EP0899493A1 - Dichtpackung zum Einsetzen in eine Maueröffnung zwecks Durchführen von Leitungen - Google Patents

Dichtpackung zum Einsetzen in eine Maueröffnung zwecks Durchführen von Leitungen Download PDFInfo

- Publication number

- EP0899493A1 EP0899493A1 EP98114446A EP98114446A EP0899493A1 EP 0899493 A1 EP0899493 A1 EP 0899493A1 EP 98114446 A EP98114446 A EP 98114446A EP 98114446 A EP98114446 A EP 98114446A EP 0899493 A1 EP0899493 A1 EP 0899493A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- sealing

- ring

- sealing ring

- packing

- ring segments

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16L—PIPES; JOINTS OR FITTINGS FOR PIPES; SUPPORTS FOR PIPES, CABLES OR PROTECTIVE TUBING; MEANS FOR THERMAL INSULATION IN GENERAL

- F16L5/00—Devices for use where pipes, cables or protective tubing pass through walls or partitions

- F16L5/02—Sealing

- F16L5/08—Sealing by means of axial screws compressing a ring or sleeve

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G3/00—Installations of electric cables or lines or protective tubing therefor in or on buildings, equivalent structures or vehicles

- H02G3/22—Installations of cables or lines through walls, floors or ceilings, e.g. into buildings

Definitions

- the invention relates to a sealing packing for insertion into a wall opening for the passage of lines. Both energy and Telephone cables as well as pipelines for flowable media such as water or gas into consideration.

- Such a packing comprises a rubber-made sealing washer Material with a circular circumference, further pressing elements on both sides the sealing washer and the sealing washer sandwich enclose between themselves. Through the entire packing are also Tension rods passed through, with which the pressing elements on both sides can be clamped so that the sealing washer is squeezed, whereby their outer diameter increases, so that the sealing washer creates the wall reveal.

- the device is installed as follows:

- the packing is inserted into the wall opening and fixed in it.

- the cables are then passed through the hole in the Seal pack passed through.

- the tension bolts are not initially stretched so that the sealing washer is not yet squeezed together becomes.

- the clamping screws for the purpose of fixing the Sealing packing tightened.

- the embodiment mentioned facilitates the assembly of sealing packs over previous embodiments, but is still room for improvement.

- the invention is therefore based on the object To design a packing according to the preamble of claim 1 in such a way that the assembly is made even easier, without additional structural Expenditure.

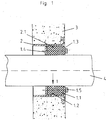

- the sealing packing 1 shown in FIG. 1 comprises a sealing ring 1.1 rubber-elastic material.

- the ring 1.1 is with a circumferential groove 1.2 Mistake. It is encased on both sides by ring segments 1.3, 1.4.

- a plurality of clamping screws 1.5 are over the circumference of the sealing packing evenly distributed.

- the sealing pack sits in a plastic sleeve.

- the sleeve points to her Inside a circumferential collar 2.1, which in the circumferential groove 1.2 intervenes.

- the federal government 2.1 can be interrupted or closed.

- the sleeve 2 is poured into a concrete wall 3.

- the packing 1 encloses a pipeline 4 for the passage of gas.

- the sealing ring 1.1 is shown by itself. You can see that he has a parting line 1.6.

- the parting line is, as you can see, against the Radial plane inclined. In the present case, the angle of inclination is approximately 45 °. However, other angles are also conceivable, for example 10, 20, 30, 40, 50, 60, 70 °.

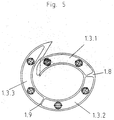

- Figure 3 is a top view of the entire packing. As you can see, there are three ring segments 1.3.1, 1.3.2 on the page shown here and 1.3.3. The ring segments are on the opposite side identical in shape to the ones here and are present in the projection same place.

- a joint 1.7 runs in the same way as the joint 1.6 in the sealing ring 1.1 between the two ring segments 1.3.1, 1.3.3.

