EP0157724A2 - Dispositif de transport pour une imprimante, en particulier pour une imprimante matricielle - Google Patents

Dispositif de transport pour une imprimante, en particulier pour une imprimante matricielle Download PDFInfo

- Publication number

- EP0157724A2 EP0157724A2 EP85730019A EP85730019A EP0157724A2 EP 0157724 A2 EP0157724 A2 EP 0157724A2 EP 85730019 A EP85730019 A EP 85730019A EP 85730019 A EP85730019 A EP 85730019A EP 0157724 A2 EP0157724 A2 EP 0157724A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- tractor

- bearings

- flap

- transport device

- flap component

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000011159 matrix material Substances 0.000 title claims abstract description 6

- 229910000639 Spring steel Inorganic materials 0.000 claims abstract description 18

- 238000010276 construction Methods 0.000 claims 1

- 238000005452 bending Methods 0.000 abstract 1

- 238000004806 packaging method and process Methods 0.000 description 3

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 239000000969 carrier Substances 0.000 description 1

- 238000002788 crimping Methods 0.000 description 1

- 239000010437 gem Substances 0.000 description 1

- 230000036316 preload Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J11/00—Devices or arrangements of selective printing mechanisms, e.g. ink-jet printers or thermal printers, for supporting or handling copy material in sheet or web form

- B41J11/26—Pin feeds

- B41J11/30—Pin traction elements other than wheels, e.g. pins on endless bands

Definitions

- the invention relates to a transport device for printers, in particular for matrix printers, which are provided with paired tractor devices for guiding and / or advancing the record carrier, with foldable components being fastened by means of spherical bearings.

- Such transport devices are used for line-by-line, step-by-step or continuous feed of record carriers, which e.g. consist of paper webs.

- record carriers which e.g. consist of paper webs.

- the tractor hatches i.e. Swing covers that hold the paper web on the pins away.

- the tractor flaps are therefore held in swivel bearings so that they can be swung out.

- the swiveling-in of foldable components that are pivoted out during operation is advantageous in order to save transport and packaging space.

- the invention is therefore based on the object of creating a simple articulated bearing for foldable components on printers and also a simple locking device for the foldable positions.

- a cut spring steel wire piece is used as a hinge pin and for fixing a closed or open position of the flap component, which is put under tension by curvature.

- a preferred embodiment of the invention is designed in such a way that on the tractor body spaced-apart tractor bearings are provided, in which the ends of the spring steel wire stucco are mounted, and that at least one valve component bearing with a through hole for the spring-standing wire piece is provided on the valve component between the tractor bearings of the tractor body is that, in addition, in the closed and open position, the flap component bearing (s) bear with outer, flat surfaces on a flat counter surface of the tractor body and that the bores in the tractor bearings and in the flap component bearing differ in their axes.

- a functionally reversed design of this solution consists in that flap component end bearings, in which the ends of the spring steel wire piece are mounted, are provided on the flap component in the feed direction.

- the tractor body between the flap component end bearings at least one tractor bearing with a through hole for the spring steel wire piece is provided that in addition in the closed and open position, the flap component parts bearings rest with flat outer surfaces on a flat counter surface of the tractor body and that the through holes in the tractor bearings and in the valve component end bearings differ in their internal axis.

- Falling out of the spring steel wire piece can be avoided by crimping the ends of the spring steel wire piece.

- the application of the invention to a matrix printer results from the fact that the flap component consists of a cover flap for the belt band of the tractor device.

- the flap component consists of a lateral guide flap for the record carrier.

- Fig. List drawn without the Aufzechchnungani.

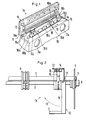

- the transport device shown is arranged in pairs to the left and right of the record carrier.

- Fig. List the left tractor device la and in Fig. 2, the right tractor device 1b visible, both tractor devices 1a, 1b are guided on a mounting rod 2 and a drive shaft 3, which themselves are set exactly in parallel by side bracket 4 and adjusting screws 5.

- the fastening rod 2 runs in FIG. 1 through the bore 2a and the drive shaft 3, which is square in cross section, runs through a square bushing which is inserted in the bore 3a.

- the drive axle 3 is in this case rotatably supported in the bushing 6 fastened in the side carrier 4.

- the Aufzelchnugesel is at one point on the wings 7 of the baffle flap 8 and later at another location on the support 9.

- the spring steel wire piece 18 runs in the through bores 10c.

- the flap component bearings 10a and 10b have outer, flat surfaces 10d which are supported on a flat counter surface 16c of the tractor body 16, the spring steel wire piece 18 running slightly curved, i.e. is under tension. This preload is achieved by an offset of approximately 0.8 mm between the axes of the through bores 10c and the bores 16d in the tractor bearings 16a and 16u.

- At least one tractor bearing (16a or 16b) centrally attached to the tractor body 16 is provided and the flap component 10 in question has bearings (10a; 10b) on its flap component parts.

- the spring steel wire piece 18 is crimped at its ends 18a, 18b to prevent it from falling out.

