EP0840706B2 - Fadenliefergerät - Google Patents

Fadenliefergerät Download PDFInfo

- Publication number

- EP0840706B2 EP0840706B2 EP96925707A EP96925707A EP0840706B2 EP 0840706 B2 EP0840706 B2 EP 0840706B2 EP 96925707 A EP96925707 A EP 96925707A EP 96925707 A EP96925707 A EP 96925707A EP 0840706 B2 EP0840706 B2 EP 0840706B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- holder

- extension arm

- adjustment mechanism

- feeding device

- yam

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000007246 mechanism Effects 0.000 claims abstract description 42

- 230000000903 blocking effect Effects 0.000 claims description 5

- 230000008859 change Effects 0.000 claims description 2

- 230000003247 decreasing effect Effects 0.000 claims 1

- 238000006073 displacement reaction Methods 0.000 claims 1

- 230000008878 coupling Effects 0.000 description 6

- 238000010168 coupling process Methods 0.000 description 6

- 238000005859 coupling reaction Methods 0.000 description 6

- 238000006243 chemical reaction Methods 0.000 description 2

- 239000004753 textile Substances 0.000 description 2

- 230000008901 benefit Effects 0.000 description 1

- 238000007664 blowing Methods 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D47/00—Looms in which bulk supply of weft does not pass through shed, e.g. shuttleless looms, gripper shuttle looms, dummy shuttle looms

- D03D47/34—Handling the weft between bulk storage and weft-inserting means

- D03D47/36—Measuring and cutting the weft

- D03D47/361—Drum-type weft feeding devices

- D03D47/364—Yarn braking means acting on the drum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H59/00—Adjusting or controlling tension in filamentary material, e.g. for preventing snarling; Applications of tension indicators

- B65H59/02—Adjusting or controlling tension in filamentary material, e.g. for preventing snarling; Applications of tension indicators by regulating delivery of material from supply package

- B65H59/06—Adjusting or controlling tension in filamentary material, e.g. for preventing snarling; Applications of tension indicators by regulating delivery of material from supply package by devices acting on material leaving the package

-

- D—TEXTILES; PAPER

- D03—WEAVING

- D03D—WOVEN FABRICS; METHODS OF WEAVING; LOOMS

- D03D47/00—Looms in which bulk supply of weft does not pass through shed, e.g. shuttleless looms, gripper shuttle looms, dummy shuttle looms

- D03D47/34—Handling the weft between bulk storage and weft-inserting means

- D03D47/36—Measuring and cutting the weft

- D03D47/361—Drum-type weft feeding devices

- D03D47/364—Yarn braking means acting on the drum

- D03D47/366—Conical

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65H—HANDLING THIN OR FILAMENTARY MATERIAL, e.g. SHEETS, WEBS, CABLES

- B65H2701/00—Handled material; Storage means

- B65H2701/30—Handled filamentary material

- B65H2701/31—Textiles threads or artificial strands of filaments

Definitions

- the invention relates to a yarn delivery device specified in the preamble of claim 1 Art.

- the holder is attached to a slide that runs along the Cantilever is movable.

- the sled is in one Boom set screw coupled by a pin sitting in the bottom of the sled, which is by means of an eccentric and a handle can be lifted to the carriage by the adjusting screw to decouple. Then the sled can be moved by hand on the boom in the gap position or pull off the boom. With the pen indented, the Gradually slide into the carriage using the set screw Gap position are shifted.

- the gap position is needed to either the thread brake body or to replace the thread brake element or to thread a new thread, if necessary by hand.

- the adjustment of the holder by means of the set screw is time consuming and tedious. The adjustment by hand requires considerable skill to Coupling the pin and adjusting the slide, being however, the original pressure setting is not is changed.

- a yarn delivery device known from EP 0 659 918 A1 can be remotely controlled by means of a compressed air cylinder-piston unit in the gap position adjust.

