EP0799092B2 - Schwertrübesortierer - Google Patents

Schwertrübesortierer Download PDFInfo

- Publication number

- EP0799092B2 EP0799092B2 EP96932513A EP96932513A EP0799092B2 EP 0799092 B2 EP0799092 B2 EP 0799092B2 EP 96932513 A EP96932513 A EP 96932513A EP 96932513 A EP96932513 A EP 96932513A EP 0799092 B2 EP0799092 B2 EP 0799092B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- nozzle

- dense

- diffuser

- baseplate

- nozzles

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 12

- 239000013013 elastic material Substances 0.000 claims description 6

- 238000004519 manufacturing process Methods 0.000 abstract description 5

- 239000010802 sludge Substances 0.000 description 22

- 229910000831 Steel Inorganic materials 0.000 description 5

- 239000002002 slurry Substances 0.000 description 5

- 239000010959 steel Substances 0.000 description 5

- 239000000463 material Substances 0.000 description 4

- 238000011144 upstream manufacturing Methods 0.000 description 4

- 239000007788 liquid Substances 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 1

- 230000001070 adhesive effect Effects 0.000 description 1

- 210000000078 claw Anatomy 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 230000001419 dependent effect Effects 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 230000006641 stabilisation Effects 0.000 description 1

- 238000011105 stabilization Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B03—SEPARATION OF SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS; MAGNETIC OR ELECTROSTATIC SEPARATION OF SOLID MATERIALS FROM SOLID MATERIALS OR FLUIDS; SEPARATION BY HIGH-VOLTAGE ELECTRIC FIELDS

- B03B—SEPARATING SOLID MATERIALS USING LIQUIDS OR USING PNEUMATIC TABLES OR JIGS

- B03B5/00—Washing granular, powdered or lumpy materials; Wet separating

- B03B5/62—Washing granular, powdered or lumpy materials; Wet separating by hydraulic classifiers, e.g. of launder, tank, spiral or helical chute concentrator type

- B03B5/623—Upward current classifiers

Definitions

- the present invention relates to a heavy sludge sorter according to the generic term of Claim 1.

- Such a sludge sorter except that the diffuser base plate has a plurality of Bores with individual nozzles arranged in them having a nozzle channel and the nozzles each provided with the appropriate check valve are known from DE 36 39 044 C1.

- a conventional heavy pulp sorter becomes a homogeneous one Upflow through a rubber plate provided with nozzles generated, which is used for mechanical stabilization located between two steel sheets, both Steel sheet corresponding recess holes exhibit.

- the use of such a rubber sheet has the disadvantage that this is due to mechanical Tolerances of these Holding devices, e.g. the steel sheets, deformed or is not held stable. This puts the pressure on the entrance side of the rubber plate is no longer even distributed and the uniformity of the upstream disturbed.

- Such a rubber sheet is also very susceptible against mechanical stress and in the event of a mechanical defect must cover the entire rubber sheet to be replaced. Furthermore, the manufacturing such rubber sheets expensive because the mechanical Bracket, i.e. both steel sheets between which themselves the rubber plate is located, with recess holes must be provided.

- One with a diffuser base plate with single nozzles provided heavy sludge sorter has the advantages that the individual nozzles are independent of the manufacturing tolerances always with the diffuser base plate even pressure are applied so that a constant upflow is always guaranteed.

- By making a diffuser base plate with Individual nozzles simplify the manufacture of the diffuser base plate, since only one plate is used and only this must be drilled.

- There a diffuser base plate, for example 1500 holes has a significant reduction of the manufacturing effort.

- By training the check valve prevents the ingress of sinking material into the pressurized water chamber if the upstream water supply fails prevented.

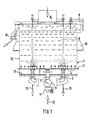

- the heavy sludge sorter has a slurry tank 1 with a bottom 31 and an adjoining cylindrical side wall 32 on.

- the sludge container 1 On the bottom side, the sludge container 1 a diffuser base plate 2, which is in a predetermined Distance from the bottom 31 of the sludge container and extends parallel to it and from the side wall is enclosed.

- the diffuser base plate 2 has a variety of recess holes in which interchangeable individual nozzles 4 are arranged.

- the pressurized water chamber 3 is delimited by the base plate 31, which this opposite diffuser base plate 2 and the cylindrical side wall 32. It is characterized by the Base plate 31 extending into the pressure chamber 3 opening upstream water supply line 6 is provided.

