EP0936152B1 - Faltschachtel - Google Patents

Faltschachtel Download PDFInfo

- Publication number

- EP0936152B1 EP0936152B1 EP99102520A EP99102520A EP0936152B1 EP 0936152 B1 EP0936152 B1 EP 0936152B1 EP 99102520 A EP99102520 A EP 99102520A EP 99102520 A EP99102520 A EP 99102520A EP 0936152 B1 EP0936152 B1 EP 0936152B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- folding box

- tab

- folding

- region

- side wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000007704 transition Effects 0.000 claims description 7

- 238000013461 design Methods 0.000 claims description 4

- 230000007423 decrease Effects 0.000 claims description 3

- 238000004321 preservation Methods 0.000 claims 1

- 238000003780 insertion Methods 0.000 description 8

- 230000037431 insertion Effects 0.000 description 8

- 238000004806 packaging method and process Methods 0.000 description 6

- 235000009508 confectionery Nutrition 0.000 description 3

- 230000003287 optical effect Effects 0.000 description 3

- 238000005520 cutting process Methods 0.000 description 2

- 238000012549 training Methods 0.000 description 2

- 244000299461 Theobroma cacao Species 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 230000002146 bilateral effect Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 235000019219 chocolate Nutrition 0.000 description 1

- 230000003247 decreasing effect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 230000002349 favourable effect Effects 0.000 description 1

- 235000013305 food Nutrition 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 230000003993 interaction Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000002574 poison Substances 0.000 description 1

- 231100000614 poison Toxicity 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/54—Lines of weakness to facilitate opening of container or dividing it into separate parts by cutting or tearing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/20—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form

- B65D5/2038—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form at least two opposed folded-up portions having a non-rectangular shape

- B65D5/2047—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form at least two opposed folded-up portions having a non-rectangular shape trapezoidal, e.g. to form a body with diverging side walls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/20—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form

- B65D5/2095—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper by folding-up portions connected to a central panel from all sides to form a container body, e.g. of tray-like form a part of the folded-up portions defining an inwardly folded ledge at the edges of the central panel

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/64—Lids

- B65D5/66—Hinged lids

- B65D5/6626—Hinged lids formed by folding extensions of a side panel of a container body formed by erecting a "cross-like" blank

- B65D5/665—Hinged lids formed by folding extensions of a side panel of a container body formed by erecting a "cross-like" blank the lid being held in closed position by self-locking integral flaps or tabs

- B65D5/6655—Local flaps or tabs provided at the lid edge opposite to the hinge

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D5/00—Rigid or semi-rigid containers of polygonal cross-section, e.g. boxes, cartons or trays, formed by folding or erecting one or more blanks made of paper

- B65D5/42—Details of containers or of foldable or erectable container blanks

- B65D5/64—Lids

- B65D5/68—Telescope flanged lids

Definitions

- the present invention relates to a folding box, in particular for storing and presenting goods with an upper part of the box with a lid unit, a lower part of a box with base unit and at least one clip, which parts are put together the closed folding box result.

- Such folding boxes are known and exist in the Rule of two separate parts that are put on top of each other can be or from a one-piece part, wherein the top can be pivoted around a fold line.

- the It is usually set up by hand and is usually gluing is also required.

- the present invention has the technical problem or based on the task of a folding box of the beginning Specify the type mentioned, a simple cut allowed, easy and quick to set up and assemble can be and visually reliably signaled to the consumer, that the folding box is in its original packaging condition located.

- the folding box according to the invention is characterized by the features of independent claim 1. Advantageous configurations and further training are the subject of the dependent Expectations.

- the folding box according to the invention is accordingly distinguished characterized in that the bottom part of the box or the top part of the box at least one on the bottom part / cover part via one Folding and tear line has molded tab, whose Width course in a line following the fold and tear line 1st area increases in a to the 1st area subsequent 2nd area decreases and one to the 2nd area Tongue unit is molded, the box top or Lower part of the box according to the position of the tab Has recess whose outer contour is essentially the Corresponds to the outer contour of the 1st and 2nd area of the tab, such that when the folding box is assembled the Tab in the recess is present in a form-fitting manner is.