- a new thread is threaded by pneumatic blowing through the Thread under the lifted thread brake element. Because the piston is acted upon by a return spring is, manual threading or Replacing the thread brake element or thread brake body the risk that the holder automatically moved back in the direction of the braking position. It’s also an expensive and time consuming solution that is unsuitable for a threading device to be threaded manually is.

- the invention is based on the object Thread delivery device of the type mentioned at the outset simple way to improve so that the Bring the holder into the split position conveniently and quickly allows and without time pressure a manual threading and / or the replacement of the thread brake body or Thread braking element is or are possible.

- the quick adjustment mechanism is structurally easy to train and accommodate in a space-saving manner, with its handle can be positioned in an optimal position to achieve a to guarantee the most comfortable handling possible, if several thread delivery devices on one textile machine be grouped closely together with accessories should.

- the extremely convenient is particularly useful Embodiment according to claim 2.

- the gap position can be easily manufactured with one hand and eliminate it again. This is expediently Handle positioned and arranged so that it is in the Braking position does not interfere and possibly largely is hidden while in the split position stands out clearly and gives an indication that that the gap position before further use of the Thread delivery device must be eliminated again.

- the mechanism or the handle with or at the free end of the boom in the course of the boom or even accessible on the housing of the thread delivery device his.

- the quick adjustment mechanism is even conceivable either from one place or another of the delivery device to be operable, i.e. more as a handle to provide regardless of the Grouping of several thread delivery devices and the working conditions optimal on the textile machine To ensure ease of use.

- the quick adjustment mechanism is structurally simple in the mostly given constructions of the thread delivery devices integrate.

- the structurally simple quick adjustment mechanism uses only one pulling element to counter the holder the force of the return spring in the gap position adjust.

- the return spring takes over in the opposite direction the adjustment task.

- the gear carrier converts the rotary movement of the actuator into the linear movement of the holder.

- the mechanism is either self-locking or equipped with a lock to the gap position easy and safe to keep for so long, as needed for threading or replacement becomes.

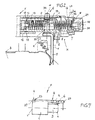

- 1, 2 and 7 are two embodiments of thread delivery devices F, each with an adjustable Holding device H for a thread brake body 4, with mutually corresponding functions, different in appearance and size Provide components with the same reference numerals are.

- Thread brake body 4 shown an annular Thread brake B works in the usual way with the Storage body 3 together.

- the thread brake body 4 is on a holder 5 in a manner not shown in detail arranged, the fork or ring-shaped can and is supported in a support body 6.

- the keeper 5 is either firmly attached to the support body 6 (Fig. 7) or (Fig. 1, 2) on the support body 6 additionally by one to the storage body 3 in an approximately radial axis 11 swiveling (cardan bracket).

- At least one lateral Guide nose 9 may be provided, which in a longitudinal Guide 10 of the boom 2 engages.

- the support body 6 has a transverse wall on the inside on, which forms an axial stop 12.

- the cross wall is Provided with a hole that from a threaded section a set screw 13 is penetrated.

- a non-rotatable and slidably arranged adjusting nut 16 is screwed onto the set screw 13.

- Between the adjusting nut 16 and the axial stop 12 can be provided with an O-ring 18 his.

- On the other side of the axial stop 12 a prestressed coil spring 19 is supported, which penetrates the support body 6 and in the embodiment 1 with its other end at one sleeve-shaped actuator 21, which is the adjusting screw 13 rotatably.

- the actuator 21 is in one Rotary socket 20 of the boom end part 2a can be rotated and protrudes outwards with a widened head part 22.

- a handle 23 is provided with which the adjusting sleeve 21 can be rotated.

- a head 14 of the Set screw 13 is held in a rotary knob 27, which carries a knurling and on the head part 22 under Interposition of a rotary latch 28 supported is.

- the actuator 21 is part of a quick adjustment mechanism Q to move the thread brake body between the respective braking position and a gap position, each in one stroke and with one-hand operation.

