EP1498534A2 - Verfahren und Vorrichtung zum Färben von Textilien - Google Patents

Verfahren und Vorrichtung zum Färben von Textilien Download PDFInfo

- Publication number

- EP1498534A2 EP1498534A2 EP04016531A EP04016531A EP1498534A2 EP 1498534 A2 EP1498534 A2 EP 1498534A2 EP 04016531 A EP04016531 A EP 04016531A EP 04016531 A EP04016531 A EP 04016531A EP 1498534 A2 EP1498534 A2 EP 1498534A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- oxygen

- textiles

- dyeing

- trough

- squeezing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06B—TREATING TEXTILE MATERIALS USING LIQUIDS, GASES OR VAPOURS

- D06B3/00—Passing of textile materials through liquids, gases or vapours to effect treatment, e.g. washing, dyeing, bleaching, sizing, impregnating

- D06B3/10—Passing of textile materials through liquids, gases or vapours to effect treatment, e.g. washing, dyeing, bleaching, sizing, impregnating of fabrics

- D06B3/18—Passing of textile materials through liquids, gases or vapours to effect treatment, e.g. washing, dyeing, bleaching, sizing, impregnating of fabrics combined with squeezing, e.g. in padding machines

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06B—TREATING TEXTILE MATERIALS USING LIQUIDS, GASES OR VAPOURS

- D06B23/00—Component parts, details, or accessories of apparatus or machines, specially adapted for the treating of textile materials, not restricted to a particular kind of apparatus, provided for in groups D06B1/00 - D06B21/00

- D06B23/14—Containers, e.g. vats

- D06B23/18—Sealing arrangements

Definitions

- the invention relates to a process for dyeing continuous textiles according to the preamble of claim 1 and an apparatus for performing the method.

- Such methods and devices are used for e.g. Indigo dyeing of textiles used, in which the dye sparingly soluble in water with the aid of alkali and reducing agent is converted into a fiber-affine water-soluble form.

- the dye can dye the fibers of textiles, which is also called padding.

- Other vat dyes such as indanthrene and Sulfur dyes are usable.

- the object of the invention is a process for dyeing textiles, in which these padded several times with dyes and then greened in an oxidation zone be improved so that saves significant amounts of chemicals and at the same time achieve a consistent dyeing result.

- a Another object is the provision of a device for carrying out the method.

- the first object is solved by the characterizing features of claim 1.

- the fact that oxygen displaces from the textiles immediately before each padding is, whereby a re-penetration of oxygen into the textiles in each case before the greening Preventing unwanted oxygen is excluded in the dyebath arrives.

- Oxygen in the dyebath causes oxidation of the dyestuff, which does not cause it is more fiber affine, that is, it is water insoluble and can no longer be effective Dyeing be used. Furthermore, the oxygen causes auxiliary substances such as reducing agents and alkali are consumed and / or converted into an ineffective form. Overall, so in the known method more dyes and auxiliaries in the Dyeing baths are dosed as needed for the actual dyeing.

- the method according to the invention avoids these disadvantages and thus prevents that dyes and auxiliaries are oxidized without being used for the dyeing process to be able to. Compared to the known methods is a saving from 30 to 40% of the total consumption of chemicals with corresponding Cost reduction possible. Furthermore, a more uniform coloring result is achieved.

- Claim 6 solves the second task.

- wash water according to claim 3 carries chemicals that according to the lost to the known processes with the wastewater, in the dyeing process, so they can be used again.

- the washing water is oxygen-free, has the required pH value and is therefore ideal for the displacement of oxygen from the textiles suitable.

- the oxygen-free atmosphere between the displacement of oxygen and the subsequent greening prevents the textiles from wetting or when wetting Take up oxygen again with dyestuff and then enter into the dyebath.

- the Maintaining the once oxygen-free atmosphere is very low Effort possible because they are practical in operation through the running textiles is not affected

- Nitrogen according to claim 5 is available in an inert and inexpensive.

