EP1486627B1 - Grossformatige OSB-Platte mit verbesserten Eigenschaften, insbesondere für den Baubereich - Google Patents

Grossformatige OSB-Platte mit verbesserten Eigenschaften, insbesondere für den Baubereich Download PDFInfo

- Publication number

- EP1486627B1 EP1486627B1 EP04022049.3A EP04022049A EP1486627B1 EP 1486627 B1 EP1486627 B1 EP 1486627B1 EP 04022049 A EP04022049 A EP 04022049A EP 1486627 B1 EP1486627 B1 EP 1486627B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- osb

- panel

- panel according

- osb panel

- plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Revoked

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04C—STRUCTURAL ELEMENTS; BUILDING MATERIALS

- E04C2/00—Building elements of relatively thin form for the construction of parts of buildings, e.g. sheet materials, slabs, or panels

- E04C2/02—Building elements of relatively thin form for the construction of parts of buildings, e.g. sheet materials, slabs, or panels characterised by specified materials

- E04C2/10—Building elements of relatively thin form for the construction of parts of buildings, e.g. sheet materials, slabs, or panels characterised by specified materials of wood, fibres, chips, vegetable stems, or the like; of plastics; of foamed products

- E04C2/16—Building elements of relatively thin form for the construction of parts of buildings, e.g. sheet materials, slabs, or panels characterised by specified materials of wood, fibres, chips, vegetable stems, or the like; of plastics; of foamed products of fibres, chips, vegetable stems, or the like

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24058—Structurally defined web or sheet [e.g., overall dimension, etc.] including grain, strips, or filamentary elements in respective layers or components in angular relation

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24058—Structurally defined web or sheet [e.g., overall dimension, etc.] including grain, strips, or filamentary elements in respective layers or components in angular relation

- Y10T428/24066—Wood grain

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24058—Structurally defined web or sheet [e.g., overall dimension, etc.] including grain, strips, or filamentary elements in respective layers or components in angular relation

- Y10T428/24074—Strand or strand-portions

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24058—Structurally defined web or sheet [e.g., overall dimension, etc.] including grain, strips, or filamentary elements in respective layers or components in angular relation

- Y10T428/24074—Strand or strand-portions

- Y10T428/24083—Nonlinear strands or strand-portions

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24058—Structurally defined web or sheet [e.g., overall dimension, etc.] including grain, strips, or filamentary elements in respective layers or components in angular relation

- Y10T428/24074—Strand or strand-portions

- Y10T428/24091—Strand or strand-portions with additional layer[s]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24058—Structurally defined web or sheet [e.g., overall dimension, etc.] including grain, strips, or filamentary elements in respective layers or components in angular relation

- Y10T428/24074—Strand or strand-portions

- Y10T428/24091—Strand or strand-portions with additional layer[s]

- Y10T428/24099—On each side of strands or strand-portions

- Y10T428/24107—On each side of strands or strand-portions including mechanically interengaged strands, strand-portions or strand-like strips

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24132—Structurally defined web or sheet [e.g., overall dimension, etc.] including grain, strips, or filamentary elements in different layers or components parallel

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24942—Structurally defined web or sheet [e.g., overall dimension, etc.] including components having same physical characteristic in differing degree

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/24—Structurally defined web or sheet [e.g., overall dimension, etc.]

- Y10T428/24942—Structurally defined web or sheet [e.g., overall dimension, etc.] including components having same physical characteristic in differing degree

- Y10T428/24992—Density or compression of components

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/249921—Web or sheet containing structurally defined element or component

- Y10T428/249924—Noninterengaged fiber-containing paper-free web or sheet which is not of specified porosity

- Y10T428/249925—Fiber-containing wood product [e.g., hardboard, lumber, or wood board, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

- Y10T428/31971—Of carbohydrate

- Y10T428/31989—Of wood

Definitions

- An OSB board in the sense of this invention consists of at least one layer which is constructed with flat wood chips, so-called strands.

- the above-described layer forms the lower and upper cover layer and between them is the middle layer (in a 3-layer design), which has no preferred orientation of the stands. This distribution is also called "random" in technical language.

- the middle layer is the innermost layer of the plate.

- a 3-layered plate thus consists of an upper and a lower cover layer and a middle layer, a 5 or more layered plate of an upper and lower cover layer, a central layer and layers between the upper and lower cover layer and the middle layer.

