EP0270858B1 - Buse de sortie équipant les orifices d'entrée d'un bain tourbillonnant - Google Patents

Buse de sortie équipant les orifices d'entrée d'un bain tourbillonnant Download PDFInfo

- Publication number

- EP0270858B1 EP0270858B1 EP87116544A EP87116544A EP0270858B1 EP 0270858 B1 EP0270858 B1 EP 0270858B1 EP 87116544 A EP87116544 A EP 87116544A EP 87116544 A EP87116544 A EP 87116544A EP 0270858 B1 EP0270858 B1 EP 0270858B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- outlet

- piston

- channel

- nozzle according

- outlet nozzle

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 68

- 238000007789 sealing Methods 0.000 claims description 16

- 239000000872 buffer Substances 0.000 claims description 8

- 239000000463 material Substances 0.000 claims description 4

- 230000015572 biosynthetic process Effects 0.000 claims description 2

- 239000011248 coating agent Substances 0.000 claims description 2

- 238000000576 coating method Methods 0.000 claims description 2

- 230000000903 blocking effect Effects 0.000 claims 1

- 238000000034 method Methods 0.000 claims 1

- 230000007704 transition Effects 0.000 claims 1

- 238000009826 distribution Methods 0.000 abstract description 21

- 230000000694 effects Effects 0.000 abstract description 10

- 238000004140 cleaning Methods 0.000 description 9

- 239000000203 mixture Substances 0.000 description 9

- 239000007788 liquid Substances 0.000 description 8

- 238000011001 backwashing Methods 0.000 description 3

- 238000010276 construction Methods 0.000 description 3

- 239000011324 bead Substances 0.000 description 2

- 239000000356 contaminant Substances 0.000 description 2

- 230000001105 regulatory effect Effects 0.000 description 2

- 238000003287 bathing Methods 0.000 description 1

- 230000037396 body weight Effects 0.000 description 1

- 238000011109 contamination Methods 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 230000009760 functional impairment Effects 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 239000012535 impurity Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 210000003127 knee Anatomy 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 210000003903 pelvic floor Anatomy 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61H—PHYSICAL THERAPY APPARATUS, e.g. DEVICES FOR LOCATING OR STIMULATING REFLEX POINTS IN THE BODY; ARTIFICIAL RESPIRATION; MASSAGE; BATHING DEVICES FOR SPECIAL THERAPEUTIC OR HYGIENIC PURPOSES OR SPECIFIC PARTS OF THE BODY

- A61H33/00—Bathing devices for special therapeutic or hygienic purposes

- A61H33/60—Components specifically designed for the therapeutic baths of groups A61H33/00

- A61H33/601—Inlet to the bath

- A61H33/6021—Nozzles

- A61H33/6057—Comprising means producing pulsating or intermittent streams

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61H—PHYSICAL THERAPY APPARATUS, e.g. DEVICES FOR LOCATING OR STIMULATING REFLEX POINTS IN THE BODY; ARTIFICIAL RESPIRATION; MASSAGE; BATHING DEVICES FOR SPECIAL THERAPEUTIC OR HYGIENIC PURPOSES OR SPECIFIC PARTS OF THE BODY

- A61H33/00—Bathing devices for special therapeutic or hygienic purposes

- A61H33/02—Bathing devices for use with gas-containing liquid, or liquid in which gas is led or generated, e.g. carbon dioxide baths

- A61H33/027—Gas-water mixing nozzles therefor

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61H—PHYSICAL THERAPY APPARATUS, e.g. DEVICES FOR LOCATING OR STIMULATING REFLEX POINTS IN THE BODY; ARTIFICIAL RESPIRATION; MASSAGE; BATHING DEVICES FOR SPECIAL THERAPEUTIC OR HYGIENIC PURPOSES OR SPECIFIC PARTS OF THE BODY

- A61H33/00—Bathing devices for special therapeutic or hygienic purposes

- A61H33/60—Components specifically designed for the therapeutic baths of groups A61H33/00

- A61H33/601—Inlet to the bath

- A61H33/6021—Nozzles

- A61H33/6063—Specifically adapted for fitting in bathtub walls

Definitions

- the invention relates to an outlet nozzle for the outlet valve of a whirlpool tub with a water supply channel and an air supply channel, in which the water flow is mixed with the air flow due to the action of an injector.

- a nozzle combination with an axially movable jet deflection plate which can achieve sealing on its circumferential line with respect to a nozzle housing.

- a water supply line opens into the nozzle housing below the jet deflection plate, while air can be supplied to the lower opening of the nozzle housing.

- the beam deflection plate has a cylindrical approach, in which irradiation openings are kept clear. When the water supply line or the opening is pressurized, the jet deflecting plate can lift axially upwards from its lower sealing position up to a stop, as a result of which water and air can escape together from the jet openings into the tub interior.

- the disadvantage here is that the position of the jet deflector can be influenced from the outside, in particular the jet deflector is pressed into the closed position under the body weight of the tub user, which due to the geometric conditions the injector effect is only relatively small and that the jet deflector is only returned to its sealing position due to its own weight reached.

- a nozzle for an air bubbler of a water basin is proposed, which is supplied through a channel with water.

- a check valve is provided at the nozzle outlet, which is opened by pump pressure and closes automatically, preferably by spring force or moved by the bath water flowing back in, as soon as the pump pressure is switched off.

- the flow rate can also be regulated by means of the check valve by opening more or less cross-section.

