EP1004833A2 - Chaudière - Google Patents

Chaudière Download PDFInfo

- Publication number

- EP1004833A2 EP1004833A2 EP99123584A EP99123584A EP1004833A2 EP 1004833 A2 EP1004833 A2 EP 1004833A2 EP 99123584 A EP99123584 A EP 99123584A EP 99123584 A EP99123584 A EP 99123584A EP 1004833 A2 EP1004833 A2 EP 1004833A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- water

- area

- return

- boiler

- space

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H9/00—Details

- F24H9/0005—Details for water heaters

- F24H9/001—Guiding means

- F24H9/0015—Guiding means in water channels

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H1/00—Water heaters, e.g. boilers, continuous-flow heaters or water-storage heaters

- F24H1/22—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating

- F24H1/24—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating with water mantle surrounding the combustion chamber or chambers

- F24H1/26—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating with water mantle surrounding the combustion chamber or chambers the water mantle forming an integral body

- F24H1/28—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating with water mantle surrounding the combustion chamber or chambers the water mantle forming an integral body including one or more furnace or fire tubes

- F24H1/285—Water heaters other than continuous-flow or water-storage heaters, e.g. water heaters for central heating with water mantle surrounding the combustion chamber or chambers the water mantle forming an integral body including one or more furnace or fire tubes with the fire tubes arranged alongside the combustion chamber

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H9/00—Details

- F24H9/0005—Details for water heaters

- F24H9/0036—Dispositions against condensation of combustion products

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F24—HEATING; RANGES; VENTILATING

- F24H—FLUID HEATERS, e.g. WATER OR AIR HEATERS, HAVING HEAT-GENERATING MEANS, e.g. HEAT PUMPS, IN GENERAL

- F24H9/00—Details

- F24H9/12—Arrangements for connecting heaters to circulation pipes

- F24H9/13—Arrangements for connecting heaters to circulation pipes for water heaters

Definitions

- the invention relates to a standing boiler for the combustion of liquid or gaseous fuels with a burner arranged on the top, the Flame is directed into a flame space open in the flame propagation direction, which is surrounded by a water space and flows downstream into a deflection space, which is connected to a flue gas collecting room via a flue gas duct training stands.

- a boiler of the above type is for example from the patent DE 195 19 963.4-13 known. This is where the combustion chamber insert, which is open at the bottom, starts Flue gases are diverted into a flue gas duct formation, which directly uses the combustion chamber is comprehensively formed, to which flue gas duct formation radially outwards the water room connects. Heat exchanger fins protrude into the flue gas duct formation inside.

- EP 0 387 859 B1 according to which particularly low ones Exhaust gas temperatures are achievable and manageable as well as falling below the dew point should not lead to corrosion damage.

- the invention has for its object corrosion damage by avoiding falling below the dew point with simple construction and simplified maintenance of the boiler ensure.

- the quickly heated water in the inner water area rises and occurs in the upper water section in a certain order by throttling Outer water space area filled with cooler water, causing mixing he follows.

- To the outer water area and thus to this by mixing tempered water are connected to the flow and return of the heating system.

- the Exchange of water between the inner and outer water area is therefore pure by convection and not by forced flow, which would be the case if the heating water would be taken from the inner water area. This keeps the temperature in the Flue gas range remains high even when heating water is drawn off.

- a buffer effect is created by the two water areas, so that the Exhaust gas temperature with different return temperatures of the water less decreases. A more constant exhaust gas temperature and dew point avoidance are achieved.

- the flue gas temperature in the boiler is the lowest where the flow temperature is highest.

- the flue gas duct formation is on the side next to the Flame space arranged so that the preferably from several parallel Flue gas ducts existing flue gas duct formation in total in an adjacent side the flue gas outlet arranged in the burner connection opens.

- the flue gas ducts consist preferably of tubes with ribs or the like in the tube interior protruding protrusions free inner wall, in particular from smooth-walled overall Pipes. This makes cleaning the flues and the boiler very important simplified. In this design, an elongated horizontal section results, in particular oval outline design of the boiler, thus saving space next to others Arrange aggregates.

- the transition area is between the two water area areas in the lower section of the water space simply designed by the Partition runs freely down into this section.

- the partition in the upper section the edge of the water space can be provided with recesses, so that transition openings may remain free in the area of these recesses, if the top edge of the partition wall is face up to the front face of the boiler connects.