- a preferred embodiment of the invention is a 3-layered plate, 5-layer or multi-layered plates, wherein there is always an odd number of layers.

- the invention is based on the technical problem of providing an OSB board suitable for use over a large area geeignt is and can also be used for example for the construction of buildings.

- the present invention describes a large-sized wood-based panel, a component produced therefrom and a method for producing a large-sized plate with high mechanical properties such as the characteristics of bending, tension and pressure, without raising the specific gravity of the plate over the usual level. Furthermore, technological features of an OSB board are described, from which one can derive these increased mechanical properties and possible uses of this OSB board.

- Influence parameters for the preferred embodiments of the present invention are the beach geometry (length, width, thickness), the orientation of the beach layers to each other, the orientation of the strands within a layer in a desired direction, the proportion and type of binder or mixture of several Binders, the proportion of additives such.

- the ratio between the thickness between the outermost layer and the middle layers or the middle layer, the density profile, which is influenced by the targeted control of process parameters and ultimately the total thickness of the plate and the plate format, which on the intended use are coordinated.

- the properties of the wood-based panels according to the invention are influenced by the beach geometry and the most uniform design of the strands of the cover layer, the ratio of thickness of the cover layers to the total thickness or the basis weight of the cover layer to the total basis weight of the plate and the average specific gravity of the plate (density).

- the two outer layers should consist in the finished product of at least 30 percent by weight of the total scattered chip quantity, which in sum of upper and lower cover layer corresponds to a proportion of at least 60%.

- the remaining 40% account for the middle layer in a 3-layer plate.

- the specific weight of the plate should not exceed 700 kg / m 3 , a value equal to or less than 650 kg / m 3 is desirable. This information refers to dry plates.

- the production of the strands is usually made of round wood, which is preferably present in debarked condition.

- the log logs are fed to a flaker, which produces strands of the desired dimension in a single operation by means of rotating tools.

- a multi-stage production of the beaches is just as conceivable as z. B. from a rotary veneer, which is crushed into strands in a further step.

- Fines are strands that are significantly different from the dimensions of the strands described above. Primarily during the production of fines should be avoided such as. B. by a gentle debarking and by regular sharpening of the cutting tools of the flaker. After Strandher ein a separation of the fine material from the beach but also conceivable.

- the proportion of fines can only be reduced to a still tolerable minimum proportion, but can not be prevented.

- the proportion of fines can be quite 10 to 15 weight percent based on the weight of the finished plate.

- the wood of the beach is not relevant. In principle, all types of wood such. As poplar, birch, beech, oak, spruce, pine and the like possible.

- the pine has proven to be particularly suitable due to its good machining properties and due to its relatively high resin content.

- paraffins or waxes are added.

- the application can take place in the form of a melt at the required elevated temperature (liquid wax application) or for emulsions at about room temperature.

- urea-formaldehyde glues UF

- melamine-formaldehyde glues MF

- phenol-formaldehyde glues PF

- binders based on isocyanate eg PMDI

- binders based on acrylates have proven successful.

- a mixture of at least two of these types of binder is used, but also mixtures of several types of glue is conceivable.

- the term "mixture” is understood to mean not only a mixture of different types of ready-to-use binders, but also a mixture of various of the cited types, which already results in the course of production as a mixture. So z.

- melamine-urea-formaldehyde glues (MUF) or melamine-urea-phenol-formaldehyde glues (MUPF) by co-cooking in the same reaction vessel (reactor) are produced.

- the individual layers of the plate may also contain different types of binders and mixtures thereof, wherein it is advantageous for multi-layer plates for stability reasons, those layers, which are each arranged - in relation to the plate surfaces - in the same position, with the same binder type or to provide the same mixture. It has thus been found that the requirements of the invention can be achieved very well in the case of a 3-layer board when the top and bottom cover layers are provided with a MUPF binder and the middle layer with an isocyanate-based binder (PMDI).

- PMDI isocyanate-based binder

- binder and the binder type are decisive for the desired mechanical and technological properties.

- the content of binder depends on the type of binder. Binder contents for UF, MF, PF and their mixtures are in the range between 10 and 15% by weight (in the case of mixtures as the sum of used components) calculated as solid resin based on the dry matter wood strands. When using isocyanates, the binder content can be reduced to 6 to 10 wt.%.

