EP1513734B1 - Bouchon de contenant auto-étancheifiant - Google Patents

Bouchon de contenant auto-étancheifiant Download PDFInfo

- Publication number

- EP1513734B1 EP1513734B1 EP03760630A EP03760630A EP1513734B1 EP 1513734 B1 EP1513734 B1 EP 1513734B1 EP 03760630 A EP03760630 A EP 03760630A EP 03760630 A EP03760630 A EP 03760630A EP 1513734 B1 EP1513734 B1 EP 1513734B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- annular disc

- storage container

- container closure

- container

- sealing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D47/00—Closures with filling and discharging, or with discharging, devices

- B65D47/04—Closures with discharging devices other than pumps

- B65D47/20—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge

- B65D47/2018—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge comprising a valve or like element which is opened or closed by deformation of the container or closure

- B65D47/2056—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge comprising a valve or like element which is opened or closed by deformation of the container or closure lift valve type

- B65D47/2081—Closures with discharging devices other than pumps comprising hand-operated members for controlling discharge comprising a valve or like element which is opened or closed by deformation of the container or closure lift valve type in which the deformation raises or lowers the valve port

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D51/00—Closures not otherwise provided for

- B65D51/16—Closures not otherwise provided for with means for venting air or gas

- B65D51/1633—Closures not otherwise provided for with means for venting air or gas whereby venting occurs by automatic opening of the closure, container or other element

- B65D51/1644—Closures not otherwise provided for with means for venting air or gas whereby venting occurs by automatic opening of the closure, container or other element the element being a valve

Definitions

- the invention relates to a container closure for liquid to pasty products containing flexible storage containers such as bottles or tubes, wherein the container closure valve-like when squeezing the storage container automatically opens to discharge the products and automatically closes again by the restoring force of the storage container.

- An elaborate device is known from EP 0 048 420 B1, consisting of a hollow cylindrical storage container with a dispenser head with dispenser pump, wherein the product located in the storage container is pressed out of the storage container via the application opening by a downward external pressure on the dispenser pump.

- dispensers of a particularly simple design in which the product is discharged by compressing the storage container from an opening in the storage container, the opening of the storage container being directed downwards, depending on the intended use and viscosity of the product. To open and close the opening then serves a simple cap, a screw or a dowel pin.

- Such a closure of a storage container is described in DE 692 02 466 T2. It consists of a closed with a lid closure body which is screwed onto the neck of a storage container, for example. Centered in the closure body is located on a concave support member provided with a slits convex elastic valve. Upon application of an external force to the storage container, the fluid product is pressed from below against the central portion of the valve, causing it to bulge outwards. The fluid product can now escape through the opening slits to the outside. After completion of the external pressure on the container by the elasticity of the valve returns this back to its normal de-stressing sealing position.

- US-A-4,785,978 proposes a container closure for flexible storage containers containing liquid to pasty products, such as bottles or tubes, with a first valve which is automatically actuated by an externally applied flexible storage container Pressure to discharge the product opens. In the absence of this pressure, this valve is automatically closed again by the elastic restoring force of the storage container and the resulting negative pressure. At the same time, aeration of the storage container takes place by means of a now opening second valve, which compensates the negative pressure in the storage container.

- the first valve is formed by a clamped with its outer edge between the outer housing and a disk-shaped component annular disc, the middle part axially movable radially releases the outlet opening of the disk-shaped component or shuts off.

- the second valve is an axially movable mandrel which closes by spring tension from below an axial sleeve of the disk-shaped component and releases the opening of the sleeve for ventilation of the storage container at a negative pressure in the storage container.

- the inventive arrangement of an elastic annular disc on a sealing pin a closable discharge opening between these two sealing elements is produced by simple means.

- the product to be discharged is pressed from below against the elastic annular disc by pressure on the storage container, it lifts off centrally from the sealing pin, whereby a discharge gap between the annular disc and the sealing pin is released.

- the annular disc is in consequence of the now prevailing in the storage tank vacuum on the sealing pin and closes it again the storage container.

- the elasticity of the sealing disc is adapted to the viscosity of the product to be discharged and to the restoring force of the storage container to ensure complete recovery of the annular disc.

