EP0718924A2 - Procédé de fixation d'un câble électrique atténuant l'effort de tension - Google Patents

Procédé de fixation d'un câble électrique atténuant l'effort de tension Download PDFInfo

- Publication number

- EP0718924A2 EP0718924A2 EP95117636A EP95117636A EP0718924A2 EP 0718924 A2 EP0718924 A2 EP 0718924A2 EP 95117636 A EP95117636 A EP 95117636A EP 95117636 A EP95117636 A EP 95117636A EP 0718924 A2 EP0718924 A2 EP 0718924A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- housing

- line

- conductors

- mass

- contact elements

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/70—Insulation of connections

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/58—Means for relieving strain on wire connection, e.g. cord grip, for avoiding loosening of connections between wires and terminals within a coupling device terminating a cable

- H01R13/582—Means for relieving strain on wire connection, e.g. cord grip, for avoiding loosening of connections between wires and terminals within a coupling device terminating a cable the cable being clamped between assembled parts of the housing

- H01R13/5825—Means for relieving strain on wire connection, e.g. cord grip, for avoiding loosening of connections between wires and terminals within a coupling device terminating a cable the cable being clamped between assembled parts of the housing the means comprising additional parts captured between housing parts and cable

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/58—Means for relieving strain on wire connection, e.g. cord grip, for avoiding loosening of connections between wires and terminals within a coupling device terminating a cable

- H01R13/5845—Means for relieving strain on wire connection, e.g. cord grip, for avoiding loosening of connections between wires and terminals within a coupling device terminating a cable the strain relief being achieved by molding parts around cable and connections

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R43/00—Apparatus or processes specially adapted for manufacturing, assembling, maintaining, or repairing of line connectors or current collectors or for joining electric conductors

- H01R43/20—Apparatus or processes specially adapted for manufacturing, assembling, maintaining, or repairing of line connectors or current collectors or for joining electric conductors for assembling or disassembling contact members with insulating base, case or sleeve

- H01R43/24—Assembling by moulding on contact members

Definitions

- the invention relates to a method for strain-relieved fixing of an electrical line in a housing made of insulating material, with which first electrical contact elements are electrically conductively connected to the conductors of the line and with which the contact elements thereafter together with the end of the line, in which the conductor of Insulating material are enclosed, introduced into the prefabricated, two-part housing and immovably fixed therein (DE-OS 42 21 238).

- contact elements are designed as plug contacts, such as pins or sockets

- the housings can be parts of plug connectors.

- the housing can also surround the connection point between two lines.

- Contact elements are then the conductors of further lines.

- counter contacts are plugged onto the plug contacts accommodated in the housing, which can also be arranged in a housing.

- their conductors are soldered or welded together, for example.

- the contact elements designed as plug pins are pressed against the other part of the housing by projections attached to one part of the housing in such a way that they are not axially movable.

- the line formed as a flat conductor ribbon cable is clamped in a step-like manner and clamped in a joint between the two parts of the housing.

- the invention has for its object to develop the above-described method so that it can be used for arbitrarily constructed lines.

- the end of an electrical line can be fixed in a simple manner in a housing without strain relief without the need for a dimensionally accurate adaptation of the housing and the line.

- only a certain amount of a mass is applied to the end of the line protruding into the housing, which mass sticks to the line or to its insulating material.

- the design of the housing and the line are arbitrary. It can round and flat cables with any number of conductors or cores can be used.

- the solid mass that sticks to the insulation material of the pipe adheres firmly to it. It acts as a thickening of the same.

- connection points between conductors and contact elements are thus effectively protected against tensile loads that could be transmitted via the line. This protection is improved when the mass extends beyond the connection points between conductors and contact elements. The amount of mass is measured relatively precisely. It is then ensured, for example, that plug-in connectors connected to the line are not covered, but remain free to make contact.

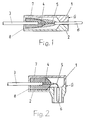

- the connector shown in Fig. 1 has a housing G consisting of two parts 1 and 2 made of plastic.

- the two parts 1 and 2 of the housing G can be connected to one another, for example, by latching elements or by Ultrasonically welded together.