- the gluing of the beaches takes place before the beach mat is formed.

- Beleimtrommeln are provided for this, which allow a continuous gluing in the run.

- the drums rotate around their own longitudinal axis and thus keep the introduced beach material constantly in motion.

- a fine glue mist is created by means of nozzles, which is reflected evenly on the beach.

- the drums have built-in components, in order to be able to constantly pick up the beach material and to transport the beach material from the inlet into the drum to the outlet.

- An oblique inclination of the drum in the longitudinal direction can assist the forward movement of the strands.

- the achievement of the desired mechanical and technological properties is influenced by the targeted orientation of the strands.

- The% set of chips, which may deviate more than +/- 15 ° from the selected direction of orientation is small. Nevertheless, in the "transverse" direction of the plate, there are still sufficient strengths and stiffnesses is always given by the scattering process, a deviation from the target orientation.

- the target orientation of the strands will depend on the position of the beach ply within the board.

- the two outermost layers, the cover layers, should be aligned parallel to the plate length as previously described for a single-layer plate.

- the strands of the single center layer are oriented without a preferred direction (random).

- a plate structure of more than 3 layers is also conceivable.

- the number of layers is always odd, the beach orientation of the cover layers and the middle layer as described above and the orientation of the other layers may be arbitrary.

- the preferred beach orientation of these other layers is crosswise to the beach orientation of each outer adjacent location.

- a random orientation of individual layers is also possible.

- the shaping of the beach mat from the various superimposed layers is accomplished by a spreader. For each layer is usually a scattering head available. Its task is to orient the glued strands in the desired direction or randomly arrange them. After spreading the mat, the pressing takes place to a stable plate-shaped product under the action of pressure and temperature. This can be done either in cycle presses (single or multi-day presses) or in continuous presses. The latter enable the production of an endless Plate tape, which can be separated into the desired formats.

- the plates can be ground after production. This achieves a homogeneous plate thickness with small thickness tolerances and improved conditions for gluing two or more plates to components as described below. However, with sufficient board surface quality and sufficient thickness tolerance of the boards, gluing without prior sanding is also possible.

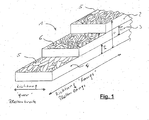

- FIG. 1 shows a wooden material plate 1 as described above, which is composed of three beach layers.

- the upper strand layer 2 shows a preferred orientation of the strands 5 in the longitudinal direction of the plate. It can be seen that the strands 5 of the topsheet 2 are not strictly parallel to the panel length are aligned, but still given a high degree of orientation.

- the middle layer 3 consists of strands 6, which are somewhat smaller in their dimensions than the strands of the cover layers 2 and 4. The orientation of the strands 6 of the middle layer 3 is randomly oriented.

- the lower cover layer 4 is constructed in mirror image to the upper cover layer 2.

- FIG. 1 shown plate 1 are selected as reference only as an example of a section of a large-sized plate and do not match the real dimensions plate length and plate width.

- FIG. 1 also shows that the thickness s1 of the two cover layers (both the lower cover layer 4 and the upper cover layer 2 constructed in mirror image) is each about 30% of the total thickness s of the plate and the thickness s2 of the middle layer 3 is about 40%.

- the individual plates 1 produced by the method described above can have a thickness s up to about 50 mm and formats of 2.8 x 15 m and can be used in a variety of applications in the construction sector.

- the plate length of 15 m should not be understood as an upper limit. However, it has been shown that both for the production and subsequent plate manipulation in the course of further processing here is a reasonable order of magnitude at 10 to 15 m.

- FIG. 2 schematically shows such a component 10 which is made of 3 individual plates 1.

- the individual plates 1 with an adhesive such. B. isocyanate at least partially over a large area bonded.

- This component can, for. B. used in house construction for exterior and interior walls, with the advantages that elements corresponding to the wall length without joints over a full storey height (up to 2.8 m) can be produced.

- the common house-building practice eg single-family house, multi-family house shows that wall elements with a length between 10 and 15 m are quite sufficient to be able to produce entire wall, ceiling and roof elements.

- FIG. 3 shows 2 different embodiments.

- the ceiling, wall or roof member 20 consists of a carrier 22, an upper plate 21 and a lower plate 23.

- the plate 21 is in itself again consists of 2 single plates 1

- the carrier 22 consists in itself again of 3 individual plates 1.

