EP0694740A2 - Chambre de combustion - Google Patents

Chambre de combustion Download PDFInfo

- Publication number

- EP0694740A2 EP0694740A2 EP95810442A EP95810442A EP0694740A2 EP 0694740 A2 EP0694740 A2 EP 0694740A2 EP 95810442 A EP95810442 A EP 95810442A EP 95810442 A EP95810442 A EP 95810442A EP 0694740 A2 EP0694740 A2 EP 0694740A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- combustion chamber

- channel

- flow

- fuel

- stage

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C13/00—Apparatus in which combustion takes place in the presence of catalytic material

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C6/00—Combustion apparatus characterised by the combination of two or more combustion chambers or combustion zones, e.g. for staged combustion

- F23C6/04—Combustion apparatus characterised by the combination of two or more combustion chambers or combustion zones, e.g. for staged combustion in series connection

- F23C6/042—Combustion apparatus characterised by the combination of two or more combustion chambers or combustion zones, e.g. for staged combustion in series connection with fuel supply in stages

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/02—Continuous combustion chambers using liquid or gaseous fuel characterised by the air-flow or gas-flow configuration

- F23R3/04—Air inlet arrangements

- F23R3/10—Air inlet arrangements for primary air

- F23R3/12—Air inlet arrangements for primary air inducing a vortex

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/02—Continuous combustion chambers using liquid or gaseous fuel characterised by the air-flow or gas-flow configuration

- F23R3/16—Continuous combustion chambers using liquid or gaseous fuel characterised by the air-flow or gas-flow configuration with devices inside the flame tube or the combustion chamber to influence the air or gas flow

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R3/00—Continuous combustion chambers using liquid or gaseous fuel

- F23R3/40—Continuous combustion chambers using liquid or gaseous fuel characterised by the use of catalytic means

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05B—INDEXING SCHEME RELATING TO WIND, SPRING, WEIGHT, INERTIA OR LIKE MOTORS, TO MACHINES OR ENGINES FOR LIQUIDS COVERED BY SUBCLASSES F03B, F03D AND F03G

- F05B2260/00—Function

- F05B2260/20—Heat transfer, e.g. cooling

- F05B2260/221—Improvement of heat transfer

- F05B2260/222—Improvement of heat transfer by creating turbulence

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C2900/00—Special features of, or arrangements for combustion apparatus using fluid fuels or solid fuels suspended in air; Combustion processes therefor

- F23C2900/07002—Premix burners with air inlet slots obtained between offset curved wall surfaces, e.g. double cone burners

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23C—METHODS OR APPARATUS FOR COMBUSTION USING FLUID FUEL OR SOLID FUEL SUSPENDED IN A CARRIER GAS OR AIR

- F23C2900/00—Special features of, or arrangements for combustion apparatus using fluid fuels or solid fuels suspended in air; Combustion processes therefor

- F23C2900/13002—Catalytic combustion followed by a homogeneous combustion phase or stabilizing a homogeneous combustion phase

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F23—COMBUSTION APPARATUS; COMBUSTION PROCESSES

- F23R—GENERATING COMBUSTION PRODUCTS OF HIGH PRESSURE OR HIGH VELOCITY, e.g. GAS-TURBINE COMBUSTION CHAMBERS

- F23R2900/00—Special features of, or arrangements for continuous combustion chambers; Combustion processes therefor

- F23R2900/03341—Sequential combustion chambers or burners

Definitions

- the present invention relates to a combustion chamber according to the preamble of claim 1.

- the invention seeks to remedy this.

- the invention as characterized in the claims, is based on the object, in a combustion chamber of the type mentioned, to minimize all pollutant emissions occurring during combustion, regardless of the type of fuel used.

- the aim here is to keep the mixture constant in the first stage so that UHC and CO emissions can be prevented.

- the mixer used in the first stage mixes fuel and air evenly, whereby in the case of oil, droplet evaporation takes place. If a premix burner according to EP-A1-0 321 809 is used for the above-mentioned mixing, then this undergoes a modification regarding the aerodynamics, which is manifested in the fact that the swirl is significantly reduced. This is done by 20-100% wider air inlet slots, or by increasing the number of these slots.

- the new premix burner is characterized by the fact that it is used alone as a mixer and is no longer able to create a backflow zone.

- this mixer Downstream of this mixer is a catalytic converter in which the fuel / air mixture is completely burned.

- the mixture is selected in such a way that typical adiabatic flame temperatures between 800 ° and 1100 ° C are reached, thus precluding thermal destruction of the catalyst is. This is a great advantage compared to other catalytic processes for high temperatures. Due to the low temperatures, there is no homogeneous gas phase reaction, but only a reaction on the active surfaces. The NOx production of such a chemical reaction is very low, much less than 1 ppmv. A largely NOx-free hot gas is available at the end of the catalyst.

- Vortex generators ensure a vortex-intensive flow in order to mix in the fuel injected downstream as quickly as possible.

- the constant temperature at the entrance to the second stage ensures that the mixture ignites independently of the amount of fuel injected into the second stage.

- Another important advantage of the invention is that the power control over the gas turbine load can be carried out essentially by adjusting the amount of fuel in the second stage.

- annular combustion chamber which essentially has the shape of a coherent annular or quasi-annular cylinder.

- a combustion chamber can also consist of a number of axially, quasi-axially or helically arranged and individually closed combustion chambers.

- the combustion chamber can also consist of a single one Pipe exist. 1 consists of a first 1 and a second stage 2, which are connected in series, and the second stage 2 consists of the actual combustion zone 11.

- the first stage 1 in the direction of flow initially consists of a number of mixers 100 arranged in the circumferential direction, the mixer itself being essentially derived from the burner according to EP-0 321 809.

- a compressor 18 acts in this mixer 100, in which the intake air 17 is compressed.

- the air 115 then supplied by the compressor has a pressure of 10-40 bar at a temperature of 300-600 ° C.

- This air 115 flows into the mixer 100, the mode of operation of which is described in more detail in FIGS. 2-5.

- the fuel / air mixture 19 provided in the mixer 100 reaches a catalyst 3, in which this mixture 19 is completely combusted.

- the mixture 19 is selected such that typical adiabatic flame temperatures between 800 and 1050 ° C. are reached, with the result that the thermal destruction of the catalyst 3 is excluded. Because of the relatively low temperature, there is no homogeneous gas phase reaction, but only a reaction on the active surfaces of the catalyst 3. The NOx production of such a chemical reaction is very low, much less than 1 ppmv. A largely NOx-free hot gas 4 is thus available at the end of the catalyst 3.