- the upper water transfer is in shape formed by several recesses in the upper edge region of the partition. Out For reasons that will be discussed in more detail later, it can be more advantageous the throttled transition in the form of a single opening in the upper section of the To provide a partition.

- the partition wall more preferably forms the outer wall of a hollow cylinder, the consists in particular of sheet steel. This makes the partition wall special simple and inexpensive. Regardless of this, the shape of the partition in the Horizontal section depending on the spatial distribution of the Flue gas duct formation in relation to the flame chamber round, polygonal or in particular be oval-shaped.

- the throttled Transition adjustable, in particular controlled temperature-dependent, for example through a bimetal, such that the flow area of the transition - in the Embodiment thus the one opening or several recesses - with the help adjustable throttle devices.

- the boiler is preferably made entirely of steel or as a whole Steel structure.

- the water space engages under the floor of the flue gases from the flame chamber into the deflecting chamber redirecting the flue gas duct formation.

- the flame chamber and the flue gas duct formation on the hydraulic side Partition put on, which divides the water space into two areas.

- the inner area between the partition and the flame chamber - possibly with reduced water content

- Overflow openings in the upper section of the water space and is only due to the The buoyancy of the hot boiler water flows through, so it is independent of that forced flow impressed on the heating circuit.

- the lift is lower when starting off Water temperature small, which results in a low volume flow and therefore a rapid rise in temperature of the heat exchange surfaces takes place. With increasing water temperature the lift and thus the volume flow increases.

- the water heats up much faster and stronger than in the outer one Water area that lies between the partition and the outer shell of the boiler and is flowed through by the heating water.

- the heating takes place by admixing the throttled Overflow openings of the partition from the inner water area and Heat emission from the heated partition.

- a boiler of the type mentioned so far is, however, in terms of hydraulic management - d.

- H. the Leading the heating water into the boiler, in the boiler itself or out of the boiler can also be optimized so that the dew point is undershot even at lower levels Boiler temperatures or heating water temperatures and also in one area only lower Utilization should be avoided in any case.

- this is achieved by that a return of the heating water in the area of the upper water transfer into the outer water space area opens in such a way that the exit impulse of the Return water a mixture of the escaping from the upper water transfer Hot water can be brought about with the water of the outer water area.

- the returning water is thus targeted or directed into the outer water area initiated that the thereby generated in the outer water area Flow, for example, by sweeping or hitting the heat in the inner water space area emerging from the upper water transfer Hot water causes this hot water with the water in the outer water area and / or optionally also mixed with the return water.

- the mouth of the return is preferably full, essentially or at least partially or with only one directional component away from the upper water crossing directed. This causes an exit pulse of the return water from the upper water transfer away, so that in the direction of flow in front of this mouth Warm water in the outer water area creates a suction effect.

- the hot water in the outer area of the water space this leads past the upper water transfer and mixes there with the escaping hot water.

- the outer water area is (at least) in its upper portion is annular.

- the return with a Inlet device for loading into the outer water area return water to be introduced with a pulse in the circumferential direction of this is provided in the form of a ring-shaped outer area of the water space, this is due to this exit impulse

- An annular flow can be achieved in the annular water area. This is particularly so due to the standing arrangement of the boiler in question, because a horizontally directed ring flow can thus occur.

- the upper water transfer could also in relation to the flow of the Return water and / or in the direction of this in the boiler operation in the outer water area adjusting flow seen downstream of the mouth of the return port arranged, but then the escaping hot water would be directly through the return water flowing in in the vicinity of the upper water transfer is increased Dimensions are cooled. Better mixing and more even temperature distribution in the outer ring area of the boiler - also in the vertical direction achievable in that the upper water overflow upstream of the mouth of the return connection is arranged. Mixed by the suction effect already indicated above then the hot water with that already in the outer water annulus Hot water, in which case part of the hot water / hot water mixture attaches to the Mouth of the return line mixed with the return water.

- the return water has due to its lower temperature the tendency to flow downwards, so that taking into account this tendency and / or taking into account the fact that the supply of hot water and colder return water to the outside Water area close together, also a vertically uniform temperature is achievable in the outer ring area or outer water area.

- the return water is the return water to take advantage of its exit pulse just flow into the boiler in the area of the upper water outlet.

- the return is an inflow baffle or the same line device for guiding the return water from the return port upwards to the return outlet located near the upper water overflow having. If you look at this inflow baffle or line device so that it through leads to the outer water area, the return water can be flushed preheat the hot water in the outer water area.