- the clip in connection with the associated recess practically represents a tamper-evident seal the upper part hooks onto the lower part Insert tab in the recess and holds both parts securely firmly.

- the plug-in tab breaks when the upper part is removed along their tear line due to the positive connection from, so that the consumer or third parties recognize immediately can, if the folding box has already been opened has been.

- the packaging is primarily for food, in particular Confectionery, suitable and shows the end consumer the original packaging of the content. This can an uncertainty of the consumer in a simple way and To be counteracted. Through the "optical” "Safe” content is recognized in the signal by the consumer With regard to the problems that have arisen repeatedly in recent times assuming "poison extortionists".

- a particularly preferred embodiment is distinguished characterized in that the transition between the 1st and 2nd Region of the tab is in the form of an edge, according to a further advantageous embodiment of the Transition between the 1st and 2nd area at the opposite Recess is formed in the form of a curve, so that on the one hand an easy insertion process when setting up the folding box and packaging of the goods guaranteed is, moreover, a permanent reliable closing function is made possible and at the same time as a result of positive locking a reliable tear off of the tab in the case of Opening the folding box can be guaranteed.

- one simple manufacture and a simple installation special preferred embodiment is characterized in that the top of the folding box and / or the bottom of the folding box Double-walled at least in some areas in its side walls is / are formed and the recess by a Free cut formed in a wall of the double wall area and / or the outer contour of the tab by a 3-sided cut-out in one wall of the double wall area is formed.

- the tab described can be associated with Recess used in a folding box, at the separate upper and lower parts are available or at which rotates the top part on the bottom part via a fold line is molded.

- the essential point is that the flap is reliably torn off when the folding box is opened becomes.

- the folding box draws according to the invention in that the floor unit is longer than at least one longitudinal edge a subsequent side wall and between the floor unit and Side wall of an envelope flap that can be folded onto the base unit is present, its fold line on the base unit side has the same length as the length of the floor unit and whose side wall fold line has the same length like the length of the side wall.

- a preferred embodiment which is particularly common for packaging sweets, in particular chocolates, is used, is characterized in that the envelope flap on all edge areas of the floor unit Lower part of the box is formed.

- One in terms of stability, simplest cardboard cutting and quick set-up and assembly particularly advantageous Design is characterized in that at least one side wall area a first side wall element and has a second side wall element over a fold line, so that the side wall area is double-walled foldable and on the first side wall element or the second side wall element an insert tab is formed on the side edge for insertion into adjacent double-walled side wall areas when unfolding the folding box.

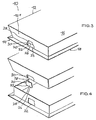

- An upper part 12 of a folding box in FIGS. 3 and 4 folding box shown in detail in folded condition 10 has a rectangular cover unit 16.

- To the Edges of the lid unit 16 are each over fold lines 17, 17.1 molded two side wall elements 19, the Front edge side wall elements 19, 19.1 on the outside via a further fold line 21 have an envelope flap 23.

- the Sidewall elements 19 and 19.1 have on their side edges even more folding flaps, the geometry of the folding flaps and side wall elements 19, 19.1 is designed such that after folding a folding body is created, the side walls starting from the cover unit 16 down with a tapering cross-sectional geometry is available are.

- FIG. 2 is a folding box bottom part 14 of his Shown cut forth that the lower part of the in the Fig. 3 and 4 corresponds to box 10 shown in detail.

- the folding box lower part 14 has a rectangular shape Bottom unit 18, with a fold line at each longitudinal edge 62 on the side edges (left and right according to FIG. 2) and at the front edges (according to FIG. 2 above and below) one Envelope flap 60.1, 60.2 is formed.

- On the envelope flap 60.1, 60.2 is over another fold line 64 first side wall element 50.1 or 50.2 and another Fold line 54 a second side wall element 52.1 or 52.2 molded.

- a folding flap 68 is formed on a further folding line 66.

- the dimensions of the base unit 18 are compared to that adjoining side wall elements 50, 52 are enlarged, so that there is a bilateral in each edge area Overhang dimension Ü results. This corresponds to the projection dimension Ü the width of the envelope flap 60.1 or 60.2.