- the heavy sludge sorter has a Discharge device 5 for draining the sinking material.

- This outlet device is through an outlet line formed by the bottom of the slurry container 1 via the pressurized water chamber 3 into the interior of the sludge tank 1 extends and the inside of the sludge tank 1 a valve controllable via a valve rod 8 having.

- the valve rod 8 extends through the sludge container 1 up to its top side 9.

- the slurry container also has a ceiling a material feed device 14 and one Light goods drain 10. Furthermore are on the side walls Displacement claws 15 for holding the slurry container arranged.

- the individual nozzles 4 of the diffuser base plate 2 is in a bore 30 the diffuser base plate 2 arranged.

- the nozzle body 18 here has a first cylindrical Section 33 and a subsequent second Section 34 on.

- the first section is cylindrical. Its outside diameter is dependent selected from the inside diameter of the bore so that the first section with a snug fit in the diffuser baseplate 2 sits.

- the adjacent second section is closed its end facing away from the first section divergent as a truncated cone.

- the nozzle body 18 engages with its first section 33 in the diffuser base plate 2 and shows on one protruding portion of the diffuser base plate Thread on.

- the nozzle is over a nut 20 and one between the diffuser base plate 2 and the nut 20 arranged sealing disc 21 in the diffuser base plate locked.

- Reference numeral 19 denotes one Sealing or adhesive surface.

- nozzle channel 17 which on the the side facing the inside of the sludge container, i.e. a narrowing on the outlet side, i.e. one Has nozzle neck.

- the second section has a cap 16 overdrawn.

- This cap 16 is made of elastic material formed and sitting under tension on the second Section and has the function of the check valve.

- the cap 16 is centered in the Cap 16 and over the outlet opening of the nozzle channel 17 arranged a crossed slot 22 which many times larger than the diameter of the outlet opening of the nozzle channel 17. That slit acts as a check valve and blocks the passage of liquid through the nozzle 4 from the sludge tank 1 in the Pressurized water chamber 3.

- liquid passes from the pressurized water chamber 3 into the turbidity tank 1 opens the check valve.

- Fig. 4 shows a further embodiment of the Nozzle base body 18.

- the Nozzle base body made of plastic, but can just like in the above design made of steel or other materials.

- the one in the diffuser floor 2 engaging first section 25 is as Spreading body formed.

- the first section 25 is biased and by the expansion effect in the bore locked.

- a second section 35 is provided to which analogous to the previous embodiment a cap forming the check valve is attached is.

- FIG Nozzle differs from the previously shown embodiments in that the check valve is not formed in the form of a cap to be put on. Instead, the second section 37 faces on the outlet side Side one coaxial with the nozzle channel arranged recess into which a plate 38 elastic material is glued, which is coaxial to the Center axis of the nozzle channel a cross-shaped Has slot 40, which is best seen in FIG. 6 is.

- the nozzle body differs 27 of the previous ones in that the first section on its side facing away from the second section End 29 is slotted like a dowel, so that it is elastically compressible. Further points the outside of the first section an undercut 39 on whose outer diameter in substantially equal to the inside diameter of the Nozzle body receiving bore in the nozzle bottom 2, and its expansion in the axial direction of the nozzle channel is equal to the thickness of the diffuser base plate 2 is. Numeral 28 denotes a by the undercut 39 formed pawl.

- the second section of the nozzle body is cylindrical educated. On this second section is like in the previously described embodiments Plastic cap attached to her on the Cap opening the elastic opening Cross-slotted section.

- the nozzles via line 6 with pressurized Water is applied so that the water passes through passes through the check valves described above. However, if the water supply is blocked, they go Elastic sections divided into a cross slot shape their starting position back and thus form a check valve.

Landscapes

- Nozzles (AREA)

- Separation Of Solids By Using Liquids Or Pneumatic Power (AREA)

- Fluid-Pressure Circuits (AREA)

- Fertilizers (AREA)

- Sorting Of Articles (AREA)

Description

- Fig. 1

- einen Schwertrübesortierer gemäß einer Ausführungsform der vorliegenden Erfindung,

- Fig. 2

- eine Ausgestaltung der auswechselbaren Einzeldüse für den Schwertrübesortierer nach Fig. 1,

- Fig. 3

- eine Ausgestaltung der Rückschlagvorrichtung der Einzeldüse nach Fig. 2,

- Fig. 4

- eine weitere Ausgestaltung des Düsengrundkörpers der auswechselbaren Einzeldüse für den Schwertrübesortierer nach Fig. 1,

- Fig. 5

- noch eine weitere Ausgestaltung der auswechselbaren Einzeldüse für den Schwertrübesortierer nach Fig. 1,

- Fig. 6

- eine Ausgestaltung der Rückschlagvorrichtung der Einzeldüse nach Fig. 5,

- Fig. 7

- eine weitere Ausgestaltung der Einzeldüse für den Schwertrübesortierer nach Fig. 1.