- the catalyst 3 itself consists of a first very active stage, which initiates the fuel conversion. A palladium oxide is preferably used as the material here. The next stages of the catalyst 3 can consist of other materials, for example of platinum.

- the flow velocity in the Catalyst 3 is less than about 30 m / s.

- the hot gases 4 flow into an inflow zone 5 and are accelerated to approximately 80-120 m / s.

- the inflow zone 5 is equipped on the inside and in the circumferential direction of the channel wall 6 with a series of vortex-generating elements 200, hereinafter only called vortex generators, which will be discussed in more detail below.

- the hot gases 4 are swirled by the vortex generators 200 such that no recirculation areas occur in the wake of the vortex generators 200 mentioned in the subsequent premixing section 7.

- this premixing section 7 which is designed as a Venturi channel, a plurality of fuel lances 8 are arranged, which take over the supply of a fuel 9 and supporting air 10. These media can be supplied to the individual fuel lances 8, for example, via a ring line (not shown).

- the swirl flow triggered by the vortex generators 200 ensures a large-scale distribution of the introduced fuel 9, if necessary also the admixed supporting air 10. Furthermore, the swirl flow ensures a homogenization of the mixture of combustion air and fuel.

- the fuel 9 injected into the hot gases 4 by the fuel lance 8 triggers self-ignition, provided that these hot gases 4 have the specific temperature which the fuel-dependent auto-ignition can trigger.

- the ring combustion chamber is operated with a gaseous fuel, a temperature of the hot gases 4 of more than 800 ° C. must be present to initiate self-ignition, which is also present here.

- a temperature of the hot gases 4 of more than 800 ° C. must be present to initiate self-ignition, which is also present here.

- This problem is remedied by, on the one hand, designing the premixing zone 7 as a venturi channel and, on the other hand, disposing the injection of the fuel 9 in the region of the largest constriction in the premixing zone 7.

- the constriction in the premixing zone 7 reduces the turbulence by increasing the axial speed, which minimizes the risk of kickback by reducing the turbulent flame speed.

- the combustion zone 11 follows the relatively short premixing zone 7.

- the transition between the two zones is formed by a radial cross-sectional jump 12, which initially indicates the flow cross-section of the combustion zone 11.

- a flame front 21 also arises in the plane of the cross-sectional jump 12.

- the vortex generators 200 are designed such that no recirculation takes place in the premixing zone 7; only after the sudden cross-sectional expansion does the swirl flow burst.

- the swirl flow supports the rapid re-application of the flow behind the cross-sectional jump 12, so that a high burn-out with a short overall length can be achieved by utilizing the volume of the combustion zone 11 as fully as possible.

- a flow-like edge zone is formed during operation, in which vortex detachments occur due to the prevailing negative pressure, which then lead to stabilization of the flame front.

- These corner vortices 20 also form the ignition zones within the second stage 2.

- the hot working gases 13 provided in the combustion zone 11 then act on a downstream turbine 14.

- the exhaust gases 15 can then be used to operate a steam cycle, in the latter case the switching then Combined system is.

- the proposed method also behaves very well with regard to a wide load range. Since the mixture in the first stage 1 is always kept largely constant, the UHC or CO emissions can also be prevented.

- the constant temperature at the entrance to the second stage 2 ensures reliable self-ignition of the mixture, regardless of the amount of fuel in the second stage 2.

- the inlet temperature is still high enough to achieve sufficient burnout in the second stage 2 even with a small amount of fuel .

- the output control via the gas turbine load essentially takes place by adapting the fuel quantity in the second stage 2.

- the controllable compressor 18 ensures that the minimum combustion temperature at the outlet of the catalytic converter 3 is not undercut at zero load.

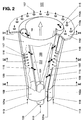

- FIGS. 3-5 In order to better understand the structure of the mixer 100, it is advantageous if the individual cuts according to FIGS. 3-5 are used simultaneously with FIG. 2. Furthermore, in order not to make FIG. 2 unnecessarily confusing, the guide plates 121a, 121b shown schematically according to FIGS. 3-5 have only been hinted at. In the description of FIG. 2, reference is made below to the remaining FIGS. 3-5 as required.

- the mixer 100 consists of two hollow, conical partial bodies 101, 102 which are nested one inside the other.

- the offset of the respective central axis or longitudinal axis of symmetry 201b, 202b of the conical partial bodies 101, 102 to one another creates a tangential air inlet slot 119, 120 on both sides, in a mirror-image arrangement (FIGS. 3-5), through which the combustion air 115 enters the interior of the Mixer 100, ie flows into the cone cavity 114.

- the conical shape of the partial bodies 101, 102 shown in the flow direction has a specific fixed angle.

- the partial bodies 101, 102 can have an increasing or decreasing cone inclination in the direction of flow, similar to a trumpet or. Tulip.

- the last two forms are not included in the drawing, since they can be easily understood by a person skilled in the art.

- the two tapered partial bodies 101, 102 each have a cylindrical starting part 101a, 102a, which, similarly to the conical partial bodies 101, 102, also run offset from one another, so that the tangential air inlet slots 119, 120 are present over the entire length of the mixer 100.

- a nozzle 103 is accommodated, the injection 104 of which coincides approximately with the narrowest cross section of the conical cavity 114 formed by the conical partial bodies 101, 102.

- the injection capacity and the type of this nozzle 103 depend on the specified parameters of the respective mixer 100.

- the mixer 100 can be designed purely conical, that is to say without cylindrical starting parts 101a, 102a.

- the conical sub-bodies 101, 102 further each have a fuel line 108, 109, which are arranged along the tangential inlet slots 119, 120 and are provided with injection openings 117, through which a gaseous fuel 113 is preferably injected into the combustion air 115 flowing through there, such as arrows 116 symbolize this.

- These fuel lines 108, 109 are preferably at the latest at the end of the tangential Inflow, prior to entering the cone cavity 114, is placed in order to obtain an optimal air / fuel mixture.

- the outlet opening of the mixer 100 merges into a front wall 110, in which a number of bores 110a are provided.

- the latter come into operation when necessary and ensure that dilution air or cooling air 110b is supplied to the front part of the transition piece 122.

- the fuel brought in through the nozzle 103 is a liquid fuel 112, which can be enriched with a recirculated exhaust gas at most.

- This fuel 112 is injected into the cone cavity 114 at an acute angle.