- the check valve acts as a baffle plate and widens the escaping water jet, which improves the mixing of air and water and reduces the size of the air bubbles.

- DE-U-8 606 463 (FIG. 10) also proposes a nozzle combination in which the extension of an air supply nozzle projects into the air-guiding channel. Coaxial to the air supply nozzle, a support flange is inserted into the basin wall, which carries an axially adjustable ring with a conical inner bore, which together with the air supply nozzle forms an annular channel, the free cross section of which can be changed by adjusting the ring. Dirty bath water can penetrate into the nozzle combination and deposit there.

- DE-U-8 606 463 (FIG.

- nozzle combination in which a water-air mixture is fed via a check valve to an axially fixed baffle plate through which the water-air mixture passes axially and under which the water-air mixture can exit into the interior of the pool through an outlet opening parallel to the pool floor.

- dirty bath water can accumulate inside the nozzle housing.

- a device must be connected upstream, with which the water-air mixture is first produced.

- a nozzle combination for the supply of compressed air is also proposed, in which in a carrier flange which in the The basin wall or the pelvic floor is clamped, a cover valve is seated, which in the idle state runs almost at the same level as the installation level, is lifted out of its seat when pressure is present and releases the outlet path for the compressed air. When the air pressure drops, the cover valve is returned to its valve seat. This can be done by the water column in the inner pool or by its own weight or by spring force.

- a check valve can be provided in the supply line.

- the compressed air can exit axially or essentially radially into the inner basin. Through the axial outlet opening, contaminated bath water can penetrate into the nozzle housing and settle there even when the nozzle combination is closed. An injector effect is not intended, a special device would be required for this. Another disadvantage is that the opening position can be affected by the pool user.

- a nozzle combination is known from EP-A-0 209 646 (FIG. 10), which belongs to the state of the art only according to ⁇ 54 (3) EPC, but which essentially corresponds to the nozzle combination of FIG. 10 of DE-U-8 606 463 additionally has an independent check valve in the outlet channel of a steering jet nozzle.

- the check valve is already loaded with a water-air mixture so that there is no longer any injector effect.

- the air supply nozzle is also provided with an outer ring-shaped stop, which means that if a ring is adjusted, the volume can be regulated until the air supply is completely shut off.

- the ring used to adjust the volume can also be equipped as an independent check valve or the restoring force of the returning bath water can be used. This creates a relatively complex construction and the additional disadvantage that on the one hand on the check valve formed by the adjustable ring the compressed air and on the other hand the water pressure acts, which creates undefined conditions.

- the object of the invention is to design an outlet nozzle of the type mentioned at the outset such that a high hydro-pneumatic massage effect can be achieved if the outlet nozzle is prevented from being contaminated by impurities present in the water of the whirlpool.

- an outlet nozzle for the outlet valve of a whirlpool tub with a water supply channel and an air supply channel in which the water flow is mixed with the air flow due to the action of an injector, in that the water supply channel merges into a radially outwardly leading annular outlet channel , which is formed in a plate-shaped distribution body and the valve body of the outlet valve, that the preferably annular air supply duct opens into an annular space between the plate-shaped distribution body and the valve body or the valve housing or the tub wall which adjoins the outlet duct radially outwards, and that with the inner surface of the distribution body, the outlet channel and / or the surfaces forming the intermediate space of at least one concentrically surrounding the water supply channel Precise piston movable relative to the valve body are formed, which in its closed position closes the outlet channel and / or the space adjoining the outlet channel in a liquid and / or gas-tight manner.

- the contaminants in the water of the whirlpool such as hair, dirt particles or the like, cannot settle in the outlet nozzle and thus lead to a functional impairment or even blockage of the outlet nozzle.

- the piston While in the open position of the piston or pistons Piston surfaces with the inner surface of the distribution body form the outlet channel and the space adjoining it radially outwards, the piston moves or the pistons move with their surfaces essentially axially toward the inner surface of the distribution body when the outlet nozzle is switched off, so that at least one opposite Areas of these surfaces ensure a liquid-tight seal of the water supply duct and / or the air supply duct.

- the at least one piston is expediently guided in the valve body or on the valve housing or on the tub wall for the axial stroke movement.

- the air supply duct has individual air supply ducts which are in flow connection with bores which extend axially in the piston.

- the bores of the air supply duct can merge into an annular duct opening into the intermediate space.

- the bores arranged in the piston or the annular duct of the air supply duct open or open into the intermediate space immediately behind an outlet slot formed in the edge region of the outlet duct.

- the surfaces of the distribution body and the piston that come into contact with one another in the closed position of the piston but at least the areas of the surfaces of the piston that come into contact with the inner surface of the distribution body as sealing surfaces, optionally with a flexible surface Coating or a pad or insert made of rubber or the like.

- the surfaces of the piston which extend to the bores or the annular channel of the air supply channel or which extend on both sides of the outlet slot of the outlet channel are arranged such that they are offset with respect to one another in such a way that they correspond to the inner surface of the distribution body Surface delimiting the space jumps back relative to the surface delimiting the outlet channel, and that the piston wall adjoining the surface delimiting the outlet channel has a recess in the region of the outlet slot or the air supply channel, via which a sealing strip of flexible material connected to the piston surface is flexible in the open position of the piston Material, possibly with the formation of the outlet slot, extends in a substantially tangential direction to the piston surface, which is pressed into the recess in the closed position of the piston.