- the axial displacement of the annular disc and the sealing pin limiting stop webs between the annular disc and the annular projection of the sealing pin are arranged. They prevent that during the axial displacement of the sealing disc to the outside during the product discharge and the sealing pin can be moved in the same direction and after the product discharge, the annular disc does not follow the inwardly displaced sealing pin.

- a stop web is guided centrally from above through the annular disc on the sealing pin and prevents its upward shift during product discharge.

- the sealing pin is mounted on a resilient element by which the sealing pin is pressed from below against the stop webs and against the annular disc.

- the spring force of the spring element is dimensioned so that the restoring force of the storage container and the negative pressure caused thereby sufficient to move the sealing pin against the spring force inwards.

- spring elements different axially effective springs can be used, for example coil springs or radially arranged leaf springs.

- FIGS. 1, 2 and 3 show a container closure 1 according to the invention in various closing or opening positions effected by the internal pressure of the storage container.

- the storage container itself is not shown.

- the container closure 1 shown in Figure 1 in the starting position, the closed position, consists of an outer annular housing 5 with radially arranged at the upper stop webs 6. From the inside - in the drawing from below - is against these stop webs 6 through the central head 17 of a Spring element with coil spring 4, a sealing pin 3 is pressed, wherein an annular projection 9 at the lower end of the sealing pin 3 a possible, beyond axial displacement to the outside - in the drawing above - limited.

- the inner diameter of the annular disc 2 corresponds to the outer diameter of an annular groove 10 of the sealing pin 3, so that the annular disc 2 and the sealing pin 3 has a common upper surface and a dense Train closure.

- the container closure 1 of FIG. 1 is in the discharge position. Due to an increased internal pressure in the storage container, caused by compression of the storage container, that was discharged Product pressed from below against the stop webs 6, the sealing pin 3 and the washer 2. Since the fixed to the housing 5 stop webs 6 and also applied to the stop webs 6 sealing pin 3 can not follow this product pressure, only the annular disc 2 bulges outwards. It forms thereby between the annular disc 2 and the sealing pin 3, a discharge gap 7, through which the product leaves the container closure 1 in the direction of arrow 11 to the outside.

- FIG. 4 shows a possible arrangement of a container closure 1 according to the invention in the dispenser head 20 of a storage container.

- the dispenser head 20 consists of an outer annular housing 21 with top clip-on cover 23.

- At the upper end of the dispenser head 20 is inside an inner ring 22 with screw thread for attachment to a correspondingly sized storage container.

- Within this inner ring 22 is an annular inner chamber 24, in which the complete container closure 1 of FIG. 1 is inserted.

- the outer annular housing 21, the Inner ring 22 and the annular inner chamber 24 are made in one piece in the illustrated embodiment.

- the spring element used for pushing up the sealing pin 3 in Figures 1 to 4 consists of an outer ring 16 with a coil spring 4 arranged therein and a central head 17 which presses by the coil spring 4 from below against the sealing pin 3.

- the upper end of the coil spring 4 is fixed to the central head 17 and the lower end to the outer ring 16.

- the existing of the spring 4, the central head 17 and the outer ring 16 spring element thus forms a construction unit, which is inserted from below into the housing 5.

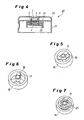

- FIGS. 5 to 7 Further exemplary possibilities for forming a spring element which can be used in the container closure according to the invention are shown in FIGS. 5 to 7.

- These spring elements consist of an outer ring 16 with a central head 17, in which case the central head 17 is no longer connected by a coil spring 4 with the outer ring 16, but by radially inwardly guided leaf springs 18, 19, 25.

- the leaf springs 18, 19, 25 arranged so that they press this after installation of the spring element with a compressive stress from below against the sealing pin 3.

- Possible embodiments are, for example, smooth leaf springs 18 (FIG. 6), leaf springs bent in a U-shape downwards (FIG. 5) or radially angled leaf springs 25 (FIG. 7).

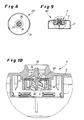

- FIGS. 8 to 10 show an alternative embodiment of a container closure according to the invention.

- FIGS. 8 and 9 show in a plan view (FIG. 8) and in a vertical section (FIG. 9) a possible dispensing head 20 'with a housing 21 in which such an alternative container closure 1' is arranged.