- the length of the Fold line 62 corresponds to the respective edge length of the base unit 18, while the length of the fold line 64 of the Length of the respective side flap corresponds to 50.1 or 50.2.

- the envelope flap 60 folded over to the base unit 18 and the side wall elements 50.1, 50.2 or 52.1, 52.2 double-walled folded, erected and the folding tab 68 is folded so that they rest on the inside on the base unit 18 is available.

- the insertion tabs 56 the side wall elements 50.1 between the existing ones Sidewall elements 50.2, 52.2 inserted.

- the box top 12 is also in a known manner and Set up way, here also a double-walled Box part is generated.

- the upper part 12 is attached.

- the tab snaps into place 20 in the recess 30.

- the flap 20 has, according to FIG. 6, its folding and Tear line 22 a 1st area 24, the width of which initially increases linearly.

- a 2nd Area 26 formed, the width of which in turn decreases linearly.

- a tongue unit 28 is molded onto the second area 26, whose width is essentially constant.

- the length L 1 of Tongue unit 28 is in the illustrated embodiment chosen so that it essentially corresponds to the length L 2, i.e. the total length of the 1st area 24 and the 2nd Area corresponds to 26.

- the transition from the 1st area 24 for the second area 26 is formed as an edge 32 on the outside contour.

- the recess 30 has an outer contour that is essentially the outer contour of the 1st area 24 and the 2nd area 26 corresponds to the tab 20. Starting from the fold line 17 also a 1st area 34 with increasing Width and an adjoining second area 36 with decreasing Width available. In contrast to the training of the Transition area of the 1st area 24 to the 2nd area 26 of the Tab 20 is the transition from the 1st area 34 to the 2nd Area 36 of the recess 30 in the form of a fillet 35 educated.

- FIG Fig. 5 Another embodiment of a folding box 40 is shown in FIG Fig. 5 is shown schematically.

- the folding box top 42 here has a rectangular cover unit 46, which via a folding line 49 to the lower part 44 of the box Base unit 48 is integrally formed.

- the lid unit 46 is therefore not removable, but pivotable about the fold line 49.

- tab 20 formed in their geometric described shape in the recess 30 of the bottom part 44 can be inserted.

- the folding box according to the invention offers the end user the advantage that he can see at a glance whether the folding box is in the original packaging condition located. Any relative movement between the top and bottom leads to the tab tearing off and thus an "optical Signal "is present that the end user before an already opened folding box warns.

- an "optical Signal" is present that the end user before an already opened folding box warns.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cartons (AREA)

Description

- Fig. 1:

- Draufsicht auf einen Kartonzuschnitt eines Schachteloberteils mit zwei Ausnehmungen,

- Fig. 2:

- Draufsicht auf einen Kartonzuschnitt eines Schachtelunterteils mit zwei Einstecklaschen und einteiligem Vorstehboden,

- Fig. 3:

- Detailperspektive des aufgestellten Oberteils gemäß Fig. 1 und aufgestellten Unterteils gemäß Fig. 2 in aufeinandergestecktem Zustand,

- Fig. 4:

- schematische Detailperspektive der Faltschachtel gemäß Fig. 3 in auseinandergezogenem Zustand,

- Fig. 5:

- schematische Perspektivdarstellung einer Faltschachtel mit drehbar an dem Schachtelunterteil angeformten Schachteloberteil mit Einstecklasche und Ausnehmung und

- Fig. 6:

- schematische Ansichtsdarstellung einer Einstecklasche.