- the parting line 1.6 in the Sealing ring 1.1 shown here in dashed lines, runs, as you can see, in Area of the joint 1.7.

- the two parting lines can also collapse.

- the angle of inclination that the two joints with the Radial plane concerned can be the same. It is also possible the angle that the parting line 1.6 forms with the radial plane, to make larger or smaller than the one that the parting line 1.7 with the radial plane in question.

- Figure 5 is very revealing because it is the assembly process illustrated. As you can see, due to the joints 1.6 of the Sealing ring 1.1 and the parting line 1.7 between the relevant Ring segments a bending of the entire packing 1 possible, and an imaginary momentary bending axis 1.8 parallel to the Longitudinal axis of the packing 1 runs and between the ring segments 1.3.1 and 1.3.2. lies. After bending or pulling in one branch the packing around the bending axis 1.8 can bend one more imaginary momentary bending axis 1.9 can be made. This is located between the ring segments 1.3.2 and 1.3.3. Figure 5 shows that Condition in which only one branch has moved in, but not the second.

- the overall diameter of the packing is not reduced but enlarged, so that the packing when inserted into a Opening, for example in a sleeve with an inwardly projecting Bund, can be reduced and thus bridging narrow spaces.

- the Sealing packing 1 moved in this way until the above-mentioned Circumferential groove 1.2 of the sealing ring 1.1, the collar 2.1 of the sleeve 2 opposite. Then the bends around the bending axes 1.8, 1.9 undone so that the packing is circular Takes shape again. Now the packing can be tightened be squeezed together by nuts on the clamping screws 1.5, so that the outer surface of the sealing washer 1.1 on the inner surface of the Sleeve 2 is full and under tension.

- Figure 6 shows an interesting application, in which also Constriction exists. As you can see, the packing 1 must go through Tube 4 or core hole are pushed, which has a relatively low clearance Width or narrowing.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Gasket Seals (AREA)

- Installation Of Indoor Wiring (AREA)

Abstract

Description

Claims (7)

- Dichtpackung zum Einsetzen in eine Maueröffnung zwecks Durchführens von Leitungen durch eine Wand.1.1 mit einem Dichtring (1.1) aus gummielastischem Material mit kreisförmigem Aussenumfang;1.2 mit beidseits des Dichtringes (1.1) vorgesehenen Presselementen (1.3, 1.4), die den Dichtring (1.1) sandwichartig zwischen sich einschliessen und als Ringsegmente gestaltet sind:-1.3 mit Zugstäben (1.5), durch den Dichtring (1.1) und durch die Ringsegmente (1.3, 1.4) hindurchgeführt sind;1.4 der Dichtring (1.1) ist in Umfangsrichtung durchtrennt;1.5 die Trennfuge (1.6) verläuft unter einem Winkel gegen die Radialebene;1.6 die Trennfuge (1.6) des Dichtringes (1.1) ist - in Draufsicht - an die Stirnseite der Dichtpackung (1) gesehen; im Bereich einer Fuge (1.7) zwischen zwei Ringsegmenten (1.3.1; 1.3.3) angeordnet;1.7 Es sind wenigstens zwei weitere Trennfugen zwischen den Ringsegmenten vorgesehen.

- Dichtpackung nach Anspruch 1, dadurch gekennzeichnet, daß beidseits des Dichtringes drei Ringsegmente (1.3.1, 1.3.2, 1.3.3) vorgesehen sind.

- Vorrichtung nach Anspruch 1 oder 2, dadurch gekennzeichnet, daß die Ringsegmente im wesentlichen gleich lang sind.

- Dichtpackung nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, daß die Trennfuge des Dichtringes unter einem Winkel von zwischen 10 und 60° vorzugsweise 45° gegen die Radialebene verläuft.

- Vorrichtung nach einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, daß im Bereich der Trennfuge (1.6) des Dichtringes (1.1) eine Trennfuge (1.7) zwischen zwei einander benachbarten Ringsegmenten (1.3.1 und 1.3.3) angeordnet ist.