- the exit pulse steers available in that the return is part of the outer wall of the boiler trained housing - especially welded to the inside of the boiler outer wall for guiding and introducing the return water into the outer water area and in particular for forming the inlet device and / or the inflow baffle.

- Such housing can be particularly flat and somewhat wider in an advantageous manner be designed so that a large heat exchange surface between the hot water and the return water is achievable and also between the partition and the Enough free space remains for the hot water.

- the housing for forming the introduction device has an opening has, the boundary walls at least partially and preferably are directed essentially in the circumferential direction.

- This mouth opening can for example as an elongated narrow opening - on a side wall of the housing - be trained. So that the mixing of the hot water is ensured preferably only a single water transfer in the upper area of the boiler - namely near the return outlet - trained.

- this single top Water leakage is located above the housing. On the one hand, this has the effect that the housing is washed by the hot water escaping from the upper water overflow is and thus the return is already preheated in heat exchange manner. To this Way is prevented in any case by a particularly cool return water somewhere in the boiler there is a zone of such low water temperature, that the dew point could be undershot. Second, through this Training an even temperature distribution over the entire vertical axis of the outer water jacket achieved.

- the mouth opening of the housing is designed such that its boundary walls the return water in the desired direction into the outer water area initiate. Taking advantage of a venturi effect or in the manner of a nozzle is the exit impulse of the return water can still be amplified when the mouth of the return is tapered.

- the inventive design of the return port allows in the lower area of the boiler, which was previously particularly sensitive to falling below the dew point, achieve an elevated temperature.

- This in turn causes the temperature profile in the inner water area of the boiler can be raised significantly. This is because that heated water in this inner water area due to the density difference rises up and emerges from the upper water overflow. But then there has to be something new Flow water from the outer water area into the inner water area, what is happening through the lower water crossing. If now in the lower area of the Boiler the temperature is raised, can be in the inner water area this way an increased temperature and a very rapid rise in temperature Achieve commissioning of the boiler.

- the heating water required for heating does not come from the inside Water area, but taken from the outer water area, so that the temperature of the inner water area essentially due to the overflow of hot water is determined by the upper water transfer and not primarily through more or less large removal of heating water.

- the heating water withdrawal point of the flow of the heating water in a preferred embodiment also not arranged in the immediate area of the upper water transfer - in Close to this water transfer is the return outlet - rather than it it is envisaged that a flow of the heating water at a point from the upper water transfer in Circumferentially spaced heating water withdrawal point from the outer Water space leads away, in particular for the heating water withdrawal in an upper, the boiler plate - front plate or the outer water space at the top Mounting plate - a removal opening is arranged.

- the removal of one at the very top arranged location of the outer water area is advantageous because there due to the hottest water accumulates in the outer water area.

- a possible ring flow in the outer water area, which can be achieved by the exit impulse of the return water is hardly disturbed.

- This ring flow has the particular advantage that a Formation of hot nests in the entire boiler area, but especially in the upper one Area, the connecting seam between the separating jacket and the upper boiler plate or Mounting plate, is counteracted.

- a flow connector could also directly connect to this removal opening, however, this is unwieldy in terms of assembly.

- the supply and return connections are close to each other, so that the Pipe connections together - especially to a common pipe connection, control and Pump element - can be connected.

- the lead a flow channel for connecting the removal opening with one on the same Boiler side as the return pipe - preferably in the vicinity and in particular above it - arranged flow connector.

- the partition is provided with an indentation in the area of this removal point, a larger opening cross-section can be reached. It could also be a larger one Part can be removed from an area within the indentation, so that the ring flow otherwise leading around the separating jacket is less disturbed.

- the exit impulse of the return water generated flow of the outside Water space area located heating water seen upstream of the upper Water transfer and / or the return outlet is arranged, it is ensured that only hot water is withdrawn from the outer water area and not that Hot water used to heat this hot water, which flows out of the upper water flows in, and also not the colder return water.

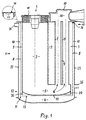

- FIG. 1 shows a first embodiment of an overall with 1 designated standing boiler, the one arranged at 2 Is heated burner, which is only indicated with regard to its flame tube and as so-called lintel burner on the upper end face - here formed by an end cover 18 for the burner connection - of the boiler 1 with the flame spreading direction downwards in a flame chamber 3 of the boiler 1 is arranged.

