EP0416717B1 - Cage de laminoir pour un laminoir planétaire - Google Patents

Cage de laminoir pour un laminoir planétaire Download PDFInfo

- Publication number

- EP0416717B1 EP0416717B1 EP90250213A EP90250213A EP0416717B1 EP 0416717 B1 EP0416717 B1 EP 0416717B1 EP 90250213 A EP90250213 A EP 90250213A EP 90250213 A EP90250213 A EP 90250213A EP 0416717 B1 EP0416717 B1 EP 0416717B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- rolling

- roll stand

- chocks

- supporting member

- segments

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000005096 rolling process Methods 0.000 title claims description 81

- 230000002787 reinforcement Effects 0.000 claims description 3

- 238000009434 installation Methods 0.000 description 5

- 230000000712 assembly Effects 0.000 description 2

- 238000000429 assembly Methods 0.000 description 2

- 229910000760 Hardened steel Inorganic materials 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 238000011179 visual inspection Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B13/00—Metal-rolling stands, i.e. an assembly composed of a stand frame, rolls, and accessories

- B21B13/18—Metal-rolling stands, i.e. an assembly composed of a stand frame, rolls, and accessories for step-by-step or planetary rolling; pendulum mills

- B21B13/20—Metal-rolling stands, i.e. an assembly composed of a stand frame, rolls, and accessories for step-by-step or planetary rolling; pendulum mills for planetary rolling

Definitions

- the invention relates to a roll stand for a planetary rolling mill with stand, stationary support bodies with rolling segments, which are mounted in chocks, and are mounted in cages around the intermediate and work rolls rotating around the support bodies; see e.g. DE-C 1 140 534.

- the Platzer planetary rolling mill named after its developer, the work rolls are brought against the centrifugal force against the intermediate rolls and these against the supporting bodies by disc spring assemblies when circulating around the stationary supporting bodies.

- the surface of the support body constitutes an exact cylinder surface. In this area of the forming zone, the rolling surface deviates from the exact circular arc shape in order to ensure a perfect, i.e. to ensure groove-free rolling surface.

- This roller geometry which deviates from the exact cylinder surface, is realized for wear reasons by means of rolling segments inserted into the support body.

- These rolling segments which form the rolling path for the intermediate rolls, are made of hardened steel and are interchangeably fastened in recesses in the supporting body.

- the rolling segments are subjected to very high mechanical loads, because in the forming zone the radial rolling forces in the stationary support body are applied via them be directed. High Hertzian pressures occur during the forming process when the support rollers roll on the roll segment. With a number of 24 support rollers per cage, each rolling segment is rolled over 24 times with each rotation of the cage.

- the invention has for its object to significantly increase the time intervals between changing the rolling segments and to reduce the work involved.

- the rolling segments currently in use are so worn out after approximately 25 hours of operation, even with optimal heat treatment, that they have to be replaced.

- the support body is now equipped with 4 rolling segments evenly distributed over the circumference, the support bodies are simply extended out of the roll stand, rotated through 90 ° and reinstalled. In this way, the next of the four rolling segments comes into the working position.

- rotating the support body coincides with every fourth regrinding of the work rolls. This means that no separate removal and installation is necessary for rotating the support bodies, since they are only rotated through 90 ° and reinstalled every fourth grinding of the work rolls, if they have to be removed anyway.

- Two rolling rings are suitable for this, one on each side of the support body.

- the intermediate rolls are also guided on a perfect circular path in the region of the three rolling segments which are not in engagement, so that a jerky placement of the intermediate rolls is avoided.

- the rolling rings In the work area, the rolling rings have recesses so that the rollers can rest on the flattening of the rolling segments.

- the chocks have a square basic shape, with the help of which the exact positioning of the rolling segments, each offset by 90 °, is achieved.

- the advantage of the rolling stand according to the invention is that the active rolling segments only after one Operating time of approx. 100 hours must be replaced, and that when the work rolls are replaced or regrind at this point anyway, the next pair of rolling segments is brought into the working position by installing the support body rotated through 90 °.

- the removal and installation of the rolling segments is no longer necessary, as is the removal and reinstallation of 5 work rolls and 5 intermediate rolls. It is also achieved that the 4 pairs of worn rolling segments are replaced when the work rolls have to be replaced, so that no additional work and assembly work is required.

- An alternative embodiment of the invention is that the chocks are octagonal and each support body has eight rolling segments. This has the advantage that the time span between the necessary replacement of the rolling segments can be doubled again.

