EP0694658A1 - Dispositif de maintien de tuiles - Google Patents

Dispositif de maintien de tuiles Download PDFInfo

- Publication number

- EP0694658A1 EP0694658A1 EP95108397A EP95108397A EP0694658A1 EP 0694658 A1 EP0694658 A1 EP 0694658A1 EP 95108397 A EP95108397 A EP 95108397A EP 95108397 A EP95108397 A EP 95108397A EP 0694658 A1 EP0694658 A1 EP 0694658A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- roof

- anchor

- fastening device

- section

- spoke

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D1/00—Roof covering by making use of tiles, slates, shingles, or other small roofing elements

- E04D1/34—Fastenings for attaching roof-covering elements to the supporting elements

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D1/00—Roof covering by making use of tiles, slates, shingles, or other small roofing elements

- E04D1/29—Means for connecting or fastening adjacent roofing elements

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D1/00—Roof covering by making use of tiles, slates, shingles, or other small roofing elements

- E04D1/34—Fastenings for attaching roof-covering elements to the supporting elements

- E04D2001/3408—Fastenings for attaching roof-covering elements to the supporting elements characterised by the fastener type or material

- E04D2001/3411—Metal wires or rods

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D1/00—Roof covering by making use of tiles, slates, shingles, or other small roofing elements

- E04D1/34—Fastenings for attaching roof-covering elements to the supporting elements

- E04D2001/3408—Fastenings for attaching roof-covering elements to the supporting elements characterised by the fastener type or material

- E04D2001/3414—Metal strips or sheet metal

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D1/00—Roof covering by making use of tiles, slates, shingles, or other small roofing elements

- E04D1/34—Fastenings for attaching roof-covering elements to the supporting elements

- E04D2001/3408—Fastenings for attaching roof-covering elements to the supporting elements characterised by the fastener type or material

- E04D2001/3438—Fasteners comprising several coacting elements

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D1/00—Roof covering by making use of tiles, slates, shingles, or other small roofing elements

- E04D1/34—Fastenings for attaching roof-covering elements to the supporting elements

- E04D2001/3452—Fastenings for attaching roof-covering elements to the supporting elements characterised by the location of the fastening means

- E04D2001/3455—Fastenings for attaching roof-covering elements to the supporting elements characterised by the location of the fastening means on the internal surface of the roof covering elements

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D1/00—Roof covering by making use of tiles, slates, shingles, or other small roofing elements

- E04D1/34—Fastenings for attaching roof-covering elements to the supporting elements

- E04D2001/3452—Fastenings for attaching roof-covering elements to the supporting elements characterised by the location of the fastening means

- E04D2001/3467—Fastenings for attaching roof-covering elements to the supporting elements characterised by the location of the fastening means through apertures, holes or slots

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04D—ROOF COVERINGS; SKY-LIGHTS; GUTTERS; ROOF-WORKING TOOLS

- E04D1/00—Roof covering by making use of tiles, slates, shingles, or other small roofing elements

- E04D1/34—Fastenings for attaching roof-covering elements to the supporting elements

- E04D2001/347—Fastenings for attaching roof-covering elements to the supporting elements characterised by the fastening pattern

- E04D2001/3482—Fastenings for attaching roof-covering elements to the supporting elements characterised by the fastening pattern the fastening means taking hold directly on elements of succeeding rows and fastening them simultaneously to the structure

Definitions

- the invention relates to a fastening device for roof tiles.

- Brackets which connect a roof tile to a roof batten.

- the object of the invention is to provide an improved fastening device for roof tiles.

- a fastening device for roof tiles which consists of an anchor which can be attached to a roof batten and a spoke which can be connected to a roof tile and which engages in an eyelet of the anchor.

- the roof battens are reliably held securely in a simple manner by the interaction of the spoke with the anchor.

- the anchor preferably consists of a bent wire. This has the advantage that the anchor can be formed in one piece, which is particularly inexpensive.

- the wire is preferably galvanized. However, it is also possible to choose other materials. It is advantageous if the anchor is made of a corrosion-resistant material that has good tensile strength.

- the anchor preferably has a section encompassing a roof batten or another part of the roof.

- the arrangement is preferably made in such a way that the anchor with this section can preferably be plugged onto the batten from below. If the anchor is held in place on the roof batten, it is particularly easy and safe to install. With the previously known solutions, it can happen that the clips previously used fall down during assembly. This is not possible according to the advantageous development of the invention, so that the assembly is simplified and made more secure.

