EP0640711B1 - Verfahren und Vorrichtung zum Entbasten von Seidengeweben - Google Patents

Verfahren und Vorrichtung zum Entbasten von Seidengeweben Download PDFInfo

- Publication number

- EP0640711B1 EP0640711B1 EP93116816A EP93116816A EP0640711B1 EP 0640711 B1 EP0640711 B1 EP 0640711B1 EP 93116816 A EP93116816 A EP 93116816A EP 93116816 A EP93116816 A EP 93116816A EP 0640711 B1 EP0640711 B1 EP 0640711B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- degumming

- silk fabric

- arms

- kier

- supporting rod

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004744 fabric Substances 0.000 title claims description 52

- 238000000034 method Methods 0.000 title claims description 8

- 230000008878 coupling Effects 0.000 claims description 5

- 238000010168 coupling process Methods 0.000 claims description 5

- 238000005859 coupling reaction Methods 0.000 claims description 5

- 230000000630 rising effect Effects 0.000 claims 1

- 239000000725 suspension Substances 0.000 description 4

- 230000001174 ascending effect Effects 0.000 description 2

- 108010013296 Sericins Proteins 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000002932 luster Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 238000011282 treatment Methods 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06B—TREATING TEXTILE MATERIALS USING LIQUIDS, GASES OR VAPOURS

- D06B17/00—Storing of textile materials in association with the treatment of the materials by liquids, gases or vapours

- D06B17/06—Storing of textile materials in association with the treatment of the materials by liquids, gases or vapours in festooned form

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06B—TREATING TEXTILE MATERIALS USING LIQUIDS, GASES OR VAPOURS

- D06B5/00—Forcing liquids, gases or vapours through textile materials to effect treatment, e.g. washing, dyeing, bleaching, sizing impregnating

- D06B5/12—Forcing liquids, gases or vapours through textile materials to effect treatment, e.g. washing, dyeing, bleaching, sizing impregnating through materials of definite length

- D06B5/22—Forcing liquids, gases or vapours through textile materials to effect treatment, e.g. washing, dyeing, bleaching, sizing impregnating through materials of definite length through fabrics

Definitions

- This invention relates to a method and a device for degumming a silk fabric.

- a method and device for degumming a fabric in a degumming kier as described in the first part of claims 1 and 3 is known from US-A-3753358 in which the silk fabric is hung in a spiral pattern as viewed from top so that its width extends vertically.

- a device comprising a degumming kier, a supporting rod arranged vertically along the central axis of said degumming kier and a plurality of arms extending radially from said supporting rod at a predetermined height, each of said arms being provided with hooks arranged in a longitudinal direction.

- GB-A-1081479 and FR-A-2228020 disclose similar fabric treatments.

- Fig. 10 illustrates another conventional method of degumming silk in which silk fabrics a folded in a longitudinal direction are hung in a rectangular degumming kier 1.

- a degumming solution b is fed into the degumming kier 1 from its top, discharged from its bottom and resupplied into the kier from its top, so that the solution is circulated through the degumming kier 1.

- the degumming solution b flows downwards in the degumming kier, whereas the silk fabrics a are folded in a longitudinal direction.

- the degumming solution does not flow uniformly into the inner layers of the folded silk fabrics, so that they cannot be degummed uniformly over the entire length thereof.

- An object of the present invention is to provide a degumming method and device which permits a uniform circulation of the degumming solution throughout the degumming kier, while facilitating the work for fixing the fabric in the kier.

- Another object is to provide a degumming method and device which improves the workability.

- the top edge of the silk fabric are fixed at a plurality of points arranged in a spiral pattern as viewed from top so as to rise gradually outwardly from the center of the spiral pattern.

- the spiral shape of the silk fabric should be such that the inclination of the plane extending from the center of spiral pattern to its outer periphery increases gradually.

- the device for degumming a silk fabric may comprise a degumming kier, a supporting rod arranged vertically along the central axis of the degumming kier, and a plurality of arms extending radially from the supporting rod at a predetermined height, each of the arms being provided with hooks arranged in a row in its longitudinal direction.