- the flame chamber 3 is one Surround water chamber 4 and open down into a deflection chamber 5, via which hot flue gases generated in the combustion chamber 3 into a total designated 6 Flue gas duct training can be conducted.

- the flue gas duct formation 6 is in the form of a bundle of parallel flue gas flues inside and outside smooth tubes 7 are formed, through which the flue gases in the opposite direction for flame propagation in the flame space 3 upwards into a flue gas collecting space 21 be directed, which is limited by a flue gas discharge 17, the flue gases in one leads not shown fireplace or the like.

- the flue gas flues can basically be distributed around the flame space 3; is in the embodiment shown the bundle of parallel tubes 7 as flue gas flues radially in a lateral direction arranged next to the flame chamber 3, so that the outer contour of the boiler 1 in Horizontal section has an oval shape overall, which is also correspondingly polygonal or can be designed polygonal.

- the water space is approximately parallel to the jacket wall by means of a - Boiler outer wall 22 - the boiler 1 extending partition 8 in one subdivided inner water space area 9 and an outer water space area 10, than these water space areas 9 and 10 on the one hand into a lower section 12 and one connected to upper section 13.

- the partition 8 is formed as a cylindrical jacket which in the Viewed horizontally, oval or polygonal and thus correspondingly simple to manufacture - in particular from sheet steel.

- a flow shield wall 20 is fixed, which prevents because of the downward bulging bottom 19 of the deflection chamber 5 when heating the heating water inside Water space area 9, on the other hand, cold water flows in too quickly.

- the flow screen wall 20 is over its circumference with - here vertical, slit-shaped - outflow openings 24 provided to avoid backwater areas.

- the water space 4 - here the outer water space area 10 - is included Provide connections for the flow 25 and the return 26 of the heating water. How from Figure 2 can be seen for the optional connection on both sides connections for the front and Return 25 or 26 may be provided.

- the wall of the flame chamber 3 and that of the flue gas duct formation 6 in the form of the tubes 7 heats up very quickly; the adjacent Water in the inner water area 9 flows due to thermal buoyancy accordingly quickly upwards, so that a drop below the dew point in the area of the lower Section 12 of the inner water area 9 is prevented very quickly.

- the Afterflow of cold water from the outer water area 10 into the inner Water area 9 is due to the throttling effect of the water transfer 14 in the upper Section 13 of the water space 4 controlled, primarily by the dimensions of the recesses 23 in the upper edge 16 of the partition 8.

- the flow shield wall 20 in the circumferential area of the bottom 19 of the deflection space 5 also prevents the dew point lower boiler area the rapid transfer of cold water from the outer water area 10 to the inner water area 9 so that the intended one rapid heating of the water in the inner water area 9 in particular endangered lower section 12 of the water space 4 is ensured.

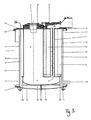

- FIG. 2 shows a perspective view of the main components of the boiler 1, which clearly shows that the manufacture of these assemblies and their assembly is particularly simple and inexpensive. Above all, the formation of the Flue gas duct formation as smooth-walled tubes 7 is particularly easy to maintain.

- the structurally particularly simple partition 8 has a buffer effect, so that the exhaust gas temperature is less affected at different return temperatures becomes what is good for avoiding dew point.

- the result is not just one Corrosion prevention, but also a more constant exhaust gas temperature. Reached overall, avoiding cold zones in the lower section of the water space and overheating in the upper section.

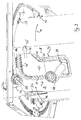

- FIGS. 3 to 9 show a second embodiment of the upright Boiler 1 with the inner partition 8 for dividing the water space 4 in the inner water area 9 and the outer water area 10 shown.

- the same parts with the same parts Reference numerals. To explain these parts in more detail, refer to the above Description of the first embodiment.

- the lower end 15 of the partition 8 also ends in the second embodiment above the base plate 31 of the boiler 1 and thus freely in the lower section 12 of the Water space 4, so that the lower water transfer 11 is formed over this free end 15 is.

- the upper edge 16 is the Partition 8 with a larger now forming the only water transfer 14 Recess and with further recesses 23 or 23 ', but which are now in the essential only guide and fastening function for holding the partition 8 have the upper end plate or mounting plate 36 provided.

- essentially cylindrical in shape with an oval Partition 8 formed in cross section is an indentation 34 towards the inside of the boiler Area of the upper edge 16 of the partition 8 is formed.