- the plates 21 and 22 are connected to the carrier 22 frictionally or positively. If the component 21 is a ceiling element, then the plate 21 assumes the function of the floor of the upper floor and the plate 23 the function of the ceiling of the lower floor.

- the component 20 consists of an upper plate 31, which is constructed only of a single plate 1, further from the carrier 32 and from the lower plate 33.

- the carrier 32 is arranged in contrast to the carrier 22 lying.

- the FIG. 4 shows the structure of a large-area component 20 which is composed of a plurality of individual plates 1.

- the length L can be up to 15 m and the width B up to 2.8 m.

- the carriers 23, 33 are firmly connected to the plates 21, 31 and 22, 32. As a result, the component in combination with the high mechanical and technological properties of the individual plates 1 itself has a high degree of wearability.

- the 3-layer OSB board of the following example was manufactured on an industrial plant.

- Stranded logs are made from decorticated pine logs with a length of approx. 150 mm, a width of between 10 and 25 mm and a thickness of between 0.5 and 0.8 mm. Fines are, as far as possible, already separated. The subsequent drying is reduced the moisture content of the strands of both layers to a value between 3 to 5%. Before gluing, the proportion of fines is minimized by means of screening devices.

- the gluing is carried out in Beleimtrommeln, wherein the top layer with about 13 wt.% Melamine-urea-phenol-formaldehyde glue (solid resin based on dry wood mass) and the middle layer with 8 wt.% Of a PMDI binder were mixed.

- the 3-layer OSB board of the following example was manufactured on an industrial plant.

- the production of the strands for the middle and top layer takes place until the mat formation on separate processing lines.

- Strands are made with a length of about 140 mm, a width between 10 and 30 mm and a thickness of about 0.6 mm. Fines are, as far as possible, already separated. Subsequent drying reduces the moisture content of the strands of both layers to between 3 and 5%. Before gluing, the proportion of fines is minimized by means of screening devices. The gluing is done in Beleimtrommeln, wherein the top layer with about 7.0 wt.% PMDI (solid resin based on wood dry matter) and the middle layer with 5.5 wt.% Of a PMDI binder were mixed.

- PMDI solid resin based on wood dry matter

- Strands with a length of approx. 140 mm, a width of between 10 and 30 mm and a thickness between 0.5 and 0.6 mm are produced from debarked pine trunks. Fines are, as far as possible, already separated. Subsequent drying reduces the moisture content of the strands to between 3 and 5%. Before gluing, the proportion of fines is minimized by means of screening devices. The gluing is done in Beleimtrommeln, with about 7,0Gew. % PMDI (solid resin based on wood dry matter) were mixed. (Vote with Wismar)

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Life Sciences & Earth Sciences (AREA)

- Wood Science & Technology (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Dry Formation Of Fiberboard And The Like (AREA)

- Panels For Use In Building Construction (AREA)

- Laminated Bodies (AREA)

- Joining Of Building Structures In Genera (AREA)

- Paper (AREA)

- Slot Machines And Peripheral Devices (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP09172833.7A EP2148020B1 (de) | 2001-06-12 | 2002-06-01 | Grossformatige osb-platte mit verbesserten eigenschaften, insbesondere für den baubereich |

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE20109675U | 2001-06-12 | ||

| DE20109675U DE20109675U1 (de) | 2001-06-12 | 2001-06-12 | Grossformatige OSB-Platte mit verbesserten Eigenschaften, insbesondere für den Baubereich |

| EP02012159A EP1267010B2 (de) | 2001-06-12 | 2002-06-01 | Grossformatige OSB-Platte mit verbesserten Eigenschaften, insbesondere für den Baubereich |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02012159A Division EP1267010B2 (de) | 2001-06-12 | 2002-06-01 | Grossformatige OSB-Platte mit verbesserten Eigenschaften, insbesondere für den Baubereich |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09172833.7A Division EP2148020B1 (de) | 2001-06-12 | 2002-06-01 | Grossformatige osb-platte mit verbesserten eigenschaften, insbesondere für den baubereich |

| EP09172833.7A Division-Into EP2148020B1 (de) | 2001-06-12 | 2002-06-01 | Grossformatige osb-platte mit verbesserten eigenschaften, insbesondere für den baubereich |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1486627A1 EP1486627A1 (de) | 2004-12-15 |

