTRY Effective date: 20091231 Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090616 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 20110624 Year of fee payment: 9 Ref country code: FR Payment date: 20110630 Year of fee payment: 9 Ref country code: CZ Payment date: 20110613 Year of fee payment: 9 Ref country code: CH Payment date: 20110623 Year of fee payment: 9 Ref country code: PT Payment date: 20110613 Year of fee payment: 9 Ref country code: TR Payment date: 20110602 Year of fee payment: 9 Ref country code: SE Payment date: 20110613 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: EE Payment date: 20110614 Year of fee payment: 9 Ref country code: AT Payment date: 20110613 Year of fee payment: 9 Ref country code: GB Payment date: 20110620 Year of fee payment: 9 Ref country code: RO Payment date: 20110530 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20110622 Year of fee payment: 9 Ref country code: IT Payment date: 20110623 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: VAE EISENBAHNSYSTEME GMBH Free format text: VAE EISENBAHNSYSTEME GMBH#ALPINESTRASSE 1#8740 ZELTWEG (AT) $ VAE GMBH#ROTENTURMSTRASSE 5-9#1010 WIEN (AT) -TRANSFER TO- VAE EISENBAHNSYSTEME GMBH#ALPINESTRASSE 1#8740 ZELTWEG (AT) $ VAE GMBH#ROTENTURMSTRASSE 5-9#1010 WIEN (AT) |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: MM4A Free format text: LAPSE DUE TO NON-PAYMENT OF FEES Effective date: 20121217 |

|

| REG | Reference to a national code |

Ref country code: LT Ref legal event code: MM9D Effective date: 20120616 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CZ Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120616 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL Ref country code: EE Ref legal event code: MM4A Ref document number: E000646 Country of ref document: EE Effective date: 20120630 Ref country code: AT Ref legal event code: MM01 Ref document number: 335643 Country of ref document: AT Kind code of ref document: T Effective date: 20120616 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20120616 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120616 Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20121217 Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120617 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20130228 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 50304598 Country of ref document: DE Effective date: 20130101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120630 Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120702 Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120616 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130101 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120616 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120630 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120616 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20131023 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120616 Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20120617 |