- the actuator 21 is on the outer circumference with at least one slant, e.g. thread-like Provided guide groove 25 into which a formed as a pin Coupling element 24 engages that in the boom end part 2a is firmly attached.

- the guide groove 25 has expediently blocking sections running in the direction of rotation 25a, into which the coupling element 24 each then occurs when an axial adjustment of the Adjusting sleeve 21 excluded under an axial pressure should be.

- the adjusting screw 13 is in the adjusting sleeve 21 rotatably mounted and carries a retaining element R, z. B. a circlip through which the reaction force of the thread brake body 4 on the adjusting sleeve 21 and this on the coupling element 24 and the boom 2, 2a is transmitted.

- the boom end part 2a contains (Fig. 1) one widened wall 30 and one to the axis of the storage body coaxial thread eyelet 29.

- the end part 2a is at 31 attached to the boom 2.

- Fig. 1 there is the thread brake body 4 in the braking position, in which it is axially predetermined Axial force is pressed against the storage body 3.

- This position is either due to the axial stop 12 intercepted adjusting nut 16 defined, or through the balance of forces between the resilient Reaction force of the thread brake body 4 and the force of the spring 19. Is the axial stop 12 in the 1 on the adjusting nut 16, then can be turned by turning the screw 13 the knob 27 of the support body 6 in its leadership adjust to the pressure of the thread brake body to change.

- the rotary handle 23 is operated and rotates the actuator 21 with one hand so that thanks to the engagement of the coupling element 24 Actuator 21 in Fig. 1 is pulled to the right and over the knob 27 pulls the adjusting screw 13, which in turn via the adjusting nut 16 supporting body 6 and pulls the thread brake body 4 into the gap position. It is expedient to turn the actuator 21 so far expediently over about half a turn, until the coupling element 24 in the left side Blocking section 25a has occurred. To reset of the thread brake body 4 is in the braking position the rotary handle 23 again with one hand in the other Actuated direction, and the actuator 21 again in the in Fig. 1 shown position. The set one Contact pressure of the thread brake body 4 is not changed.

- the embodiment of the thread delivery device F 2 has a holding device H, the Support body 6 also by means of a quick adjustment mechanism Q between a braking position and a The gap position is adjustable.

- the set screw 13 In the end part 2a of the boom 2 is the set screw 13 by means of the retaining element R (e.g. a Segerring) axially immovable, however rotatably fixed.

- the rotary knob 27 works with a right-hand end face of the end part 2a together, in the locking recesses for the rotary locking 28 are molded are.

- the spring 19 is supported with its right-hand side End directly on a counter surface 32 of the end part 2a from.

- the holder 5 is with a pivot pin 33 in Support body 6 pivotable about the axis 11.

- a safety device C can be provided be with which the support body 6 in the gap position is intercepted against the force of the spring 19.

- the safety gear C is a manually operated engagement or Release element 34 recognizable, the one against Spring loading indentable or under spring loading Operate disengageable catch element, not shown lets that behind a stop, not shown of the support body 6 engages.

- the safety device C is expediently formed so that it can be pressed by pressing the engagement element 34 engages as soon as the thread brake body 4th has reached the gap position.

- Mechanism Q is also activated. Sofem the quick adjustment mechanism Q - as in Fig. 1st -

- the safety device automatically holds the gap position C not necessary. Such an execution is in view preference for convenient one-hand operation to give.

- Mechanism Q is only schematic indicated actuator 7 in the end part of the boom 2 on that via a motion-transmitting connection 8 is connected to the carrier body 6.

- the actuator 7 may be similar to the actuator 21 in Fig. 1.

- the mechanism is also conceivable To train Q differently, for example as in 3 to 6 indicated.

- the set screw 13 can be moved longitudinally together with the support body 6, with the quick adjustment mechanism Q, which is formed by means of the hand lever 23 Handle can be operated.

- the set screw 13 can either in the support body 6 or in the mechanism Screw Q together.