- An electrical line 3 is introduced into the housing G on one side, which has, for example, two wires 4, of which only one can be seen.

- Connector pins 6 are connected in an electrically conductive manner to the conductors 5 of the wires 4. This can be done, for example, by soldering, by welding or by squeezing.

- the connector pins 6 can protrude from the housing G. In any case, they are accessible on the side opposite line 3 for plugging in mating contacts.

- the end of the line 3 is embedded within the housing G in a mass 7 which is firmly glued to the insulating material of the line 3 or the wires 4.

- the mass 7 is, for example, a hot melt adhesive. It also bears against the wall 8 of the housing G, through which the line 3 is inserted into the same. Tensile stresses which are exerted on the line 3 in the axial direction are accordingly absorbed by the mass 7. They cannot affect the connection points between the conductors 5 and the plug pins 6.

- the connector pins 6 themselves are so firmly attached in the housing G that they are also not movable in the axial direction.

- the mass 7, as indicated by dashed lines, can also extend beyond the connection points between the conductors 5 and the plug pins 6. It can also rest against the wall 8 of the horizontally extending walls of parts 1 and 2.

- FIG. 1 While a rectilinear design of the plug connector is shown in FIG. 1, an angled embodiment is shown in FIG.

- the construction of this connector is basically the same as that of the connector according to FIG. 1. The difference is that the connector pins 6 are angled by 90 ° with respect to the line 3. The line 3 is again against the mass 7 Tension loads in housing G secured. The connection points between the conductors 5 and the connector pins 6 are accordingly strain relieved. In this case, a load on the connector pins 6 in the axial direction cannot have a disruptive effect on the connection points with the conductors 5 even if the connector pins 6 are mounted in the housing G with little play in the axial direction.

- the mass 7 can, for example, be introduced into the housing G after it has been closed.

- part 1 of the housing may have an opening through which the mass 7 is poured in a metered amount. It must be ensured that the mass 7 is in any case on the one hand against the wall 8 of the housing G. On the other hand, the mass 7 must adhere to the insulating material of the line 3 or the wires 4 over a sufficiently long length. In the case of a larger quantity, the mass 7 extends beyond the connection points between the conductors 5 and the plug pins 6. The mass 7 also sticks to its base in this area.

- the material of the mass 7 in the solid state can, for example, be attached in the form of granules or strips in the housing G.

- half-shells made of hot-melt adhesive which are in contact with the line after the housing has been closed. The material adheres to the housing G in all cases. After the housing has been closed, it is briefly converted into the flowable state by external heat so that it can spread and stick to the insulating material of the line 3 or the wires 4.

- the supply of the required heat from the outside can expediently be achieved in that the parts 1 and 2 of the housing G are welded to one another by ultrasound.

- the material of mass 7 flows in the required manner and adheres to line 3 or to wires 4.

- the mass 7 can simultaneously serve to additionally connect the two parts 1 and 2 of the housing G to one another if it fills almost the entire clear cross section of the housing G at this end of the housing G.

- the method according to the invention can be used for lines and housings of any design.

- the method can also advantageously be used with ribbon cables or flat cables, as can be seen from FIGS. 3 and 4. 3 and 4, in contrast to FIGS. 1 and 2, no connector, but the connection point between two electrical lines 9 and 10 is shown.

- line 9 is a flat conductor ribbon cable and line 10 is a round conductor ribbon cable.

- the lines 9 and 10 each have seven conductors in the illustrated embodiment.

- the line 9 has flat conductors 11, while the line 10 has, for example, round stranded conductors 12.

- the number and cross-sectional shape of the lines 9 and 10 are arbitrary.

- the conductors 11 are embedded in a common insulation, while the conductors 12 are individually insulated.

- the insulated conductors 12 are combined to form the above-mentioned round conductor ribbon line as line 10. But it could also be single conductors.

- connection points 13 shown as black dots. The connection points 13 can also be produced by soldering when the conductors 11 and 12 are already inserted in the lower part 2.

- the upper part 1 of the housing G is then snapped onto the lower part 2 or welded to the same by ultrasound.