| EP1486627B1 true EP1486627B1 (de) | 2014-08-20 |

Family

ID=7957954

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02012159A Expired - Lifetime EP1267010B2 (de) | 2001-06-12 | 2002-06-01 | Grossformatige OSB-Platte mit verbesserten Eigenschaften, insbesondere für den Baubereich |

| EP04022049.3A Revoked EP1486627B1 (de) | 2001-06-12 | 2002-06-01 | Grossformatige OSB-Platte mit verbesserten Eigenschaften, insbesondere für den Baubereich |

| EP09172833.7A Expired - Lifetime EP2148020B1 (de) | 2001-06-12 | 2002-06-01 | Grossformatige osb-platte mit verbesserten eigenschaften, insbesondere für den baubereich |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP02012159A Expired - Lifetime EP1267010B2 (de) | 2001-06-12 | 2002-06-01 | Grossformatige OSB-Platte mit verbesserten Eigenschaften, insbesondere für den Baubereich |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP09172833.7A Expired - Lifetime EP2148020B1 (de) | 2001-06-12 | 2002-06-01 | Grossformatige osb-platte mit verbesserten eigenschaften, insbesondere für den baubereich |

Country Status (12)

| Country | Link |

|---|---|

| US (1) | US7226652B2 (enExample) |

| EP (3) | EP1267010B2 (enExample) |

| JP (1) | JP4307992B2 (enExample) |

| AT (1) | ATE278079T1 (enExample) |

| CA (1) | CA2450741C (enExample) |

| DE (2) | DE20109675U1 (enExample) |

| DK (1) | DK1267010T4 (enExample) |

| ES (1) | ES2229012T5 (enExample) |

| PL (1) | PL213694B1 (enExample) |

| PT (1) | PT1267010E (enExample) |

| RU (1) | RU2268968C2 (enExample) |

| WO (1) | WO2002101170A1 (enExample) |

Families Citing this family (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10306118A1 (de) * | 2003-02-14 | 2004-09-09 | Kronotec Ag | Bauplatte |

| CA2530615A1 (en) * | 2003-06-30 | 2005-01-06 | Dsm Ip Assests B.V. | Oriented strand boards |

| DE10344598B3 (de) * | 2003-09-25 | 2005-03-03 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Nachformbare Holzwerkstoffplatte und Verfahren zu deren Herstellung |

| DE20316621U1 (de) * | 2003-10-28 | 2004-02-12 | Fritz Egger Gmbh & Co | Emissionsarme OSB-Platte |

| DE102005038734A1 (de) | 2005-08-16 | 2007-02-22 | Michanickl, Andreas, Prof.Dr. | Leichte Mehrschicht-Holzwerkstoffplatte |

| US20110000167A1 (en) * | 2009-07-06 | 2011-01-06 | Dimke Robert G | Wood door core including osb layers and method |

| HRP20151044T1 (hr) * | 2011-04-20 | 2016-01-01 | John Griem | Postupak proizvodnje vatrootpornih ploäśa od drvenih vlakana |

| RU2515839C2 (ru) * | 2012-03-16 | 2014-05-20 | Федеральное государственное бюджетное образовательное учреждение высшего профессионального образования "Братский государственный университет" | Композиция для производства древесностружечных плит |

| US20150050443A1 (en) * | 2013-08-14 | 2015-02-19 | Boa-Franc | Composite engineered floor board having an oriented strand board (osb) stabilizing base |

| DE102014220459A1 (de) * | 2014-10-09 | 2016-04-14 | Mayfair Vermögensverwaltungs Se | Platte, Brett oder Paneel |

| US20170151758A1 (en) * | 2015-12-01 | 2017-06-01 | Norbord Inc. | Oriented Strand Board |

| WO2018061923A1 (ja) | 2016-09-30 | 2018-04-05 | 大建工業株式会社 | 木質積層材及びその製造方法 |

| PT3620282T (pt) * | 2017-04-25 | 2022-01-13 | SWISS KRONO Tec AG | Painel à base de madeira osb |

| JP6448738B1 (ja) | 2017-09-29 | 2019-01-09 | 大建工業株式会社 | 高密度木質積層材の製造方法 |

| JP7064552B1 (ja) | 2020-10-30 | 2022-05-10 | 大建工業株式会社 | 木質ボード |

| JP2022118558A (ja) * | 2021-02-02 | 2022-08-15 | 大建工業株式会社 | 木質ボード用の木質小薄片及びその製造方法 |