- the invention is based on a simplified illustrated embodiment of Threads further explained.

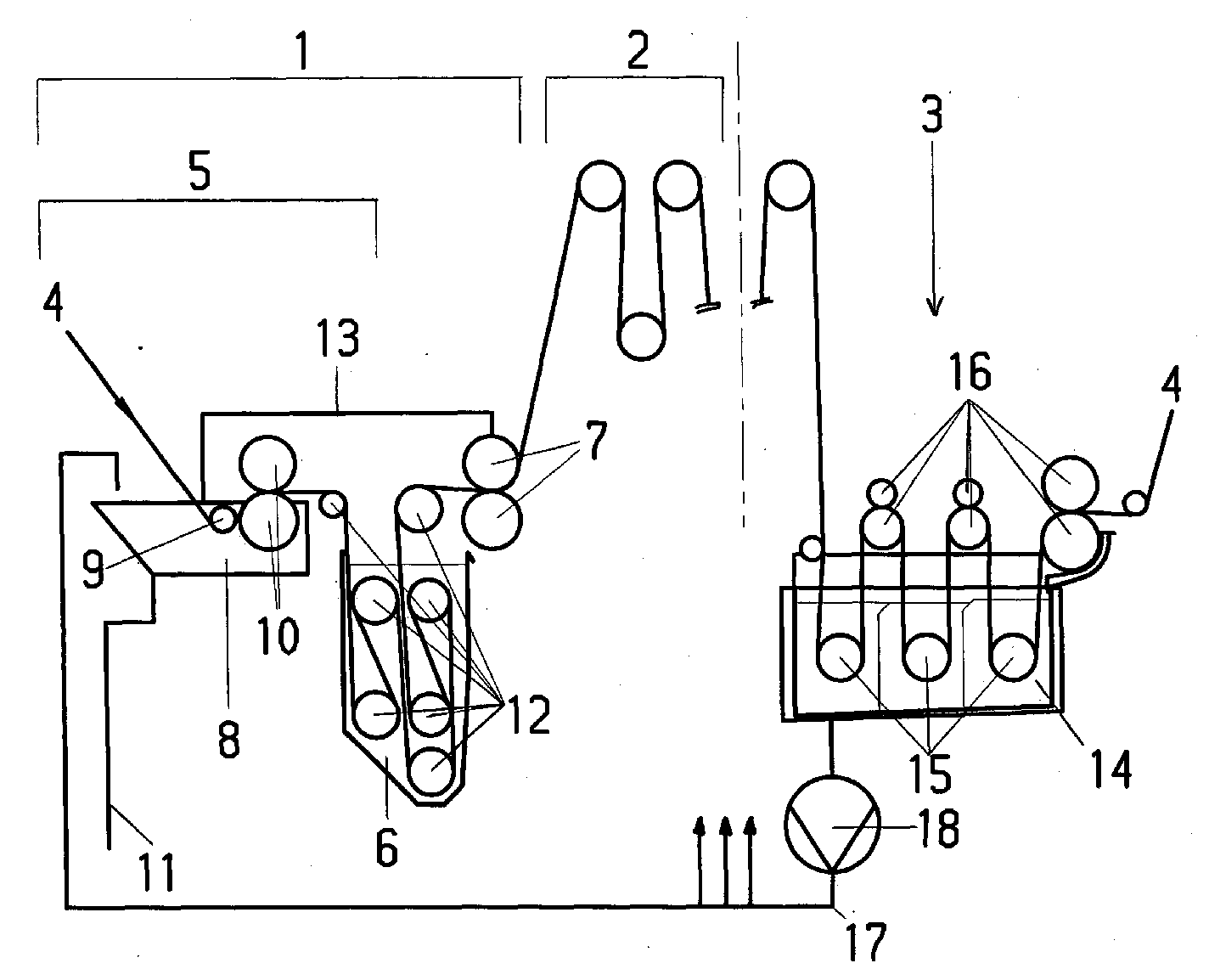

- the figure shows a diagram of a part of the device according to the invention for dyeing of threads.