- This advantageous embodiment according to the invention makes it possible to provide only a reciprocating piston with bores for the air supply and at the same time to keep the height of the intermediate space larger than the width of the outlet slot for a uniform flow of the water-air mixture and low noise.

- the recess in the piston wall is provided with an axial depth which is approximately the result of the piston surface assigned to the intermediate space and over itself Air supply channel or the bores in the piston tangential inwardly extending line is specified.

- the front section of the sealing strip which projects beyond the expansion and in the open position of the piston with the inner surface of the distribution body forms the outlet slot, is pressed into the recess in the closed position, the resulting bead of the flexible sealing strip being pressed against the inner surface of the distribution body.

- the piston can be moved from the closed position into the open position against the force of a spring energy store by the force or pressure of the water flowing out of the water supply channel.

- the spring force accumulator is advantageously formed by springs, rubber buffers or the like, which are arranged in an annular space that essentially concentrically surrounds the water supply channel between the piston and a bearing surface of the valve body.

- the annular space provided in the valve body has a wall area extending axially upward from the support surface for receiving the piston mounted on the spring force accumulator, that an inner wall area arranged concentrically to the water supply channel of the piston forms an annular gap with the wall region of the valve body facing it, and that the annular space opens into a return channel which extends axially downward in the valve body and which is possibly connected to the outflow of the whirlpool tub via a shut-off device.

- cleaning of the outlet nozzle according to the invention is advantageously achieved by injecting a cleaning liquid through the water supply channel into the outlet nozzle, and thus an outlet channel which is sealed against the ingress of water and possibly against a supplied air, and which is injected via the water supply channel into the Valve body provided annular space flows and from there through a return channel into the drain of the jacuzzi.

- the pressure of the cleaning liquid emerging from the outlet openings of the water supply channel is to be determined such that the piston or pistons remain or remain in their closed position. This achieves an effective backwashing or cleaning of the outlet nozzle according to the invention.

- ring-shaped rubber buffers concentrically surrounding the water supply channel are provided on both sides of the air supply channel, which at least in the closed position of the piston keep an area of the annular space free and thereby separate them from one another in two liquid and / or gas-tight manner Divide sections with the radially outer section communicating with the air supply duct.

- the annular gap expediently has approximately half of the Width of the outlet slot corresponding width of 0.1 to 1 mm, preferably 0.6 mm, so that in the open position of the piston even in the absence of a shut-off element between the return channel and the outflow of the whirlpool, only a small amount of the water introduced into the water supply channel during operation the outlet nozzle is lost.

- the distribution body can be held, for example, by a bayonet, screw, suction, plug-in or magnetic connection on the valve body, which may have an axial extension, or be formed integrally therewith. Further advantageous features of the outlet nozzle according to the invention emerge from claims 14 to 20. These serve essentially a simple construction with high effectiveness of the emerging massage jet.

- the outlet nozzle according to the invention can in particular also be operated with a pulsating water supply and / or air supply.

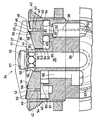

- the single figure schematically illustrates in section an embodiment of an outlet nozzle according to the invention with a closing mechanism and a backwash system.

- the outlet nozzle shown in the drawing for the outlet valve 34 of a whirlpool has a valve body 39 with a centrally arranged water supply channel 35, which is provided with outlet openings 56 opening radially into an outlet channel 36.

- the outlet channel 36 is through the inner surface 41 of an extension 67 provided with an engagement groove 68 of the Valve body 39 attachable plate-shaped distribution body 37 and formed by a surface 44 of a piston 49.

- the height of the outlet channel 36 is reduced from the radially inside to the radially outside by the surface 44 of the piston 49 tapering obliquely towards the tub wall 42 from the radially inside to the radially outside and the inner surface 41 of the distribution body 37 from a radially inner one, approximately parallel to the tub wall 42 extending section merges into an obliquely inclined area, whereby an outlet slot 45 is formed on the radially outer circumference of the outlet channel 36.

- This outlet channel 36 which tapers radially from the inside to the outside, gives the water emerging from the outlet openings 56 the speed required to exert a suction effect on the outlet behind the outlet slot 45 directly behind the outlet slot 45 via an axially extending upward in the valve body 39 if necessary, exercise air introduced into the air supply duct 38, which has individual air supply ducts 53.

- the mixing of the water with the sucked-in air takes place in a space 46 adjoining the outlet channel 36 radially outwards.

- This space 46 is formed by the outer edge region of the inner surface 41 of the distribution body 37 and the surface 48 of the piston 49.

- the intermediate space 46 which is designed as an annular channel, extends away from the tub wall 42 at a slight angle.

- the intermediate space 46 has an approximately constant width which exceeds the width of the outlet slot 45 by a factor of 2 in the exemplary embodiment chosen here.

- the piston 49 which has the surfaces 44 and 48, is received in an annular space 61 of the valve body 39 with an axial wall region concentrically surrounding the water supply channel 35 63 and a radially outwardly extending bearing surface 62.

- spring force accumulators 60 are provided in the form of rubber buffers on which the piston 49 is supported with its underside and which oppose one another support the bearing surface 62 of the annular space 61.

- the two annular spring force accumulators 60 concentrically surrounding the water supply channel 35 are arranged on both sides of the bores 54 of the air supply channel 38 which extend axially upwards and merge into an annular channel 47.