Claims (10)

- Faltschachtel (10; 40), insbesondere zur Aufbewahrung und Präsentation von Waren, mitdadurch gekennzeichnet, daßeinem Schachteloberteil (12; 42) mit Deckeleinheit (16; 46),einem Schachtelunterteil (14; 44) mit Bodeneinheit (18; 48) undzumindest einer am Schachtelunterteil (14; 44) oder am Schachteloberteil (12; 42) angeformte Stecklasche (20),welche Teile zusammengefügt eine geschlossene Faltschachtel (10; 40) ergeben,die Stecklasche am Bodenteil (18; 48) des Schachtelunterteils oder am Deckekteil (16) des Schachteloberteils über eine Falt- und Reißlinie (22) angeformt ist, deren Breitenverlauf in einem an die Falt- und Reißlinie (22) anschließenden ersten Bereich (24) zunimmt, in einem an den ersten Bereich (24) anschließenden zweiten. Bereich (26) abnimmt und an den zweiten Bereich (26) eine Zungeneinheit (28) angeformt ist,das Schachteloberteil (12; 42) oder das Schachtelunterteil (14; 44) entsprechend der Position der Lasche (20) eine Ausnehmung (30) aufweist, deren Außenkontur im wesentlichen der Außenkontur des ersten und des zweiten Bereiches (26, 28) der Lasche (20) entspricht, derart, daß bei zusammengefügter Faltschachtel (10; 40) die Lasche (20) in der Ausnehmung (30) formschlüssig steckend vorhanden ist.

- Faltschachtel nach Anspruch 1,

dadurch gekennzeichnet, daß der Übergang zwischen dem ersten und dem zweiten. Bereich (24, 26) der Lasche (20) in Form einer Kante (32) ausgebildet ist. - Faltschachtel nach Anspruch 1 und/oder 2,

dadurch gekennzeichnet, daß der Übergang zwischen dem ersten und zweiten Bereich (34, 36) der Ausnehmung (30) in Form einer Rundung (35) ausgebildet ist. - Faltschachtel nach einem oder mehreren der vorstehenden Ansprüche,

dadurch gekennzeichnet, daß das Faltschachteloberteil (12; 42) und/oder das Faltschachtelunterteil (14; 44) zumindest bereichsweise in ihren Seitenwänden doppelwandig ausgebildet sind und die Ausnehmung (30) durch einen Freischnitt in einer Wandung des Doppelwandbereichs gebildet wird und/oder die Außenkontur der Lasche (20) durch einen 3-Seiten-Freischnitt in einer Wandung des Doppelwandbereiches gebildet ist. - Faltschachtel nach einem oder mehreren der vorstehenden Ansprüche,

dadurch gekennzeichnet, daß das Faltschachtelunterteil (14) und das Faltschachteloberteil (12) von einem jeweils getrennten Kartonzuschnitt gebildet ist. - Faltschachtel nach einem oder mehreren der Ansprüche 1 bis 4,

dadurch gekennzeichnet, daß das Faltschachtelunterteil (44) zusammen mit dem Faltschachteloberteil (42) von einem gemeinsamen, einstückigen Kartonzuschnitt gebildet ist. - Faltschachtel nach einem oder mehreren der vorstehenden Ansprüche,

dadurch gekennzeichnet, daß die Länge L 1 der Zungeneinheit (28) der Lasche (20) im wesentlichen der Länge L 2 des ersten und zweiten Bereiches (24, 26) der Lasche (20) entspricht. - Faltschachtel nach einem oder mehreren der vorstehenden Ansprüche,

dadurch gekennzeichnet, daß die Bodeneinheit (18; 48) zumindest an einem Längsrand eine größere Länge besitzt als eine anschließende Seitenwand (50.1, 50.2) und zwischen Bodeneinheit (18; 48) und Seitenwand (50.1, 50.2) eine auf die Bodeneinheit (18; 48) faltbare Umschlaglasche (60.1, 60.2) vorhanden ist, deren bodeneinheitseitig vorhandene Faltlinie (62) dieselbe Länge aufweist wie die Länge der Bodeneinheit (18; 48) und deren seitenwandseitige Faltlinie (64) dieselbe Länge aufweist wie die Länge der Seitenwand (50.1, 50.2). - Faltschachtel nach Anspruch 8,

dadurch gekennzeichnet, daß die Umschlaglasche (60) mit anschließenden Seitenwänden (50.1, 50.2) an sämtlichen Randbereichen der Faltschachtel angeformt ist. - Faltschachtel nach Anspruch 8 und/oder 9,