- Between the support body 6 and a stop 32 is the return spring 19 arranged that the support body 6 in the braking position presses, and when you press the Quick adjustment mechanism Q is deformed.

- a Set nut 16 which is relative to the support body 6 is non-rotatable, but axially displaceable, determines the respective position of the support body 6, sofem not the balance between the pressing force of the thread brake element not shown in Fig.

- the Quick adjustment mechanism Q one to one across Rotatable axis lying in the longitudinal direction of the boom Gear carrier 36, e.g. a gear that is in a boom-fixed pivot bearing 37 by means of the handle 23 is rotatable and into counter teeth 35, e.g. of actuator 21 of FIG. 1, or (not shown) in a counter toothing of the set screw engages.

- Pawl 38 engages behind a nose 40 in the split position the storage 37 to the support body, not shown in to block the gap position.

- the gap position will in Fig. 6 by lifting the handle 23 and twisting the toothing carrier 36 counterclockwise set.

- Fig. 7 it is indicated that in the yarn delivery device the quick adjustment mechanism Q does not is arranged at the free end of the boom 2 (as 1 to 6), but at the free end of the Boom 2 facing away from the support body 6 or even on the housing 1 of the thread delivery device, expediently accessible from the front side 1 'of the housing 1.

- the handle will be in the optimal Position arranged.

- the knob 27 of the adjusting screw can either be at the free end of the boom or accessible on the housing 1 from the housing side 1 ′ be provided.

- Mechanism Q might as well optionally from more than one position on the delivery device F can be actuated.

- the different embodiments of the Quick adjustment mechanism Q are mainly for thread delivery devices provided where the thread only threaded manually or manually using a threading needle is, and / or in which an exchange of the thread brake body or the thread brake element required can be.

- this is for those Thread braking elements useful, which under the Influence of the threading needle could suffer because of the direct contact and the application of force to the Threading needle can be damaged.

- these are thread brakes of modern design with in Circumferential direction of uninterrupted thread braking element or one made of metal or plastic fins existing thread brake element.

- the through the quick adjustment mechanism adjustable, relative large stroke between the braking position and the gap position useful for thread brakes that need to be replaced relatively much free space compared to the storage body 3 need.

- the thread brake body 4 mostly gimbal supported, so the thread brake element perfectly relative to Can center the storage body. 1 is one such gimbal support through the axis 11 and which is only shown as a short black line in the axis, vertical support axis between the Holder 5 and the thread brake element 4 indicated.

- the mobility of the holder about the axis 11 is expediently in a constructive way on only a few Degrees limited.

- the mobility of the thread brake element around the perpendicular to axis 11 Axis can also be limited by a pawl K. be a move by a few Angle degree allows or with a bristle ring this couples practically immovably to the holder 5.

- a pawl K be a move by a few Angle degree allows or with a bristle ring this couples practically immovably to the holder 5.

- the handle K also has the advantage of manual threading, a to prevent unwanted tipping of the thread brake element, through which the thread brake element in the Lay the threading path of the threading needle or thread could.

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Transmission Devices (AREA)

- Spinning Or Twisting Of Yarns (AREA)

- Tension Adjustment In Filamentary Materials (AREA)

- Looms (AREA)

Abstract

Description

- Fig. 1

- einen Länggschnitt des Fadenliefergeräts mit einem Einhand-Schnellverstell-Mechanismus,

- Fig. 2

- einen Teil eines Längsschnitts einer alternativen Ausführungsform eines Fadenliefergeräts,

- Fig. 3-6

- verschiedene Ausführungsformen von Einhand-Schnellverstell-Mechanismen, und

- Fig. 7

- eine schematische Seitenansicht eines Fadenliefergerätes, bei dem mehrere Möglichkeiten zur Unterbringung eines Schnellverstell-Mechanismus als Alternativen oder Kombinationen angedeutet sind.