- the reliable attachment of the anchor to the roof batten can preferably be achieved in that the distance between the parts of the anchor surrounding the roof batten is slightly smaller than the thickness of the roof batten, so that the anchor is held on the roof batten by the frictional force generated by the bending.

- a further advantageous development is characterized in that the distance of the eyelet from the section of the anchor resting on the rear side of the roof batten is greater than the thickness of the roof batten and the thickness of the roof tile. In this way it is ensured that the eyelet projects beyond the roof tile, so that the spoke can engage in the eyelet particularly simply and reliably.

- the spoke penetrates a hole in the roof tile. In this way, the spoke can be connected to the roof tile in a particularly simple manner.

- the spoke can have a straight section, at the end of which a bend can be provided.

- This configuration can be combined particularly advantageously with the further development, according to which the spoke penetrates a hole in the roof tile. In this case, the spoke passes through the hole with its straight section.

- the bend which is preferably at right angles, but which can also include another angle with the straight section, then prevents the spoke from falling out of the hole. This also simplifies assembly and makes it safer.

- the spoke preferably consists of spring steel. But it can also consist of other suitable materials.

- the material used for the spoke is preferably corrosion-resistant. Furthermore, the material should have good flexural strength since it is generally subjected to bending. It should also have a certain elasticity in order to be able to return to its starting position when deflected.

- the roof tile has a fastening lug.

- the fastening lug is preferably located on the back of the roof tile. It is advantageous if the hole already mentioned above is provided in the fastening lug.

- the fastening lug can then be dimensioned such that it can absorb the forces exerted on the roof tile by the spoke via the fastening lug.

- the armature consists of a bent sheet metal. This is generally associated with a larger material requirement. In this way, however, the anchor can be produced in a particularly simple manner.

- the eyelet is preferably punched out of the sheet metal. This can happen before the sheet is bent. However, it can also take place during the bending of the sheet or afterwards.

- the anchor has a bend at its end adjoining the eyelet.

- the armature consists of a bent sheet metal.

- the bend is preferably designed such that it points in the direction of the roof tiles when the anchor is installed.

- the fastening device according to the invention is particularly suitable for fastening hollow pans. However, it can also be used with advantage for fastening other roof tiles, for example pans, but also for interlocking tiles and similar tiles, as well as roof tiles of all kinds.

- the fastening device according to the invention serves in particular as a storm protection for roof tiles.

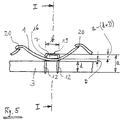

- the roof tile 1 lies on the front upper edge of the cross section of the rectangular crossbar 3 with its rearward projecting hanging nose 2 located at its upper end.

- the lower section 4 of an anchor 5 encompasses the lower half of the roof batten 3.

- the spoke 8 passes through the eyelet 7 of the armature 5.

- the spoke 8 passes through a rearward-projecting fastening lug 10 provided on the underside of the next upper roof tile 9 in its lower region, in which a straight hole which accommodates the spoke 8 is provided, which runs essentially parallel to the longitudinal direction of the roof tile 9.

- the armature 5 is bent from a single galvanized wire; so it is one piece.

- the section 4 encompassing the roof batten 3 in turn consists of a front section 11, a lower section 12 and a rear section 13.

- the front section 11 and the rear section 13 run essentially parallel to one another. Their distance from each other is slightly less than the thickness d of the roof batten, so that the compressive force that arises due to the elasticity of the anchor 5 during spreading generates a frictional force between the anchor 5 and the roof batten 3 that is sufficiently large to prevent the anchor 5 from falling to prevent from the roof batten 3.

- the angle between the front section 11 and the middle section 12 is slightly less than 90 °.

- the angle between the middle section 12 and the rear section 13 is somewhat larger than 90 °. As a result, the clamping effect is further improved.

- the rear section 13 of the anchor 5 lies against the rear side of the roof batten 3. It extends beyond the rear upper end of the roof batten 3. There is then a forward-facing bend 14, which is followed by an inclined section 15, which in the exemplary embodiment shown extends at an angle of approximately 45 °, but for which other angle sizes can also be selected.

- a section 16 pointing forward bends which forms the eyelet 7 at its front end.

- the front section 16 runs essentially at right angles to the rear section 13 and to the front section 11 and almost parallel to the central section 12.

- the section 16 pointing forward also runs essentially at right angles to the longitudinal direction of the roof tile 1.