- the mass 7 can be filled according to the above statements through openings in the upper part 1 in the housing G. It can also be activated by supplying heat (ultrasound) if it was previously attached to at least part of the housing G.

- the mass 7 encloses the ends of the lines 9 and 10 and their conductors 11 and 12 including the connection points 13, as can be seen in FIG. 4.

- flat conductors can also be connected to the conductors 11 of the line 9. It is also possible, for example, to weld the respective conductors to one another if their cross sections permit this.

- the conductors 12 of the further line 10 are also fixed in the housing G, so that no tensile loads can be transmitted from there to the connection points 13 of the conductors 11 and 12 either.

- a suitable material for the mass 7 is, for example, a hot-melt adhesive which is solid at room temperature of approximately 20 ° C. and becomes flowable by the application of heat.

- a hot melt adhesive sticks both to the insulating material of the line 3 or the wires 4 and to the walls of the housing G.

Landscapes

- Connections Effected By Soldering, Adhesion, Or Permanent Deformation (AREA)

- Multi-Conductor Connections (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4446768 | 1994-12-24 | ||

| DE4446768 | 1994-12-24 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0718924A2 true EP0718924A2 (fr) | 1996-06-26 |

| EP0718924A3 EP0718924A3 (fr) | 1997-08-13 |

Family

ID=6537243

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP95117636A Withdrawn EP0718924A3 (fr) | 1994-12-24 | 1995-11-09 | Procédé de fixation d'un câble électrique atténuant l'effort de tension |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0718924A3 (fr) |

| DE (1) | DE19510341A1 (fr) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0836253A2 (fr) * | 1996-10-11 | 1998-04-15 | Alcatel | Dispositif de protection d'une ligne électrique |

| CN109478751A (zh) * | 2016-07-12 | 2019-03-15 | 株式会社自动网络技术研究所 | 电气连接组件的制造方法 |

| US11894649B2 (en) | 2020-10-30 | 2024-02-06 | Amphenol Corporation | Electrical connector and method of making the same |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE10053280A1 (de) * | 2000-10-27 | 2002-05-16 | Hirschmann Austria Gmbh Rankwe | Steckverbinder mit Flachbandleitung und Zugentlastung |

| DE102004034804A1 (de) | 2004-07-19 | 2006-03-16 | Saint-Gobain Sekurit Deutschland Gmbh & Co. Kg | Elektrische Leitungsverbindung mit Querschnittsübergang und Verbundscheibe |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4221238A1 (de) | 1991-10-07 | 1993-04-08 | Kabelmetal Electro Gmbh | Vorrichtung zur stromuebertragung zwischen zwei endstellen |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4083902A (en) * | 1977-01-10 | 1978-04-11 | Raychem Corporation | Method of sealing a connector |

| US4643924A (en) * | 1985-03-25 | 1987-02-17 | Raychem Corporation | Protective article comprising an elastic gel |

| EP0272039A2 (fr) * | 1986-12-19 | 1988-06-22 | AT&T Corp. | Appareil ayant des connexions électriques encastrées dans une masse durcissante |

| WO1990007808A1 (fr) * | 1988-12-24 | 1990-07-12 | Schunk Ultraschalltechnik Gmbh | Procede et dispositif d'enveloppement de la jonction entre deux elements electroconducteurs |

| FR2663791A1 (fr) * | 1990-06-22 | 1991-12-27 | Tecnoffra | Dispositif d'etancheite des boitiers de connexions electriques. |

| DE4116748C1 (en) * | 1991-05-23 | 1992-10-01 | Leopold Kostal Gmbh & Co Kg, 5880 Luedenscheid, De | Multi-lead electrical coupling component - has sealing material channel and trough extending from plug region to achieve watertightness |

| US5110306A (en) * | 1991-07-24 | 1992-05-05 | W. L. Gore & Associates, Inc. | Compact connector assembly and termination guide therefor |