- Dichtpackung nach einem der Ansprüche 1 bis 6, dadurch gekennzeichnet, daß die beiden Trennfugen (1.6 und 1.7) wenigstens annähernd unter demselben Winkel zur Radialebene verlaufen.

- Dichtpackung nach einem der Ansprüche 1 bis 7, dadurch gekennzeichnet, daß der Dichtring (1.1) eine Umfangsnut (1.2) zum Einführen eines Bundes (2.1) aufweist.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19736494 | 1997-08-22 | ||

| DE19736494A DE19736494A1 (de) | 1997-08-22 | 1997-08-22 | Dichtpackung zum Einsetzen in eine Maueröffnung zwecks Durchführen von Leitungen |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0899493A1 true EP0899493A1 (de) | 1999-03-03 |

| EP0899493B1 EP0899493B1 (de) | 2001-11-07 |

Family

ID=7839786

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP98114446A Expired - Lifetime EP0899493B1 (de) | 1997-08-22 | 1998-08-01 | Dichtpackung zum Einsetzen in eine Maueröffnung zwecks Durchführen von Leitungen |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0899493B1 (de) |

| AT (1) | ATE208474T1 (de) |

| DE (2) | DE19736494A1 (de) |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1211450A1 (de) * | 2000-11-21 | 2002-06-05 | Hauff-Technik GmbH & Co. KG | Dichtungsvorrichtung für Kabel- und Rohrdurchgänge |

| EP1867904A1 (de) | 2006-06-17 | 2007-12-19 | Fibre Optics CT GmbH, Consulting & Testing | Mauerwerk-, Rohr-, Kanal-Abdichtung |

| CZ302427B6 (cs) * | 2003-12-15 | 2011-05-11 | Kolejnicová ucpávka | |

| CN102709863A (zh) * | 2012-04-10 | 2012-10-03 | 山西省电力公司太原供电分公司 | 电缆穿管端头密封器 |

| WO2012140071A1 (de) * | 2011-04-15 | 2012-10-18 | Aco Severin Ahlmann Gmbh & Co. Kg | Montagehilfe |

| EP2597344A1 (de) * | 2011-11-25 | 2013-05-29 | Hauff-Technik GmbH & Co. KG | Adapterring zum Einsetzen in ein Rohrelement einer Leitungsdurchführung |

| CN103486338A (zh) * | 2013-09-02 | 2014-01-01 | 国家电网公司 | 一种电缆穿护管防水封堵装置 |

| WO2019057248A1 (de) * | 2017-09-22 | 2019-03-28 | Mueller Dirk | Endstopfen für linersysteme |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE29906645U1 (de) * | 1999-04-15 | 2000-08-24 | DOYMA GmbH & Co, 28876 Oyten | Durchführungs-Vorrichtung zum abgedichteten Durchführen mindestens einer Leistung durch einen in der Wand o.dgl. ausgebildeten Durchbruch |

| DE10007527C2 (de) * | 2000-02-18 | 2003-05-22 | Hauff Technik Gmbh & Co Kg | Dichtpackung zum Hindurchführen von Leitungen durch eine Wand |

| DE202004011202U1 (de) * | 2004-07-16 | 2005-11-24 | Doyma Gmbh & Co | Moduldichtung für Leitungsdurchführungen |

| DE102006058701A1 (de) * | 2006-12-13 | 2008-06-26 | Rheinmetall Defence Electronics Gmbh | Durchführungsdichtung |

| CN105909879B (zh) * | 2016-05-26 | 2018-06-12 | 瑞洲建设集团有限公司 | 地下室混凝土外墙柔性防水穿墙套管结构及施工方法 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1940855A1 (de) * | 1969-08-11 | 1971-02-25 | Thunderline Corp | Durchfuehrungsdichtung |

| DE3828693C1 (de) | 1988-08-24 | 1989-10-26 | Plastoform Gmbh & Co Kg, 4973 Vlotho, De | |