- An advantageous development of the invention consists in that the two rolling rings of a support body can be rotated relative to the support body by a rotating device and can be braced against the support body by clamping devices. This makes it possible to turn the rolling rings relative to the support body by 90 ° or 45 ° in a simple and quick manner. This rotation is necessary so that the cut-outs of the rolling rings match the processing zone again. With these devices, the rolling rings are rotated without disassembly and assembly work and under the pressure of the disc spring packets. In order to turn the rolling rings, are arranged between the rolling segments (preferably the four) solved, with the help of which the rings are clamped against the support body during operation.

- each support body is expediently rotated synchronously by the required 90 ° or 45 °.

- the rolling rings on the side facing the support body are provided with an internal toothing.

- Drive pinions engage in this internal toothing and are mounted on a common shaft that runs in a bore in the support body and is rotatably mounted therein.

- the drive takes place by means of a drive unit with a stepper motor arranged in one of the chocks, so that an exact positioning in the installed state can be carried out without measuring and regulating device and without visual inspection.

- a hydraulic reinforcement and a self-locking gear are arranged between it and the pinion.

- This self-locking gear (eg a worm gear) has the advantage that it reliably prevents shaking in the operating state, ie a gradual overcoming of the clamping force of the clamping device.

- the clamping devices are advantageously designed as clamping cylinders which are arranged in bores in the support body.

- the clamping force is generated by disc springs, the loosening for turning the rolling rings is done by pressurizing the cylinder space.

- the free end of the piston rod has a head or a slot nut which engages in an annular groove of the rolling segment, which is incorporated on the surface facing the support body. When the cylinder is relieved, the spring force of the disc spring pulls the Roll-off ring firmly against the support body.

- the edge lengths or the distance between the side surfaces of the latter are smaller than the outer diameter of the planetary gear set.

- Two strips are provided for each chock, which are screwed onto the vertical side surfaces of the chocks according to the installation position and are mounted accordingly when the support body is turned by 90 ° or 45 °. This is the only manual action when rotating the support body.

- the support bodies In order to facilitate the respective rotation of the support bodies, they can be equipped with pivot pins at each end, which protrude beyond the chocks. This means that the support body can be rotated by 90 ° or after the planetary roller has moved out of the stand. 45 ° in a rotating device standing next to the roll stand.

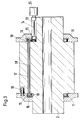

- Fig. 1 the upper part of a planetary mill is shown in cross section.

- the chock 1, in which the support body 2 is held in the stand 4, is guided in the stand 4 by means of strips 3. These strips 3 are unscrewed when the chocks 1 are rotated (in the example by 90 °) and screwed back into the new mounting position on the vertical side faces of the chocks 1.

- the four rolling segments 5 are screwed into the support body 2 offset by 90 °. Due to the geometry of the rolling segments 5 which differs from an exact cylindrical shape, the work rolls 6, which are supported on the intermediate rolls 7, are guided in the roll gap in such a way that the rolling material 8 receives a perfect surface.

- the work rolls 6 are drawn in the direction of the support body axis 9 as they rotate around the support body 2 by disc spring assemblies (not shown).

- the four clamping devices 10 arranged in the support body 2 lie between the rolling segments 5.

- each support body 2 is provided with a rolling ring 11 at both ends, as shown in FIG. 2.

- These rolling rings 11, on which the intermediate rolls 7 roll, can be rotated on the supporting body 2, but are arranged in a locked manner during the rolling, and apart from a recess 12 in the area of the roll gap circular profile.

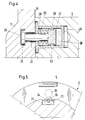

- Fig. 3 the two devices are shown, by means of which the two rolling rings 11 can be locked or rotated on the support body 2. Only one of the eight clamping devices 10, which are arranged in each support body 2, is shown here. To rotate the rolling rings 11 mounted on the support body 2, the clamping devices 10 (details are explained with reference to FIG. 4) are released. The drive takes place via the drive unit 35 (details are explained with reference to FIG. 6) and a shaft 14 mounted in a recess 13 of the support body 2. The pinion 15 fastened on the shaft 14 is in engagement with one of the two drive pinions 16, which are on a shaft 18 extending in a bore 17 of the support body 2 are fastened. These drive pinions 16 are in engagement with the internal toothing 19 of the rolling rings 11.

- the rolling ring 11 has an annular groove 20 into which the head or the sliding block 21 of the tie rod 22 engages.

- the tie rod 22 also represents the piston rod of the clamping cylinder 23, which is arranged in a bore 24 of the support body 2.

- the plate spring 25 which is supported on the one hand on the inner wall 26 of the clamping cylinder 23 and on the other hand on the piston 27 provided with a seal 28, the rolling ring 11 with the inner surface 29 is pulled firmly against the support body 2.

- the cylinder spaces 30 are subjected to such a high pressure that the tensioning force of the plate springs 25 is overcome.