- a device comprises a plurality of wetting stages 1 and each wetting stage 1 downstream oxidation routes 2 and a washing device 3. Furthermore, the device does not - - means for feeding threads 4 in which the threads are e.g. in a creel unwound from spools and directed to dyeing, and means for drying the dyed threads 4.

- Each wetting stage 1 comprises means 5 for displacing oxygen from the threads 4, a dyeing trough 6 and a second squeezing 7th

- the means for displacing 5 include a trough 8 with at least a first guide roller 9 and arranged at the exit of the threads 4 from the trough 8 first Quetschwerk 10. At the trough 8, an overflow pipe 11 is fixed, which with a Outflow is connected.

- the dyeing trough 6 At a short distance in the direction of the threads 4 behind the first squeezing 10 is the dyeing trough 6 with a plurality of second guide rollers 12 is arranged. To the second guide rollers 12, the threads 4 are guided so that this sufficient long distance in the dyeing trough 6 run. In the outlet area of the Därbetrogs 6 above a Klarbeflottenspiegels the second squeezer 7 is arranged so that squeezed Fleet back into the dyeing trough 6 flows.

- a hood 13 is arranged so that she dives with a part into the fleet of trough 8 and by the way against the trough 8, the dyeing trough 6 and the second squeezing 7 largely airtight connected.

- the hood 13 is connected via a line, not shown, to a Nitrogen source connectable.

- the washing device 3 is arranged. These comprises a washing trough 14 and a series of third deflecting rollers 15 and third Crushing 16.

- the washing trough 14 is connected by a line 17 with branches connected to each of the troughs 8; depending on the local conditions is in the line 17 arranged a pump 18.

- the washing device 3 is followed by an unillustrated dryer.

- the threads 4 are withdrawn from the creel and as a group of threads for dyeing, wherein at least one described in the following dyeing is going through.

- the threads 4, which have absorbed oxygen from the air, are initially in the trough 8 immersed, which is filled with washing water from the washing trough 14.

- the Wash water has a favorable pH of about 11 or higher and contains Remains of dye and excipients such as alkali and reducing agent. Through this Characteristics of the wash water, the oxygen is largely to completely removed from the threads 4, and these take up a part of the dye. To this Way must dosed much less dye and excipients in the dyeing trough 6 become.

- the threads are guided over the second guide rollers 11 so that they have sufficient contact time for mass transfer with the dyeing liquor.

- the Dyeing liquor will be the required amounts of water, dye and excipients dosed.

- the threads are 4 in the second Crushing 7 pressed again.

- the squeezing pressures in the first and in the second squeezing 10, 7 the same size, so that the threads 4 in the inlet of the Därbetrogs 6 have the same humidity as in its outlet and a dilution of the dyeing liquor is prevented.

- the entire area from the first to the second squeezer 7, 10 is below the Hood 13 provided with an inert atmosphere.

- the device for dyeing the air under the hood 13 replaced by nitrogen, the e.g. is supplied from a compressed gas cylinder via the associated line. While Normal operation is no or only occasional replenishment of nitrogen required.

- the threads are washed in the washing trough 14.

- they are alternately immersed in the washing trough 14 several times in succession and squeezed in the third Quetatken 16. This will be excess Dye and excipients from the threads 4 removed.

- the threads 4 are dried and further processed, e.g. wound.