- the combustion chamber / flue gas routing unit designated overall by 35 (see FIG. 4) - Flame chamber 3 and exhaust duct 5 - 7 - is at its upper end on the mounting plate 36 attached to which also for the burner connection and to cover the Flame chamber 3 formed end cover 18 and the flue gas collection chamber 21 having smoke exhaust 17 is attached.

- Fig. 4 the boiler wall 22 is shown on the left and the partition 8 on the right, while in the In the middle, the combustion chamber / flue gas guide unit 35 with the mounting plate 36 attached to it is shown above the base plate or base plate 31.

- the return 26 has a return port 37 through which the Return water to the inside of the boiler wall is feasible and an inflow baffle 27 on, by means of a targeted deflection of the return water into the outer water area 10 is achievable.

- the inflow baffle 27 is formed by a housing 38 which through the outside 4 to 9, the boiler wall 22 shown broken away and towards the inside is formed by a housing wall part 39 welded to this boiler wall.

- the housing wall part 39 comprises an inwardly directed plate 40 and relative narrow side boundaries - side walls 41 and top wall 41 '(see FIG. 9) and lower wall 41 '' -, so that the housing 38 is relatively flat overall.

- the Housing 38 has a section 47 leading upwards with parallel sections opposite side walls 41, which at its upper end in one angled section 48 passes. The free end of the angled portion 48 tapers through side wall boundaries 41, 41 'inclined towards each other a mouth opening 42, as can be seen particularly well in FIGS. 8 and 9.

- the inflow baffle 27 is designed so that the return water first up and then to the side through a nozzle-like tapered mouth opening 42 in the circumferential direction 46 of the annular outer water space region 10, d. H. in this outer water annulus 10 tangential direction 46, in the outer Water annulus area 10 is led out; see in particular FIGS. 5 and 9, in which the housing wall part 39 is shown without the boiler wall 22. How 9 shows the only upper overflow opening - the upper water transfer 14 directly above the housing 38 and in fact adjacent to an upper side wall boundary, d. H. the top wall 41 'of the housing wall part 39 is arranged, the mouth opening 42 is directed away from the upper water transfer 14.

- the mounting plate 36 In addition to the larger recess 14 for the upper water transfer also at the upper edge 16 existing smaller recesses 23, 23 'are bulges 49 the mounting plate 36 inserted so that there is no overflow of water between the inner 9 and the outer water area 10 takes place. As in Fig. 9 can be seen, there is a removal opening 43 in the region of the indentation 34 which can be removed through the flow 25 heating water.

- the lead 25 also has one Flow connector 44 on the same in the vicinity of the return connector 37 Boiler side (here the back of the boiler 1) is led to the outside.

- the distance of the Flow connector 44 and the return connector 37 is dimensioned such that a modular Heating circuit unit (not shown) with common connection for flow and return, Valves, control elements and possibly a pump can be connected to it.

- the flow 25 further has a flow channel 29 with a vent connection 30.

- the Flow channel 29 is guided essentially above the mounting plate 36, and the vent connection is at the highest point in the entire hydraulic range - Water filling area - of the boiler 1, namely on this flow channel.

- a filling and Drain valve 28 is in the lower region of the boiler 1 on the outer wall 22 of the boiler intended.

- the hot water which due to the density difference in the inner water area 9 during boiler operation flows upwards and exits at the upper water overflow 14 now mixed by the outlet pulse 45 of the return water. Through the exit impulse 45 is thus in the outer water area 10 over the entire vertical axis get even temperature distribution.

- the temperature in the lower section 12 of the Water space 4 is therefore compared to the embodiment described in the main application elevated.

- the temperature profile in the inner water area 9 is due to the Temperature increase in the lower section 12 already when the hot water overflows significantly increased by the water transfer 14, since warmer water also the lower water transfer 11 is sucked. This has the effect of falling below the dew point and additionally prevent condensation.

- the exit pulse 45 is increased due to the nozzle-like tapering of the mouth opening 42 compared to a normal inflow. Due to a strong exit pulse 45 of the return water, a circular or tangential circulation of the hot water is created in the outer water space area 10, which circulation additionally causes the formation of hot water Nests "especially in the upper area - the connection point of the partition 8 to the mounting plate 36 - counteracts.