- Fig. 5 shows the arrangement of the shaft 14 in the Recess 13 of the support body 2.

- the pillow block bearing is designated 31.

- the pinion 15, a drive pinion 16 and a rolling segment 5 can also be seen.

- the drive unit 12 (FIG. 6) consists of a stepper motor 32 which is flanged to a hydraulic amplifier 33 (for example an electrohydraulic rotary amplifier, type SVIR from Hartmann & Lämmle).

- the output side of the hydraulic reinforcement 33 is connected to a self-locking gear 34 (for example a worm gear).

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Metal Rolling (AREA)

- Reduction Rolling/Reduction Stand/Operation Of Reduction Machine (AREA)

- Rolling Contact Bearings (AREA)

Claims (7)

- Cage pour un laminoir planétaire, comportant des colonnes (4), des corps d'appui fixes (2), montés dans des empoises (1) et présentant des segments de roulement (5), et des cylindres intermédiaires (7) et de travail (6) montés dans des cages autour des corps d'appui,

caractérisée en ce que les empoises (1) présentent une forme de base quadratique, chaque corps d'appui (2) est muni de quatre segments de roulement (5) répartis régulièrement à la périphérie et, à chaque extrémité, d'une bague de roulement rotative (11) présentant un évidement (12). - Cage de laminoir selon le préambule de la revendication 1,

caractérisée en ce que les empoises (1) présentent une forme de base octogonale, chaque corps d'appui (2) est muni de huit segments de roulement (5) répartis régulièrement à la périphérie et, à chaque extrémité, d'une bague de roulement rotative (11) présentant un évidement (12). - Cage de laminoir selon la revendication 1 ou 2,

caractérisée en ce que les deux bagues de roulement (11) de chaque corps d'appui (2) peuvent être tournées par un dispositif de rotation par rapport au corps d'appui (2) et peuvent être serrées contre le corps d'appui (2) par des dispositifs de serrage (10). - Cage de laminoir selon la revendication 3,

caractérisée en ce que les bagues de roulement (11) présentent une denture interne (19), et le dispositif de rotation est constitué d'un moteur pas à pas (32), monté à l'extérieur des empoises (1), d'un amplificateur hydraulique (33), d'une transmission à blocage automatique (34), et d'un arbre (18), s'étendant dans des perçages (17) du corps d'appui (2), à pignons d'entraînement (16) fixés sur celui-ci. - Cage de laminoir selon la revendication 3 ou 4,

caractérisée en ce que les dispositifs de serrage (10) sont constitués de vérins de serrage (23) à rondelles-ressorts (25), qui sont agencés dans les corps d'appui (2), et de tirants d'ancrage (22), et en ce que les bagues de roulement (11) présentent, pour recevoir les tirants d'ancrage (22), des gorges annulaires (20) sur la surface (29) en regard du corps d'appui (2). - Cage de laminoir selon une des revendications 1 à 5,

caractérisée en ce que les empoises (1) sont équipées, chacune, de deux barres (3) qui sont vissées de façon correspondant à la position de montage des corps d'appui (2). - Cage de laminoir selon une de revendications 1 à 6,

caractérisée en ce que les corps d'appui (2) présentent, à chaque extrémité, des tourillons faisant saillie vers l'extérieur au-dessus des empoises (1).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3928962A DE3928962C1 (fr) | 1989-08-29 | 1989-08-29 | |

| DE3928962 | 1989-08-29 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0416717A2 EP0416717A2 (fr) | 1991-03-13 |

| EP0416717A3 EP0416717A3 (en) | 1991-04-10 |

| EP0416717B1 true EP0416717B1 (fr) | 1993-03-31 |

Family

ID=6388357

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90250213A Expired - Lifetime EP0416717B1 (fr) | 1989-08-29 | 1990-08-16 | Cage de laminoir pour un laminoir planétaire |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US5035131A (fr) |

| EP (1) | EP0416717B1 (fr) |

| CA (1) | CA2024120A1 (fr) |

| DE (2) | DE3928962C1 (fr) |

| ES (1) | ES2040039T3 (fr) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4041367A1 (de) * | 1990-12-20 | 1992-07-02 | Mannesmann Ag | Walzgeruest fuer ein planetenwalzwerk |

| TW206929B (fr) * | 1992-03-16 | 1993-06-01 | Yoshida Keiichiro | |

| US6334583B1 (en) | 2000-02-25 | 2002-01-01 | Hui Li | Planetary high-energy ball mill and a milling method |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2932997A (en) * | 1954-06-11 | 1960-04-19 | Sendzimir Tadeusz | Dual drive planetary reducing mills |

| DE1260417B (de) * | 1957-01-26 | 1968-02-08 | Peter Platzer Dr | Planeten-Walzwerk |

| US3522720A (en) * | 1968-04-04 | 1970-08-04 | Tadeusz Sendzimir | Planetary workroll cages for planetary rolling mills |

| DE2556974C3 (de) * | 1975-12-18 | 1981-10-08 | J. Fischer Kg, 5902 Netphen | Profilwalzmaschine |

| EP0316072A3 (fr) * | 1987-11-09 | 1990-08-29 | Ian Wilson Technology Limited | Laminoir |