- other textiles such as e.g. a web treatable.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Treatment Of Fiber Materials (AREA)

- Coloring (AREA)

Abstract

Description

- 1

- Benetzungsstufe

- 2

- Oxidationsstrecke

- 3

- Waschvorrichtung

- 4

- Fäden

- 5

- Mittel zu Verdrängen

- 6

- Färbetrog

- 7

- zweites Quetschwerk

- 8

- Trog

- 9

- erste Umlenkwalze

- 10

- erstes Quetschwerk

- 11

- Überlaufleitung

- 12

- zweite Umlenkwalze

- 13

- Haube

- 14

- Waschtrog

- 15

- dritte Umlenkwalze

- 16

- drittes Quetschwerk

- 17

- Leitung

- 18

- Pumpe

Claims (12)

- Verfahren zum Färben von durchlaufenden Textilien,

bei dem die Textilien mehrfach in mindestens einem Trog mit Farbstoff geklotzt und anschließend in einer Oxidationsstrecke vergrünt werden und

bei dem weiter die Textilien gewaschen und getrocknet werden,

dadurch gekennzeichnet, dass Sauerstoff unmittelbar vor jedem Klotzen aus den Textilien (4) verdrängt wird,

wobei ein Wiedereindringen von Sauerstoff in die Textilien (4) jeweils vor dem Vergrünen verhindert wird. - Verfahren nach Anspruch 1, dadurch gekennzeichnet, dass der Sauerstoff durch Tauchen in einer Flüssigkeit und anschließendes Quetschen verdrängt wird.

- Verfahren nach Anspruch 1 oder 2, dadurch gekennzeichnet, dass die Flüssigkeit Waschwasser ist.

- Verfahren nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, dass jeweils zwischen der Verdrängung des Sauerstoffs und der anschließenden Vergrünung eine sauerstofffreie Atmosphäre aufrecht erhalten wird.

- Verfahren nach Anspruch 4, dadurch gekennzeichnet, dass eine Stickstoffatmosphäre eingesetzt wird.

- Vorrichtung zu Färben von durchlaufenden Textilien,

mit einer Vielzahl von Färbetrögen, wobei an jedem eine Zuleitung für Farbstoff angeschlossen ist,

mit einem jedem der Färbetröge nachgeschalteten zweiten Quetschwerk,

mit einer Vielzahl von Oxidationsstrecken, die jeweils hinter den zweiten Quetschwerken angeordnet sind,

mit einem Waschtrog und

mit einem Trockner,

dadurch gekennzeichnet, dass unmittelbar vor jedem Färbetrog (6) Mittel zum Verdrängen (5) von Sauerstoff aus den Textilien (4) angeordnet sind und

dass weitere Mittel (13) angeordnet sind, die jeweils zwischen den Mitteln zum Verdrängen (5) und dem zweiten Quetschwerk (7) einen Kontakt der. Textilien (4) mit Sauerstoff verhindern. - Vorrichtung nach Anspruch 6, dadurch gekennzeichnet, dass die Mittel zum Verdrängen (5) einen Trog (8) und ein erstes Quetschwerk (10) umfassen.

- Vorrichtung nach Anspruch 7, dadurch gekennzeichnet, dass jeder Trog (8) hydraulisch mit dem Waschtrog (14) verbunden ist.

- Vorrichtung nach Anspruch 7 oder 8, dadurch gekennzeichnet, dass der Quetschdruck im ersten und im zweiten Quetschwerk (7, 10) gleich groß ist.

- Vorrichtung nach Anspruch 9, dadurch gekennzeichnet, dass das erste Quetschwerk (7) mit dem zweiten Quetschwerk (10) gekoppelt ist.

- Vorrichtung nach einem der Ansprüche 6 bis 10, dadurch gekennzeichnet, dass die weiteren Mittel eine Haube (13) umfassen.