- the heating water tapping point 34/43 - area of the indentation 34 and the tapping opening 43 - is upstream of the orifice with respect to this circulation 42, so that no cold return water is drawn through the flow 25. Moreover is the removal opening 43 circumferentially spaced - and likewise upstream of the current here - from the hot water-emitting opening the upper water crossing 14.

- the hot water flowing in through the upper water transition 14 also heats the Housing 38, so that a preheating of the return water before its final inflow into the water space 4 of the boiler 1.

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Incineration Of Waste (AREA)

- Combustion Of Fluid Fuel (AREA)

- Heat-Pump Type And Storage Water Heaters (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19854910A DE19854910B4 (de) | 1998-11-27 | 1998-11-27 | Heizkessel |

| DE19854910 | 1998-11-27 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1004833A2 true EP1004833A2 (fr) | 2000-05-31 |

| EP1004833A3 EP1004833A3 (fr) | 2002-09-11 |

Family

ID=7889312

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99123584A Withdrawn EP1004833A3 (fr) | 1998-11-27 | 1999-11-26 | Chaudière |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP1004833A3 (fr) |

| DE (1) | DE19854910B4 (fr) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1179713A2 (fr) * | 2000-07-13 | 2002-02-13 | Swisscondens AG | Chaudière |

| EP1369647A2 (fr) * | 2002-06-04 | 2003-12-10 | Bradford White Corporation | Chaudière à haut rendement |

| WO2006111317A1 (fr) * | 2005-04-18 | 2006-10-26 | Unical Ag S.P.A. | Appareil d'echange thermique, en particulier un bruleur de condensation de tube de fumee |

| FR2919711A1 (fr) * | 2007-08-02 | 2009-02-06 | E U R L Jean Marie Thevenon Sa | Echangeur thermique vertical a flux inverses |

| CN101392952A (zh) * | 2008-10-22 | 2009-03-25 | 威海柯碧思木业有限公司 | 取暖用自循环锅炉 |

| US8807093B2 (en) | 2011-05-19 | 2014-08-19 | Bock Water Heaters, Inc. | Water heater with multiple heat exchanging stacks |

| US10184690B2 (en) | 2017-02-09 | 2019-01-22 | Bock Water Heaters, Inc. | Condensing water heater and condensation control system |

| EP4361523A1 (fr) * | 2022-10-31 | 2024-05-01 | Apen Group S.p.A. | Chaudière à condensation avec brûleur et accumulateur pour installations hybrides avec pompe à chaleur |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102005039426B4 (de) * | 2005-08-18 | 2018-06-14 | Udo Hellwig | Hochleistungsenergiewandler |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0387859B1 (fr) | 1989-03-14 | 1995-06-21 | Pyropac AG | Chaudière de chauffage |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1560514A (fr) * | 1968-01-22 | 1969-03-21 | ||

| GB1383545A (en) * | 1971-06-26 | 1974-02-12 | Nippon Musical Instruments Mfg | Liquid heating boilers |

| DE3210327C2 (de) * | 1982-03-20 | 1988-08-18 | Wolf Klimatechnik GmbH, 8302 Mainburg | Zylindrischer Heizungskessel |

| DE3329777A1 (de) * | 1983-08-18 | 1985-03-07 | Georg Fischer GmbH & Co Maschinen- u. Kesselfabrik, 8870 Günzburg | Heizungskessel fuer fluessige und gasfoermige brennstoffe |

| DE3601000A1 (de) * | 1985-07-02 | 1987-06-19 | Vaillant Joh Gmbh & Co | Wasserheizkessel |

| DE4400686C1 (de) * | 1994-01-12 | 1995-06-22 | Elco Kloeckner Heiztech Gmbh | Verbrennungsgasführung |

| DE19519963C2 (de) * | 1995-05-31 | 1997-07-17 | Pyropac Ag | Heizkessel |

-

1998

- 1998-11-27 DE DE19854910A patent/DE19854910B4/de not_active Expired - Fee Related

-

1999

- 1999-11-26 EP EP99123584A patent/EP1004833A3/fr not_active Withdrawn

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0387859B1 (fr) | 1989-03-14 | 1995-06-21 | Pyropac AG | Chaudière de chauffage |