Claims (11)

- Fadenliefergerät (F) mit einem Gehäuse (1), einem Gehäuseausleger (2) und einem im Gehäuseausleger angeordneten Halter (5) eines ringförmigen Fadenbremskörpers (4), der wenigstens ein axial an einen Speicherkörper (3) des Fadenliefergeräts (F) andrückbares Fadenbremselement aufweist, wobei der Halter längs des Gehäuseauslegers verschiebbar geführt und ohne Änderung der Andrückkraft-Einstellung zwischen wenigstens einer Bremsstellung mit einstellbarer Andrückkraft des Fadenbremselements und wenigstens einer Spaltstellung bewegbar ist, in der das Fadenbremselement vom Speicherkörper abgehoben ist, dadurch gekennzeichnet, daß am oder im Ausleger (2) ein Schnellverstell - Mechanismus (Q) für den Halter (5) vorgesehen ist, wobei der Schnellverstell-Mechanismus eine Handhabe (23) aufweist, durch deren Handbetätigung der Halter (5) in einem Hub über eine zweichen der Handhabe (23) und dem Halter (5) vorgesehen Bewegungs- and/oder Kraftüber- oder Untersetzung zumindest am der Bremsstellung manuell in die Spaltstellung bewegt wird.

- Fadenliefergerät nach Anspruch 1, gekennzeichnet durch einen Einhand-Schnellverstell-Mechanismus (Q).

- Fadenliefergerät nach wenigstens einem der Ansprüche 1 und 2, dadurch gekennzeichnet, daß der Schnellverstell-Mechanismus (Q), vorzugsweise zumindest die Handhabe (23), am dem Gehäuse (1) abgewandten Ende des Auslegers (2) angeordnet ist.

- Fadenliefergerät nach wenigstens einem der Ansprüche 1 und 2, dadurch gekennzeichnet, daß der Schnellverstell-Mechanismus (Q), vorzugsweise zumindest dessen Handhabe (23), an der dem Gehäuse (1) zugewandten Seite des Halters (5) am Ausleger (2) oder in etwa in Verlängerung des Auslegers (2) im Gehäuse (1), vorzugsweise an der dem Ausleger (2) abgewandten Gehäuseseite (1') zugänglich angeordnet ist.

- Fadenliefergerät nach wenigstens einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, daß der SChnellverstell-Mechanismus (Q), vorzugsweise zumindest in der der Spaltstellung entsprechenden Endlage, eine selbsttätige Halter-Blockierung (25a, 38, 40) aufweist.

- Fadenliefergerät nach wenigstens einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, daß der Schnellverstell-Mechanismus (Q) ein im Ausleger (2) um eine parallel oder quer zur Auslegerlängsrichtung liegende Achse drehbar gelagertes Stellglied (21) aufweist, an dem die Handhabe (23) angreift und das mit dem Halter (5) in Längsrichtung des Auslegers (2) bewegungsübertragend verbunden ist.

- Fadenliefergerät nach wenigstens einem der Ansprüche 1 bis 6, dadurch gekennzeichnet, daß der Schnellverstell-Mechanismus (Q) mit einer in Längsrichtung des Auslegers (2) liegenden Einstellschraube (13) für die Andrückkraft des Fadenbremselements (4) gekoppelt ist.

- Fadenliefergerät nach wenigstens einem der Ansprüche 1 bis 7, dadurch gekennzeichnet, daß das Stellglied (21) ein im Ausleger (2) drehbare, axial verschiebbar gelagerte Hülse ist, in der die Verstellschraube (13) drehbar, jedoch axial gefangen, gehalten ist, daß an der Hülse als Handhabe (23) ein Drehgriff befestigt ist, und daß entweder die Hülse im Außenumfang eine zur Drehrichtung schräge Führungsbahn (25) für wenigstens ein im Ausleger (2) angebrachtes Eingriffselement (24) oder der Ausleger (2) eine schräge Führungsbahn (25) für die als Drehgriff ausgebildete Handhabe (23) aufweist.