-

1995

- 1995-03-22 DE DE19510341A patent/DE19510341A1/de not_active Withdrawn

- 1995-11-09 EP EP95117636A patent/EP0718924A3/fr not_active Withdrawn

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4221238A1 (de) | 1991-10-07 | 1993-04-08 | Kabelmetal Electro Gmbh | Vorrichtung zur stromuebertragung zwischen zwei endstellen |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0836253A2 (fr) * | 1996-10-11 | 1998-04-15 | Alcatel | Dispositif de protection d'une ligne électrique |

| EP0836253A3 (fr) * | 1996-10-11 | 1999-03-31 | Alcatel | Dispositif de protection d'une ligne électrique |

| CN109478751A (zh) * | 2016-07-12 | 2019-03-15 | 株式会社自动网络技术研究所 | 电气连接组件的制造方法 |

| CN109478751B (zh) * | 2016-07-12 | 2020-12-11 | 株式会社自动网络技术研究所 | 电气连接组件的制造方法 |

| US11894649B2 (en) | 2020-10-30 | 2024-02-06 | Amphenol Corporation | Electrical connector and method of making the same |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0718924A3 (fr) | 1997-08-13 |

| DE19510341A1 (de) | 1996-06-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE19800099C2 (de) | Verfahren zur Herstellung eines Leitungsverbinders | |

| DE69205916T2 (de) | Struktur zum mit Laserstrahl Schweissen von elektrischen Verbindungen. | |

| DE1765654A1 (de) | Anschlussvorrichtung fuer gedruckte Schaltungen | |

| DE19934967C2 (de) | Wasserdichter Verbinder | |

| DE4439645C1 (de) | Stromanschlußelement für eine heizbare Autoglasscheibe | |

| EP0542005A1 (fr) | Procédé de fabrication de connexion électrique entre deux conduites électriques | |

| DE2735838C2 (de) | Elektrische Anschlußklemme und elektrisches Kabelverbindungsglied | |

| DE69712028T2 (de) | Struktur und Verfahren einer Verbindung eines elektrischen Drahts mit einer Endklemme | |

| EP0496972A1 (fr) | Connecteur à fiche spécialement pour connection détachable des conducteurs électriques | |

| DE19922139B4 (de) | Verfahren zur Montage eines Flachkabels an einem Stecker, Stecker für ein Flachkabel und Bauteil zum Erregen von Ultraschallschwingungen zur Verwendung bei diesem Verfahren | |

| EP0090317A2 (fr) | Dispositif pour connecter des conducteurs électriques en forme de fil ou de brin | |

| DE19823900C2 (de) | Anschlusselement, Verbindungsaufbau zwischen einem Anschlusselement und einem ummantelten Draht und Verfahren zum Verbinden eines Anschlusselements mit einem ummantelten Draht | |

| DE2355873C2 (de) | Kabelverbinder | |

| EP0718924A2 (fr) | Procédé de fixation d'un câble électrique atténuant l'effort de tension | |

| DE4222685C2 (de) | Steckkontaktelement | |

| DE19949386C2 (de) | Geräte-Anschlusskasten mit Schneidtechnik | |

| WO2006040183A1 (fr) | Element d'etancheite pour cable plat flexible (ffc), fpc et autres conducteurs plats avec/ et sans conducteur rond | |

| EP0272470A1 (fr) | Fiche électrique et procédé pour sa fabrication | |

| DE102015121832B4 (de) | Steckverbinder zur elektrischen Direktkontaktierung und Steckverbindung | |

| EP1083627B1 (fr) | Connecteur électrique | |

| DE19525801C2 (de) | Vorrichtung zum elektrisch leitenden Verbinden von zwei elektrischen Leitungen | |

| EP3782235A1 (fr) | Connecteur direct | |

| DE2165442A1 (de) | Steckerverbindung fuer elektrische leitungen und verfahren zur herstellung der steckerverbindung.- | |

| DE3719210C2 (de) | Verfahren zur Herstellung eines Kupplungsteils eines elektrischen Steckverbinders | |

| EP1122823B1 (fr) | Contact à sertir |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR IT SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR IT SE |

|

| 17P | Request for examination filed |

Effective date: 19970711 |

|

| 17Q | First examination report despatched |

Effective date: 19990212 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 20000328 |