| JP2022118559A (ja) * | 2021-02-02 | 2022-08-15 | 大建工業株式会社 | 木質ボードの製造方法 |

| JP7064630B1 (ja) | 2021-02-19 | 2022-05-10 | 大建工業株式会社 | 木質積層ボード |

| JP7064638B1 (ja) | 2021-05-28 | 2022-05-10 | 大建工業株式会社 | 木質複合材、内装材、床材及び防音床材 |

| JP7072781B1 (ja) | 2021-09-09 | 2022-05-23 | 大建工業株式会社 | 木質複合材及び床材 |

| JP7536976B1 (ja) | 2023-09-12 | 2024-08-20 | 大建工業株式会社 | パーティクルボード及びパーティクルボードの製造方法 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4751131A (en) * | 1986-02-14 | 1988-06-14 | Macmillan Bloedel Limited | Waferboard lumber |

| US5470631A (en) * | 1990-04-03 | 1995-11-28 | Masonite Corporation | Flat oriented strand board-fiberboard composite structure and method of making the same |

| NZ260980A (en) * | 1993-07-14 | 1996-08-27 | Yamaha Corp | Wood board; core layer of wooden strips & foaming binder and surface layer of oriented strand board with wooden strips & binder |

| DE19503343A1 (de) * | 1994-12-17 | 1996-06-20 | Thomas Kuennemeyer | Wagenkastenaufbau, insbes. für ein Lastkraftfahrzeug oder für einen Lastkraftfahrzeuganhänger |

| US6053052A (en) * | 1995-11-16 | 2000-04-25 | Timberco, Inc. | Panel performance test system |

| DE19544866A1 (de) * | 1995-12-01 | 1997-06-05 | Siempelkamp Gmbh & Co | Vorrichtung zum Streuen von Spänen, insbesondere von Langspänen, im Zuge der Herstellung von spanorientierten Spanplatten |

| DE19700138A1 (de) * | 1997-01-03 | 1998-07-09 | Hofa Homann Gmbh & Co Kg | Schalungsplatte, insbesondere Großflächen-Schalungsplatte |

| US5951795A (en) * | 1997-06-19 | 1999-09-14 | Forintek Canada Corp. | Method of making a smooth surfaced mat of bonded wood fines used in panel manufacture |

| DE19746383A1 (de) | 1997-10-21 | 1999-04-22 | Hofa Homann Gmbh & Co Kg | Verfahren und Vorrichtung zur Herstellung von Faserplatten sowie nach dem Verfahren hergestellte Faserplatten |

| US6197414B1 (en) * | 1997-12-25 | 2001-03-06 | Matsushita Electric Works, Ltd. | Fiberboard and manufacturing method thereof |

| US6098679A (en) * | 1998-03-17 | 2000-08-08 | Noranda Forest Inc. | Dimensionally stable oriented strand board (OSB) and method for making the same |

| DE19843493B4 (de) * | 1998-09-22 | 2005-04-28 | Ihd Inst Fuer Holztechnologie | Plattenförmiger Werkstoff aus Holzspänen und Bindemitteln für einen Einsatz im Bauwesen und Möbelbau sowie Verfahren zu seiner Herstellung |

| DE19902673A1 (de) * | 1999-01-23 | 2000-07-27 | Thermopal Dekorplatten Gmbh & | Verfahren zur Herstellung einer auf Holzwerkstoff basierenden Schichtplatte sowie Schichtplatte und Holzwerkstoffplatte |

| DE29904919U1 (de) * | 1999-01-23 | 1999-09-09 | Thermopal-Dekorplatten GmbH & Co KG, 88299 Leutkirch | Schichtplatte und Holzwerkstoffplatte |

| DE19913589A1 (de) * | 1999-03-25 | 2000-09-28 | Siempelkamp Gmbh & Co | Holzwerkstoffplatte, insbesondere OSB-Platte |

| DE19919821A1 (de) * | 1999-05-01 | 2000-11-02 | Dieffenbacher Gmbh Maschf | Anlage zur Herstellung von Holzwerkstoffplatten |

| DE20015725U1 (de) * | 2000-03-24 | 2001-08-09 | Kronotec Ag, Luzern | Holzpartikelplatte, insbesondere Schalungsplatte |