- the arms should be inclined upwardly outwards. Further, such a device should further comprise a vertically movable sleeve concentrically threaded around the supporting rod, the arms extending from the sleeve.

- the arms should be designed so as to be pivotable up and down about their inner ends.

- the device should be further provided with a sleeve vertically movably mounted on the upper part of the supporting rod so as to be driven from outside, and coupling levers connecting the sleeve to the arms so that the arms can be pivoted by the vertical movement of the sleeve through the coupling levers.

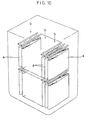

- the degumming kier should preferably be shaped cylindrically.

- Gaps between the adjacent layers of the spirally wound silk fabric extend through the entire height of the fabric.

- the degumming solution can flow freely through these gaps. Since such gaps are present over the entire area in the degumming kier, the degumming solution is circulated uniformly over the entire area in the degumming kier.

- the hooks for hanging the silk fabric are arranged so that outer ones are located higher than inner ones, an operator can hang the fabric on inner hooks without being hindered by outer ones. Even though the hooks are arranged upwardly outwards, the fabric can be fixed at the same level by gradually lowering the entire arms.

- the silk fabric may shrink while degumming. But since it is fixed to the hooks along the top edge, only the portion near the bottom edge shrinks markedly while its top portion scarcely shrinks, so that the fabric might be distorted in the longitudinal direction.

- the top edge of the fabric should be moved in such a way that the inclination of the plane defined by the top edge of the fabric increases gradually from its center to outer periphery. With this arrangement, the distances between the circumferentially adjacent fixing points can be reduced gradually. This can compensate for any shrinkage of the fabric. Thus, the fabric is kept free from distortion.

- the spirally wound silk fabric has a cylindrical outer configuration.

- the degumming kier should also have a cylindrical shape because by doing so, a degumming solution can be circulated smoothly while keeping its amount to a minimum.

- the degumming solution can be distributed uniformly throughout the degumming kier, so that the silk fabric can be degummed uniformly. Also, the silk fabric can be hung easily.

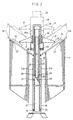

- a supporting rod 12 extends vertically along the axis of a cylindrical degumming kier 11.

- the kier has a lid 13 driven by a cylinder 14 between open and closed positions and is filled with a degumming solution b .

- the solution is discharged from the bottom of the kier 11 and sucked up by a pump P through a strainer 15, fed through a supply pipe 16 and sprayed back into the kier 11 through a perforated tray 17. The solution is thus circulated.

- a rotary sleeve 18 is rotatably mounted on the supporting rod 12 through a thrust bearing 19 and metals 20 (Fig. 2).

- a guide cylinder 21 is secured by screws to the top end of the rotary sleeve 18.

- a square-threaded hollow shaft 22 is inserted in the top end of the supporting rod 12 and coupled thereto by a key 23 (Fig. 3).

- a vertically movable hollow shaft (referred to as “sleeve” in the claims) 24 is coaxially threaded into the square-threaded shaft 22.

- the hollow shaft 24 can be moved up and down along the square-threaded hollow shaft 22 (supporting rod 12) by rotating it about its own axis. Its movement is guided by a guide lever 25 provided at the bottom end of the hollow shaft 24 and slidably fitted in a vertical guide groove 21a formed in the guide cylinder 21 (Fig. 4).

- the vertically movable hollow shaft 24 and the rotary sleeve 18 are not rotatable relative to each other.

- Arms 26 extend radially outwardly from the mid-portion of the hollow shaft 24 so as to be arranged at equal intervals (Fig. 4).

- the arms 26 are pivotable about their inner ends.

- the number of arms 26 is determined according to how a silk fabric a is suspended.

- Hooks 27 are provided on each arm 26 at equal intervals in its longitudinal direction.

- a guide cylinder 28 is secured to the vertically movable hollow shaft 24 through a boss 28' (Fig. 2).

- a sleeve 29 is vertically movably threaded on the hollow shaft 24 at its portion surrounded by the guide cylinder 28.

- a ring 30 is rotatably fitted on the sleeve 29.

- Support plates 31 protrude from the ring 30 outwardly through grooves 28a formed in the guide cylinder 28.