Claims (8)

- Schwertrübesortierer mit

einem Behälter (1), der einen Boden (31) und daran seitlich angrenzende Seitenwände (32) und eine in einem Abstand von dem Boden (31) angeordnete Diffusorgrundplatte (2) mit einer Mehrzahl von Düsen (4) aufweist,

einer Zufuhrleitung (6), die die dem Boden (31) zugewandte Seite der Diffusorgrundplatte (2) mit Wasser unter Druck beaufschlagt, und einer Auslaßleitung (5),

wobei die Diffusorgrundplatte (2) eine Mehrzahl von Bohrungen (30) mit darin angeordneten einzelnen Düsen mit einem Düsenkanal (17) aufweist und die Düsen (4) jeweils mit einem in Richtung der Zufuhrleitung (6) sperrenden Rückschlagventil (16, 22; 38, 40) vorgesehen sind, das aus einem geschlitzten elastischen Material besteht,

das elastische Material mittig über der Ausgangsseite des Düsenkanals (17) einen gekreuzten Schlitz (22, 40) aufweist, die Düsen (4) das Rückschlagventil (16, 22; 38, 40) jeweils als Bestandteil aufweisen und der gekreuzte Schlitz (22) um ein Vielfaches größer ist als der Durchmesser der Austriffsöffnung des Düsenkanals (17). - Schwertrübesortierer nach Anspruch 1, dadurch gekennzeichnet, daß das Rückschlagventil (16, 22; 38, 40) durch eine ausgangsseitig auf der Öffnung des Düsenkanals (17) angebrachte und den gekreuzten Schlitz aufweisende Folie ausgebildet ist.

- Schwertrübesortierer nach Anspruch 1 oder 2,

dadurch gekennzeichnet, daß jede der Düsen (4) einen Düsengrundkörper (18) aufweist, auf den als Rückschlagventil eine Kappe (16) aus dem elastischen Material aufgesetzt ist, die den gekreuzten Schlitz (22) aufweist. - Schwertrübesortierer nach Anspruch 1 oder 2,

dadurch gekennzeichnet, daß jede der Düsen (4) einen Düsengrundkörper (18, 27) aufweist, an dem über der Ausgangsseite des Düsenkanals (17) eine Platte (38) aus dem elastischen Material befestigt ist, die den gekreuzten Schlitz (40) aufweist. - Schwertrübesortierer nach einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, daß jede der Düsen auswechselbar in der Diffusorgrundplatte (2) befestigt ist.

- Schwertrübesortierer nach einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, daß die Düse (4) den Düsenkanal (17) im wesentlichen koaxial zu der Bohrung (30) verlaufend, einen ersten Abschnitt (25, 33, 39) zum Ineingriffbringen mit der Diffusorgrundplatte (2) und einen daran angrenzenden zweiten Abschnitt (34, 35, 27) zum Aufnehmen des Rückschlagventils aufweist.

- Schwertrübesortierer nach Anspruch 6, dadurch gekennzeichnet, daß der erste Abschnitt (25, 33, 39) auf seiner dem zweiten Abschnitt abgewandten Seite so ausgebildet ist, daß eine Arretierung in der Diffusorgrundplatte (2) erfolgt.

- Schwertrübesortierer nach Anspruch 6 oder 7,

dadurch gekennzeichnet, daß auf dem zweiten Abschnitt (34, 35, 27) auf der dem ersten Abschnitt abgewandten Seite eine an der Stelle der Austrittsöffnung des Düsenkanals (17) den gekreuzten Schlitz aufweisende Kappe (16) aufgesetzt ist.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19536303A DE19536303A1 (de) | 1995-09-29 | 1995-09-29 | Schwertrübesortierer |

| DE19536303 | 1995-09-29 | ||

| PCT/EP1996/004011 WO1997012682A1 (de) | 1995-09-29 | 1996-09-12 | Schwertrübesortierer |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0799092A1 EP0799092A1 (de) | 1997-10-08 |

| EP0799092B1 EP0799092B1 (de) | 1999-08-25 |

| EP0799092B2 true EP0799092B2 (de) | 2004-06-16 |

Family

ID=7773566

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP96932513A Expired - Lifetime EP0799092B2 (de) | 1995-09-29 | 1996-09-12 | Schwertrübesortierer |