-

2001

- 2001-06-12 DE DE20109675U patent/DE20109675U1/de not_active Expired - Lifetime

-

2002

- 2002-06-01 PT PT02012159T patent/PT1267010E/pt unknown

- 2002-06-01 PL PL364372A patent/PL213694B1/pl unknown

- 2002-06-01 EP EP02012159A patent/EP1267010B2/de not_active Expired - Lifetime

- 2002-06-01 DK DK02012159.6T patent/DK1267010T4/da active

- 2002-06-01 CA CA002450741A patent/CA2450741C/en not_active Expired - Lifetime

- 2002-06-01 ES ES02012159T patent/ES2229012T5/es not_active Expired - Lifetime

- 2002-06-01 DE DE50201140T patent/DE50201140D1/de not_active Expired - Lifetime

- 2002-06-01 AT AT02012159T patent/ATE278079T1/de active

- 2002-06-01 EP EP04022049.3A patent/EP1486627B1/de not_active Revoked

- 2002-06-01 WO PCT/EP2002/006023 patent/WO2002101170A1/de not_active Ceased

- 2002-06-01 RU RU2004100301/03A patent/RU2268968C2/ru active

- 2002-06-01 JP JP2003503909A patent/JP4307992B2/ja not_active Expired - Fee Related

- 2002-06-01 US US10/480,563 patent/US7226652B2/en not_active Expired - Lifetime

- 2002-06-01 EP EP09172833.7A patent/EP2148020B1/de not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP2148020A2 (de) | 2010-01-27 |

| EP2148020B1 (de) | 2019-05-15 |

| PL364372A1 (en) | 2004-12-13 |

| PL213694B1 (pl) | 2013-04-30 |

| EP1267010B1 (de) | 2004-09-29 |

| JP4307992B2 (ja) | 2009-08-05 |

| US7226652B2 (en) | 2007-06-05 |

| RU2004100301A (ru) | 2005-06-10 |

| JP2004529012A (ja) | 2004-09-24 |

| DE50201140D1 (de) | 2004-11-04 |

| WO2002101170A1 (de) | 2002-12-19 |

| RU2268968C2 (ru) | 2006-01-27 |

| DE20109675U1 (de) | 2002-10-24 |

| ATE278079T1 (de) | 2004-10-15 |

| ES2229012T3 (es) | 2005-04-16 |

| PT1267010E (pt) | 2005-02-28 |

| US20040241414A1 (en) | 2004-12-02 |

| EP2148020A3 (de) | 2011-12-28 |

| DK1267010T3 (da) | 2005-02-07 |

| EP1486627A1 (de) | 2004-12-15 |

| CA2450741A1 (en) | 2002-12-19 |

| EP1267010A1 (de) | 2002-12-18 |

| EP1267010B2 (de) | 2010-12-01 |

| CA2450741C (en) | 2007-04-17 |

| ES2229012T5 (es) | 2011-04-13 |

| DK1267010T4 (da) | 2011-02-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1486627B1 (de) | Grossformatige OSB-Platte mit verbesserten Eigenschaften, insbesondere für den Baubereich | |

| DE60032125T2 (de) | Verbundbauelemente und herstellungsverfahren | |

| WO2011141171A1 (de) | Mehrschichtiger furnierholz-formkörper | |

| WO2010097209A1 (de) | Holzwerkstoffplatte sowie ein verfahren zum herstellen einer holzwerkstoffplatte | |

| EP2688722B1 (de) | Verfahren zum bekanten von holzwerkstoffplatten | |

| EP2351635B1 (de) | Hirnholzkörper mit Balsahölzern und Verfahren zu deren Herstellung | |

| EP4010158B1 (de) | Werkstoffplatte und verfahren zur herstellung einer werkstoffplatte | |

| EP3216574A1 (de) | Verfahren zum herstellen einer osb | |

| EP3725481A1 (de) | Plattenförmiger werkstoff und verfahren zu dessen herstellung | |

| DE10024543A1 (de) | Verfahren und Anlage zur kontinuierlichen Herstellung einer Mehrschichtplatte | |

| WO2004092511A1 (de) | Fussbodenpaneel aus zwei verschiedenen holz-werkstoffen und verfahren zu dessen herstellung | |