- the annular disc 31 with the sealing pin 30 no longer together in the form of a flat surface the upper end of the container closure 1', where they could be easily damaged, but they are here at the bottom of an upward open funnel-shaped dispenser opening 35 and thus protected within the upper part of the container closure 1 '.

- a pin-like stop web 33 is arranged, which is connected via three support legs 34 fixed to the housing 5 'and guided from above onto the sealing pin 30 and limits its axial displacement upwards.

- the sealing pin 30 is pressed from below with spring force by a spring element 4 against this pin-like stop web 33.

- the remaining between the sealing pin 30 and the open funnel-shaped dispenser opening 35 annular space is closed by an annular disc 31 which is clamped with its outer edge between the stop webs 32 from below and the annular wall 36 of the funnel-shaped dispenser opening 35 from above.

- FIG. 10 Details of this container closure 1 'are more clearly shown in FIG. 10 in an enlarged partial detail of FIG.

- the container closure 1 In the same operation as in the container closure 1 (see Fig. 1 - 4) is in the container closure 1 'on the stop webs 32 and the sealing pin 30 resting annular disc 31 bulges in the discharge by the outgoing from the storage tank pressure in its center to the outside, thereby in the same way as in the container closure 1 between the sealing pin 30 and the annular disc 31 forms a discharge gap through which the material to be dispensed is discharged upward.

- the sealing pin 30 can hereby the axial displacement of the annular disc 31 do not follow upwards, since an axial displacement upwards by the stationary over the support legs 34 with the housing 5 'connected mandrel-like stop web 33 is prevented.

- stop webs 32 arranged below the annular disk 31 prevent the annular disk 31 from axially displacing downward or protruding inwards.

- the sealing pin 30 shifts against the spring force of the spring element 4 axially downwards and thus opens exactly as in the container closure 1 a ventilation gap between the sealing pin 30 and the annular disc 31, whereby up to the pressure equalization of the material still present in the funnel-shaped dispenser opening 35 back into the Storage tank is sucked.

- the container closure shown in the illustrated embodiments is not the sole training option of a container closure according to the invention. This can be varied depending on the product and the storage container adapted to this within wide limits with respect to its dimensions, without departing from the concept of the invention with its claims formulated.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

- Cartons (AREA)

Claims (7)

- Fermeture de récipient (1, 1') pour récipients de stockage flexibles contenant des produits liquides à pâteux, par exemple bouteilles ou tubes, constituée d'un boîtier (5, 5') comportant au centre un disque annulaire (2, 31) élastique et en dessous un tourillon d'étanchéité (3, 30) centrale axialement mobile disposé,

qui lors de la compression du récipient de stockage, sous l'effet d'un gauchissement axial de la partie centrale du disque annulaire (2, 31), s'ouvre automatiquement, à la manière d'une soupape, pour décharger les produits et ensuite se referme automatiquement sous l'effet de la force de rappel du récipient de stockage,

caractérisée en ce que• le gauchissement axial de la partie centrale du disque annulaire (2, 31) vers le bas est limité par plusieurs traverses de butée (6, 32) ;• le mouvement axial du tourillon d'étanchéité (3, 30) vers le haut est limité par au moins une traverse de butée (6, 33) ;• le tourillon d'étanchéité (3, 30) est logé sur un élément élastique (4, 18, 19, 25) et est comprimé par cet élément élastique (4, 18, 19, 25) par le bas contre les traverses de butée (6, 33) et de manière étanche contre le disque annulaire (2, 31). - Fermeture de récipient (1) selon la revendication 1,

caractérisée en ce que

les traverses de butée (6) sont disposées entre le disque annulaire (2) et une saillie annulaire (9) du tourillon d'étanchéité (3). - Fermeture de récipient (1') selon la revendication 1,

caractérisée en ce que

la traverse de butée (33) est guidée de manière centrale d'en haut, à travers le disque annulaire (31), vers le tourillon d'étanchéité (30). - Fermeture de récipient (1, 1') selon la revendication 1, 2 ou 3,

caractérisée en ce que

l'élément élastique (4) est un ressort en spirale. - Fermeture de récipient (1, 1') selon la revendication 1, 2 ou 3,