- Vorrichtung nach Anspruch 11, dadurch gekennzeichnet, dass die Haube (13) an eine Stickstoffquelle anschließbar ist.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE10332715 | 2003-07-18 | ||

| DE10332715A DE10332715B4 (de) | 2003-07-18 | 2003-07-18 | Verfahren und Vorrichtung zum Färben von Textilien |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1498534A2 true EP1498534A2 (de) | 2005-01-19 |

| EP1498534A3 EP1498534A3 (de) | 2005-09-28 |

Family

ID=33461989

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP04016531A Withdrawn EP1498534A3 (de) | 2003-07-18 | 2004-07-14 | Verfahren und Vorrichtung zum Färben von Textilien |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20050028303A1 (de) |

| EP (1) | EP1498534A3 (de) |

| CN (1) | CN1291095C (de) |

| DE (1) | DE10332715B4 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007080134A1 (en) * | 2006-01-13 | 2007-07-19 | Master S.R.L. | Device and process for indigo dyeing |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7913524B2 (en) * | 2004-04-28 | 2011-03-29 | Gaston Systems, Inc. | Apparatus for dyeing textile substrates with foamed dye |

| EP2513603A1 (de) * | 2009-12-15 | 2012-10-24 | Mapquest, Inc. | Computerimplementierte verfahren und systeme für mehrstufige geografische abfrage |

| ITUA20163921A1 (it) * | 2016-05-30 | 2017-11-30 | Mayer Textilmaschf | Apparecchiatura multifunzionale per la tintura in continuo di catene di ordito per tessuti. |

| US11952694B2 (en) * | 2018-09-12 | 2024-04-09 | Master S.R.L. | Multipurpose machine and methods for dyeing fabrics and warp yarns |

| CN110804882A (zh) * | 2019-12-12 | 2020-02-18 | 杭州彩润科技有限公司 | 板蓝根植物染料用于散纤维染色的高效使用方法 |

| CN111041738A (zh) * | 2019-12-23 | 2020-04-21 | 江阴祥盛纺印机械制造有限公司 | 低耗染槽及降低染槽内染色助剂消耗量的方法 |

| CN112281350B (zh) * | 2020-10-21 | 2023-05-09 | 宁波甬南染整有限公司 | 一种棉麻布匹染色用具有余料挤出结构的浸染装置 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3833012A1 (de) * | 1988-09-29 | 1990-04-05 | Sucker & Franz Mueller Gmbh | Verfahren zum continuefaerben von baumwollware und faerbeanlage zum durchfuehren des verfahrens |

| DE4122546A1 (de) * | 1991-07-08 | 1993-01-14 | Anlagen Und Maschinenbau Karl | Verfahren und vorrichtung zum auftragen einer behandlungsflotte auf eine warenbahn |

| DE4241419A1 (de) * | 1992-12-09 | 1994-06-16 | Sucker & Franz Mueller Gmbh | Verfahren zum Indigofärben |

| DE4314402B4 (de) * | 1993-05-03 | 2006-02-02 | Moenus Textilmaschinen Gmbh | Vorrichtung zum Indigofärben |

| DE4342313C2 (de) * | 1993-12-11 | 1997-04-03 | Sucker Mueller Hacoba Gmbh | Verfahren und Vorrichtung zum Applizieren von Indigo-Farbstoff |

| DE19613954A1 (de) * | 1996-04-06 | 1997-10-09 | Gullshield Ltd | Verfahren zum kontinuierlichen Färben von Kettgarn und Vorrichtung zur Durchführung des Verfahrens |

| DE19707147C1 (de) * | 1997-02-22 | 1998-04-16 | Sucker Mueller Hacoba Gmbh | Verfahren zum Applizieren von Indigo-Farbstoff |

-

2003

- 2003-07-18 DE DE10332715A patent/DE10332715B4/de not_active Expired - Fee Related

-

2004

- 2004-07-14 US US10/890,579 patent/US20050028303A1/en not_active Abandoned

- 2004-07-14 EP EP04016531A patent/EP1498534A3/de not_active Withdrawn

- 2004-07-16 CN CNB200410071277XA patent/CN1291095C/zh not_active Expired - Lifetime

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2007080134A1 (en) * | 2006-01-13 | 2007-07-19 | Master S.R.L. | Device and process for indigo dyeing |

| US7908894B2 (en) | 2006-01-13 | 2011-03-22 | Master S.R.L. | Device and process for indigo dyeing |