dadurch gekennzeichnet, daß zumindest ein Seitenwandbereich ein erstes Seitenwandelement (50.1) und über eine Faltlinie (54) ein zweites Seitenwandelement (52.1) aufweist, so daß der Seitenwandbereich doppelwandig faltbar ausgebildet ist und an dem ersten Seitenwandelement (50.1) oder dem zweiten Seitenwandelement (52.1) am seitlichen Rand eine Einstecklasche (56) angeformt ist zum Einstecken in benachbarte doppelwandige Seitenwandbereiche beim Auffalten der Faltschachtel.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19805452 | 1998-02-11 | ||

| DE19805452A DE19805452A1 (de) | 1998-02-11 | 1998-02-11 | Faltschachtel |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0936152A1 EP0936152A1 (de) | 1999-08-18 |

| EP0936152B1 true EP0936152B1 (de) | 2003-12-10 |

Family

ID=7857313

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP99102520A Expired - Lifetime EP0936152B1 (de) | 1998-02-11 | 1999-02-10 | Faltschachtel |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0936152B1 (de) |

| DE (2) | DE19805452A1 (de) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102007023015A1 (de) † | 2007-05-15 | 2008-11-20 | Dietmar Fassbach | Behälter zum Transport von warmen Speisen, insbesondere Pizza |

| DE202007011660U1 (de) * | 2007-08-17 | 2007-10-18 | Smurfit Kappa Herzberger Wellpappe Gmbh | Versandverpackung mit Originalitätsverschluss |

| CN111453122B (zh) * | 2020-05-21 | 2025-02-28 | 天津博容包装制品有限公司 | 包装箱、包材、工装及成箱方法 |

| US11377252B2 (en) | 2020-05-28 | 2022-07-05 | Pratt Corrugated Holdings, Inc. | Locking box |

| US11840379B2 (en) | 2020-08-24 | 2023-12-12 | Pratt Corrugated Holdings, Inc | Tamper-evident box |

| USD1057557S1 (en) | 2020-08-31 | 2025-01-14 | Pratt Corrugated Holdings, Inc. | Locking tab for tamper-evident box |

| USD1037847S1 (en) | 2020-09-08 | 2024-08-06 | Pratt Corrugated Holdings, Inc. | Locking tab for a box |

| DE102020132335A1 (de) * | 2020-12-04 | 2022-06-09 | Van Genechten Packaging N.V. | Papier- oder Kartonverpackung |

| USD1056702S1 (en) | 2022-02-08 | 2025-01-07 | Pratt Corrugated Holdings, Inc. | Shoebox |

| US12441506B2 (en) | 2022-02-08 | 2025-10-14 | Pratt Corrugated Holdings, Inc. | Shoebox |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1396369A (fr) * | 1964-02-11 | 1965-04-23 | Allard & Fils | Système pour l'assemblage, le blocage et la fermeture de tout ou partie d'un emballage en carton ou similaire |

| US4516718A (en) * | 1983-09-20 | 1985-05-14 | Westvaco Corporation | Carton with automatic lock |

| ES1004169Y (es) * | 1988-01-25 | 1990-02-16 | Iberoamericana Del Embalaje, S. A. | Contenedor con tapa perfeccionado. |

| US5402930A (en) * | 1992-03-30 | 1995-04-04 | Jamestown Container Corporation | High quality inexpensive pizza box |

-

1998

- 1998-02-11 DE DE19805452A patent/DE19805452A1/de not_active Withdrawn

-

1999

- 1999-02-10 EP EP99102520A patent/EP0936152B1/de not_active Expired - Lifetime

- 1999-02-10 DE DE59907975T patent/DE59907975D1/de not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0936152A1 (de) | 1999-08-18 |

| DE59907975D1 (de) | 2004-01-22 |

| DE19805452A1 (de) | 1999-08-12 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69719960T2 (de) | Klappschachtel | |

| EP0082388B1 (de) | Zuschnitt für eine für Zigaretten oder Zigarillos bestimmte Schachtel | |