| WO1996025616A1 (de) * | 1995-02-14 | 1996-08-22 | Karl Kortmann | Stützvorrichtung für rohre in mauerdurchführungen |

| DE19601288A1 (de) * | 1995-05-10 | 1996-11-14 | Dsi Rohrleitungsbau Zubehoer | Vorrichtung zum Abdichten eines Ringraumes |

| DE19649499A1 (de) | 1996-11-29 | 1998-06-04 | Hauff Technik Gmbh & Co Kg | Vorrichtung zum Hindurchführen von Strängen, wie Kabeln oder Rohrleitungen durch eine Wand |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE9208255U1 (de) * | 1992-06-20 | 1992-09-03 | Doyma-Rohrdurchführungstechnik Hans-Ullrich Ihlenfeldt, 2806 Oyten | Rohr-Dichtungseinsatz |

-

1997

- 1997-08-22 DE DE19736494A patent/DE19736494A1/de not_active Withdrawn

-

1998

- 1998-08-01 EP EP98114446A patent/EP0899493B1/de not_active Expired - Lifetime

- 1998-08-01 AT AT98114446T patent/ATE208474T1/de not_active IP Right Cessation

- 1998-08-01 DE DE59802036T patent/DE59802036D1/de not_active Expired - Lifetime

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1940855A1 (de) * | 1969-08-11 | 1971-02-25 | Thunderline Corp | Durchfuehrungsdichtung |

| DE3828693C1 (de) | 1988-08-24 | 1989-10-26 | Plastoform Gmbh & Co Kg, 4973 Vlotho, De | |

| WO1996025616A1 (de) * | 1995-02-14 | 1996-08-22 | Karl Kortmann | Stützvorrichtung für rohre in mauerdurchführungen |

| DE19601288A1 (de) * | 1995-05-10 | 1996-11-14 | Dsi Rohrleitungsbau Zubehoer | Vorrichtung zum Abdichten eines Ringraumes |

| DE19649499A1 (de) | 1996-11-29 | 1998-06-04 | Hauff Technik Gmbh & Co Kg | Vorrichtung zum Hindurchführen von Strängen, wie Kabeln oder Rohrleitungen durch eine Wand |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1211450A1 (de) * | 2000-11-21 | 2002-06-05 | Hauff-Technik GmbH & Co. KG | Dichtungsvorrichtung für Kabel- und Rohrdurchgänge |

| CZ302427B6 (cs) * | 2003-12-15 | 2011-05-11 | Kolejnicová ucpávka | |

| EP1867904A1 (de) | 2006-06-17 | 2007-12-19 | Fibre Optics CT GmbH, Consulting & Testing | Mauerwerk-, Rohr-, Kanal-Abdichtung |

| WO2012140071A1 (de) * | 2011-04-15 | 2012-10-18 | Aco Severin Ahlmann Gmbh & Co. Kg | Montagehilfe |

| EP2597344A1 (de) * | 2011-11-25 | 2013-05-29 | Hauff-Technik GmbH & Co. KG | Adapterring zum Einsetzen in ein Rohrelement einer Leitungsdurchführung |

| CN102709863A (zh) * | 2012-04-10 | 2012-10-03 | 山西省电力公司太原供电分公司 | 电缆穿管端头密封器 |

| CN103486338A (zh) * | 2013-09-02 | 2014-01-01 | 国家电网公司 | 一种电缆穿护管防水封堵装置 |

| CN103486338B (zh) * | 2013-09-02 | 2015-09-30 | 国家电网公司 | 一种电缆穿护管防水封堵装置 |

| WO2019057248A1 (de) * | 2017-09-22 | 2019-03-28 | Mueller Dirk | Endstopfen für linersysteme |

| US11204122B2 (en) | 2017-09-22 | 2021-12-21 | Dirk Müller | End stopper for liner systems |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0899493B1 (de) | 2001-11-07 |