Also Published As

| Publication number | Publication date |

|---|---|

| DE10332715A1 (de) | 2005-02-24 |

| EP1498534A3 (de) | 2005-09-28 |

| DE10332715B4 (de) | 2007-05-24 |

| US20050028303A1 (en) | 2005-02-10 |

| CN1291095C (zh) | 2006-12-20 |

| CN1576436A (zh) | 2005-02-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2759977C2 (de) | Vorrichtung zur Indigofärbung von Kettfäden aus Baumwoll-Spinngarnen | |

| EP0093446B1 (de) | Verfahren und Vorrichtung zum kontinuierlichen Färben und/oder Veredeln von nassen, textilen Warenbahnen | |

| WO2008138282A1 (de) | Verfahren und vorrichtung zum färben eines textilen substrates | |

| DE10332715B4 (de) | Verfahren und Vorrichtung zum Färben von Textilien | |

| DE813698C (de) | Verfahren und Vorrichtung zum Faerben, Bleichen oder einer anderen Nassbehandlung von Geweben | |

| DD155439A5 (de) | Verfahren und vorrichtung zum kontinuierlichen faerben von kettgarnen | |

| EP0311796B1 (de) | Verfahren zur kontinuierlichen Nassbehandlung einer Warenbahn | |

| DE2823793A1 (de) | Verfahren und hochdruckdaempfer zur kontinuierlichen behandlung einer textilgutbahn | |

| DE2539350B1 (de) | Verfahren zum kontinuierlichen faerben von cellulosefasern oder deren mischungen mit synthesefasern mit auf der faser erzeugten wasserunloeslichen azofarbstoffen | |

| DE19735969B4 (de) | Fadenfärbeanlage | |

| DE4409953A1 (de) | Vorrichtung und Verfahren für das kontinuierliche Färben von Maschenware in Schlauchform | |

| DE19749212A1 (de) | Verfahren zum kontinuierlichen Färben von cellulosischen Rundstrick- und Rundwirkwaren mit Reaktivfarbstoffen | |

| EP0320701B1 (de) | Verfahren und Vorrichtung zur diskontinuierlichen Nassbehandlung von gestricktem oder gewirktem Textilgut | |

| DE2539336C2 (de) | Verfahren zum kontinuierlichen Färben von Cellulosefaser!! oder deren Mischungen mit Synthesefasern mit auf der Faser erzeugten wasserunlöslichen Azofarbstoffen | |

| DE2063179B2 (de) | Verfahren zum faerben von spinnkabel im hydratisierten zustand | |

| EP0856602A1 (de) | Verfahren und Vorrichtung zur Applikation von Küpenfarbstoff, insbesondere Indigo auf eine Fadenschar | |

| DE3423154C2 (de) | Verfahren und Vorrichtung zum kontinuierlichen Auswaschen von bahnförmigem Textilgut | |

| DE3151465A1 (de) | "verfahren und vorrichtung zur behandlung von faserkabeln" | |

| DE2002971A1 (de) | Verfahren zum Austausch des Waschwassers einer aus mehreren Baedern zusammengestellten Waschmaschine | |

| DE3045647C2 (de) | ||

| DE4005979C2 (de) | ||

| CH668999A5 (de) | Vorrichtung zum kontinuierlichen faerben von kettgarnen. | |

| DE2951695C2 (de) | ||

| DE102008056308A1 (de) | Verfahren und Vorrichtung zum Färben eines textilen Substrates | |

| DE2758817C2 (de) | Verfahren zum Färben von Cellulose fasern oder deren Mischungen mit Synthesefasern mit Schwefelfarbstoffen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL HR LT LV MK |

|

| 17P | Request for examination filed |

Effective date: 20060328 |

|

| AKX | Designation fees paid |

Designated state(s): CH DE IT LI TR |

|

| 17Q | First examination report despatched |

Effective date: 20070221 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: SUCKER TEXTILMASCHINEN GMBH |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20091230 |