| EP0650907B1 (de) | Klappschachtel, insbesondere für Zigaretten | |

| EP2434915A1 (de) | Zigarettenpapierbüchel | |

| EP1086029A1 (de) | Klappschachtel für zigaretten oder dergleichen | |

| EP0936152B1 (de) | Faltschachtel | |

| DE3340798A1 (de) | Verpackung in form einer schachtel aus karton | |

| EP0775636B1 (de) | Schiebeschachtel | |

| DE19522894B4 (de) | Starres Päckchen mit angelenktem Deckel für längliche Gegenstände, insbesondere Zigaretten | |

| DE19809466A1 (de) | Kartontasche mit Originalitätsverschluß | |

| DE19829125A1 (de) | Verpackung für Wischblätter | |

| DE102007018772A1 (de) | Aufklappbare Packungen mit Doppelscharnier für Rauchartikel | |

| EP1341698B1 (de) | Faltschachtel | |

| DE9411144U1 (de) | Faltschachtel und Faltschachtelzuschnitt | |

| EP0098314A1 (de) | Faltschachtel mit einer aufreissbaren Ausgussöffnung | |

| EP0058640A1 (de) | Zuschnitt für eine Faltschachtel | |

| EP3118138B1 (de) | Verpackung und zuschnitt zur herstellung einer verpackung | |

| DE4429146A1 (de) | Faltschachtel sowie Materialzuschnitt und Verfahren zur Herstellung einer Faltschachtel | |

| DE10022526A1 (de) | Einrastverschluß für Verpackungen | |

| DE4117353C2 (de) | ||

| DE4334760A1 (de) | Faltbarer Verpackungsbehälter | |

| DE9115273U1 (de) | Faltschachtel | |

| CH639340A5 (en) | Folding box with a tear-off pouring opening | |

| AT412964B (de) | Faltschachtel | |

| DE19915951A1 (de) | Faltschachtel |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE CH DE FR GB LI |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 20000105 |

|

| AKX | Designation fees paid |

Free format text: BE CH DE FR GB LI |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: CD CARTONDRUCK AG |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE CH DE FR GB LI |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D Free format text: NOT ENGLISH |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REF | Corresponds to: |

Ref document number: 59907975 Country of ref document: DE Date of ref document: 20040122 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: ISLER & PEDRAZZINI AG |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 20040319 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed |

Effective date: 20040913 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PCAR Free format text: ISLER & PEDRAZZINI AG;POSTFACH 1772;8027 ZUERICH (CH) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20120221 Year of fee payment: 14 Ref country code: FR Payment date: 20120228 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20120222 Year of fee payment: 14 Ref country code: BE Payment date: 20120221 Year of fee payment: 14 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59907975 Country of ref document: DE Representative=s name: MUELLER, CLEMENS & HACH, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59907975 Country of ref document: DE Representative=s name: MUELLER, CLEMENS & HACH, DE Effective date: 20120829 Ref country code: DE Ref legal event code: R081 Ref document number: 59907975 Country of ref document: DE Owner name: MULTI PACKAGING SOLUTIONS GMBH, DE Free format text: FORMER OWNER: CD CARTONDRUCK AG, 74182 OBERSULM, DE Effective date: 20120829 Ref country code: DE Ref legal event code: R081 Ref document number: 59907975 Country of ref document: DE Owner name: CD CARTONDRUCK GMBH, DE Free format text: FORMER OWNER: CD CARTONDRUCK AG, 74182 OBERSULM, DE Effective date: 20120829 |

|

| BERE | Be: lapsed |

Owner name: *CD CARTONDRUCK A.G. Effective date: 20130228 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20130210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130228 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130228 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20131031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130228 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130210 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130228 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59907975 Country of ref document: DE Representative=s name: MUELLER, CLEMENS & HACH, DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R082 Ref document number: 59907975 Country of ref document: DE Representative=s name: MUELLER, CLEMENS & HACH, DE Effective date: 20140922 Ref country code: DE Ref legal event code: R081 Ref document number: 59907975 Country of ref document: DE Owner name: MULTI PACKAGING SOLUTIONS GMBH, DE Free format text: FORMER OWNER: CD CARTONDRUCK GMBH, 74182 OBERSULM, DE Effective date: 20140922 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20150223 Year of fee payment: 17 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59907975 Country of ref document: DE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20160901 |