caractérisée en ce que

l'élément élastique est constitué de ressorts à lames lisses (18) ou pliés en forme de u (19), disposés radialement. - Fermeture de récipient (1, 1') selon l'une ou plusieurs des revendications 1 à 5,

caractérisée en ce que

le disque annulaire (2, 31) et le tourillon d'étanchéité (3, 30), en coopération avec les traverses de butée (6, 32, 33), sont montés pour permettre les positions suivantes :• position de fermeture avec le récipient de stockage sans pression ; le disque annulaire (2, 31) repose de manière étanche sur le tourillon d'étanchéité (3, 30) et sur les traverses de butée (6, 32), et le tourillon d'étanchéité (3, 30) adhère par dessous aux traverses de butée (6, 33),• position de déchargement avec une surpression dans le récipient de stockage ; le disque annulaire (2,31) est décollé du tourillon d'étanchéité (3, 30) et des traverses de butée (6, 32), et le tourillon d'étanchéité (3, 30) continue à adhérer par dessous aux traverses de butée (6, 33) ; le déchargement du matériau s'effectue à travers la fente de déchargement (7) formée vers le haut entre le disque annulaire (2, 31) et le tourillon d'étanchéité (3, 30),• position d'aération avec sous-pression dans le récipient de stockage ; le disque annulaire (2, 31) repose à nouveau sur les traverses de butée (6, 32), le tourillon d'étanchéité (3, 30) est déplacé vers le bas contre la tension de ressort de l'élément élastique (4, 18, 19, 25), l'aération du récipient de stockage s'effectue à travers la fente d'aération (8) formée vers le bas entre le disque annulaire (2, 31) et le tourillon d'étanchéité (3,30). - Fermeture de récipient (1) selon une ou plusieurs des revendications 1 à 6,

caractérisée en ce que

l'élasticité du disque annulaire (2, 31) et la tension de ressort de l'élément élastique (4, 18, 19, 25) sont adaptées à la viscosité du produit à décharger et à l'élasticité ou à la force de rappel du récipient de stockage.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE20209615U DE20209615U1 (de) | 2002-06-20 | 2002-06-20 | Selbstabdichtender Behälterverschluss |

| DE20209615U | 2002-06-20 | ||

| PCT/EP2003/006374 WO2004000672A1 (fr) | 2002-06-20 | 2003-06-17 | Bouchon de contenant autoetancheifiant |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1513734A1 EP1513734A1 (fr) | 2005-03-16 |

| EP1513734B1 true EP1513734B1 (fr) | 2006-07-12 |

Family

ID=27675262

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP03760630A Expired - Lifetime EP1513734B1 (fr) | 2002-06-20 | 2003-06-17 | Bouchon de contenant auto-étancheifiant |

Country Status (8)

| Country | Link |

|---|---|

| US (1) | US20050139620A1 (fr) |

| EP (1) | EP1513734B1 (fr) |

| CN (1) | CN100430303C (fr) |

| AT (1) | ATE332850T1 (fr) |

| DE (2) | DE20209615U1 (fr) |

| EA (1) | EA005758B1 (fr) |

| ES (1) | ES2265113T3 (fr) |

| WO (1) | WO2004000672A1 (fr) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN100484843C (zh) * | 2006-07-28 | 2009-05-06 | 陈学办 | 一种旋转压缩开启并能自动关闭的瓶盖 |

| RU2016141735A (ru) * | 2014-03-25 | 2018-04-27 | ГУАЛА ПЭК С.п.А. | Горлышко для гибкого пакета с устройством пробки |

| US9573752B2 (en) * | 2014-12-24 | 2017-02-21 | Drink Saporé Inc. | Liquid container apparatus |

| GB201601232D0 (en) * | 2016-01-22 | 2016-03-09 | Rieke Packaging Systems Ltd | Dispensing closures and dispensers |

| JP6847526B2 (ja) * | 2017-05-31 | 2021-03-24 | 株式会社吉野工業所 | 吐出容器 |

| DE102018208110A1 (de) * | 2018-05-23 | 2019-11-28 | F. Holzer Gmbh | Abgabekopf und Abgabevorrichtung zur dosierten Abgabe flüssiger Präparate sowie Verwendungsmöglichkeiten |