-

1989

- 1989-08-29 DE DE3928962A patent/DE3928962C1/de not_active Expired - Fee Related

-

1990

- 1990-08-16 ES ES199090250213T patent/ES2040039T3/es not_active Expired - Lifetime

- 1990-08-16 EP EP90250213A patent/EP0416717B1/fr not_active Expired - Lifetime

- 1990-08-16 DE DE9090250213T patent/DE59001114D1/de not_active Expired - Fee Related

- 1990-08-28 US US07/573,853 patent/US5035131A/en not_active Expired - Fee Related

- 1990-08-28 CA CA002024120A patent/CA2024120A1/fr not_active Abandoned

Also Published As

| Publication number | Publication date |

|---|---|

| CA2024120A1 (fr) | 1991-03-01 |

| DE59001114D1 (de) | 1993-05-06 |

| EP0416717A2 (fr) | 1991-03-13 |

| DE3928962C1 (fr) | 1990-12-06 |

| ES2040039T3 (es) | 1993-10-01 |

| EP0416717A3 (en) | 1991-04-10 |

| US5035131A (en) | 1991-07-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69502550T2 (de) | Profilanpassung für Vielwalzengerüste | |

| DE69205925T2 (de) | Cluster-Walzwerk mit Balligkeitsregelungssystem. | |

| EP1668263B1 (fr) | Ensemble support rotatif d'un corps rotatif | |

| DE2506449A1 (de) | Vorgespanntes universalwalzwerk | |

| DE593557C (de) | Walzwerk mit fliegend angeordneten Arbeitswalzen | |

| DE2646769A1 (de) | Presswalze mit durchbiegungskontrollvorrichtung | |

| DE68904079T2 (de) | Walzwerk und Walzwerkanlage. | |

| DE3609290A1 (de) | Schraegwalzwerk | |

| DE2530401A1 (de) | Walzenvorrichtung | |

| EP0416717B1 (fr) | Cage de laminoir pour un laminoir planétaire | |

| DE2341485A1 (de) | Druckfluidum-rotationsmaschine | |

| DE2119389C3 (de) | Baukastensystem für den Aufbau beliebiger Ständeranordnungen von Walzenmaschinen, insbesondere Kalandern | |

| EP0386861B1 (fr) | Laminoir planétaire et dispositif de rectification des cylindres de travail | |

| CH688191A5 (de) | Spindel. | |

| EP0203279B1 (fr) | Cylindre, de préférence cylindre de contre-pression d'un cylindre gravé dont la chemise peut être courbée | |

| DE10144743B4 (de) | Walzgerüst zum Walzen von stab- oder rohrförmigem Gut | |

| DE4035275C1 (fr) | ||

| DE705907C (de) | Exzenteranstellung fuer die Walzen von Walzwerken | |

| DE1752283C3 (de) | Mehrgerüstiges Universalwalzwerk, insbesondere Drahtwalzwerk mit drei Walzen pro Gerüst | |

| DE69003473T2 (de) | Walzgerüst mit leicht wechselbaren Walzgesenken. | |

| DE2303467A1 (de) | Walzgeruest fuer stangen, bloecke oder bleche | |

| DE2435916A1 (de) | Rollende lagerung vornehmlich fuer vorschubeinrichtungen von drehschmiedewalzwerk-drehstangen | |

| EP1699574A1 (fr) | Procede et dispositif pour soumettre a une precontrainte des paliers coniques a rouleaux d'un cylindre de laminoir | |

| DE19509768C2 (de) | Lager | |

| DE463891C (de) | Vorrichtung zur Lagerung der Walzen bei Walzwerken |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): DE ES FR GB IT |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE ES FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19910319 |

|

| 17Q | First examination report despatched |

Effective date: 19920519 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE ES FR GB IT |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 59001114 Country of ref document: DE Date of ref document: 19930506 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19930705 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2040039 Country of ref document: ES Kind code of ref document: T3 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19950714 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19950721 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19950802 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19950912 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19960816 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 19960817 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19960816 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19970430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19970501 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 19990601 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050816 |