- Fadenliefergerät nach wenigstens einem der Ansprüche 1 bis 8, dadurch gekennzeichnet, daß zwischen dem Halter (5) und einem auslegerfesten Widerlager (32) eine Rückstellfeder (19) angeordnet ist, und daß der Halter (5) in einer Bewegungsrichtung mittels des Schnellverstell-Mechanismus (Q) gegen die Kraft der Rückstellfeder (9) und in der entgegengesetzten Richtung unter der Kraft der Rückstellfeder (19) bewegbar ist.

- Fadenliefergerät nach den Ansprüchen 1 und 9, dadurch gekennzeichnet, daß der Schnellverstell-Mechanismus (Q) ein mittels eines Spannelements (15) manuell spannbares Zugelement (27), vorzugsweise einen Seil- oder Kettenzug, aufweist, das am Halter (5) oder an einem mit dem Halter (5) verbundenen Teil angekuppelt ist.

- Fadenliefergerät nach wenigstens einem der Ansprüche 1 bis 9, dadurch gekennzeichnet, daß der Schnellverstell-Mechanismus (Q) einen um eine quer zur Auslegerlängsrichtung liegende Achse im Ausleger (2) drehbaren Verzahnungsträger (36) aufweist, der in eine Gegenverzahnung (35) des mit dem Halter (5) verbundenen Teils, vorzugsweise des Stellglieds (21) oder der Stellschraube (13), eingreift.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE29623532U DE29623532U1 (de) | 1995-07-24 | 1996-07-10 | Fadenliefergerät |

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19526948 | 1995-07-24 | ||

| DE19526948 | 1995-07-24 | ||

| DE19533310 | 1995-09-08 | ||

| DE19533310A DE19533310A1 (de) | 1995-07-24 | 1995-09-08 | Fadenliefergerät |

| PCT/EP1996/003021 WO1997003908A1 (de) | 1995-07-24 | 1996-07-10 | Fadenliefergerät |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0840706A1 EP0840706A1 (de) | 1998-05-13 |

| EP0840706B1 EP0840706B1 (de) | 2000-02-09 |

| EP0840706B2 true EP0840706B2 (de) | 2003-09-03 |

Family

ID=26017069

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96925707A Expired - Lifetime EP0840706B2 (de) | 1995-07-24 | 1996-07-10 | Fadenliefergerät |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US5947403A (de) |

| EP (1) | EP0840706B2 (de) |

| CN (1) | CN1076706C (de) |

| RU (1) | RU2129089C1 (de) |

| WO (1) | WO1997003908A1 (de) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19634972A1 (de) * | 1996-08-29 | 1998-03-05 | Iro Ab | Vorrichtung zum Bremsen eines Fadens und Fadenliefergerät |

| IT247942Y1 (it) * | 1999-05-11 | 2002-09-16 | Lgl Electronics Spa | Dispositivo di ritegno a sgancio del supporto portafreno diapparecchi alimentatori di trama per macchine tessili. |

| ITTO20020023U1 (it) * | 2002-02-01 | 2003-08-01 | Lgl Electronics Spa | ,,dispositivo di ritegno del supporto portafreno in dispositivi alimentatori di trama,, |

| SE0400861D0 (sv) * | 2004-04-01 | 2004-04-01 | Iropa Ag | Garnmatningsanordning |

| DE602007007101D1 (de) * | 2007-11-30 | 2010-07-22 | Memminger Iro Gmbh | Fadenzuführungsvorrichtung und Fadenbremse |

| JP2017077949A (ja) * | 2015-10-21 | 2017-04-27 | 村田機械株式会社 | 糸巻取装置 |

| CN108884610B (zh) * | 2015-12-16 | 2020-10-13 | 范德威尔(中国)纺织机械有限公司 | 具有用于纱线张力调节的电动机组件的喂纱器 |

| WO2019032007A1 (en) | 2017-08-08 | 2019-02-14 | Iro Aktiebolag | ADJUSTABLE WIRE BRAKE |

| CN108315863B (zh) * | 2018-05-07 | 2024-02-20 | 吴江市佳鼎电子有限公司 | 储纬器 |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0534263A1 (de) † | 1991-09-20 | 1993-03-31 | L.G.L. ELECTRONICS S.p.A. | Selbstregulierende Fadenbremse für eine Schussfadenliefervorrichtung |