| EP3868479A1 (fr) * | 2019-03-27 | 2021-08-25 | The Fountainhead Group, Inc. | Pulvérisateur alimenté par gravité |

| WO2020224893A1 (fr) * | 2019-05-09 | 2020-11-12 | Asml Netherlands B.V. | Dispositif de guidage |

| JP6589158B1 (ja) * | 2019-05-23 | 2019-10-16 | 株式会社ベッセル・ジャパン | エアーバックレス構造 |

| CN114521185B (zh) * | 2019-07-23 | 2024-08-06 | 里克包装系统有限公司 | 具有内部塞件密封的全聚合物泵分配器 |

| JP6816911B1 (ja) * | 2019-08-01 | 2021-01-20 | 株式会社辰巳菱機 | 負荷試験装置 |

| JP7556663B2 (ja) | 2021-06-30 | 2024-09-26 | 株式会社吉野工業所 | 吐出キャップ |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE913874C (de) * | 1951-11-01 | 1954-06-21 | Rudolf Valtl | Selbsttaetiger Tubenverschluss |

| DE932237C (de) * | 1952-08-14 | 1955-08-25 | Rudolf Valtl | Selbsttaetiger Tubenverschluss |

| SE384662B (sv) * | 1974-04-08 | 1976-05-17 | B Nilson | Sjelvstengande forslutning for forpackningar |

| GB1593084A (en) * | 1977-06-24 | 1981-07-15 | Metal Box Co Ltd | Dispensing closures |

| DE8235857U1 (de) * | 1982-12-21 | 1984-05-24 | Wella Ag, 6100 Darmstadt | Selbsttaetiger Verschluss fuer flexible Behaelter |

| US4739906A (en) * | 1986-07-14 | 1988-04-26 | Blairex Laboratories, Inc. | Storage bottle for contact lens cleaning solution having a self closing valve assembly |

| US4785978A (en) * | 1987-03-02 | 1988-11-22 | Japan Crown Cork Co., Ltd. | Container closure provided with automatic opening-closing mechanism |

| US5273191A (en) * | 1991-08-20 | 1993-12-28 | Philip Meshberg | Dispensing head for a squeeze dispenser |

| US5197638A (en) * | 1991-10-30 | 1993-03-30 | Allergan, Inc. | Self sealing product delivery system |

| WO1993025319A1 (fr) * | 1992-06-17 | 1993-12-23 | Yoshino Kogyosho Co., Ltd. | Buse de sortie pour pompe |

| DE9311684U1 (de) * | 1993-08-05 | 1994-12-15 | Wolff, Ernst, 33330 Gütersloh | Verschluß für Behälter mit flüssigem oder pastenförmigem Inhalt |

| DE9403170U1 (de) * | 1994-02-25 | 1994-06-16 | Linneweber, Wolfgang, 33605 Bielefeld | Selbstschließender Verschluß |

| DE4417488A1 (de) * | 1994-05-19 | 1995-11-23 | Pfeiffer Erich Gmbh & Co Kg | Austragvorrichtung für Medien |

| FR2769595B1 (fr) * | 1997-10-10 | 1999-11-19 | Oreal | Tete de distribution a reprise d'air amelioree, et ensemble de conditionnement et de distribution equipe d'une telle tete |

| FR2806705B1 (fr) * | 2000-03-27 | 2002-05-03 | Oreal | Capsule de distribution et recipient equipe d'une telle capsule |

| US6616012B2 (en) * | 2001-07-27 | 2003-09-09 | Richard C. G. Dark | Fluid dispensing valve and method of use |

-

2002

- 2002-06-20 DE DE20209615U patent/DE20209615U1/de not_active Expired - Lifetime

-

2003

- 2003-06-17 DE DE50304238T patent/DE50304238D1/de not_active Expired - Fee Related

- 2003-06-17 EA EA200401321A patent/EA005758B1/ru not_active IP Right Cessation

- 2003-06-17 AT AT03760630T patent/ATE332850T1/de not_active IP Right Cessation

- 2003-06-17 WO PCT/EP2003/006374 patent/WO2004000672A1/fr not_active Application Discontinuation

- 2003-06-17 CN CNB038143151A patent/CN100430303C/zh not_active Expired - Fee Related