- An annular frame 32 is secured to the free ends of the support plates 31 (Fig. 4).

- the annular frame 32 carries rollers 33 on its underside at portions opposite the arms 26.

- the rollers 33 are received in respective guide frames 34 of the arms 26 (Fig. 6).

- the rollers move in the guide frames 34, so that the arms 26 pivot up and down.

- the lid 13 has in the center an opening in which is fitted a packing 37 (see Fig. 1).

- a handle shaft 35 By inserting a handle shaft 35, the opening can be liquid-tightly sealed.

- the handle shaft 35 has a square tip which is inserted in a square hole formed in the top end face of the sleeve 29. By turning the handle shaft 35 in this state, the sleeve 29 can be moved up and down with respect to the vertically movable hollow shaft 24.

- a suspension mechanism including the supporting rod 12 is taken out of the degumming kier 11 and placed on the ground by means of a crane.

- the vertically movable hollow shaft 24 is raised until the arms 26 reach their highest position.

- silk fabric a is hitched, from inside to outside, to the hooks 27 on the arms 26 so that it is hung from the hooks in a spiral pattern as shown in Fig. 9.

- the silk fabric can be attached to the inner hooks of each arm without being hindered by the outer ones of the same arm.

- the hollow shaft 24 can be rotated to lower it. By doing so, one can attach the fabric at the same height. Thus, the operator can do his work easily.

- the suspension mechanism is brought back into the degumming kier 11 so that the supporting rod 12 is disposed on the center axis as shown in Fig. 1.

- the lid 13 is then closed.

- the handle shaft 35 is pulled out as shown by chain line in Fig. 1 to prevent its tip from abutting the sleeve 29.

- the handle shaft 35 is pushed in until its tip is received in the square hole 29a formed in the sleeve 29.

- degumming solution b is supplied into the degumming kier 11 and circulated through the kier to degum the silk fabric.

- the handle shaft 35 is turned gradually to move the sleeve 29 upwards and thus to pivot the arms 26 upwards.

- the plane containing the top edge of the silk fabric becomes gradually steep (Fig. 9).

- the distances between the circumferentially adjacent hooks decrease gradually.

- the ascending speed of the sleeve 29 varies according to the kind of silk fabric and may be determined through actual operations or experiments.

- the handle shaft 35 may be driven by a motor. In this case, the arms 26 can be moved automatically by controlling the motor speed.

- the suspension mechanism is taken out of the kier 11 together with the degummed silk fabric and the silk fabric is detached from the hooks 27.

- the vertically movable hollow shaft 24 is turned in such a direction that it ascends. By doing so, the fabric can be detached from the hooks at the same height.

- the arms 26 come to the position shown by chain lines in Fig. 2.

- the mechanism for pivoting the arms 26 may comprise the sleeve 29 and coupling levers 36 coupled to the sleeve 29 and the respective arms 26 through pins.

- a liquid-tight door may be provided on one side of the degumming kier 11. This door allows access to the interior of the kier, so that it is not necessary to take the suspension mechanism out of the kier in order to hang a silk fabric.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Textile Engineering (AREA)

- Treatment Of Fiber Materials (AREA)

- Coloring (AREA)

- Chemical Or Physical Treatment Of Fibers (AREA)

- Treatments For Attaching Organic Compounds To Fibrous Goods (AREA)

Claims (4)

- Verfahren zum Entbasten eines Seidengewebes (a) in einem Entbastungs-Beuchapparat (11), wobei der obere Rand des Seidengewebes (a) an einer Vielzahl von Befestigungspunkten (27) eines Trägeraufbaus (26) nacheinander befestigt wird, so daß das Seidengewebe (a) von oben betrachtet in einem Spiralmuster aufgehängt ist, wobei sich seine Breite vertikal erstreckt,

dadurch gekennzeichnet, daßdie Befestigungspunkte (27) des Trägeraufbaus auf unterschiedlichen Höhen sind, die vom Mittelpunkt des Spiralmusters nach außen hin fortschreitend ansteigen, unddas Seidengewebe (a) an den Befestigungspunkten (27) nacheinander vom Mittelpunkt des Spiralmusters nach außen hin befestigt wird, während der Trägeraufbau (26) fortschreitend abgesenkt wird, so daß der Befestigungsvorgang an jedem der Befestigungspunkte (27) auf derselben Höhe durchgeführt werden kann. - Verfahren zum Entbasten eines Seidengewebes (a) nach Anspruch 1,