Family Cites Families (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1133900B (it) * | 1980-10-15 | 1986-07-24 | Roy Electrotex Spa | Mezzi per effettuare la frenatura del filato in uscita in dispositivi alimentatori di filato a tensione costante e regolabile,particolarmente per macchine tessili |

| SU1516535A1 (ru) * | 1987-11-23 | 1989-10-23 | Костромской технологический институт | Накопитель уточной нити к бесчелночному ткацкому станку |

| EP0330951B1 (de) * | 1988-03-02 | 1992-01-29 | L.G.L. ELECTRONICS S.p.A. | Fadenliefervorrichtung, insbesondere für Webmaschinen |

| IT1236993B (it) * | 1989-12-29 | 1993-05-12 | Roy Electrotex Spa | Alimentatore di trama per telai di tessitura a pinze e a proiettili |

| DE4007131C2 (de) * | 1990-03-07 | 1999-12-30 | Iro Patent Ag Baar | Liefervorrichtung für laufende Fäden |

| SE9101941D0 (sv) * | 1991-06-18 | 1991-06-18 | Iro Ab Vistaholm | Traadlagrings- och matningsanordning |

| IT1259551B (it) * | 1992-04-22 | 1996-03-20 | Lgl Electronics Spa | Dispositivo elettropneumatico per l'infilaggio automatico di apparecchi alimentatori di trama a macchine tessili ed apparecchio alimentatore di trama incorporante detto dispositivo |

| SE9400248D0 (sv) * | 1994-01-26 | 1994-01-26 | Iro Ab | Styrbar utgångsbroms för garnmatningsanordning till textilmaskiner, i synnerhet vävmaskiner av projektil eller gripar-typ |

| IT1268111B1 (it) * | 1994-10-10 | 1997-02-20 | Lgl Electronics Spa | Dispositivo di frenatura modulata positiva del filato, per apparecchi alimentatori di trama |

-

1996

- 1996-07-10 WO PCT/EP1996/003021 patent/WO1997003908A1/de not_active Ceased

- 1996-07-10 EP EP96925707A patent/EP0840706B2/de not_active Expired - Lifetime

- 1996-07-10 US US09/011,122 patent/US5947403A/en not_active Expired - Fee Related

- 1996-07-10 RU RU98103245A patent/RU2129089C1/ru not_active IP Right Cessation

- 1996-07-10 CN CN96195853A patent/CN1076706C/zh not_active Expired - Lifetime

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0534263A1 (de) † | 1991-09-20 | 1993-03-31 | L.G.L. ELECTRONICS S.p.A. | Selbstregulierende Fadenbremse für eine Schussfadenliefervorrichtung |

Also Published As

| Publication number | Publication date |

|---|---|

| US5947403A (en) | 1999-09-07 |

| WO1997003908A1 (de) | 1997-02-06 |

| CN1192187A (zh) | 1998-09-02 |

| EP0840706A1 (de) | 1998-05-13 |

| RU2129089C1 (ru) | 1999-04-20 |

| CN1076706C (zh) | 2001-12-26 |

| EP0840706B1 (de) | 2000-02-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69600675T2 (de) | Werkzeugkopf | |

| EP0840706B2 (de) | Fadenliefergerät | |

| DE1245250B (de) | Vorrichtung zum wahlweisen Einspannen von Werkzeugen mit steilem oder flachem Aussenkonus in einer Spindel | |

| DE3323150C2 (de) | ||

| DE1966347C3 (de) | Werkstückstützlager einer Werkzeugmaschine. Ausscheidung aus: 1964489 | |