| DE202018101347U1 (de) | Brettsperrholzelement | |

| EP1892088A2 (de) | Verfahren und Vorrichtung zur Herstellung einer Leichtbauplatte und Leichtbauplatte | |

| DE10036034A1 (de) | Drei-oder mehrlagige Verbundplatte | |

| AT526148B1 (de) | Holzverbundelement und Verfahren zu dessen Herstellung | |

| DE10049050A1 (de) | Verfahren zur Herstellung einer Mehrschichtplatte und eine nach diesem Verfahren hergestellte Mehrschichtplatte | |

| EP0018355B1 (de) | Holzspanplatte und Verfahren zu deren Herstellung | |

| EP1792699B1 (de) | Verfahren zur Herstellung einer Balsaholzspanplatte | |

| EP2078599B1 (de) | Spanplatte | |

| WO2021023784A1 (de) | Verfahren zum herstellen einer werkstoffplatte | |

| WO2000029180A1 (de) | Holzbauelement | |

| WO2005018890A1 (de) | Verfahren zur herstellung einer mehrschichtigen holzfaserplatte | |

| WO2005039845A1 (de) | Nachformbare holzwerkstoffplatte und verfahren zu deren herstellung | |

| EP2842707B1 (de) | Verfahren zur Herstellung eines aus mehreren Schnitthölzern bestehenden Konstruktionsschichtholzes | |

| WO2024230945A2 (de) | Verfahren und vorrichtung (anlage) zur herstellung einer werkstoffplatte, werkstoffplatte, sowie verwendung einer werkstoffplatte |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 1267010 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| 17P | Request for examination filed |

Effective date: 20050525 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AXX | Extension fees paid |

Extension state: RO Payment date: 20050525 |

|

| 17Q | First examination report despatched |

Effective date: 20070219 |

|

| R17C | First examination report despatched (corrected) |

Effective date: 20070219 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: FRITZ EGGER GMBH & CO. OG |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| INTG | Intention to grant announced |

Effective date: 20140428 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AC | Divisional application: reference to earlier application |

Ref document number: 1267010 Country of ref document: EP Kind code of ref document: P |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE TR |

|

| AX | Request for extension of the european patent |

Extension state: RO |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: REF Ref document number: 683564 Country of ref document: AT Kind code of ref document: T Effective date: 20140915 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: LANGUAGE OF EP DOCUMENT: GERMAN |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R096 Ref document number: 50215969 Country of ref document: DE Effective date: 20141002 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: VDEP Effective date: 20140820 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141222 Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140820 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140820 Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140820 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20141121 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140820 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140820 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140820 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R026 Ref document number: 50215969 Country of ref document: DE |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 14 |

|

| 26 | Opposition filed |

Opponent name: FLOORING TECHNOLOGIES LTD. Effective date: 20150520 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140820 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150630 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20150630 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 15 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: FLOORING TECHNOLOGIES LTD. Effective date: 20150520 |

|

| PLCK | Communication despatched that opposition was rejected |

Free format text: ORIGINAL CODE: EPIDOSNREJ1 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 16 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE PATENT HAS BEEN GRANTED |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140820 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: TR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20140820 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 20200619 Year of fee payment: 19 Ref country code: DE Payment date: 20200618 Year of fee payment: 19 Ref country code: IE Payment date: 20200618 Year of fee payment: 19 Ref country code: FR Payment date: 20200618 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20200618 Year of fee payment: 19 Ref country code: BE Payment date: 20200622 Year of fee payment: 19 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20200619 Year of fee payment: 19 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R064 Ref document number: 50215969 Country of ref document: DE Ref country code: DE Ref legal event code: R103 Ref document number: 50215969 Country of ref document: DE |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| RDAF | Communication despatched that patent is revoked |

Free format text: ORIGINAL CODE: EPIDOSNREV1 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT REVOKED |

|

| RDAG | Patent revoked |

Free format text: ORIGINAL CODE: 0009271 |

|

| REG | Reference to a national code |

Ref country code: FI Ref legal event code: MGE |

|

| 27W | Patent revoked |

Effective date: 20210505 |

|

| GBPR | Gb: patent revoked under art. 102 of the ep convention designating the uk as contracting state |

Effective date: 20210505 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MA03 Ref document number: 683564 Country of ref document: AT Kind code of ref document: T Effective date: 20210505 |