- a conical fuel profile 105 is thus formed from the nozzle 103 and is enclosed by the rotating combustion air 115 flowing in tangentially. In the axial direction, the concentration of the fuel 112 is continuously reduced to an optimal mixture by the inflowing combustion air 115.

- the mixer 100 is operated with a gaseous fuel 113, this is preferably done via opening nozzles 117, the formation of this fuel / air mixture taking place directly at the end of the air inlet slots 119, 120.

- the fuel 112 is injected via the fuel nozzle 103, the optimum, homogeneous fuel concentration over the cross section is achieved at the end of the mixer 100.

- the combustion air 115 is additionally preheated or enriched with a recirculated exhaust gas, this sustainably supports the evaporation of the liquid fuel 112.

- the same considerations also apply if, instead of gaseous, liquid fuels are supplied via the lines 108, 109.

- Another way of preventing the formation of a backflow zone is to increase the number of air inlet slots, and at the same time the number of partial bodies increases accordingly.

- the axial speed within the mixer 100 can be changed by a corresponding supply, not shown, of an axial combustion air flow.

- the construction of the mixer 100 is furthermore excellently suitable for changing the size of the tangential air inlet slots 119, 120, with which a relatively large operational bandwidth can be recorded without changing the overall length of the mixer 100.

- the partial bodies 101, 102 can also be displaced relative to one another in another plane, as a result of which even an overlap thereof can be controlled. It is even possible to interleave the partial bodies 101, 102 in a spiral manner by counter-rotating movement.

- the guide plates 121a, 121b have a flow introduction function, which, depending on their length, extend the respective end of the tapered partial bodies 101, 102 in the direction of flow relative to the combustion air 115.

- the channeling of the combustion air 115 into the cone cavity 114 can be optimized by opening or closing the guide plates 121a, 121b around a pivot point 123 located in the region of the entry of this channel into the cone cavity 114, in particular this is necessary if the original gap size of the tangential air inlet slots 119, 120 is to be changed from the above motives.

- these dynamic arrangements can also be provided statically are formed by the need for baffles as a fixed component with the tapered partial bodies 101, 102.

- Mixer 100 can also be operated without baffles, or other aids can be provided for this.

- a vortex generator 200, 201, 202 essentially consists of three freely flowing triangular surfaces. These are a roof surface 210 and two side surfaces 211 and 213. In their longitudinal extent, these surfaces run at certain angles in the direction of flow.

- the side walls of the vortex generators 200, 201, 202, which preferably consist of right-angled triangles, are fixed with their long sides on the channel wall 6 already mentioned, preferably gas-tight. They are oriented so that they form a joint on their narrow sides, including an arrow angle ⁇ .

- the joint is designed as a sharp connecting edge 216 and is perpendicular to each channel wall 6 with which the side surfaces are flush.

- the two side surfaces 211, 213 including the arrow angle ⁇ are symmetrical in shape, size and orientation in FIG. 4, they are arranged on both sides of an axis of symmetry 217 which is oriented in the same direction as the channel axis.

- the roof surface 210 lies against the same channel wall 6 as the side surfaces 211, 213 with a very narrow edge 215 running transversely to the flow channel. Its longitudinal edges 212, 214 are flush with the longitudinal edges of the side surfaces 211 protruding into the flow channel , 213.

- the roof surface 210 extends at an angle of inclination ⁇ to the channel wall 6, the longitudinal edges 212, 214 of which, together with the connecting edge 216, form a point 218.

- the vortex generator 200, 201, 202 can also be provided with a bottom surface with which he is suitably attached to the channel wall 6. Such a floor area is, however, unrelated to the mode of operation of the element.

- the mode of operation of the vortex generator 200, 201, 202 is as follows: When flowing around the edges 212 and 214, the main flow is converted into a pair of opposing vortices, as is schematically outlined in the figures.

- the vortex axes lie in the axis of the main flow.

- the number of swirls and the location of the vortex breakdown (vortex breakdown), if the latter is aimed for, are determined by appropriate selection of the angle of attack ⁇ and the arrow angle ⁇ .

- the vortex strength or the number of swirls is increased, and the location of the vortex bursting shifts upstream into the region of the vortex generator 200, 201, 202 itself.

- these two angles ⁇ and ⁇ are due to structural conditions and determined by the process itself.

- These vortex generators only have to be adapted in terms of length and height, as will be explained in more detail below under FIG. 9.

- the connecting edge 216 of the two side surfaces 211, 213 forms the downstream edge of the vortex generator 200.

- the edge 215 of the roof surface 210 which runs transversely to the flow through the channel is thus the edge which is first acted upon by the channel flow.

- FIG. 7 shows a so-called half "vortex generator” based on a vortex generator according to FIG. 6.

- the vortex generator 201 shown here only one of the two side surfaces is provided with the arrow angle ⁇ / 2.

- the other side surface is straight and oriented in the direction of flow.

- this vortex generator only one vortex is generated on the arrowed side, as is shown in the figure. Accordingly, it is downstream this vortex generator does not have a vortex-neutral field, but a swirl is forced on the flow.

- FIG. 8 differs from FIG. 6 in that the sharp connecting edge 216 of the vortex generator 202 is the point which is first acted upon by the channel flow. The element is therefore rotated by 180 °. As can be seen from the illustration, the two opposite vortices have changed their sense of rotation.

- FIG. 9 shows the basic geometry of a vortex generator 200 installed in a channel 5.

- the height h of the connecting edge 216 will be coordinated with the channel height H, or the height of the channel part which is assigned to the vortex generator that the vortex generated immediately downstream of the vortex generator 200 already reaches such a size that the full channel height H is filled. This leads to a uniform speed distribution in the cross-section applied.

- Another criterion that can influence the ratio of the two heights h / H to be selected is the pressure drop that occurs when the vortex generator 200 flows around. It goes without saying that the pressure loss coefficient also increases with a larger ratio h / H.

- the vortex generators 200, 201, 202 are mainly used when it comes to mixing two flows.

- the main flow 4 as hot gases attacks the transverse edge 215 or the connecting edge 216 in the direction of the arrow.

- the secondary flow in the form of a gaseous and / or liquid fuel, which is possibly enriched with a portion of supporting air (see FIG. 1), has a much smaller one Mass flow as the main flow. In the present case, this secondary flow is introduced into the main flow downstream of the vortex generator, as can be seen particularly well from FIG. 1.

- vortex generators 200 are distributed at a distance over the circumference of the channel 5.

- the vortex generators can also be strung together in the circumferential direction so that no gaps are left on the channel wall 6.

- the vortices to be generated are ultimately decisive for the choice of the number and the arrangement of the vortex generators.

- FIGS. 10-16 show further possible forms of introducing the fuel into the hot gases 4. These variants can be combined in a variety of ways with one another and with a central fuel injection, as can be seen, for example, from FIG. 1.

- the fuel is also injected via wall bores 221, which are located directly next to the side surfaces 211, 213 and in their longitudinal extent in the same channel wall 6, on the the vortex generators are arranged.

- the introduction of the fuel through the wall bores 221 gives the generated vortices an additional impulse, which extends the lifespan of the vortex generator.

- the fuel is injected via a slot 222 or via wall bores 223, both arrangements being located directly in front of the edge 215 of the roof surface 210 running transversely to the flowed channel and in the longitudinal extension thereof in the same channel wall 6 on which the Vortex generators are arranged.

- the geometry of the wall bores 223 or the slot 222 is selected such that the fuel is introduced into the main flow 4 at a certain injection angle and largely shields the post-placed vortex generator as a protective film against the hot main flow 4 by flow around it.

- the secondary flow (cf. above) is first introduced into the hollow interior of the vortex generators via guides (not shown) through the channel wall 6. This creates an internal cooling facility for the vortex generators without providing any additional equipment.

- the fuel is injected via wall bores 224, which are located inside the roof surface 210 directly behind and along the edge 215 running transversely to the flow channel.

- the vortex generator is cooled here more externally than internally.

- the emerging secondary flow forms when flowing around the roof surface 210 a protective layer shielding it against the hot main flow 4.

- the fuel is injected via wall bores 225, which are staggered within the roof surface 210 along the line of symmetry 217.

- the channel walls 6 are particularly well protected from the hot main flow 4, since the fuel is first introduced on the outer circumference of the vortex.

- the fuel is injected via wall bores 226, which are located in the longitudinal edges 212, 214 of the roof surface 210.

- This solution ensures good cooling of the vortex generators, since the fuel escapes from its extremities and thus completely flushes the inner walls of the element.

- the secondary flow is fed directly into the resulting vortex, which leads to defined flow conditions.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Combustion Of Fluid Fuel (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4426351 | 1994-07-25 | ||

| DE4426351A DE4426351B4 (de) | 1994-07-25 | 1994-07-25 | Brennkammer für eine Gasturbine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0694740A2 true EP0694740A2 (fr) | 1996-01-31 |

Family

ID=6524114

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP95810442A Withdrawn EP0694740A2 (fr) | 1994-07-25 | 1995-07-05 | Chambre de combustion |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US5626017A (fr) |

| EP (1) | EP0694740A2 (fr) |

| JP (1) | JPH08189641A (fr) |

| CN (1) | CN1121570A (fr) |

| DE (1) | DE4426351B4 (fr) |

Cited By (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0745809A1 (fr) * | 1995-06-02 | 1996-12-04 | ABB Management AG | Générateur de tourbillons pour chambre de combustion |

| EP0718561B1 (fr) * | 1994-12-24 | 2001-03-14 | ABB (Schweiz) AG | Brûleur |

| EP1255080A1 (fr) * | 2001-04-30 | 2002-11-06 | ALSTOM (Switzerland) Ltd | Brûleur catalytique |

| EP1279898A3 (fr) * | 2001-07-26 | 2003-04-16 | ALSTOM (Switzerland) Ltd | Brûleur à prémélange offrant une haute stabilité de flamme |

| WO2005095855A1 (fr) * | 2004-03-30 | 2005-10-13 | Alstom Technology Ltd | Dispositif et procede pour stabiliser une flamme |

| US7069727B2 (en) | 2003-02-11 | 2006-07-04 | Alstom Technology Ltd. | Method for operating a gas turbo group |

| EP2071155A2 (fr) * | 2007-12-14 | 2009-06-17 | United Technologies Corporation | Ensemble formant nacelle ayant des turbulateurs |

| WO2009109448A1 (fr) * | 2008-03-07 | 2009-09-11 | Alstom Technology Ltd | Ensemble brûleur et son utilisation |

| WO2009109454A1 (fr) * | 2008-03-07 | 2009-09-11 | Alstom Technology Ltd | Procédé et ensemble brûleur servant à produire du gaz chaud et utilisation dudit procédé |

| US8057224B2 (en) * | 2004-12-23 | 2011-11-15 | Alstom Technology Ltd. | Premix burner with mixing section |

| US8192147B2 (en) | 2007-12-14 | 2012-06-05 | United Technologies Corporation | Nacelle assembly having inlet bleed |

| US8282037B2 (en) | 2007-11-13 | 2012-10-09 | United Technologies Corporation | Nacelle flow assembly |

| US8468833B2 (en) | 2008-03-07 | 2013-06-25 | Alstom Technology Ltd | Burner arrangement, and use of such a burner arrangement |

| WO2013139914A1 (fr) * | 2012-03-23 | 2013-09-26 | Alstom Technology Ltd | Dispositif de combustion |

| EP2700878A3 (fr) * | 2012-08-24 | 2014-03-26 | Alstom Technology Ltd | Procédé pour mélanger un air de dilution dans un système de combustion séquentielle d'une turbine à gaz |

| WO2014063835A1 (fr) * | 2012-10-24 | 2014-05-01 | Alstom Technology Ltd | Combustion séquentielle avec mélangeur de gaz d'appoint |

| CN105371301A (zh) * | 2015-10-08 | 2016-03-02 | 北京航空航天大学 | 一种高温射流点火自稳焰的分级燃烧室 |

| AU2012320439B2 (en) * | 2011-10-07 | 2016-05-19 | Wobben Properties Gmbh | Method and device for mounting a rotor of a wind energy plant |

| EP3267107A1 (fr) * | 2016-07-08 | 2018-01-10 | Ansaldo Energia IP UK Limited | Procédé de commande d'un ensemble de turbine à gaz |

| EP3889506A1 (fr) * | 2020-03-31 | 2021-10-06 | Siemens Aktiengesellschaft | Composant de brûleur d'un brûleur et brûleur d'une turbine à gaz doté d'un tel composant |

| WO2021197654A1 (fr) * | 2020-03-31 | 2021-10-07 | Siemens Aktiengesellschaft | Composant de brûleur d'un brûleur, et brûleur d'une turbine à gaz présentant un composant de brûleur de ce type |

Families Citing this family (87)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19614001A1 (de) * | 1996-04-09 | 1997-10-16 | Abb Research Ltd | Brennkammer |

| DE19649486A1 (de) * | 1996-11-29 | 1998-06-04 | Abb Research Ltd | Brennkammer |

| US6000930A (en) * | 1997-05-12 | 1999-12-14 | Altex Technologies Corporation | Combustion process and burner apparatus for controlling NOx emissions |

| US6155819A (en) * | 1998-06-12 | 2000-12-05 | Precision Combustion, Inc. | Dry, low NOx catalytic pilot |

| AU2341100A (en) * | 1998-08-17 | 2000-04-17 | Ramgen Power Systems, Inc. | Apparatus and method for fuel-air mixing before supply of low pressure lean pre-mix to combustor |

| US6339925B1 (en) * | 1998-11-02 | 2002-01-22 | General Electric Company | Hybrid catalytic combustor |

| DE19905996A1 (de) | 1999-02-15 | 2000-08-17 | Abb Alstom Power Ch Ag | Brennstofflanze zum Eindüsen von flüssigen und/oder gasförmigen Brennstoffen in eine Brennkammer |

| DE19905995A1 (de) * | 1999-02-15 | 2000-08-17 | Asea Brown Boveri | Brennstofflanze zum Eindüsen von flüssigen und/oder gasförmigen Brennstoffen in eine Brennkammer sowie Verfahren zum Betrieb einer solchen Brennstofflanze |

| DE10056243A1 (de) * | 2000-11-14 | 2002-05-23 | Alstom Switzerland Ltd | Brennkammer und Verfahren zum Betrieb dieser Brennkammer |

| US6652265B2 (en) | 2000-12-06 | 2003-11-25 | North American Manufacturing Company | Burner apparatus and method |

| DE10061527A1 (de) | 2000-12-11 | 2002-06-13 | Alstom Switzerland Ltd | Vormischbrenneranordnung mit katalytischer Verbrennung sowie Verfahren zum Betrieb hierzu |

| DE50212351D1 (de) * | 2001-04-30 | 2008-07-24 | Alstom Technology Ltd | Vorrichtung zum Verbrennen eines gasförmigen Brennstoff-Oxidator-Gemischs |

| US6564555B2 (en) | 2001-05-24 | 2003-05-20 | Allison Advanced Development Company | Apparatus for forming a combustion mixture in a gas turbine engine |

| US7603841B2 (en) * | 2001-07-23 | 2009-10-20 | Ramgen Power Systems, Llc | Vortex combustor for low NOx emissions when burning lean premixed high hydrogen content fuel |

| DE10164097A1 (de) * | 2001-12-24 | 2003-07-03 | Alstom Switzerland Ltd | Vormischbrenner mit hoher Flammenstabilität |

| JP2003306307A (ja) * | 2002-04-09 | 2003-10-28 | Nissan Motor Co Ltd | 燃料改質装置 |

| DE10330023A1 (de) * | 2002-07-20 | 2004-02-05 | Alstom (Switzerland) Ltd. | Wirbelgenerator mit kontrollierter Nachlaufströmung |

| EP1439349A1 (fr) * | 2003-01-14 | 2004-07-21 | Alstom Technology Ltd | Procédé de combustion et brûleur pour sa mise en oeuvre |

| US7096671B2 (en) * | 2003-10-14 | 2006-08-29 | Siemens Westinghouse Power Corporation | Catalytic combustion system and method |

| US7421843B2 (en) * | 2005-01-15 | 2008-09-09 | Siemens Power Generation, Inc. | Catalytic combustor having fuel flow control responsive to measured combustion parameters |

| DE102005061486B4 (de) | 2005-12-22 | 2018-07-12 | Ansaldo Energia Switzerland AG | Verfahren zum Betreiben einer Brennkammer einer Gasturbine |

| US7797944B2 (en) * | 2006-10-20 | 2010-09-21 | United Technologies Corporation | Gas turbine engine having slim-line nacelle |

| US7870721B2 (en) * | 2006-11-10 | 2011-01-18 | United Technologies Corporation | Gas turbine engine providing simulated boundary layer thickness increase |

| SE530775C2 (sv) * | 2007-01-05 | 2008-09-09 | Zemission Ab | Värmeanordning för katalytisk förbränning av vätskeformiga bränslen samt en spis innefattande en sådan värmeanordning |

| US8727267B2 (en) * | 2007-05-18 | 2014-05-20 | United Technologies Corporation | Variable contraction ratio nacelle assembly for a gas turbine engine |

| US8402739B2 (en) * | 2007-06-28 | 2013-03-26 | United Technologies Corporation | Variable shape inlet section for a nacelle assembly of a gas turbine engine |

| US9228534B2 (en) | 2007-07-02 | 2016-01-05 | United Technologies Corporation | Variable contour nacelle assembly for a gas turbine engine |

| US8671658B2 (en) | 2007-10-23 | 2014-03-18 | Ener-Core Power, Inc. | Oxidizing fuel |

| EP2058590B1 (fr) * | 2007-11-09 | 2016-03-23 | Alstom Technology Ltd | Procédé de fonctionnement d'un brûleur |

| JP5574969B2 (ja) * | 2007-11-27 | 2014-08-20 | アルストム テクノロジー リミテッド | 予混合バーナ内で水素を燃焼させるための方法および装置 |

| EP2072899B1 (fr) | 2007-12-19 | 2016-03-30 | Alstom Technology Ltd | Procédé d'injection de carburant |

| EP2116766B1 (fr) * | 2008-05-09 | 2016-01-27 | Alstom Technology Ltd | Brûleur avec lance à combustible |

| CN102224379B (zh) * | 2008-09-22 | 2014-09-24 | 达塞尔·卡尔灵顿 | 空气流动控制后壳体构件 |

| US8701413B2 (en) | 2008-12-08 | 2014-04-22 | Ener-Core Power, Inc. | Oxidizing fuel in multiple operating modes |

| EP2253888B1 (fr) * | 2009-05-14 | 2013-10-16 | Alstom Technology Ltd | Brûleur d'une turbine à gaz ayant un générateur de vortex avec une lance à combustible |

| DE102010037688A1 (de) * | 2009-09-24 | 2011-03-31 | General Electric Co. | Fastback-Turbulatorstruktur und ein dieselbe enthaltender Turbinenleitapparat |

| US8408872B2 (en) * | 2009-09-24 | 2013-04-02 | General Electric Company | Fastback turbulator structure and turbine nozzle incorporating same |

| EP2496883B1 (fr) | 2009-11-07 | 2016-08-10 | Alstom Technology Ltd | Brûleur à prémélange pour chambre de combustion de turbine à gaz |

| EP2496885B1 (fr) | 2009-11-07 | 2019-05-29 | Ansaldo Energia Switzerland AG | Brûleur avec un système de refroidissement permettant d'accroître le rendement d'une turbine à gaz |

| EP2496884B1 (fr) | 2009-11-07 | 2016-12-28 | General Electric Technology GmbH | Système d'injection de brûleur de postcombustion |

| WO2011054739A2 (fr) | 2009-11-07 | 2011-05-12 | Alstom Technology Ltd | Système d'injection pour brûleur de réchauffage |

| EP2496882B1 (fr) | 2009-11-07 | 2018-03-28 | Ansaldo Energia Switzerland AG | Système d'injection pour brûleur de réchauffage avec lances à combustible |

| JP2011102669A (ja) * | 2009-11-10 | 2011-05-26 | Mitsubishi Heavy Ind Ltd | ガスタービン燃焼器及びガスタービン |

| EP2420731B1 (fr) * | 2010-08-16 | 2014-03-05 | Alstom Technology Ltd | Brûleur post-combustion |

| CH704829A2 (de) | 2011-04-08 | 2012-11-15 | Alstom Technology Ltd | Gasturbogruppe und zugehöriges Betriebsverfahren. |

| EP2522912B1 (fr) | 2011-05-11 | 2019-03-27 | Ansaldo Energia Switzerland AG | Redresseur de flux et mélangeur |

| RU2550370C2 (ru) | 2011-05-11 | 2015-05-10 | Альстом Текнолоджи Лтд | Центробежная форсунка с выступающими частями |

| CN103732991B (zh) * | 2011-08-17 | 2016-03-02 | 大阳日酸株式会社 | H2用燃烧器及h2用燃烧器的燃烧方法 |

| US9273606B2 (en) | 2011-11-04 | 2016-03-01 | Ener-Core Power, Inc. | Controls for multi-combustor turbine |

| US9567903B2 (en) | 2012-03-09 | 2017-02-14 | Ener-Core Power, Inc. | Gradual oxidation with heat transfer |

| US9359947B2 (en) | 2012-03-09 | 2016-06-07 | Ener-Core Power, Inc. | Gradual oxidation with heat control |

| US9267432B2 (en) * | 2012-03-09 | 2016-02-23 | Ener-Core Power, Inc. | Staged gradual oxidation |

| US9347664B2 (en) | 2012-03-09 | 2016-05-24 | Ener-Core Power, Inc. | Gradual oxidation with heat control |

| US9353946B2 (en) | 2012-03-09 | 2016-05-31 | Ener-Core Power, Inc. | Gradual oxidation with heat transfer |

| US9534780B2 (en) | 2012-03-09 | 2017-01-03 | Ener-Core Power, Inc. | Hybrid gradual oxidation |

| US9328916B2 (en) | 2012-03-09 | 2016-05-03 | Ener-Core Power, Inc. | Gradual oxidation with heat control |

| US9371993B2 (en) | 2012-03-09 | 2016-06-21 | Ener-Core Power, Inc. | Gradual oxidation below flameout temperature |

| US9273608B2 (en) | 2012-03-09 | 2016-03-01 | Ener-Core Power, Inc. | Gradual oxidation and autoignition temperature controls |

| US9359948B2 (en) | 2012-03-09 | 2016-06-07 | Ener-Core Power, Inc. | Gradual oxidation with heat control |

| US9381484B2 (en) | 2012-03-09 | 2016-07-05 | Ener-Core Power, Inc. | Gradual oxidation with adiabatic temperature above flameout temperature |

| US9328660B2 (en) | 2012-03-09 | 2016-05-03 | Ener-Core Power, Inc. | Gradual oxidation and multiple flow paths |

| US9726374B2 (en) | 2012-03-09 | 2017-08-08 | Ener-Core Power, Inc. | Gradual oxidation with flue gas |

| US9234660B2 (en) | 2012-03-09 | 2016-01-12 | Ener-Core Power, Inc. | Gradual oxidation with heat transfer |

| RU2561956C2 (ru) | 2012-07-09 | 2015-09-10 | Альстом Текнолоджи Лтд | Газотурбинная система сгорания |

| EP2700879B1 (fr) * | 2012-08-24 | 2019-03-27 | Ansaldo Energia Switzerland AG | Procédé pour mélanger un air de dilution dans un système de combustion séquentielle d'une turbine à gaz, et système de combustion séquentielle pour une turbine à gaz comprenant un injecteur d'air de dilution |

| SE537347C2 (sv) * | 2012-08-31 | 2015-04-07 | Reformtech Heating Holding Ab | Apparat för förbränning |

| CA2830031C (fr) | 2012-10-23 | 2016-03-15 | Alstom Technology Ltd. | Bruleur pour chambre de combustion tubulaire unique |

| EP2725302A1 (fr) | 2012-10-25 | 2014-04-30 | Alstom Technology Ltd | Agencement de brûleur de postcombustion |

| EP2837883B1 (fr) | 2013-08-16 | 2018-04-04 | Ansaldo Energia Switzerland AG | Chambre de combustion tubulaire pré-mélangée ayant des aubes ondulées pour le deuxième étage d'une turbine à gaz séquentielle |

| EP2894405B1 (fr) * | 2014-01-10 | 2016-11-23 | General Electric Technology GmbH | Dispositif à combustion séquentielle avec un gaz de dilution |

| WO2015150114A1 (fr) | 2014-04-03 | 2015-10-08 | Siemens Aktiengesellschaft | Brûleur, turbine à gaz munie dudit brûleur et injecteur de combustible |

| EP2933559A1 (fr) | 2014-04-16 | 2015-10-21 | Alstom Technology Ltd | Agencement de mélange de carburant et chambre de combustion avec un tel agencement |

| US10364684B2 (en) | 2014-05-29 | 2019-07-30 | General Electric Company | Fastback vorticor pin |

| CA2950011C (fr) | 2014-05-29 | 2020-01-28 | General Electric Company | Generateur de turbulence fastback |

| CN107076416B (zh) | 2014-08-26 | 2020-05-19 | 西门子能源公司 | 用于燃气涡轮发动机中的声共振器的薄膜冷却孔装置 |

| EP2993404B1 (fr) * | 2014-09-08 | 2019-03-13 | Ansaldo Energia Switzerland AG | Mélangeur de gaz ou d'air de dilution pour une chambre de combustion d'une turbine à gaz |

| US10233775B2 (en) | 2014-10-31 | 2019-03-19 | General Electric Company | Engine component for a gas turbine engine |

| US10280785B2 (en) | 2014-10-31 | 2019-05-07 | General Electric Company | Shroud assembly for a turbine engine |

| EP3023696B1 (fr) | 2014-11-20 | 2019-08-28 | Ansaldo Energia Switzerland AG | Lance à lobes pour chambre de combustion d'une turbine à gaz |

| EP3029378B1 (fr) | 2014-12-04 | 2019-08-28 | Ansaldo Energia Switzerland AG | Brûleur séquentiel pour une turbine à gaz axiale |

| EP3051206B1 (fr) * | 2015-01-28 | 2019-10-30 | Ansaldo Energia Switzerland AG | Agencement de combustion séquentielle d'une turbine à gaz avec un mélangeur et un amortisseur |

| CN104832912A (zh) * | 2015-04-08 | 2015-08-12 | 石家庄新华能源环保科技股份有限公司 | 一种多级接力燃烧装置 |

| EP3133342A1 (fr) * | 2015-08-20 | 2017-02-22 | Siemens Aktiengesellschaft | Brûleur à double carburant prémélangé avec un composant d'injection éfilé de carburant liquide principal |

| EP3354984B1 (fr) | 2017-01-31 | 2020-09-09 | Ansaldo Energia Switzerland AG | Injecteur à lobes pour une chambre de combustion de turbine à gaz |

| CN113932249B (zh) * | 2020-06-29 | 2022-10-18 | 中国航发商用航空发动机有限责任公司 | 燃烧室和前置扩压器 |

| CN112676054A (zh) * | 2020-12-17 | 2021-04-20 | 青岛科技大学 | 一种漩涡引导型超音速火焰喷涂喷枪装置 |

| US12085004B1 (en) * | 2023-03-31 | 2024-09-10 | Shandong University Of Science And Technology | Swirl structure-based exhaust aftertreatment device for underground mining diesel vehicle |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0321809A1 (fr) | 1987-12-21 | 1989-06-28 | BBC Brown Boveri AG | Procédé pour la combustion de combustible liquide dans un brûleur |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE370773C (de) * | 1923-03-06 | Eisenbahnwagen Und Maschinen F | Lueftungseinrichtung fuer Eisenbahnfahrzeuge | |

| US3974646A (en) * | 1974-06-11 | 1976-08-17 | United Technologies Corporation | Turbofan engine with augmented combustion chamber using vorbix principle |

| US4047877A (en) * | 1976-07-26 | 1977-09-13 | Engelhard Minerals & Chemicals Corporation | Combustion method and apparatus |

| FR2392231A1 (fr) * | 1977-05-23 | 1978-12-22 | Inst Francais Du Petrole | Turbine a gaz comportant une chambre de combustion entre les etages de la turbine |

| DE3474714D1 (en) * | 1983-12-07 | 1988-11-24 | Toshiba Kk | Nitrogen oxides decreasing combustion method |

| DE3742891A1 (de) * | 1987-12-17 | 1989-06-29 | Bayerische Motoren Werke Ag | Gasturbinenanlage |

| US5013236A (en) * | 1989-05-22 | 1991-05-07 | Institute Of Gas Technology | Ultra-low pollutant emission combustion process and apparatus |

| DE4202018C1 (en) * | 1992-01-25 | 1993-04-29 | Abb Patent Gmbh, 6800 Mannheim, De | Combustion chamber for gas turbine plant - has two catalyst holders consisting of honeycomb segments with flame holder downstream of them. |

| MX9206040A (es) * | 1992-03-05 | 1994-03-31 | Southwest Res Inst | Combustible y aditivo para reducir las emisiones de particulas procedentes de motores de encendido por compresion. |

| US5452574A (en) * | 1994-01-14 | 1995-09-26 | Solar Turbines Incorporated | Gas turbine engine catalytic and primary combustor arrangement having selective air flow control |

-

1994

- 1994-07-25 DE DE4426351A patent/DE4426351B4/de not_active Expired - Lifetime

-

1995

- 1995-05-25 US US08/449,752 patent/US5626017A/en not_active Expired - Lifetime

- 1995-07-05 EP EP95810442A patent/EP0694740A2/fr not_active Withdrawn

- 1995-07-20 JP JP7184330A patent/JPH08189641A/ja active Pending

- 1995-07-24 CN CN95108625A patent/CN1121570A/zh active Pending

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0321809A1 (fr) | 1987-12-21 | 1989-06-28 | BBC Brown Boveri AG | Procédé pour la combustion de combustible liquide dans un brûleur |

Cited By (35)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0718561B1 (fr) * | 1994-12-24 | 2001-03-14 | ABB (Schweiz) AG | Brûleur |

| EP0745809A1 (fr) * | 1995-06-02 | 1996-12-04 | ABB Management AG | Générateur de tourbillons pour chambre de combustion |

| EP1255080A1 (fr) * | 2001-04-30 | 2002-11-06 | ALSTOM (Switzerland) Ltd | Brûleur catalytique |

| US6609905B2 (en) | 2001-04-30 | 2003-08-26 | Alstom (Switzerland) Ltd. | Catalytic burner |

| EP1279898A3 (fr) * | 2001-07-26 | 2003-04-16 | ALSTOM (Switzerland) Ltd | Brûleur à prémélange offrant une haute stabilité de flamme |

| US7069727B2 (en) | 2003-02-11 | 2006-07-04 | Alstom Technology Ltd. | Method for operating a gas turbo group |

| WO2005095855A1 (fr) * | 2004-03-30 | 2005-10-13 | Alstom Technology Ltd | Dispositif et procede pour stabiliser une flamme |

| US7467942B2 (en) | 2004-03-30 | 2008-12-23 | Alstom Technology Ltd. | Device and method for flame stabilization in a burner |

| US8057224B2 (en) * | 2004-12-23 | 2011-11-15 | Alstom Technology Ltd. | Premix burner with mixing section |

| US8282037B2 (en) | 2007-11-13 | 2012-10-09 | United Technologies Corporation | Nacelle flow assembly |

| US9004399B2 (en) | 2007-11-13 | 2015-04-14 | United Technologies Corporation | Nacelle flow assembly |

| US8596573B2 (en) | 2007-11-13 | 2013-12-03 | United Technologies Corporation | Nacelle flow assembly |

| EP2071155A2 (fr) * | 2007-12-14 | 2009-06-17 | United Technologies Corporation | Ensemble formant nacelle ayant des turbulateurs |

| US8186942B2 (en) | 2007-12-14 | 2012-05-29 | United Technologies Corporation | Nacelle assembly with turbulators |

| US8192147B2 (en) | 2007-12-14 | 2012-06-05 | United Technologies Corporation | Nacelle assembly having inlet bleed |

| EP2071155A3 (fr) * | 2007-12-14 | 2012-02-22 | United Technologies Corporation | Ensemble formant nacelle ayant des turbulateurs |

| US8459985B2 (en) | 2008-03-07 | 2013-06-11 | Alstom Technology Ltd | Method and burner arrangement for the production of hot gas, and use of said method |

| WO2009109454A1 (fr) * | 2008-03-07 | 2009-09-11 | Alstom Technology Ltd | Procédé et ensemble brûleur servant à produire du gaz chaud et utilisation dudit procédé |

| US8468833B2 (en) | 2008-03-07 | 2013-06-25 | Alstom Technology Ltd | Burner arrangement, and use of such a burner arrangement |

| WO2009109448A1 (fr) * | 2008-03-07 | 2009-09-11 | Alstom Technology Ltd | Ensemble brûleur et son utilisation |

| US10119519B2 (en) | 2011-10-07 | 2018-11-06 | Wobben Properties Gmbh | Method and device for mounting a rotor of a wind energy plant |

| AU2012320439B2 (en) * | 2011-10-07 | 2016-05-19 | Wobben Properties Gmbh | Method and device for mounting a rotor of a wind energy plant |

| US9568198B2 (en) | 2012-03-23 | 2017-02-14 | General Electric Technology Gmbh | Combustion device having a distribution plenum |

| WO2013139914A1 (fr) * | 2012-03-23 | 2013-09-26 | Alstom Technology Ltd | Dispositif de combustion |

| EP2700878A3 (fr) * | 2012-08-24 | 2014-03-26 | Alstom Technology Ltd | Procédé pour mélanger un air de dilution dans un système de combustion séquentielle d'une turbine à gaz |

| AU2013219140B2 (en) * | 2012-08-24 | 2015-10-08 | Ansaldo Energia Switzerland AG | Method for mixing a dilution air in a sequential combustion system of a gas turbine |

| WO2014063835A1 (fr) * | 2012-10-24 | 2014-05-01 | Alstom Technology Ltd | Combustion séquentielle avec mélangeur de gaz d'appoint |

| RU2627759C2 (ru) * | 2012-10-24 | 2017-08-11 | Ансалдо Энерджиа Свитзерлэнд Аг | Последовательное сгорание со смесителем разбавляющего газа |

| US10330319B2 (en) | 2012-10-24 | 2019-06-25 | Ansaldo Energia Switzerland AG | Sequential combustion with dilution gas mixer |

| CN105371301B (zh) * | 2015-10-08 | 2017-12-08 | 北京航空航天大学 | 一种高温射流点火自稳焰的分级燃烧室 |

| CN105371301A (zh) * | 2015-10-08 | 2016-03-02 | 北京航空航天大学 | 一种高温射流点火自稳焰的分级燃烧室 |

| EP3267107A1 (fr) * | 2016-07-08 | 2018-01-10 | Ansaldo Energia IP UK Limited | Procédé de commande d'un ensemble de turbine à gaz |

| EP3889506A1 (fr) * | 2020-03-31 | 2021-10-06 | Siemens Aktiengesellschaft | Composant de brûleur d'un brûleur et brûleur d'une turbine à gaz doté d'un tel composant |

| WO2021197654A1 (fr) * | 2020-03-31 | 2021-10-07 | Siemens Aktiengesellschaft | Composant de brûleur d'un brûleur, et brûleur d'une turbine à gaz présentant un composant de brûleur de ce type |

| US12050012B2 (en) | 2020-03-31 | 2024-07-30 | Siemens Energy Global GmbH & Co. KG | Burner component of a burner, and burner of a gas turbine having a burner component of this type |

Also Published As

| Publication number | Publication date |

|---|---|

| JPH08189641A (ja) | 1996-07-23 |

| CN1121570A (zh) | 1996-05-01 |

| US5626017A (en) | 1997-05-06 |

| DE4426351A1 (de) | 1996-02-01 |

| DE4426351B4 (de) | 2006-04-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0694740A2 (fr) | Chambre de combustion | |

| EP0387532B1 (fr) | Chambre de combustion d'une turbine à gaz | |

| EP0718561B1 (fr) | Brûleur | |

| EP0401529B1 (fr) | Chambre de combustion d'une turbine à gaz | |

| EP0733861A2 (fr) | Chambre de combustion à combustion étagée | |

| EP0777081B1 (fr) | Brûleur à prémélange | |

| EP0629817B1 (fr) | Foyer | |

| DE4416650A1 (de) | Verbrennungsverfahren für atmosphärische Feuerungsanlagen | |

| DE19757189B4 (de) | Verfahren zum Betrieb eines Brenners eines Wärmeerzeugers | |

| EP0918190A1 (fr) | Brûleur pour la mise en oeuvre d'un générateur de chaleur | |

| EP0675322A2 (fr) | Brûleur à prémélange | |

| EP0687860A2 (fr) | Chambre de combustion à allumage automatique | |

| EP0481111B1 (fr) | Chambre de combustion pour turbine à gaz | |

| EP0724114A2 (fr) | Brûleur | |

| EP0851172B1 (fr) | Brûleur et méthode pour la mise en oeuvre d'une chambre de combustion avec un combustible liquide et/ou gazeux | |

| EP0521325A1 (fr) | Chambre de combustion | |

| EP0775869A2 (fr) | Brûleur à prémélange | |

| EP0994300B1 (fr) | Brûleur pour la conduite d'un générateur de chaleur | |

| EP0931980A1 (fr) | Brûleur pour la mise en oeuvre d'un générateur de chaleur | |

| EP0909921B1 (fr) | Brûleur pour la mise en oeuvre d'un générateur de chaleur | |

| EP0751351B1 (fr) | Chambre de combustion | |

| EP0483554B1 (fr) | Procédé pour la réduction au minimum des émissions de NOx dans une combustion | |

| DE19537636B4 (de) | Kraftwerksanlage | |

| DE4242003A1 (de) | Prozesswärmeerzeuger | |

| EP0866268B1 (fr) | Procédé de fonctionnement d'un brûleur stabilisé par vortex et brûleur mettant en oeuvre le procédé |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE FR GB NL |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19980220 |