- the distance a of the eyelet 7 from the section 13 of the anchor 5 resting on the rear side of the roof batten 3 is greater than the thickness d of the roof batten 3 and the thickness D of the roof tile 1. This ensures that the eyelet 7 by the measure a - (d + D) protrudes from the front 17 of the roof tile 1, so that the spoke 8 can engage in the eyelet 7.

- the front end 19 of the armature 5 has a width b which is several times greater than the thickness or the diameter of the spoke 8. Furthermore, the front end 19 of the armature 5 runs essentially in the manner shown in FIG right angle to the subsequent section 16.

- the way that the armature 5 does not have to be positioned exactly in the middle of the brick 1 is achieved in the manner which is particularly clearly visible from FIG. 5. Even if the anchor 5 is shifted slightly on the roof batten 3 or if the anchor 5 has not been positioned in the exact right place, the spoke 8 can still engage in the eyelet 7 of the anchor 5. The spoke 8 is then not exactly in the middle of the section 19. However, this does not impair the functionality of the fastening device.

- the roof tiles 1, 9 are designed as hollow panes, the brim 20 which lies at the left end of the hollow pan and which is curved downward engages over the right upper end of the hollow pan following on the left side.

- the armature 5 is shown from the view of the arrow 21 in FIG. 1.

- FIG. 3 shows the armature 5 from the view of the arrow 22 in FIG. 2.

- the armature 5 is shown in a perspective view.

- FIG. 5 shows the hollow tile 1, the roof batten 3 and the anchor 5 from the perspective of arrow 23 in FIG. 1.

- FIG. 1 shows a section along the line I-I in FIG. 5.

- the anchor 5 engages around a roof batten 3.

- the anchor 5 it is also possible for the anchor 5 to be fastened or fastened to another part of the roof.

- the fastening device consists of two parts, namely the anchor 5 and the spoke 8.

- the roof tile 9 On the back of the roof tile 9 (the roof tile 1 is identical to the roof tile 9) there is a fastening possibility for the spoke 8, which in the exemplary embodiment consists of the fastening lug 10 the hole therein for receiving the spoke 8.

- the fastening elements namely the armature 5 and the spoke 8 are designed to be favorable according to their type of loading.

- a force directed towards the armature acts on the armature and is introduced through the spoke 8 into the eyelet 7 of the armature 5.

- Section 16 is only loaded on train, section 15 is mainly loaded on train and only slightly on bending.

- the section 13, which is actually loaded on bending, rests on the back of the roof batten 3, so that its bending stress is also only slight.

- the anchor 5 is almost exclusively subjected to tension, which is very favorable from a load point of view. Accordingly, it is sufficient to choose a material for the armature 5 that is high Has tensile strength. Good flexural strength does not have to be present.

- the material should also be corrosion-resistant.

- stainless steel is also particularly suitable, but is relatively expensive.

- the spoke 8 is also subjected to bending, so that the material selected for it should also be resistant to bending.

- Spring steel is particularly advantageous.

- other materials can also be considered.

- the material for the spoke 8 should also be corrosion-resistant. It should also have a certain elasticity in order to be able to return to the starting position after a deflection caused by wind forces or other forces.

- the fastening device fixes the next lower roof tile 1 between the next upper roof tile 9 and the roof batten 3 or the other roof element. It is a two-part fastening system consisting of anchor 5 and spoke 8. However, since these two parts fasten two roof tiles 1, 9, only one fastening part is required per roof tile.

- each roof tile using a fastening device according to the invention.

- a fastening device for only part of the roof tiles, for example fastening every second, third, fourth, etc. roof tile.

- the composite effect of the overlapping roof tiles also holds those roof tiles on which there is no fastening device.

- the assembly is done as follows: First the anchor 5 from stuck to the roof batten 3 below. Then the roof tile 1 is placed on the roof batten 3. Then the spoke 8 is inserted from above into the hole in the fastening lug 10 of another roof tile 9. The roof tile 9 prepared in this way is then placed on the next top roof batten, in such a way that the lower end of the spoke 8 passes through the eyelet 7 in the manner shown in FIG. 1.

- the front section 11 of the anchor 5 can be slightly bent inwards.

- the upper end of the front section 11 is therefore closer to the rear section 13 than the junction of the sections 11 and 12.

- the upper part 6 of the anchor 5 engages over the upper end and the hanging lug 2 of the (next lower) roof tile 1, which rests on the roof batten 3, to which the anchor 5 is also attached.

- the spoke 8, which is connected to the next roof tile 9, engages in the eyelet 7 of this anchor 5.

- the upper end of the next lower roof tile 1, including its hanging nose is clamped in the manner described between the roof batten 3, the upper part 6 of the anchor 5 and the lower part of the spoke 8 and the lower part of the next lower roof tile 9.

- Holding forces can be absorbed by the fastening system according to the invention, which are significantly higher than in previously known solutions.

- the fastening lug 10 is dimensioned such that it can absorb the required forces.

- FIGS. 6 and 7 show a modified embodiment in which the armature 5 consists of a bent sheet metal.

- the sheet is bent or folded at various points, so that essentially the same shape arises as in the embodiment already described above.

- the eyelet 7 is punched out of the sheet.

- the armature 5 has a bend 24 at its end adjoining the eyelet 7.

- the bend 24 forms an angle with the forwardly pointing section 16, in which the eyelet 7 formed by the punching is located.

- section 16 does not run parallel to section 12, but at an angle to the outside, that is to say to the end of the bend 24.

- An obtuse angle is included between the section 16 and the bend 24, which is dimensioned such that the bend 24 runs approximately parallel to the section 11.

- the bend 24 is directed outwards from the section 16.

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Mechanical Engineering (AREA)

- Roof Covering Using Slabs Or Stiff Sheets (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4421098A DE4421098A1 (de) | 1994-06-16 | 1994-06-16 | Befestigungsvorrichtung für Dachziegel |

| DE4421098 | 1994-06-16 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0694658A1 true EP0694658A1 (fr) | 1996-01-31 |

Family

ID=6520770

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP95108397A Withdrawn EP0694658A1 (fr) | 1994-06-16 | 1995-05-31 | Dispositif de maintien de tuiles |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0694658A1 (fr) |

| DE (1) | DE4421098A1 (fr) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19854771C1 (de) * | 1998-11-27 | 2000-02-17 | Ossenberg Schule & Soehne | Vorrichtung zur Befestigung von Dacheindeckungsteilen an der Lattung eines Daches |

| EP1462585A1 (fr) * | 2003-03-28 | 2004-09-29 | Friedrich Ossenberg-Schule & Söhne GmbH. & Co. KG. | Crochet de retenue de tuile |

| WO2006032488A1 (fr) * | 2004-09-24 | 2006-03-30 | Creaton Ag | Dispositif pour fixer des tuiles faitieres posees seches |

| US8082716B1 (en) | 2009-02-19 | 2011-12-27 | Worley Ronald J | Roofing tile system |

| US8087206B1 (en) | 2009-02-19 | 2012-01-03 | Worley Ronald J | Roofing tile system |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008046341A1 (de) * | 2008-09-09 | 2010-03-11 | Nibra-Dachkeramik Gmbh & Co Kg | Sicherheitsvorrichtung zur Sicherung von Eindeckelementen für Dächer und Fassaden |

| DE102008057852B4 (de) * | 2008-11-18 | 2015-09-10 | Wienerberger Gmbh | Sturmklammer zum Festlegen eines Ziegels oder dergleichen Dach- oder Fassadeneindeckelementes auf einer Unterkonstruktion |

| EP2672032A1 (fr) * | 2012-06-06 | 2013-12-11 | Monier Roofing Components GmbH | Crochet anti-tempête à utilisation universelle |

| DE102014011027A1 (de) * | 2014-07-24 | 2016-01-28 | Eternit Ag | Dachsteine oder Dachziegel und Halteklammern für ein Dacheindeckungssystem mit Windsogsicherung |

| NO340620B1 (en) * | 2015-08-26 | 2017-05-15 | Tee As | Taksteinklips for å sikre en sidekant av en nedre del av en takstein til en lekt. |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE173698C (fr) * | ||||

| FR670491A (fr) * | 1928-06-19 | 1929-11-29 | Perfectionnements dans les tuiles mécaniques et dans leur dispositif d'accrochage aux liteaux | |

| DE604484C (de) * | 1934-10-22 | Vollmeyer & Sohn | Zweiteiliger gelenkiger Halter zur Befestigung von Dachziegeln an Dachlatten | |

| AU521428B2 (en) * | 1978-02-10 | 1982-04-01 | John Lysaght (Australia) Limited | Adjustable tile hold-down clip |

| GB2172620A (en) * | 1985-01-23 | 1986-09-24 | Madison Lang Limited | Roofing systems |

-

1994

- 1994-06-16 DE DE4421098A patent/DE4421098A1/de not_active Withdrawn

-

1995

- 1995-05-31 EP EP95108397A patent/EP0694658A1/fr not_active Withdrawn

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE173698C (fr) * | ||||

| DE604484C (de) * | 1934-10-22 | Vollmeyer & Sohn | Zweiteiliger gelenkiger Halter zur Befestigung von Dachziegeln an Dachlatten | |

| FR670491A (fr) * | 1928-06-19 | 1929-11-29 | Perfectionnements dans les tuiles mécaniques et dans leur dispositif d'accrochage aux liteaux | |

| AU521428B2 (en) * | 1978-02-10 | 1982-04-01 | John Lysaght (Australia) Limited | Adjustable tile hold-down clip |

| GB2172620A (en) * | 1985-01-23 | 1986-09-24 | Madison Lang Limited | Roofing systems |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19854771C1 (de) * | 1998-11-27 | 2000-02-17 | Ossenberg Schule & Soehne | Vorrichtung zur Befestigung von Dacheindeckungsteilen an der Lattung eines Daches |

| EP1462585A1 (fr) * | 2003-03-28 | 2004-09-29 | Friedrich Ossenberg-Schule & Söhne GmbH. & Co. KG. | Crochet de retenue de tuile |

| WO2006032488A1 (fr) * | 2004-09-24 | 2006-03-30 | Creaton Ag | Dispositif pour fixer des tuiles faitieres posees seches |

| US8082716B1 (en) | 2009-02-19 | 2011-12-27 | Worley Ronald J | Roofing tile system |

| US8087206B1 (en) | 2009-02-19 | 2012-01-03 | Worley Ronald J | Roofing tile system |

Also Published As

| Publication number | Publication date |

|---|---|

| DE4421098A1 (de) | 1995-12-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102007011194B3 (de) | Befestigungsclip zur Befestigung von Rohren | |

| DE19805062A1 (de) | Kabelbinder aus Metall | |

| EP0694658A1 (fr) | Dispositif de maintien de tuiles | |

| DE3046297A1 (de) | Anordnung zur befestigung von vertaefelungselementen | |

| AT500454B1 (de) | Endklemme für ein isoliertes oberirdisches kabel | |

| DE3248438A1 (de) | Halterung fuer gitterzaeune | |

| DE3038019C2 (de) | Rasterdecke | |

| DE2626443B2 (de) | Befestigung von Plattenverbindern | |

| DE2229988C2 (de) | Zaun mit Zaunfeldern aus Baustahl-Bewehrungsmatten | |

| DE4413959B4 (de) | Kennzeichnungsvorrichtung für elektrische Leiter | |

| AT402833B (de) | Vorrichtung zur befestigung von firstabdeckungen am dachfirst einer dacheindeckung | |

| DE19635677B4 (de) | Rohr- schlauch- oder sonstige schellenartige Verbindung | |

| DE3941097C1 (en) | Cable channel or tray support - has coupling element fixable from above in form of shaft fitting selectable slots and with projection to act like hook | |

| DE2749247C3 (de) | Gehrungsverbindung für Türrahmenbekleidungen | |

| DE4404390C2 (de) | Haltevorrichtung für Wandschalungen | |

| DE202005016907U1 (de) | Spange zur Befestigung eines Pflanzstabes an einem Spanndraht | |

| AT369825B (de) | Daemmstoffhalter fuer fassadenverkleidungen | |

| DE19900612C2 (de) | Vorrichtung zum Aufhängen von Gegenständen an Deckenverkleidungen | |

| DE3240311A1 (de) | Vorrichtung zur nachgiebigen verbindung ineinandergelegter profile | |

| DE2128553B2 (de) | Anordnung zum Befestigen eines Kupplungsstucks fur Betonschalungen | |

| DE29605344U1 (de) | Vorrichtung zur Befestigung von Firstabdeckungen an dem Dachfirst einer Dacheindeckung | |

| DE2703674B2 (de) | Vorrichtung zum Halten von Dacheindeckungsplatten auf einem Kehlblech | |

| DE29800938U1 (de) | Abfangkonsole | |

| DE2431367C2 (de) | Türzarge aus Metall | |

| DE202019104235U1 (de) | Verbinder von Zaunteilen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): BE DE DK NL SE |

|

| 17P | Request for examination filed |

Effective date: 19960311 |

|

| 17Q | First examination report despatched |

Effective date: 19980429 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION HAS BEEN WITHDRAWN |

|

| 18W | Application withdrawn |

Withdrawal date: 19991104 |