- the rubber buffer 60 is formed between the piston 44 and the support surfaces 62 of the valve body 49, an intermediate space of the annular space 61 which is divided by the spring force accumulators 60 designed as a rubber buffer into two sections 50, 51 which are separated from one another in a liquid-tight and / or gas-tight manner, the radially outer section 51 for the passage of air communicates with the bores 54 of the piston 49 and the section of the air supply duct 38 coming from below.

- the restoring force of the spring force accumulator 60 is to be selected so that during operation of the outlet valve 34 by the pressure of the water emerging via the outlet openings 56 and, supported by the pressure of the water-air mixture formed in the intermediate space 46, the pistons 49 with their surfaces 44 and 48 axially downward is pressed into the open position. If, on the other hand, the outlet valve 34 is slatted off, the restoring force of the spring-core accumulator 60 brings about an axial stroke of the piston 49, the end region of its surface 44 and its surface 48 being pressed against the inner surface 41 of the distribution body 37 and thus the outlet valve 34 against inflow of bathing water seal from the whirlpool tub.

- the sections of the surfaces 44 and 48 that come into contact with the inner surface 41 of the distribution body 37 in the closed position of the piston 49 are provided with a sealing strip 59.

- the piston 49 has a recess 58 immediately below the outlet slot 45 and in the piston wall 57 delimiting the annular gap 47 for the supply of air, which in the open position of the adjacent sealing strip 59 is protruded to form the underside of the outlet slot 45.

- the sealing strip 59 is pressed into the recess 58, the resulting bead of the sealing strip 59 on the knee of the recess 58 being pressed firmly against the inner surface 41 of the distribution body 37 and sealing the interior of the outlet channel 36 in a liquid-tight manner.

- the radially inner annular spring force accumulator 60 serves as a seal for the radially inner section 50 of the annular space by means of the spring force accumulator 60, the clearance of the annular space 61 with respect to the radially outwardly extending further section 51 for the air supply, so that water or cleaning fluid cannot penetrate into the air supply system.

- the pressure of the rinsing liquid entering via the water supply channel 36 and entering the outlet channel 36 via the outlet openings 56 is to be set so that the piston 49 remains in its closed position.

- the outlet nozzle With the invented outlet nozzle, a new kind of massage feeling is created by an intensive water-air mixture due to the excellent injector effect, which flows out essentially parallel to the tub wall and from which fine air bubbles rise in the tub water to massage the tub user.

- the outlet nozzle according to the invention enables an automatic, reliable sealing of its interior from the bath water of the whirlpool, which would otherwise lead to contamination of the supply system and germ deposition in the latter, when the operating system is shut down.

- the supply system can be backwashed by backwashing with water or a cleaning liquid in an advantageous manner when the plant is at a standstill, without the cleaning liquid getting into the whirlpool bath.

Landscapes

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Epidemiology (AREA)

- Pain & Pain Management (AREA)

- Physical Education & Sports Medicine (AREA)

- Rehabilitation Therapy (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Veterinary Medicine (AREA)

- Nozzles (AREA)

- Percussion Or Vibration Massage (AREA)

Claims (21)

- Buse pour l'injecteur (34) d'une baignoire à bain bouillonnant comportant un conduit d'arrivée d'eau (35) et un conduit d'arrivée d'air (38), dans laquelle le débit d'eau et le débit d'air sont mélangés par effet d'injecteur, le conduit d'arrivée d'eau (35) se raccordant à un conduit de sortie (36) annulaire menant radialement vers l'extérieur, qui est formé entre un élément distributeur (37) en forme de disque et le corps (39) de l'injecteur (34), le conduit d'arrivée d'air (38, 47, 53, 54), de préférence annulaire, débouchant dans un espace intermédiaire (46) annulaire qui se raccorde radialement vers l'extérieur au conduit de sortie (36) entre l'élément distributeur (37) en forme de disque et le corps d'injecteur (39) ou le boîtier d'injecteur (40) ou encore la paroi de la baignoire (42), et les surfaces (44, 48) formant avec la surface intérieure (41) de l'élément distributeur (37) le conduit de sortie (36) et/ou l'espace intermédiaire (46) étant constituées par au moins un piston (49) entourant le conduit d'arrivée d'eau (35), sensiblement concentrique à celui-ci, qui est mobile par rapport à l'élément distributeur (37), lequel piston ferme de manière étanche au liquide et/ou au gaz, en position de fermeture, le conduit de sortie (36) et/ou l'espace intermédiaire (46) raccordé au conduit de sortie (36).

- Buse selon la revendication 1 caractérisée en ce que le piston (49), au nombre d'au moins un, est guidé à l'intérieur du corps d'injecteur (39) ou du boîtier d'injecteur (40) ou encore sur la paroi de la baignoire (42).

- Buse selon la revendication 1 ou 2 caractérisée en ce que le conduit d'arrivée d'air (38) présente plusieurs conduits d'arrivée d'air indépendants (53) qui sont en communication de fluide avec des perçages (54) axiaux à l'intérieur du piston (49).

- Buse selon la revendication 3 caractérisée en ce que les perçages (54) du conduit d'arrivée d'air (38) se raccordent à un conduit annulaire (47) débouchant dans l'espace intermédiaire (46).

- Buse selon la revendication 3 ou 4 caractérisée en ce que les perçages (54) ou le conduit annulaire (47) du conduit d'arrivée d'air (38) débouchent dans l'espace intermédiaire (46) immédiatement derrière une fente de sortie (45) formée dans la région périphérique du conduit de sortie (36).