dadurch gekennzeichnet, daß

der von der Seite betrachtete, vom oberen Rand des Seidengewebes (a) und einer vertikalen Achse gebildete Winkel mit fortschreitender Entbastung fortschreitend vergrößert wird. - Vorrichtung zum Entbasten eines Seidengewebes (a), mit einem Entbastungs-Beuchapparat (11); einer Trägerstange (12), die entlang der Mittelachse des Entbastungs-Beuchapparats (11) vertikal angeordnet ist; und einer Vielzahl von Armen (26), die sich von der Trägerstange (12) auf einer vorbestimmten Höhe radial erstrecken; wobei jeder der Arme (26) mit in seiner Längsrichtung beabstandeten Haken (27) versehen ist,

dadurch gekennzeichnet, daß

die Arme (26) nach außen hin nach aufwärts geneigt sind; und daß die Vorrichtung weiterhin eine um die Trägerstange (12) herum konzentrisch aufgeschraubte, vertikal bewegliche Hülse (29) sowie die Hülse (29) mit den Armen (26) verbindende Koppelhebel (31) aufweist, so daß die Arme (26) mittels der vertikalen Bewegung der Hülse (29) über die Koppelhebel (31) geschwenkt werden können. - Vorrichtung zum Entbasten eines Seidengewebes (a) nach Anspruch 3,

dadurch gekennzeichnet, daß

die Arme (26) um ihre inneren Enden herum nach oben und nach unten schwenkbar sind; und daß die vertikal bewegliche Hülse (29) auf einem oberen Teil der Trägerstange (12) gelagert ist, um von außen her angetrieben zu werden.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP21642293A JP3187616B2 (ja) | 1993-08-31 | 1993-08-31 | 絹織物の精練 |

| JP216422/93 | 1993-08-31 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0640711A1 EP0640711A1 (de) | 1995-03-01 |

| EP0640711B1 true EP0640711B1 (de) | 1997-08-06 |

Family

ID=16688322

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP93116816A Expired - Lifetime EP0640711B1 (de) | 1993-08-31 | 1993-10-18 | Verfahren und Vorrichtung zum Entbasten von Seidengeweben |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0640711B1 (de) |

| JP (1) | JP3187616B2 (de) |

| KR (1) | KR970004711B1 (de) |

| CN (1) | CN1051821C (de) |

| DE (1) | DE69312935T2 (de) |

| TW (1) | TW251323B (de) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ZA200804379B (en) | 2005-12-16 | 2009-09-30 | Unilever Plc | Surface-active material and its application |

| RU2009118385A (ru) | 2006-10-17 | 2010-11-27 | Юнилевер Н.В. (Nl) | Пищевая композиция, содержащая пузырьки газа, и способ ее приготовления |

| CN104278454B (zh) * | 2014-09-24 | 2016-02-17 | 张家港市华益纺织有限公司 | 一种用于丝织物精练的夹层练桶 |

| CN106435763B (zh) * | 2016-10-20 | 2018-12-04 | 东华大学 | 丝素蛋白纤维规模化生产的全自动脱胶装备及其使用方法 |

| CN113235168B (zh) * | 2021-06-29 | 2022-08-26 | 四川梓潼林江苎麻纺织有限责任公司 | 一种苎麻的脱胶装置及脱胶方法 |

| CN113832752A (zh) * | 2021-10-27 | 2021-12-24 | 天津工业大学 | 一种基于超临界二氧化碳的染整方法 |

| CN114293266B (zh) * | 2021-12-27 | 2024-01-26 | 河南民兴生物科技股份有限公司 | 一种蚕丝脱胶装置和方法 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH361556A (de) * | 1958-01-17 | 1962-04-30 | Scholl Ag | Einrichtung, um Behandlungsmittel, z.B. eine Farbflotte, durch zylindrisch gewickeltes Textilgut durchströmen zu lassen |

| GB1081479A (en) * | 1964-09-01 | 1967-08-31 | Dupius & Co D | Apparatus for spirally winding fabric of like webs |

| BE768515A (fr) * | 1970-11-11 | 1971-11-03 | Masuda Masa | Methode et appareil destines au traitement liquide d'un tissu long et large |

| ES414924A1 (es) * | 1973-05-05 | 1976-02-01 | Marti Gavalda | Mecanismo para el arrollado de tejidos en proceso de vapo- rizado de estampados. |