- the flap component 10 can in each case be placed upright, ie vertically and fixed.

- the outer, flat counter surface 16c of the tractor body 16 extends at 90 ° to corresponding surfaces 10d of the flap component bearings 10a, 10b.

- This principle can be used both for the cover flap 12 over the Hiemenband 15 as well as for the lateral Leitwandklappe 8 for the recording medium and any at all K lappbau tone a printer, in particular a M d trix horrers be employed.

Landscapes

- Handling Of Sheets (AREA)

- Advancing Webs (AREA)

- Hinge Accessories (AREA)

- Macromonomer-Based Addition Polymer (AREA)

- Polymers With Sulfur, Phosphorus Or Metals In The Main Chain (AREA)

- Liquid Developers In Electrophotography (AREA)

- Combination Of More Than One Step In Electrophotography (AREA)

- Character Spaces And Line Spaces In Printers (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT85730019T ATE62627T1 (de) | 1984-04-03 | 1985-02-06 | Transportvorrichtung fuer drucker, insbesondere fuer matrixdrucker. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3412852 | 1984-04-03 | ||

| DE3412852A DE3412852C2 (de) | 1984-04-03 | 1984-04-03 | Transportvorrichtung für Drucker, insbesondere für Matrixdrucker |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0157724A2 true EP0157724A2 (fr) | 1985-10-09 |

| EP0157724A3 EP0157724A3 (en) | 1988-06-08 |

| EP0157724B1 EP0157724B1 (fr) | 1991-04-17 |

Family

ID=6232780

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85730019A Expired - Lifetime EP0157724B1 (fr) | 1984-04-03 | 1985-02-06 | Dispositif de transport pour une imprimante, en particulier pour une imprimante matricielle |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4650358A (fr) |

| EP (1) | EP0157724B1 (fr) |

| JP (1) | JPS60212366A (fr) |

| AT (1) | ATE62627T1 (fr) |

| DE (2) | DE3412852C2 (fr) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4758107A (en) * | 1986-05-02 | 1988-07-19 | Sakase Kagaku Kogyo Kabushiki Kaisha | Web feed tractor for printer |

| US4780013A (en) * | 1986-05-02 | 1988-10-25 | Sakase Kagaku Kogyo Kabushiki Kaisha | Web feed tractor for printer |

| JPS6399969A (ja) * | 1986-10-17 | 1988-05-02 | Canon Inc | 記録装置のピンフイ−ド装置 |

| DE8711771U1 (de) * | 1987-08-31 | 1987-10-29 | Nixdorf Computer Ag, 4790 Paderborn | Transporteinrichtung zum Transport eines Aufzeichnungsträgers durch einen Drucker |

| US4817842A (en) * | 1988-01-29 | 1989-04-04 | International Business Machines Corporation | Door and spring assembly for a paper feed mechanism |

| EP0352397B1 (fr) * | 1988-07-26 | 1993-01-07 | MANNESMANN Aktiengesellschaft | Appareil pour commander la vitesse des moteurs électriques à modulation d'impulsion en durée, notamment des moteurs à courant continu |

| US4955520A (en) * | 1989-03-24 | 1990-09-11 | Precision Handling Devices, Inc. | Web feed device having an improved lid mechanism |

| US5488467A (en) * | 1994-06-24 | 1996-01-30 | Rjs, Inc. | Laser printer paper handling system |

| EP2537900B1 (fr) | 2011-06-21 | 2015-09-30 | Omya International AG | Procédé de production de carbonate de calcium précipité |

| CN109262070B (zh) * | 2018-11-08 | 2020-04-17 | 温州普睿达机械科技有限公司 | 一种管道加工切割喷码一体机 |

| CN114715707B (zh) * | 2022-03-31 | 2023-01-03 | 先之科半导体科技(东莞)有限公司 | 一种便于调整的晶片料带传动结构 |

Family Cites Families (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2342477A (en) * | 1941-08-08 | 1944-02-22 | Waterbury Button Company | Plastic hinge cap |

| US2442873A (en) * | 1944-04-28 | 1948-06-08 | Trig Corp | Molded plastic receptacle hinge |

| US2797434A (en) * | 1953-12-23 | 1957-07-02 | Chrysler Corp | Hood or deck lid hinge |

| US2707800A (en) * | 1954-08-16 | 1955-05-10 | Popper Emil | Spring hinge for bracelets, watch bands, and the like |

| US2987332A (en) * | 1958-11-17 | 1961-06-06 | Bonmartini Glovanni | Resilient torque-transmitting hinge structure |

| US3388420A (en) * | 1966-09-15 | 1968-06-18 | Gen Motors Corp | Integral hinge and hinge bias structure |

| DE1524445B2 (de) * | 1966-12-24 | 1973-02-15 | IBM Deutschland, 7000 Stuttgart | Vorrichtung zum voneinander unabhaengigen transportieren von zwei papierbahnen |

| US3545034A (en) * | 1969-01-31 | 1970-12-08 | Gen Motors Corp | Over-center door hinge |