- Buse selon l'une des revendications 1 ou 5 caractérisée en ce que les surfaces (41, 44, 48) de l'élément distributeur (37) et du piston (49) venant en contact les unes avec les autres lorsque le piston est en position de fermeture, et au moins les parties des surfaces (44, 48) du piston (49) venant au contact de la surface intérieure (41) de l'élément distributeur (37), sont réalisées sous forme de surfaces d'étanchéité, qui sont munies le cas échéant d'un revêtement souple ou d'une couche ou d'une garniture de caoutchouc ou analogue.

- Buse selon la revendication 6 caractérisée en ce que, en position d'ouverture du piston (49), les surfaces (44, 48) qui s'étendent jusqu'aux perçages (54) ou jusqu'au conduit annulaire (47) du conduit d'arrivée d'air (38) ou qui s'étendent de part et d'autre de la fente de sortie (45) du conduit de sortie (36) sont décalées de manière telle que la surface (48) qui délimite, avec la surface intérieure (41) de l'élément distributeur (37), l'espace intermédiaire (46) est en retrait par rapport à la surface (44) qui délimite le conduit de sortie (36), et en ce que la paroi du piston (57) qui se raccorde à la surface (44) présente, dans la région de la fente de sortie (45) ou du conduit d'arrivée d'air (38), un évidement au-dessus duquel est située, en position d'ouverture du piston (49), une lèvre d'étanchéité (59) en matériau souple liée à la surface du piston (44), formant le cas échéant la fente de sortie (45), qui s'étend essentiellement dans la direction tangentielle par rapport à la surface du piston (44), laquelle lèvre est comprimée dans l'évidement (58), lorsque le piston (49) est en position de fermeture.

- Buse selon l'une des revendications 1 ou 7 caractérisée en ce que le piston (49) peut être amené de sa position de fermeture vers sa position d'ouverture, à l'encontre de la force d'un accumulateur élastique (60), par la force ou la pression de l'eau sortant du conduit d'arrivée d'eau (35).

- Buse selon la revendication 8 caractérisée en ce que l'accumulateur élastique (60) est formé par des ressorts, des tampons de caoutchouc (60) ou analogues, qui sont logés dans un espace annulaire (61) entourant le conduit d'arrivée d'eau (35), essentiellement concentrique avec celui-ci, prévu entre le piston (49) et une surface d'appui (62) du corps d'injecteur (39).

- Buse selon la revendication 9 caractérisée en ce que la chambre annulaire (61) prévue dan le corps d'injecteur (39) présente une partie de paroi (63) s'étendant axialement vers le haut à partir de la surface d'appui (62) qui reçoit le piston (49) reposant sur l'accumulateur élastique (60), en ce qu'une partie de paroi interieure (64) du piston (49), concentrique avec le conduit d'arrivée d'eau (35), forme avec la partie de paroi (63) du corps d'injecteur (39) du corps d'injecteur (39) tournée vers elle un espace annulaire (65), et en ce que l'espace annulaire (61) débouche dans un conduit de retour (66) s'étendant axialement vers le bas à l'intérieur du corps d'injecteur (39), qui est relié le cas échéant à la vidange de la baignoire à bain bouillonnant par l'intermédiaire d'une vanne d'arrêt.

- Buse selon la revendication 10 caractérisée en ce qu'il est prévu des tampons en caoutchouc (60) annulaires concentriques au conduit d'arrivée d'eau (35) qui entourent de part et d'autre le conduit d'arrivée d'air (38) et maintiennent dégagée une partie de l'espace annulaire (61), au moins lorsque le piston (49) est en position de fermeture, et qui divisent celui-ci en deux parties (50, 51) séparées l'une de l'autre de manière étanche à l'eau et/ou au gaz, la partie (51) située radialement à l'extérieur étant reliée au conduit d'arrivée d'air (38).

- Buse selon la revendication 10 ou 11 caractérisée en ce que l'espace annulaire (65) a une largeur de 0,1 à 1 mm, de préférence 0,6 mm, qui correspond sensiblement à la moitié de la largeur de la fente de sortie (45).

- Buse selon l'une des revendications 1 à 12 caractérisée en ce que l'élément distributeur (37) est fixé au moyen d'une fixation à baïonnette, à vis, à ventouse, à encliquetage ou à aimant sur le corps d'injecteur (39), qui comporte le cas échéant un prolongement axial (67), ou est réalisé d'une pièce avec celui-ci.

- Buse selon l'une des revendications 1 à 13 caractérisée en ce que le conduit d'arrivée d'eau (35) est muni d'orifices de sortie (56) radiaux disposés dans la région du conduit de sortie (36).

- Buse selon l'une des revendications 1 à 14 caractérisée en ce que le corps d'injecteur (39) comporte un prolongement axial (67) muni d'une gorge d'accrochage (68) pour le montage de l'élément distributeur (37), réalisé le cas échéant en matériau souple.

- Buse selon l'une des revendications 1 à 15 caractérisée en ce que la surface intérieure (41) de l'élément distributeur (37) en forme de disque s'étend, dans la région périphérique du conduit de sortie (36), radialement de l'intérieur vers l'extérieur avec un faible angle d'inclinaison en direction de la paroi de la baignoire (42) en formant la fente de sortie (45) radiale.

- Buse selon l'une des revendications 1 à 16 caractérisée en ce que la surface intérieure (41) de l'élément distributeur (37) en forme de disque, dans l'espace intermédiaire (46) se raccordant au conduit de sortie (36), s'éloigne de la paroi de la baignoire (42) avec un faible angle d'inclinaison.