-

1993

- 1993-08-31 JP JP21642293A patent/JP3187616B2/ja not_active Expired - Fee Related

- 1993-10-18 DE DE69312935T patent/DE69312935T2/de not_active Expired - Fee Related

- 1993-10-18 EP EP93116816A patent/EP0640711B1/de not_active Expired - Lifetime

- 1993-10-21 KR KR1019930021914A patent/KR970004711B1/ko not_active IP Right Cessation

- 1993-10-22 TW TW082108806A patent/TW251323B/zh active

- 1993-11-11 CN CN93114369A patent/CN1051821C/zh not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| KR950006071A (ko) | 1995-03-20 |

| JP3187616B2 (ja) | 2001-07-11 |

| EP0640711A1 (de) | 1995-03-01 |

| DE69312935D1 (de) | 1997-09-11 |

| CN1102675A (zh) | 1995-05-17 |

| KR970004711B1 (ko) | 1997-04-02 |

| JPH0770910A (ja) | 1995-03-14 |

| TW251323B (de) | 1995-07-11 |

| DE69312935T2 (de) | 1998-03-12 |

| CN1051821C (zh) | 2000-04-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0640711B1 (de) | Verfahren und Vorrichtung zum Entbasten von Seidengeweben | |

| EP1109962B1 (de) | Waschmaschine | |

| JPH115065A (ja) | 洗浄装置 | |

| US5099661A (en) | Circular knitting machine | |

| EP0263979B1 (de) | Anlage zum Ausmauern der Innenwand eines Gefässes | |

| EP1344860B1 (de) | Behälter zum Färben von Textilmaterialen | |

| GB2203813A (en) | Parts washer | |

| EP1602764B1 (de) | Korb, Maschine und Anlage zum Färben von Textilmaterialien | |

| JPH11503971A (ja) | 焼結品のオイル処理のための装置 | |

| JP2843297B2 (ja) | 炊飯装置における給水装置 | |

| CN215302656U (zh) | 一种自动翻转起锅装置 | |

| EP0513514B1 (de) | Reifenvulkanisiervorrichtung | |

| CN220046522U (zh) | 一种中药蒸煮锅 | |

| US4852270A (en) | Hydroextractor for yarns on a reel | |

| CN111411482B (zh) | 一种衣物处理设备及控制方法 | |

| US2207682A (en) | Stock dyeing apparatus | |

| WO1999035319A1 (en) | Centrifuge device for wet treatment of textile material | |

| JPS636668B2 (de) | ||

| JP3710026B2 (ja) | 炊飯装置 | |

| CZ231791A3 (cs) | Pračka se samotížným usměrněným oběhem pracího media | |

| JPH0728803B2 (ja) | 炊飯装置 | |

| AU3568700A (en) | Laundry machine | |

| CN112301590A (zh) | 一种自动开盖出料的筒纱染色缸 | |

| US3986375A (en) | Apparatus for space dyeing yarn and product | |

| JPS6145094Y2 (de) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19941213 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): DE FR GB IT |

|

| 17Q | First examination report despatched |

Effective date: 19951204 |

|

| GRAG | Despatch of communication of intention to grant |

Free format text: ORIGINAL CODE: EPIDOS AGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAH | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOS IGRA |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19970806 |

|

| REF | Corresponds to: |

Ref document number: 69312935 Country of ref document: DE Date of ref document: 19970911 |

|

| ITF | It: translation for a ep patent filed | ||

| EN | Fr: translation not filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19990831 Year of fee payment: 7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19991215 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20001018 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20001018 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010703 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051018 |