Country Status (5)

| Country | Link |

|---|---|

| EP (1) | EP0799092B2 (de) |

| AT (1) | ATE183671T1 (de) |

| DE (2) | DE19536303A1 (de) |

| DK (1) | DK0799092T4 (de) |

| WO (1) | WO1997012682A1 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4182094A4 (de) * | 2020-07-16 | 2025-05-07 | Kale, Tebogo | Klassifikator und verfahren zum klassifizieren |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9833790B2 (en) * | 2015-07-09 | 2017-12-05 | Jesse W. Rhodes, JR. | Assembly and method for gravitationally separating gold from small particles |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3013668C2 (de) † | 1980-04-09 | 1982-11-18 | Schauenburg Maschinen- und Anlagen-Bau GmbH, 4330 Mülheim | Vorrichtung für die Naßaufbereitung und Entwässerung von Sand |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2105126A (en) * | 1936-04-01 | 1938-01-11 | New Jersey Zinc Co | Classification |

| US3485365A (en) * | 1968-01-11 | 1969-12-23 | Dorr Oliver Inc | Hydraulic upflow classification apparatus |

| GB1298027A (en) * | 1970-06-11 | 1972-11-29 | Wilkinson Rubber Linatex Ltd | Improvements in or relating to classifiers |

| FR2418676A1 (fr) * | 1978-03-03 | 1979-09-28 | Irrifrance | Arroseur statique pour systemes d'arrosage |

| US4539103A (en) * | 1982-04-15 | 1985-09-03 | C-H Development And Sales, Inc. | Hydraulic separating method and apparatus |

| US4807761A (en) * | 1983-09-22 | 1989-02-28 | C-H Development & Sales, Inc. | Hydraulic separating method and apparatus |

| DE4118020A1 (de) * | 1991-06-01 | 1992-12-03 | Schauenburg Masch | Verfahren zum abscheiden spezifisch leichter bestandteile aus einer truebe durch aufstromsortierung und messvorrichtung dazu |

-

1995

- 1995-09-29 DE DE19536303A patent/DE19536303A1/de not_active Ceased

-

1996

- 1996-09-12 WO PCT/EP1996/004011 patent/WO1997012682A1/de not_active Ceased

- 1996-09-12 EP EP96932513A patent/EP0799092B2/de not_active Expired - Lifetime

- 1996-09-12 AT AT96932513T patent/ATE183671T1/de not_active IP Right Cessation

- 1996-09-12 DK DK96932513T patent/DK0799092T4/da active

- 1996-09-12 DE DE59602867T patent/DE59602867D1/de not_active Expired - Fee Related

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3013668C2 (de) † | 1980-04-09 | 1982-11-18 | Schauenburg Maschinen- und Anlagen-Bau GmbH, 4330 Mülheim | Vorrichtung für die Naßaufbereitung und Entwässerung von Sand |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4182094A4 (de) * | 2020-07-16 | 2025-05-07 | Kale, Tebogo | Klassifikator und verfahren zum klassifizieren |

Also Published As

| Publication number | Publication date |

|---|---|

| DK0799092T4 (da) | 2004-07-19 |

| EP0799092A1 (de) | 1997-10-08 |

| DE19536303A1 (de) | 1997-04-03 |

| DE59602867D1 (de) | 1999-09-30 |

| EP0799092B1 (de) | 1999-08-25 |

| ATE183671T1 (de) | 1999-09-15 |

| DK0799092T3 (da) | 1999-12-13 |

| WO1997012682A1 (de) | 1997-04-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE19528812B4 (de) | Aggregat für eine Fahrzeugbremsanlage | |

| DE2323846A1 (de) | Spritz- bzw. spruehduese | |

| WO1994012789A1 (de) | Ventil, insbesondere druckventil für eine radialkolbenpumpe, mit wenigen komponenten | |

| DE1603535A1 (de) | Spielzeug-Blasinstrument | |

| EP0724486A1 (de) | Sprühblock eines sprühwerkzeugs | |

| EP0799092B2 (de) | Schwertrübesortierer | |

| DE69916616T2 (de) | Spender für fluide medien | |

| DE4133973C2 (de) | Vorrichtung zum Versprühen eines Flüssigkeitsstrahls mit rotierender Achse auf einer konischen Fläche | |

| DE2453670A1 (de) | Einrichtung zum verteilen von gasen in fluessigkeiten | |

| DE60304293T2 (de) | Sprühfeuchtwerk | |

| EP0821087B1 (de) | Offenend-Spinnvorrichtung | |

| DE69725919T2 (de) | Harzinjektor mit Muffel | |

| DE3807626A1 (de) | Befestigungsvorrichtung | |

| DE4124599C1 (de) | ||

| DE102019102882A1 (de) | Halterung für ein Kraftfahrzeugkennzeichen | |

| EP0332157B1 (de) | Anordnung zur Verbindung einer Verteilvorrichtung mit einer Fluidzuleitung | |

| EP0291925B1 (de) | Bohrlochverschlussstopfen | |

| DE8203649U1 (de) | Düsenhalter für landwirtschaftliche Spritzgeräte, insbesondere Feldspritzen | |

| DE20019722U1 (de) | Befestigungsvorrichtung | |

| EP1270223B1 (de) | Vorrichtung zur Versorgung einer Einrichtung zur Aufnahme von hochviskosen Medien | |

| DE378501C (de) | Vorrichtung zum Duengen unter gleichzeitiger Bewaesserung | |

| DE9410772U1 (de) | Vorrichtung zur dichten Befestigung einer Unterkonstruktion an einer Wand o.dgl. | |

| DE202019100673U1 (de) | Halterung für ein Kraftfahrzeugkennzeichen | |

| CH524731A (de) | Sockel zur nachgiebigen Befestigung eines Pfostens und Verfahren zur Herstellung des Sockels | |

| DE8034885U1 (de) | Schaumerzeugungskopf |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19970414 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK FR GB LI NL |

|

| 17Q | First examination report despatched |

Effective date: 19971113 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK FR GB LI NL |

|

| REF | Corresponds to: |

Ref document number: 183671 Country of ref document: AT Date of ref document: 19990915 Kind code of ref document: T |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: NV Representative=s name: R. A. EGLI & CO. PATENTANWAELTE Ref country code: CH Ref legal event code: EP |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19990827 |

|

| REF | Corresponds to: |

Ref document number: 59602867 Country of ref document: DE Date of ref document: 19990930 |

|

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| PLAV | Examination of admissibility of opposition |

Free format text: ORIGINAL CODE: EPIDOS OPEX |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLAV | Examination of admissibility of opposition |

Free format text: ORIGINAL CODE: EPIDOS OPEX |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| 26 | Opposition filed |

Opponent name: SCHAUENBURG MASCHINEN- UND ANLAGEN-BAU GMBH Effective date: 20000518 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: SCHAUENBURG MASCHINEN- UND ANLAGEN-BAU GMBH |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| PLBF | Reply of patent proprietor to notice(s) of opposition |

Free format text: ORIGINAL CODE: EPIDOS OBSO |

|

| PLAW | Interlocutory decision in opposition |

Free format text: ORIGINAL CODE: EPIDOS IDOP |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: IF02 |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| APAC | Appeal dossier modified |

Free format text: ORIGINAL CODE: EPIDOS NOAPO |

|

| APAE | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOS REFNO |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 20040616 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH DE DK FR GB LI NL |

|

| GBTA | Gb: translation of amended ep patent filed (gb section 77(6)(b)/1977) | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: AEN Free format text: AUFRECHTERHALTUNG DES PATENTES IN GEAENDERTER FORM |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T4 |

|

| NLR2 | Nl: decision of opposition |

Effective date: 20040616 |

|

| NLR3 | Nl: receipt of modified translations in the netherlands language after an opposition procedure | ||

| ET3 | Fr: translation filed ** decision concerning opposition | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20050831 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20050919 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20050920 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20050922 Year of fee payment: 10 Ref country code: AT Payment date: 20050922 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20050923 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 20050926 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20050930 Year of fee payment: 10 |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060912 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060930 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060930 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061002 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070401 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20070403 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20060912 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20070401 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST Effective date: 20070531 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20060912 |

|

| BERE | Be: lapsed |

Owner name: *BRAUER AUFBEREITUNGSMASCHINEN G.M.B.H. & CO. FORD Effective date: 20060930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20061002 |