- Buse selon l'une des revendications 1 à 17 caractérisée en ce que la surface intérieure (41) de l'élément distributeur (37) en forme de disque, dans la zone de raccordement entre le conduit de sortie (36) et l'espace intermédiaire (46), forme un col de Venturi (43) avec les parties de l'injecteur (34) situées en regard.

- Buse selon l'une des revendications 1 à 18 caractérisée en ce que la surface (44) du piston (49) est inclinée radialement de l'extérieur vers l'intérieur en direction de la paroi de la baignoire (42).

- Buse selon l'une des revendications 1 à 19 caractérisée en ce que la surface (48) du piston (49), dans la région de l'espace intermédiaire (46), est sensiblement parallèle à la surface interne (41) de l'élément distributeur (37), la hauteur de l'espace intermédiaire (46) étant le cas échéant supérieure à la largeur de la fente de sortie (45).

- Application d'une buse selon l'une des revendication 1 à 20 caractérisée en ce que son alimentation en eau et/ou son alimentation en air a lieu de manière pulsatoire.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT87116544T ATE69721T1 (de) | 1986-11-27 | 1987-11-10 | Austrittsduese fuer das austrittsventil einer whirlpool-wanne. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3640497 | 1986-11-27 | ||

| DE19863640497 DE3640497A1 (de) | 1986-11-27 | 1986-11-27 | Austrittsduese fuer das austrittsventil einer whirlpool-wanne |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0270858A2 EP0270858A2 (fr) | 1988-06-15 |

| EP0270858A3 EP0270858A3 (en) | 1989-06-07 |

| EP0270858B1 true EP0270858B1 (fr) | 1991-11-27 |

Family

ID=6314874

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP87116544A Expired - Lifetime EP0270858B1 (fr) | 1986-11-27 | 1987-11-10 | Buse de sortie équipant les orifices d'entrée d'un bain tourbillonnant |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4896384A (fr) |

| EP (1) | EP0270858B1 (fr) |

| AT (1) | ATE69721T1 (fr) |

| DE (3) | DE8631764U1 (fr) |

| ES (1) | ES2028849T3 (fr) |

Families Citing this family (41)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3745018C2 (de) * | 1987-05-06 | 1995-11-23 | Guenter Schuessler | Wasserbecken mit Luftsprudelvorrichtung mit zirkulierbaren Zuleitungen |

| ATE106713T1 (de) * | 1988-12-29 | 1994-06-15 | Toto Ltd | Whirlpool-wanne, versehen mit heisswassereinstrahlregelung. |

| US5144702A (en) * | 1988-12-29 | 1992-09-08 | Toto Ltd. | Blow-off nozzle structure capable of automatically varying the blow-off volume of water |

| DE68916223D1 (de) * | 1988-12-29 | 1994-07-21 | Toto Ltd | Whirlpool-Wanne mit einer durch einen Wechselrichter geregelten Umwälzpumpe. |

| DE3902117C1 (fr) * | 1989-01-25 | 1990-09-13 | Guenter 6074 Roedermark De Schuessler | |

| DE3903477A1 (de) * | 1989-02-06 | 1990-08-09 | Viegener Ii Fa Franz | Mischgehaeuse mit drehbar gelagerter einlassduese fuer whirlpool-wannen |

| DE3941006A1 (de) * | 1989-12-12 | 1991-06-13 | Bernd Kellerberg | Whirlpoolduese |

| DE4005688A1 (de) * | 1990-02-23 | 1991-08-29 | Schuessler Guenter | Hydromassageduese mit dekompressionsraum und entwaesserungsablauf |

| US5251343A (en) * | 1992-05-05 | 1993-10-12 | Paramount Leisure Industries, Inc. | Swimming pool pop-up fitting |

| FR2692173B1 (fr) * | 1992-06-10 | 1994-09-02 | Sames Sa | Dispositif de projection électrostatique d'un produit de revêtement en poudre à tête d'ionisation tournante. |

| EP0608140A3 (en) * | 1993-01-22 | 1995-12-13 | Cca Inc | Mechanical foam fire fighting equipment and method. |

| DE9304009U1 (de) * | 1993-03-18 | 1994-02-10 | Schiller, Reinhard, 91177 Thalmässing | Massagedüse |

| DE4322812C1 (de) * | 1993-07-08 | 1994-09-01 | Altura Leiden Holding | Düse für eine Wanne |

| US6351859B1 (en) | 1997-08-19 | 2002-03-05 | John V. Maiuccoro | Hydrotherapy tub coplanar flow |

| US5926865A (en) * | 1997-09-23 | 1999-07-27 | Witinski; Joseph L. | Cover for turbo jet dispensing head employed in swiming pool filtering system |

| US6182303B1 (en) * | 1999-12-16 | 2001-02-06 | Saratoga Spa & Bath Co., Inc. | Multiple slot fluid flow |

| US20030080206A1 (en) * | 2001-03-08 | 2003-05-01 | Thomas Duerr | Powder bell purge tube |

| US6643859B1 (en) * | 2001-05-15 | 2003-11-11 | Saratoga Spa & Bath Co., Inc. | Fluid flow system with flow diverter |

| US6859953B1 (en) | 2002-09-13 | 2005-03-01 | Steven E. Christensen | Jet propulsion system for spa or jetted bath using control of air draw to Venturi jets with a three-way air control valve |