| DE2225555A1 (de) | Spulenhalter | |

| DE19533310A1 (de) | Fadenliefergerät | |

| DE3319623C2 (de) | Bandsäge zum Teilen von Tierkörpern | |

| DE2008080C3 (de) | Verbindung der Doppelexzenter bei Oszillations-Vorrichtungen für Stranggießkokillen in Metall-, insbesondere in Stahl-Stranggießanlagen | |

| DE4000469C2 (de) | Hülsenspannvorrichtung zum Aufwickeln von schmalen Bahnen oder Streifen aus Papier, Folie oder dgl., insbesondere Bändchen aus Dünnstfolie | |

| DE4421209C1 (de) | Verfahren und Vorrichtung zum Dämpfen der Schlingerbewegung von Fahrzeuganhängern | |

| DE726846C (de) | Vorrichtung zum Spannen von Werkstuecken durch Pressluft oder Druckfluessigkeit | |

| DE4229221C2 (de) | Zange mit verstellbarer Maulweite | |

| EP1414727A2 (de) | Wendevorrichtung | |

| DE4428634C2 (de) | Spritzpistole mit einem Griffstück und einem betätigbaren Ventilstößel | |

| DE29623532U1 (de) | Fadenliefergerät | |

| DE19754275C2 (de) | Handschraubgerät | |

| DE2120462C3 (de) | Gewindeschneidapparat für eine Supportdrehmaschine | |

| DE2163161C3 (de) | Fadenverbinder für eine längs der Spindelreihen einer Spinnmaschine od.dgl. verfahrbare Wartungsvorrichtung | |

| DE2140820A1 (de) | Faserbandaufloesevorrichtung fuer offen-end-spinnvorrichtungen | |

| DE918546C (de) | Vorrichtung zum Einfaedeln von Faeden | |

| DE19614626A1 (de) | Feststellvorrichtung für Lenkrollen | |

| DE1286847B (de) | Selbsttaetige mechanische Nachstellvorrichtung | |

| DE29946C (de) | Nähmaschinen-Schiffchen | |

| DE1181116B (de) | Pneumatisch betaetigtes Geraet zum Anbringen von C-foermigen Klammern um das zusammen-gedrehte oder -geraffte Ende von Beuteln oder Saecken |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19980119 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE CH DE FR IT LI NL SE |

|

| 17Q | First examination report despatched |

Effective date: 19980813 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE CH DE FR IT LI NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20000209 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: BOVARD AG PATENTANWAELTE |

|

| REF | Corresponds to: |

Ref document number: 59604430 Country of ref document: DE Date of ref document: 20000316 |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| PLBQ | Unpublished change to opponent data |

Free format text: ORIGINAL CODE: EPIDOS OPPO |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| 26 | Opposition filed |

Opponent name: L.G.L. ELECTRONICS S.P.A. Effective date: 20001102 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: L.G.L. ELECTRONICS S.P.A. |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20010719 Year of fee payment: 6 |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20030716 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20030718 Year of fee payment: 8 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20030903 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): BE CH DE FR IT LI NL SE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN Free format text: AUFRECHTERHALTUNG DES PATENTES IN GEAENDERTER FORM |

|

| NLR2 | Nl: decision of opposition |

Effective date: 20030903 |

|

| NLR3 | Nl: receipt of modified translations in the netherlands language after an opposition procedure | ||

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: RPEO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20040711 |

|

| EN | Fr: translation not filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20050201 |

|

| EUG | Se: european patent has lapsed | ||

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20050201 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20100726 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Owner name: IRO AB Free format text: IRO AB#VISTAHOLM P.O. BOX 54#523 01 ULRICEHAMN (SE) -TRANSFER TO- IRO AB#VISTAHOLM P.O. BOX 54#523 01 ULRICEHAMN (SE) |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20110926 Year of fee payment: 16 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110731 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20110731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20130201 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 59604430 Country of ref document: DE Effective date: 20130201 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20150723 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20150728 Year of fee payment: 20 |