- 2003-06-17 ES ES03760630T patent/ES2265113T3/es not_active Expired - Lifetime

- 2003-06-17 US US10/509,860 patent/US20050139620A1/en not_active Abandoned

- 2003-06-17 EP EP03760630A patent/EP1513734B1/fr not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP1513734A1 (fr) | 2005-03-16 |

| CN1662424A (zh) | 2005-08-31 |

| DE20209615U1 (de) | 2003-07-31 |

| CN100430303C (zh) | 2008-11-05 |

| EA005758B1 (ru) | 2005-06-30 |

| DE50304238D1 (de) | 2006-08-24 |

| ATE332850T1 (de) | 2006-08-15 |

| ES2265113T3 (es) | 2007-02-01 |

| WO2004000672A1 (fr) | 2003-12-31 |

| EA200401321A1 (ru) | 2005-02-24 |

| US20050139620A1 (en) | 2005-06-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102008019224B4 (de) | Ventilanordnung für einen unter Druck stehenden Fluidbehälter | |

| EP1513426B1 (fr) | Tete de diffusion dotee d'une valve d'arret | |

| DE60037198T2 (de) | Hochvolumenaerosolventil | |

| DE102004010845B3 (de) | Verschluß für einen fließfähiges Gut enthaltenden Behälter | |

| EP1513734B1 (fr) | Bouchon de contenant auto-étancheifiant | |

| DE2739893A1 (de) | Zusammendrueckbare flasche aus elastisch verformbarem material | |

| DE3320966A1 (de) | Fluessigkeitsspender | |

| DE3323287A1 (de) | Fuer quetschflaschen geeignetes ventil fuer die abgabe von zaehfluessigen fuellguetern | |

| CH652372A5 (de) | Vorrichtung zur ausgabe von pastoesen medien. | |

| DE2112195A1 (de) | Vorrichtung zur Ausgabe von Fluessigkeiten | |

| DE2721982A1 (de) | Dosierungsgeraet fuer fluessigkeiten | |

| CH644678A5 (de) | Dispenserventil, insbesondere fuer viskoese produkte. | |

| DE1057289B (de) | Zerstaeuber fuer in einem aus Glas bestehenden Behaelter unter Druck gehaltene Stoffe, insbesondere Fluessigkeiten | |

| DE69005490T2 (de) | Gerät zum Abfüllen einer bestimmten Flüssigkeitsmenge. | |

| DE2630972A1 (de) | Schliessdeckel fuer kessel | |

| DE20208386U1 (de) | Becherförmiger Behälter und Deckel | |

| DE69812621T2 (de) | In Öffnungs- sowie Schliessstellung abgedichter, handbetätigter Spender | |

| DE20203882U1 (de) | Spender zur Applikation fließfähiger Produkte | |

| DE3418530A1 (de) | Vorrichtung zum verstopfen von behaeltern mit einem hals | |

| DE602005005214T2 (de) | Ventile für trinkbecher | |

| DE2831463A1 (de) | Spuelvorrichtung fuer eine getraenke- entnahme-anlage | |

| DE3331529A1 (de) | Fuer quetschflaschen geeignetes ventil fuer die abgabe von zaehfluessigen fuellguetern | |

| CH426534A (de) | Verschluss mit selbstschliessender Austrittsöffnung für zusammendrückbare Behälter | |

| DE1058440B (de) | Spruehventil | |

| DE102020109821A1 (de) | Spender für pastöse Massen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 20040805 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL LT LV MK |

|

| DAX | Request for extension of the european patent (deleted) | ||

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20060712 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060712 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060712 Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060712 Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060712 Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060712 Ref country code: RO Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060712 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060712 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20060725 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 50304238 Country of ref document: DE Date of ref document: 20060824 Kind code of ref document: P |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061012 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061012 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061012 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061212 |

|

| ET | Fr: translation filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2265113 Country of ref document: ES Kind code of ref document: T3 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20070413 |

|

| BERE | Be: lapsed |

Owner name: RPC WIKO G.M.B.H. & CO. KG Effective date: 20070630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070630 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20070617 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070630 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20080229 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070630 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070630 Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20080101 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20061013 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070617 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060712 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070617 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20070618 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070702 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070618 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070617 Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060712 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20060712 Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20070113 |