| US6889921B2 (en) * | 2002-09-30 | 2005-05-10 | Illinois Tool Works Inc. | Bell cup skirt |

| WO2004105677A1 (fr) * | 2003-05-30 | 2004-12-09 | Kipley Roydon Marks | Baignoire a bulles |

| US20050023385A1 (en) * | 2003-07-29 | 2005-02-03 | Kui-Chiu Kwok | Powder robot gun |

| US7128277B2 (en) * | 2003-07-29 | 2006-10-31 | Illinois Tool Works Inc. | Powder bell with secondary charging electrode |

| US20050056212A1 (en) * | 2003-09-15 | 2005-03-17 | Schaupp John F. | Split shroud for coating dispensing equipment |

| ITRE20030091A1 (it) * | 2003-09-29 | 2005-03-30 | American Standard Italia S R L | Bocchetta per vasche da idromassaggio. |

| US20050173556A1 (en) * | 2004-02-09 | 2005-08-11 | Kui-Chiu Kwok | Coating dispensing nozzle |

| ITRE20040055A1 (it) | 2004-05-19 | 2004-08-19 | American Standard Europe Bvba | Bocchetta per vasche da idromassaggi |

| DE202005001403U1 (de) * | 2005-01-28 | 2005-04-07 | Villeroy & Boch | Sanitärwanne |

| US7246757B2 (en) * | 2005-05-02 | 2007-07-24 | Victor Air Tools Co., Ltd. | Nozzle cover of air brush |

| US7950077B2 (en) | 2005-12-05 | 2011-05-31 | Bowles Fluidics Corporation | Spa jet yielding increased air entrainment rates |

| US9248075B2 (en) * | 2006-04-19 | 2016-02-02 | Michael Spencer | Laminar jet and hydrotherapy bath system |

| GB0625583D0 (en) * | 2006-12-21 | 2007-01-31 | Itw Ltd | Paint spray apparatus |

| US8371517B2 (en) | 2007-06-29 | 2013-02-12 | Illinois Tool Works Inc. | Powder gun deflector |

| US20090020626A1 (en) * | 2007-07-16 | 2009-01-22 | Illinois Tool Works Inc. | Shaping air and bell cup combination |

| US8096264B2 (en) * | 2007-11-30 | 2012-01-17 | Illinois Tool Works Inc. | Repulsion ring |

| US10155233B2 (en) * | 2008-04-09 | 2018-12-18 | Carlisle Fluid Technologies, Inc. | Splash plate retention method and apparatus |

| US20120005819A1 (en) * | 2010-07-09 | 2012-01-12 | As Ip Holdco, L.L.C. | Whirlpool Jet Nozzle Assembly and Jet Apparatus |

| US20140101840A1 (en) * | 2012-10-12 | 2014-04-17 | Lmi Roto, Llc | Spa Jet Face |

| CZ25534U1 (cs) * | 2013-01-29 | 2013-06-17 | BERNDORF BÄDERBAU s.r.o. | Víceúcelová tryska |

| CN216949694U (zh) * | 2021-12-31 | 2022-07-12 | 上海荣威塑胶工业有限公司 | 喷水装置及地上水池 |

| DE102022000534A1 (de) | 2022-02-11 | 2023-08-17 | Truma Gerätetechnik GmbH & Co. KG | Vorrichtung zum Erwärmen einer Flüssigkeit sowie Vorrichtung zum Führen einer Flüssigkeit |

Family Cites Families (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB712905A (en) * | 1951-04-25 | 1954-08-04 | L G Mouchel And Partners Ltd | Improvements in or relating to the distribution of water in water-cooling towers |

| CH302791A (de) * | 1951-11-20 | 1954-10-31 | Waltert Sen Xaver | Leitungsanlage für die Zu- und Ableitung einer Flüssigkeit in einen bzw. aus einem Behälter. |

| US3217986A (en) * | 1964-03-20 | 1965-11-16 | Gulf Research Development Co | Nozzle |

| GB1015109A (en) * | 1964-09-23 | 1965-12-31 | Avy Lewis Miller | Swimming pool |

| US3462085A (en) * | 1967-12-01 | 1969-08-19 | Crompton & Knowles Corp | Circular nozzle |

| BE787281A (fr) * | 1971-08-19 | 1972-12-01 | Peabody Engineering Corp | Tuyere de pulverisation peripherique |

| US4211368A (en) * | 1975-06-09 | 1980-07-08 | Legros Francis R | Device for aerating and chemically activating shower water |

| US3985303A (en) * | 1975-10-09 | 1976-10-12 | Steimle Wayne D | Hydromassage device with directional jet control |

| DE2823253A1 (de) * | 1977-11-30 | 1979-05-31 | Bisa Karl | Vorrichtung zum verteilen von fluessigen und pulverfoermigen materialien unter bildung von aerosol oder schaum |

| US4320541A (en) * | 1979-11-13 | 1982-03-23 | Neenan John S | Method and apparatus for providing a pulsating air/water jet |

| AR224785A1 (es) * | 1980-05-19 | 1982-01-15 | Dupont Robert | Valvula de retencion con inyector direccional |

| US4314670A (en) * | 1980-08-15 | 1982-02-09 | Walsh William A Jun | Variable gas atomization |

| GB2114021B (en) * | 1982-01-19 | 1985-05-22 | Clive Richard Randle | Baths |

| JPS58180255A (ja) * | 1982-04-16 | 1983-10-21 | Matsushita Electric Ind Co Ltd | 噴霧装置 |