| DE59802036D1 (de) | 2001-12-13 |

| ATE208474T1 (de) | 2001-11-15 |

| DE19736494A1 (de) | 1999-02-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2413623C3 (de) | Flüssigkeitsdichte, eingangsseitige Abdichtung von mindestens zwei in ein Muffengehäuse parallel einmündenden Kabeln | |

| EP0899493B1 (de) | Dichtpackung zum Einsetzen in eine Maueröffnung zwecks Durchführen von Leitungen | |

| DE9017866U1 (de) | Kabelführungsrohrbündel aus einer Mehrzahl von Kunststoffrohren | |

| EP0611911A1 (de) | Abdichtende Verbindung von Kunststoff-Metall-Kunststoff-Verbundrohren | |

| DE1506848C3 (de) | Rohrleitung für den pneumatischen oder hydraulischen Transport kurzer, gleichartiger Materialpfropfen | |

| CH619524A5 (en) | Releasable pipe connection, especially for plastic pipes | |

| DE3422793C2 (de) | ||

| DE4035557A1 (de) | Haubenmuffe | |

| DE19745474C2 (de) | Vorrichtung zur Durchführung einer Gasleitung, eines Kabels oder dgl. durch eine Gebäudewand | |

| DE4139825C1 (en) | Hollow connector for securing ribbed cable to bush - has elliptical-section outer cylinder, deformable to allow release of locking ribs from cable | |

| DE3102710C2 (de) | ||

| DE2513982C3 (de) | Rohrdichtung | |

| EP2817549B1 (de) | Bauteilverbinder zum verbinden von zylindrischen bauteilen | |

| DE2341112B2 (de) | Verschlußgehäuse für mindestens ein Ende eines elektrischen Kabels | |

| DE7035177U (de) | Schutzvorrichtung fuer leitungen. | |

| DE19607085C1 (de) | Vorrichtung zum Abdichten eines Schutzrohres | |

| DE3707432C2 (de) | ||

| EP1265020A2 (de) | Flexible Gasleitung | |

| DE2923259C2 (de) | Schutzvorrichtung gegen aus einer undichten Rohrleitungsflanschverbindung austretende Medien | |

| DE102022107221A1 (de) | Verwendung eines Durchführungssystems | |

| DE4009403A1 (de) | Rohrleitungskupplung, rohrleitung sowie verfahren zur montage einer rohrleitung | |

| EP0916888A1 (de) | Rohrkupplung | |

| DE3941413C1 (en) | Joint for underground ventilation ducts - has hose fitted to inside of pipe at area of joint | |

| DE19537479A1 (de) | Anschlußanordnung für ein Wellrohr | |

| DE2434600C2 (de) | Kabelmuffe für Spleißverbindungen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU NL SE |

|

| AX | Request for extension of the european patent |

Free format text: AL;LT;LV;MK;RO;SI |

|

| 17P | Request for examination filed |

Effective date: 19990122 |

|

| AKX | Designation fees paid |

Free format text: AT BE CH CY DE DK ES FI FR GB GR IE IT LI LU NL |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| 17Q | First examination report despatched |

Effective date: 20001124 |

|

| RBV | Designated contracting states (corrected) |

Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU NL SE |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FI FR GB GR IE IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20011107 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20011107 Ref country code: IE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20011107 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20011107 Ref country code: GB Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20011107 Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20011107 Ref country code: FI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20011107 |

|

| REF | Corresponds to: |

Ref document number: 208474 Country of ref document: AT Date of ref document: 20011115 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D Free format text: GERMAN |

|

| REF | Corresponds to: |

Ref document number: 59802036 Country of ref document: DE Date of ref document: 20011213 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020207 Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020207 |

|

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 20011107 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20020530 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020801 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020801 |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FD4D |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020831 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020831 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020831 |

|

| EN | Fr: translation not filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| BERE | Be: lapsed |

Owner name: *HAUFF-TECHNIK G.M.B.H. & CO. K.G. Effective date: 20020831 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20170823 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59802036 Country of ref document: DE |