Cited By (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1179713A2 (fr) * | 2000-07-13 | 2002-02-13 | Swisscondens AG | Chaudière |

| EP1179713A3 (fr) * | 2000-07-13 | 2003-08-06 | Swisscondens AG | Chaudière |

| US7900589B2 (en) | 2002-06-04 | 2011-03-08 | Bradford White Corporation | High efficiency water heater |

| EP1369647A3 (fr) * | 2002-06-04 | 2005-01-19 | Bradford White Corporation | Chaudière à haut rendement |

| US7559293B2 (en) | 2002-06-04 | 2009-07-14 | Bradford White Corporation | High efficiency water heater |

| EP1369647A2 (fr) * | 2002-06-04 | 2003-12-10 | Bradford White Corporation | Chaudière à haut rendement |

| WO2006111317A1 (fr) * | 2005-04-18 | 2006-10-26 | Unical Ag S.P.A. | Appareil d'echange thermique, en particulier un bruleur de condensation de tube de fumee |

| US7819090B2 (en) | 2005-04-18 | 2010-10-26 | Unical Ag S.P.A. | Heat exchange apparatus, particularly fire tube condensing boiler |

| FR2919711A1 (fr) * | 2007-08-02 | 2009-02-06 | E U R L Jean Marie Thevenon Sa | Echangeur thermique vertical a flux inverses |

| CN101392952A (zh) * | 2008-10-22 | 2009-03-25 | 威海柯碧思木业有限公司 | 取暖用自循环锅炉 |

| CN101392952B (zh) * | 2008-10-22 | 2013-03-20 | 威海柯碧思木业有限公司 | 取暖用自循环锅炉 |

| US8807093B2 (en) | 2011-05-19 | 2014-08-19 | Bock Water Heaters, Inc. | Water heater with multiple heat exchanging stacks |

| US10184690B2 (en) | 2017-02-09 | 2019-01-22 | Bock Water Heaters, Inc. | Condensing water heater and condensation control system |

| EP4361523A1 (fr) * | 2022-10-31 | 2024-05-01 | Apen Group S.p.A. | Chaudière à condensation avec brûleur et accumulateur pour installations hybrides avec pompe à chaleur |

Also Published As

| Publication number | Publication date |

|---|---|

| EP1004833A3 (fr) | 2002-09-11 |

| DE19854910B4 (de) | 2004-09-02 |

| DE19854910A1 (de) | 2000-06-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2035128B2 (de) | Freiluft-durchlauferhitzer | |

| EP1004833A2 (fr) | Chaudière | |

| DE4207500C2 (de) | Heizkessel mit verringerter NO¶x¶-Emission | |

| DE3905762C2 (fr) | ||

| DE2337282A1 (de) | Fliessbett-waermebehandlungsvorrichtung | |

| DE2518836C2 (de) | Tauch-Heißgas-Flüssigkeitserhitzer | |

| DE19509780C1 (de) | Fahrzeugheizgerät | |

| DE4113412C2 (de) | Vorrichtung zur Verbrennung von flüssigem oder gasförmigem Brennstoff für eine Feuerungsanlage | |

| DE4425302C2 (de) | Gußeiserner Gliederheizkessel | |

| DE3321116A1 (de) | Raumheizgeraet fuer kleinraeume | |

| DE2749089A1 (de) | Ofen | |

| EP0618410A2 (fr) | Echangeur de chaleur pour chaudière à condensation | |

| DE3421746A1 (de) | Waermeaustauscher | |

| DE19957000A1 (de) | Heizkessel | |

| EP1221571B1 (fr) | Appareil de combustion avec refroidissement | |

| EP0981024B1 (fr) | Chaudière avec brûleur inversé | |

| DE3546368A1 (de) | Heizkessel | |

| DE10203116B4 (de) | Heizgerät mit einem becherförmigen Wärmeübertrager | |

| DE3227504C2 (de) | Vorrichtung zum Wärmen und/oder Warmhalten von Behältern und deren Inhalt | |

| EP0292580B1 (fr) | Chaudière de chauffage | |

| EP0497224B1 (fr) | Chaudière de chauffage à basse température pour brûler des combustibles liquides ou gazeux | |

| DE9105410U1 (de) | Zentralheizungskessel | |

| DE8107430U1 (de) | "brennstoffbefeuerter heizkessel" | |

| DE3348037C2 (fr) | ||

| DE3015377A1 (de) | Heizungskessel fuer warmwasserheizungsanlagen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: WIRTH, CHRISTOPH Inventor name: LITFIN, DIETHARD |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20020830 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU MC NL PT SE |

|

| 17Q | First examination report despatched |

Effective date: 20030911 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20041123 |