| US4477026A (en) * | 1982-09-30 | 1984-10-16 | Imperial Underground Sprinkler Co. | Bubbler head structure |

| US4486907A (en) * | 1983-09-12 | 1984-12-11 | Carter Heard L | Self-flushing rotatable pop-up water delivery head for pool cleaning systems |

| US4655394A (en) * | 1984-12-19 | 1987-04-07 | Spraying Systems Co. | Dual purpose foam generating and high pressure nozzle |

| DE3607788A1 (de) * | 1985-04-26 | 1986-12-04 | Günter 6074 Rödermark Schüssler | Wasserbecken mit luftsprudelvorrichtung |

| IT1200742B (it) * | 1985-09-17 | 1989-01-27 | Teuco Guzzini Srl | Vasca da bagno con impianto per idromassagio perfezionato |

| DE3630806A1 (de) * | 1986-09-10 | 1988-03-17 | Schuessler Guenter | Duesenkombination zur erzeugung eines luftsprudels in einem wasserbecken |

-

1986

- 1986-11-27 DE DE8631764U patent/DE8631764U1/de not_active Expired

- 1986-11-27 DE DE19863640497 patent/DE3640497A1/de active Granted

-

1987

- 1987-11-10 AT AT87116544T patent/ATE69721T1/de not_active IP Right Cessation

- 1987-11-10 ES ES198787116544T patent/ES2028849T3/es not_active Expired - Lifetime

- 1987-11-10 EP EP87116544A patent/EP0270858B1/fr not_active Expired - Lifetime

- 1987-11-10 DE DE8787116544T patent/DE3774846D1/de not_active Expired - Fee Related

- 1987-11-17 US US07/122,238 patent/US4896384A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| DE3774846D1 (de) | 1992-01-09 |

| EP0270858A3 (en) | 1989-06-07 |

| US4896384A (en) | 1990-01-30 |

| DE3640497A1 (de) | 1988-06-09 |

| ES2028849T3 (es) | 1992-07-16 |

| EP0270858A2 (fr) | 1988-06-15 |

| DE8631764U1 (de) | 1987-06-25 |

| DE3640497C2 (fr) | 1990-08-30 |

| ATE69721T1 (de) | 1991-12-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0270858B1 (fr) | Buse de sortie équipant les orifices d'entrée d'un bain tourbillonnant | |

| DE19839248B4 (de) | Spülventil | |

| DE2607873C2 (fr) | ||

| EP0392238B1 (fr) | Dispositif de décharge pour médias | |

| EP2918741B1 (fr) | Blocage de refoulement | |

| EP0526508A1 (fr) | Buse rotative pour un appareil de nettoyage a haute pression. | |

| DE2532838C3 (de) | Doppelsitzventil mit Leckkontrolle | |

| DE2943074T1 (fr) | ||

| DE60020868T2 (de) | Ventilanlage für Fahrzeugspülsystem | |

| EP0090090A2 (fr) | Procédé pour le nettoyage des cavités de soupapes à double siège | |

| DE69100934T2 (de) | Toilette mit niedrigem Wasserverbrauch bei pulsierender Spülung. | |

| DE1231986B (de) | Ventil fuer die Steuerung von Bremsen | |

| EP1941196A1 (fr) | Soupape d inversion sanitaire | |

| DE102019117920A1 (de) | Saugvorrichtung und Verfahren zur Abreinigung eines Filters | |

| EP0195389B1 (fr) | Déconnecteur de tuyaux | |

| EP0621066B1 (fr) | Installation de filtre de rinçage à contre-courant | |

| DE19506003A1 (de) | Einstrahldüse | |

| DE202010008017U1 (de) | Ventilvorrichtung | |

| DE3841301C2 (fr) | ||

| DE69103194T2 (de) | Vorrichtung zum Reinigen einer Hydromassagedüse. | |

| WO2024114967A1 (fr) | Dispositif et procédé de filtration de liquides, en particulier dans des vannes de remplissage | |

| WO1991008728A1 (fr) | Buse pour bain bouillonnant | |

| DE3834328C2 (de) | Klosettdruckspüler | |

| DE2111829C3 (de) | Selbstreinigender Sprühkopf | |

| DE4004982A1 (de) | Whirlpoolwanne |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL |

|

| 17P | Request for examination filed |

Effective date: 19881126 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL |

|

| 17Q | First examination report despatched |

Effective date: 19900509 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE ES FR GB IT LI LU NL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19911127 |

|

| REF | Corresponds to: |

Ref document number: 69721 Country of ref document: AT Date of ref document: 19911215 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3774846 Country of ref document: DE Date of ref document: 19920109 |

|

| ITF | It: translation for a ep patent filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| ET | Fr: translation filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2028849 Country of ref document: ES Kind code of ref document: T3 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19920921 Year of fee payment: 6 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19921016 Year of fee payment: 6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19921110 |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19921130 Ref country code: LI Effective date: 19921130 Ref country code: CH Effective date: 19921130 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19921130 Year of fee payment: 6 Ref country code: ES Payment date: 19921130 Year of fee payment: 6 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19930124 Year of fee payment: 6 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19931110 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: LAPSE BECAUSE OF THE APPLICANT RENOUNCES Effective date: 19931111 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19940601 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19931110 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19940729 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19940802 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20010402 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051110 |