| JPS552043A (en) * | 1978-06-22 | 1980-01-09 | Oki Electric Ind Co Ltd | Fixing system for continuous supply device |

| DE3036642A1 (de) * | 1980-09-29 | 1982-05-13 | Philips Patentverwaltung Gmbh, 2000 Hamburg | Transportvorrichtung fuer papierbahnen in buchungsmaschinen |

| IT1135127B (it) * | 1981-01-22 | 1986-08-20 | Honeywell Inf Systems | Meccanismo di trasporto carta per stampante |

| FR2499618A1 (fr) * | 1981-02-06 | 1982-08-13 | Lucas Noel | Charniere multiposition |

| US4390002A (en) * | 1981-08-14 | 1983-06-28 | Unarco Industries, Inc. | Hinge for cover of kettle cooker |

| US4493680A (en) * | 1982-12-02 | 1985-01-15 | Florkey's Conveyor Service, Inc. | Wear compensating link pin |

-

1984

- 1984-04-03 DE DE3412852A patent/DE3412852C2/de not_active Expired

-

1985

- 1985-02-06 AT AT85730019T patent/ATE62627T1/de not_active IP Right Cessation

- 1985-02-06 EP EP85730019A patent/EP0157724B1/fr not_active Expired - Lifetime

- 1985-02-06 DE DE8585730019T patent/DE3582511D1/de not_active Expired - Fee Related

- 1985-02-26 JP JP60037346A patent/JPS60212366A/ja active Granted

- 1985-04-02 US US06/719,241 patent/US4650358A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| DE3412852A1 (de) | 1985-10-03 |

| DE3412852C2 (de) | 1986-07-17 |

| JPS60212366A (ja) | 1985-10-24 |

| DE3582511D1 (de) | 1991-05-23 |

| ATE62627T1 (de) | 1991-05-15 |

| US4650358A (en) | 1987-03-17 |

| EP0157724A3 (en) | 1988-06-08 |

| JPH0431314B2 (fr) | 1992-05-26 |

| EP0157724B1 (fr) | 1991-04-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2913186C2 (de) | Kippbares Rollenlager | |

| DE3044806C2 (fr) | ||

| DE2840053C2 (de) | Scharnier für eine Haube eines Kraftfahrzeuges | |

| DE2551989A1 (de) | Kassette fuer ein endloses farbband fuer druckende bueromaschinen | |

| DE102020110154A1 (de) | Verbindungsstruktur zur Verhinderung des Schwankens von gegenläufigen Schiebetüren | |

| DE2834342C2 (de) | Lager für Wendeflügelfenster | |

| EP0157724A2 (fr) | Dispositif de transport pour une imprimante, en particulier pour une imprimante matricielle | |

| DE3128169C2 (de) | Abnehmbarer Tragegriff | |

| DE2137975C2 (de) | Formulartraktor mit Transportstiften | |

| DE60225625T2 (de) | Abkantpresse für Bleche mit einer beweglichen Anschlageinrichtung | |

| DE2447472B2 (de) | Vorlagenhaltevorrichtung für ein Kopiergerät | |

| DE60306881T2 (de) | Kettenförderer | |

| DE3876236T2 (de) | Traktorklappen fuer einen papiervorschubmechanismus. | |

| DE4190357C2 (de) | Feilschablone für das Feilen von Sägeketten | |

| DE1179349B (de) | Fernbetaetigbares Handhabungsgeraet (Manipulator) | |

| DE69500498T2 (de) | Mehrzweck-Gepäckträger für Kraftfahrzeuge, insbesondere zum Transportieren von Skiern, Surfbrettern oder ähnlichem | |

| DE2601152C2 (de) | Elektrisches Trockenrasiergerät | |

| DE3008540C2 (de) | Vorrichtung an Schreibwalzenlagergestell von Schreib- oder ähnlichen Maschinen zum Verstellen der Schreibwalze in Abdruckrichtung | |

| DE3143215C2 (de) | Streckwerk für eine Spinnmaschine | |

| DE3041103C2 (de) | Sicherheitsgurtanordnung | |

| DE3536215C2 (fr) | ||

| DE3136192C2 (de) | Papierführung für Drucker | |

| EP0292683A2 (fr) | Bras de compas pour porte de véhicule automobile | |

| DE3545787C2 (fr) | ||

| DE2637870C3 (de) | Sicherheitsskibindung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI NL |

|

| 17P | Request for examination filed |

Effective date: 19850907 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB IT LI NL |

|

| 17Q | First examination report despatched |

Effective date: 19891013 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI NL |

|

| REF | Corresponds to: |

Ref document number: 62627 Country of ref document: AT Date of ref document: 19910515 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 3582511 Country of ref document: DE Date of ref document: 19910523 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19920206 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19920228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19920229 Ref country code: CH Effective date: 19920229 |

|

| 26N | No opposition filed | ||

| BERE | Be: lapsed |

Owner name: MANNESMANN A.G. Effective date: 19920228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19920901 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19930113 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19930120 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19930322 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19940206 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19940206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19941031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19941101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |