EP0157724A2 - Transport device for a printer, especially for a matrix printer - Google Patents

Transport device for a printer, especially for a matrix printer Download PDFInfo

- Publication number

- EP0157724A2 EP0157724A2 EP85730019A EP85730019A EP0157724A2 EP 0157724 A2 EP0157724 A2 EP 0157724A2 EP 85730019 A EP85730019 A EP 85730019A EP 85730019 A EP85730019 A EP 85730019A EP 0157724 A2 EP0157724 A2 EP 0157724A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- tractor

- bearings

- flap

- spring steel

- transport device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000011159 matrix material Substances 0.000 title claims abstract description 6

- 229910000639 Spring steel Inorganic materials 0.000 claims abstract description 19

- 238000010276 construction Methods 0.000 claims 1

- 238000005452 bending Methods 0.000 abstract 1

- 238000004806 packaging method and process Methods 0.000 description 3

- 238000003780 insertion Methods 0.000 description 2

- 230000037431 insertion Effects 0.000 description 2

- 239000000969 carrier Substances 0.000 description 1

- 238000002788 crimping Methods 0.000 description 1

- 239000010437 gem Substances 0.000 description 1

- 230000036316 preload Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J11/00—Devices or arrangements of selective printing mechanisms, e.g. ink-jet printers or thermal printers, for supporting or handling copy material in sheet or web form

- B41J11/26—Pin feeds

- B41J11/30—Pin traction elements other than wheels, e.g. pins on endless bands

Definitions

- the invention relates to a transport device for printers, in particular for matrix printers, which are provided with paired tractor devices for guiding and / or advancing the record carrier, with foldable components being fastened by means of spherical bearings.

- Such transport devices are used for line-by-line, step-by-step or continuous feed of record carriers, which e.g. consist of paper webs.

- record carriers which e.g. consist of paper webs.

- the tractor hatches i.e. Swing covers that hold the paper web on the pins away.

- the tractor flaps are therefore held in swivel bearings so that they can be swung out.

- the swiveling-in of foldable components that are pivoted out during operation is advantageous in order to save transport and packaging space.

- the invention is therefore based on the object of creating a simple articulated bearing for foldable components on printers and also a simple locking device for the foldable positions.

- a cut spring steel wire piece is used as a hinge pin and for fixing a closed or open position of the flap component, which is put under tension by curvature.

- a preferred embodiment of the invention is designed in such a way that on the tractor body spaced-apart tractor bearings are provided, in which the ends of the spring steel wire stucco are mounted, and that at least one valve component bearing with a through hole for the spring-standing wire piece is provided on the valve component between the tractor bearings of the tractor body is that, in addition, in the closed and open position, the flap component bearing (s) bear with outer, flat surfaces on a flat counter surface of the tractor body and that the bores in the tractor bearings and in the flap component bearing differ in their axes.

- a functionally reversed design of this solution consists in that flap component end bearings, in which the ends of the spring steel wire piece are mounted, are provided on the flap component in the feed direction.

- the tractor body between the flap component end bearings at least one tractor bearing with a through hole for the spring steel wire piece is provided that in addition in the closed and open position, the flap component parts bearings rest with flat outer surfaces on a flat counter surface of the tractor body and that the through holes in the tractor bearings and in the valve component end bearings differ in their internal axis.

- Falling out of the spring steel wire piece can be avoided by crimping the ends of the spring steel wire piece.

- the application of the invention to a matrix printer results from the fact that the flap component consists of a cover flap for the belt band of the tractor device.

- the flap component consists of a lateral guide flap for the record carrier.

- Fig. List drawn without the Aufzechchnungani.

- the transport device shown is arranged in pairs to the left and right of the record carrier.

- Fig. List the left tractor device la and in Fig. 2, the right tractor device 1b visible, both tractor devices 1a, 1b are guided on a mounting rod 2 and a drive shaft 3, which themselves are set exactly in parallel by side bracket 4 and adjusting screws 5.

- the fastening rod 2 runs in FIG. 1 through the bore 2a and the drive shaft 3, which is square in cross section, runs through a square bushing which is inserted in the bore 3a.

- the drive axle 3 is in this case rotatably supported in the bushing 6 fastened in the side carrier 4.

- the Aufzelchnugesel is at one point on the wings 7 of the baffle flap 8 and later at another location on the support 9.

- the spring steel wire piece 18 runs in the through bores 10c.

- the flap component bearings 10a and 10b have outer, flat surfaces 10d which are supported on a flat counter surface 16c of the tractor body 16, the spring steel wire piece 18 running slightly curved, i.e. is under tension. This preload is achieved by an offset of approximately 0.8 mm between the axes of the through bores 10c and the bores 16d in the tractor bearings 16a and 16u.

- At least one tractor bearing (16a or 16b) centrally attached to the tractor body 16 is provided and the flap component 10 in question has bearings (10a; 10b) on its flap component parts.

- the spring steel wire piece 18 is crimped at its ends 18a, 18b to prevent it from falling out.

- the flap component 10 can in each case be placed upright, ie vertically and fixed.

- the outer, flat counter surface 16c of the tractor body 16 extends at 90 ° to corresponding surfaces 10d of the flap component bearings 10a, 10b.

- This principle can be used both for the cover flap 12 over the Hiemenband 15 as well as for the lateral Leitwandklappe 8 for the recording medium and any at all K lappbau tone a printer, in particular a M d trix horrers be employed.

Landscapes

- Handling Of Sheets (AREA)

- Advancing Webs (AREA)

- Hinge Accessories (AREA)

- Polymers With Sulfur, Phosphorus Or Metals In The Main Chain (AREA)

- Macromonomer-Based Addition Polymer (AREA)

- Liquid Developers In Electrophotography (AREA)

- Combination Of More Than One Step In Electrophotography (AREA)

- Character Spaces And Line Spaces In Printers (AREA)

Abstract

Description

Die Erfindung betrifft eine Transportvorrichtung für Drucker, insbesondere für Matrixdrucker, die für die Führung und/oder den vorschub des Aufzeichnungstrkgers mit paarweise angeordneten Traktorvorrichtungen versehen sind, wobei klappbare Bauteile mittels Gelenklagern befestigt sind.The invention relates to a transport device for printers, in particular for matrix printers, which are provided with paired tractor devices for guiding and / or advancing the record carrier, with foldable components being fastened by means of spherical bearings.

Derartige Transportvorrichtungen dienen dem zeilenweisen, schrittweisen oder kontinuierlichen Vorschub von Aufzeichnungsträgern, die z.B. aus Papierbahnen bestehen. Für einen störungsfreien Betrieb eines Druckers ist es von Bedeutung, die Papierbahn mit ihrem Anfang fachgerecht in die Vorschub- bzw. Führungsorgane der Transportvorrichtung einzulegen.Such transport devices are used for line-by-line, step-by-step or continuous feed of record carriers, which e.g. consist of paper webs. For trouble-free operation of a printer, it is important to properly insert the beginning of the paper web into the feed or guide elements of the transport device.

Beim Einlegen der Papierbahn in die Stifte des Riemenbandes eines Traktors ist es z.B. erforderlich, die Traktorklappen, d.h. Abdeckungen, die die Papierbahn auf den Stiften halten, wegzuschwenken. Trktorklappen sind daher abschwenkbar in Gelenklagern gehalten.When inserting the paper web into the pins of the belt strap of a tractor it is e.g. required, the tractor hatches, i.e. Swing covers that hold the paper web on the pins away. The tractor flaps are therefore held in swivel bearings so that they can be swung out.

Das Einführen der Papierbahn von der Unterseite oder von der Rückseite des Druckers macht bei einigen Druchkerbauformen ebenfalls das Abschwenken von klappbaren Bauteilen mittels Gelenklagern erforderlich.The introduction of the paper web from the underside or from the back of the printer also makes it necessary to swivel foldable components by means of spherical bearings in some types of printer.

Für den Transport ist das Einschwenken von während des Betriebes ausgeschwenkten klappbaren Bauteilen von Vorteil, um Transport- bzw. Verpackungsraum zu sparen.For transport, the swiveling-in of foldable components that are pivoted out during operation is advantageous in order to save transport and packaging space.

Allen erwähnten Beispielen haftet der Nachteil an, daß klappbare Bauteile an Druckern fUr die Gelenklager einen erheblichen Aufwand benötigen. Ein zusätzlicher Aufwand entsteht, wenn der klappbare Bauteil in seinen Klapp-Positionen zusätzlich noch fixiert werden soll. Ein diesbezüglicher Aufwand Ist wirtschaftlich kaum noch zu vertreten.All the examples mentioned have the disadvantage that foldable components on printers require considerable effort for the spherical plain bearings. Additional effort arises if the foldable component is to be additionally fixed in its foldable positions. An effort in this regard is hardly economically viable.

Der Erfindung llegt daher die Aufgabe zugrunde, für klappbare Bauteile an Druckern ein einfaches Gelenklager zu schaffen und ebenso eine einfache Feststellvorrichtung für die Klapp-Positionen.The invention is therefore based on the object of creating a simple articulated bearing for foldable components on printers and also a simple locking device for the foldable positions.

Die gestellte Aufgabe wird erfindungsgemäß dadurch gelöst, daß als Gelenkzapfen und zur Fixierung einer Schließ- oder Offenstellung des Klappenbauteils ein abgelängtes Federstahldrahtstck dient, das durch Krümmung unter Vorspannung gesetzt ist. Diese Erfindung verwirklicht auf wirtschaftliche und einfache Weise ein Gelenk und erlaubt gleichzeitig die Feststellung des Klappendauteils in gewünschten Endpositionen,The object is achieved in that a cut spring steel wire piece is used as a hinge pin and for fixing a closed or open position of the flap component, which is put under tension by curvature. This invention realizes an articulation in an economical and simple manner and at the same time allows the valve end part to be fixed in the desired end positions,

Eine bevorzugte Ausführungsform der Erfindung ist dahingehend gestaltet, daß am Traktorkörper in Vorschbrichtung beabstandete Traktorlager vorgesehen sind, in denen die Enden des Federstahldrahtstucks gelagert sind, daß ferner an dem Klappenbauteil zwischen den Traktorlagern des Traktorkörpers zumindest ein Klappenbauteil-Lager mit einer Durchgangsbohrung für das Federstanldrahtstück vorgesehen ist, daß außerdem in Schließ- und Offenstellung das bzw. die Klappenbauteil-Lager mit äußeren, ebenen Flächen auf einer ebenen Gegenflache des Traktorkorpers anliegen und daß die Bohrungen in den Traktorlagern und in dem Klappenbauteli-Lager in ihrer Achse voneinander abweichen.A preferred embodiment of the invention is designed in such a way that on the tractor body spaced-apart tractor bearings are provided, in which the ends of the spring steel wire stucco are mounted, and that at least one valve component bearing with a through hole for the spring-standing wire piece is provided on the valve component between the tractor bearings of the tractor body is that, in addition, in the closed and open position, the flap component bearing (s) bear with outer, flat surfaces on a flat counter surface of the tractor body and that the bores in the tractor bearings and in the flap component bearing differ in their axes.

Eine funktionell umgekehrte Gestaltung dieser Lösung besteht darin, daß am Klappenbauteil in Vorschubrichtng beabstandete Klappenbautellenden-Lager vorgesehen sind, in denen die Enden des Federstahldrahtstückes gelagert sind, daß ferner an. dem Traktorkörper zwischen den Klappenbauteilenden-Lagern zumindest ein Traktorlager mit einer Durchgangsbohrung für das Federstahldrahtstück vorgesehen ist, daß außerdem in Schließ- und Offenstellung die Klappenbauteilanden-Lager mit äußeren ebenen Flächen auf einer ebenen Gegenfläche des Traktorkörpers anliegen und daß die Durchgangsbohrungen in den Traktorlagern und in den Klappenbauteilenden-Lagern in inrer Achse voneinander abweichen.A functionally reversed design of this solution consists in that flap component end bearings, in which the ends of the spring steel wire piece are mounted, are provided on the flap component in the feed direction. the tractor body between the flap component end bearings at least one tractor bearing with a through hole for the spring steel wire piece is provided that in addition in the closed and open position, the flap component parts bearings rest with flat outer surfaces on a flat counter surface of the tractor body and that the through holes in the tractor bearings and in the valve component end bearings differ in their internal axis.

Ein herausfallen des Federstahldrahtstückes kann vermieden werden, indem die Enden des Federstahldrahtstückes angequetscht sind.Falling out of the spring steel wire piece can be avoided by crimping the ends of the spring steel wire piece.

Die erfindungsgemäßen Wirkungen treten bei Klappenbautilen für Drueker schon dann ein, wenn die parallelen Achsen der Bohrungen in den Iraktorlagern und in den Klappenbauteil-Lagern einen Abstand von etwa 0,8 mm aufweisen.The effects according to the invention already occur in valve components for Druekers when the parallel axes of the bores in the Iraqi bearings and in the valve component bearings are at a distance of approximately 0.8 mm.

Die praktischen Fixierstellungen werden vorteilhafterweise dadurch erzlelt. daß die äußere ebene Gegenfläche des Traktorkörpers zu der Fläche der Klappenbauteil-Lager für Schließ- bzw. Offenstellung unter einem Winkel von 90° zueinander verlaufen.The practical fixing positions are advantageously achieved. that the outer flat counter surface of the tractor body to the surface of the flap component bearing for the closed or open position at an angle of 90 ° to each other.

Die Anwendung der Erfindung auf einen Matrixdrucker ergibt sich dadurch, daß das Klappenbautil aus einer Abdeckklappe für das Riemenband der Traktorvorrichtung besteht.The application of the invention to a matrix printer results from the fact that the flap component consists of a cover flap for the belt band of the tractor device.

Eine andere Anwendbarkeit wird dadurch erzielt. daß das Klappenbautell aus einer seitlichen Führungsklappe für den Aufzeichnungsträger besteht.Another applicability is thereby achieved. that the flap component consists of a lateral guide flap for the record carrier.

Ausführungsbeispiele der Erfindung sind in der Zeichnung dargestellt und werden nachfolgend näher beschrieben.Embodiments of the invention are shown in the drawing and are described in more detail below.

Es zeigen:

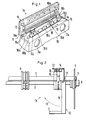

- Fig. 1 den oberen Teil einer Traktorvorrichtung eines Matrixdruckers in perspektivischer Ansicht und

- Fig. 2 den rechten Teil einer Transportvorrichtung mit Traktorvorrichtung und einer zusätzlichen Führung für den Aufzeichnungsträger etwa in Transportrichtung des Aufzeichnungsträgers gesehen.

- Fig. 1 shows the upper part of a tractor device of a matrix printer in a perspective view

- Fig. 2 seen the right part of a transport device with a tractor device and an additional guide for the record carrier approximately in the transport direction of the record carrier.

Die Transportvorrichtung gemäß Fig. list ohne den Aufzelchnungsträger gezeichnet. Die dargestellte Transportvorrichtung ist jedoch paarweise links und rechts vom Aufzeichnungsträger angeordnet. In Fig. list die llnke Traktorvorrichtung la und in Fig. 2 die rechte Traktorvorrichtung 1b sichtbar, wobei beide Traktorvorrichtungen 1a, 1b auf einer Befestigungsstange 2 und einer Antriebsachse 3 geführt sind, die selbst durch Seitenträger 4 und Einstellschrauben 5 genau parallel eingestellt sind. Die Befestigungsstange 2 verläuft in Fig. 1 durch die Bohrung 2a und die im Querschnitt quadratische Antriebsachse 3 verläuft durch eine Vierkantbuchse, die in der Bohrung 3a eingesetzt ist. Die Antriebsachse 3 ist hierbei in der im Seitentrager 4 befestigten Buchse 6 drehgelagert. Der Aufzelchnugsträger liegt an einer Stelle auf den Flügeln 7 der Leitwandklappe 8 und später an einer anderen Stelle auf der Auflage 9 auf.The transport device according to Fig. List drawn without the Aufzechchnungträger. However, the transport device shown is arranged in pairs to the left and right of the record carrier. In Fig. List the left tractor device la and in Fig. 2, the

Die beiden in den Fig. 1 und 2 dargestellten Ausführungsbeispiele besitzen für ihre Klappenbauteile 10 Gelenklager 11. Gemäß Flg. 1 besteht das dortige Klappenbauteil 10 aus einer Abdeckklappe 12 und gemäß Fig. 2 besteht das dortige Klappenbauteil 10 aus der Leitwandklappe 8. Währenddem die Leitwandklappe 8 zu Transport- bzw. Verpackungszwecken in Richtung 13 einschweenkbaer ist, dient das Auf-und Einschwenken der Traktorklappe 12 dem Einlegen des randgelochten Aufzeichnungsträgers, d. h. der randgelochten Papierbahn. Die Papierbahn wird mit ihrer Lochung in die Stifte 14 des Riemenbandes 15 eingelegt, das im Traktorkörper 16 geführt ist. Anschließend wird die Abdeckklappe 12 aus der dargestellten senkrechten Position in die waagerechte Position, in der sie das Riemenband 15 abdeckt, geschwenkt. Die Gelenklager 11 sind nunmehr wie nachfolgend beschrieben ausgebildet:

- Die

Gelenklager 11 weisen Gelenkzapfen 17 in Form vonabgelängten Federstahldrahtstücken 18 auf. AmTraktorkörper 16 sind inVorschubrichtung 19 beabstandet Traktorlager.16a und 16b vorgesehen, in denen dieEnden 18a und 18b desFederstahldrahtstückes 18 gelagert sind. DerKlappenbauteil 10 trägt zwei Klappenbauteil-Lager 10a und 100. die Jewells mit einerDurchgangsbohrung 10c versehen sind.

- The

spherical bearings 11 have pivot pins 17 in the form of cut springsteel wire pieces 18.Tractor bearings 16a and 16b, in which theends steel wire piece 18 are mounted, are spaced apart on thetractor body 16 in thefeed direction 19. Theflap component 10 carries two flap component bearings 10a and 100. The jewels are provided with athrough hole 10c.

In den Durchgangsbohrungen 10c verläuft das Federstahldrahtstück 18. Die Klappenbauteil-Lager 10a und 10b besitzen äußere, ebene Flächen 10d, die sich auf einer ebenen Gegenfläche 16c des Traktorkörpers 16 aufstützen, wobei das Federstahldrahtstück 18 leicht gekrümmt verlauft, d.h. unter Vorspannung gesetzt ist. Diese Vorspannung wird durch einen Versatz von ca. 0,8 mm zwischen den Achsen der Durchgangsbonrungen 10c und der Bohrungen 16d in den Traktorlagern 16a bzw. 16u erreicht.The spring

Es werden die beschriebenen Wirkungen auch dadurch erzielt, daß zumindest ein am Traktorkörper 16 mittig befestigtes Traktorlager (16a oder 16b) vorgesehen ist und das betreffende Klappenbauteil 10 an seinen Klappenbauteilenden Lager (10a;10b) aufweist.The effects described are also achieved in that at least one tractor bearing (16a or 16b) centrally attached to the

Das Federstahldrahtstück 18 ist an seinen Enden 18a, 18b gequetscht, um ein Herausfallen zu vertneiden.The spring

Für das Einlegen der Papierbahn bzw. das Verpacken ist es vorteilhaft, wenn das Klappenbauteil 10 jeweils aufrecht, d.h. senkrecht gestellt und fixiert werden kann. Hierzu verläuft die äußere, ebene Gegenfläche 16c des Traktorkörpers 16 unter 90° zu korrespondierenden Flächen 10d der Klappenbautelllager 10a, 10b. Dieses Prinzip kann sowohl für die Abdeckklappe 12 über dem Hiemenband 15 als auch für die seitliche Leitwandklappe 8 für den Aufzeichnungsträger und beliebig an allen Klappbauteilen eines Druckers, insbesondere eines Mdtrixdruckers, angewendet werden.For the insertion of the paper web or the packaging, it is advantageous if the

Claims (8)

dadurch gekennzeichnet,

daß als Gelenkzapfen (17) und zur Fixierung einer Schließ- oder Offenstellung des Klappenbauteils (10) ein abgelängtes Federstahldrahtstück (18) dient, das durch Krümmung unter Vorspannung gesetzt ist.1. Transport device for printers, in particular for matrix printers, which are provided for the guidance and / or the advancement of the record carrier with paired tractor devices, with small components being fastened with spherical bearings,

characterized,

that serves as a pivot pin (17) and for fixing a closed or open position of the flap component (10) a cut spring steel wire piece (18), which is set by curvature under tension.

dadurch gekennzeichnet,

daß am Traktorkörper (16) in Vorschubrichtung (19) beabstandete Traktorlager (16a,16b) vorgesehen sind, in denen die Enden (18a,18b) des Federstahldrahtsttlcks (18) gelagert sind, daß ferner an dem Klappenbauteil (10) zwischen den Traktorlagern (16a,16b) des Traktorkörpers ;16 ) zumindest ein Kappenbauteil -Lager (10a, 10b) mit einer Durchgangsbohrung (10c) für das federstahldrantssück (18) vorgesehen ist, daß außerdem in Schließ- und Offenstellung das bzw. die Klappenbautell-Lager (10a,10b) mit äußeren, ebenen Flächen (10d) auf einer ebenen Gegenfläche (16c) des Traktorkörpers (16) anliegen und daß die Bohrungen (16d) in den lraktorlagern (16a,16b) und in dem Klappenbauteil-Lager (10a bzw. 10b) in ihrer Achse voneinander abweichen.2. Transport device according to claim 1,

characterized,

that on the tractor body (16) in the feed direction (19) spaced tractor bearings (16a, 16b) are provided, in which the ends (18a, 18b) of the spring steel wire piece (18) are mounted, that furthermore on the flap component (10) between the tractor bearings ( 16a, 16b) of the tractor body; 16) at least one cap component bearing (10a, 10b) with a through hole (10c) for the spring steel drift back (18) is provided, that in addition in the closed and open position, the flap component bearing (10a , 10b) with outer, flat surfaces (10d) on a flat counter surface (16c) of the tractor body (16) and that the bores (16d) in the rotor bearings (16a, 16b) and in the flap component bearing (10a or 10b ) differ in their axis.

dadurch gekennzeichnet,

daß am Klappenbauteil (10) in Vorschubrichtung (19) beabstandete Klappenbauteiienden-Lager vorgesehen sind, in denen die Enden (18a,18b) des Federstahldrahtstückes (18) gelagert sind, daß ferner an dem Traktorkörper (16) zwischen den Klappenbdutellenden-Lagern zumindest ein Traktorlager (16a bzw. 16b) mit einer Durchgangsbohrung (10c) für das Federstahldrahtstück (18) vorgesehen ist, daß außerdem in Schließ- und Offenstellung die Klappenbauteilenden-Layer mit äußeren ebenen Flächen auf einer ebenen Gegenfläche (16c) des Traktorkörpers (16) anliegen und daß die Durchgangsbohrungen (10c) in den Traktorlagern (16a bzw. 16b) und in den Klappenbauteilanden-Lagern in ihrer Achse voneinander abweichen.3. Transport device according to claim 1,

characterized,

that on the flap component (10) in the feed direction (19) spaced flap component end bearings are provided, in which the ends (18a, 18b) of the spring steel wire piece (18) are mounted, that furthermore on the tractor body (16) between the flap butt end bearings at least one Tractor bearing (16a or 16b) with a through hole (10c) for the spring steel wire piece (18) is provided that, in the closed and open position, the flap component end layers lie with outer flat surfaces on a flat counter surface (16c) of the tractor body (16) and that the through bores (10c) in the tractor bearings (16a and 16b) and in the flap component bearing differ from one another in their axes.

dadurch gekennzeichnet,

daß die Enden (18a,18b) des Federstahl drahtstückes (18) angequetscht sind.4. Transport device according to claims 1 to 3,

characterized,

that the ends (18a, 18b) of the spring steel wire piece (18) are crimped.

dadurch gekennzeichnet,

daß die parallelen Achsen der Bohrungen (10c bzw. 16d) in den Traktorlagern (16a,16b) und In den Klappenbautail-Lagern (10a,10b) einen Abstand von etwa 0,8 mm aufweisen.5. Transport device according to claims 1 to 4,

characterized,

that the parallel axes of the bores (10c and 16d) in the tractor bearings (16a, 16b) and in the flap construction bearings (10a, 10b) are at a distance of about 0.8 mm.

dadurch gekennzeichnet,

daß die äußere, ebene Gegenfläche (16c) des Traktorkörpers (16) zu der Fläche (10d) der Klappenbauteil-Lager (10a,10b) für SchlieB- bzw. Offenstellung unter einem Winkel von 90° zueinander verlaufen.6. Transport device according to claims 1 to 5,

characterized,

that the outer, flat counter surface (16c) of the tractor body (16) to the surface (10d) of the flap component bearing (10a, 10b) for the closed or open position at an angle of 90 ° to each other.

dadurch gekennzeichnet,

daß das Klappenbauteil (10) aus einer Abdeckklappe (12) für das Riemenband (15) der Traktorvorrfchtung (la) besteht.7. Transport device according to claims 1 to 6,

characterized,

that the flap component (10) consists of a cover flap (12) for the belt (15) of the tractor device (la).

dadurch gekennzeichnet,

daß das Klappenbauteil (10) aus einer seitlichen Führungsklappe (8) für den Aufze1chnungsträger besteht.8. Transpsportvorrichtng according to claims 1 to 7,

characterized,

that the flap component (10) consists of a lateral guide flap (8) for the recording medium.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT85730019T ATE62627T1 (en) | 1984-04-03 | 1985-02-06 | TRANSPORT DEVICE FOR PRINTERS, ESPECIALLY FOR MATRIX PRINTERS. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3412852A DE3412852C2 (en) | 1984-04-03 | 1984-04-03 | Transport device for printers, in particular for matrix printers |

| DE3412852 | 1984-04-03 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0157724A2 true EP0157724A2 (en) | 1985-10-09 |

| EP0157724A3 EP0157724A3 (en) | 1988-06-08 |

| EP0157724B1 EP0157724B1 (en) | 1991-04-17 |

Family

ID=6232780

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP85730019A Expired - Lifetime EP0157724B1 (en) | 1984-04-03 | 1985-02-06 | Transport device for a printer, especially for a matrix printer |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4650358A (en) |

| EP (1) | EP0157724B1 (en) |

| JP (1) | JPS60212366A (en) |

| AT (1) | ATE62627T1 (en) |

| DE (2) | DE3412852C2 (en) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4780013A (en) * | 1986-05-02 | 1988-10-25 | Sakase Kagaku Kogyo Kabushiki Kaisha | Web feed tractor for printer |

| US4758107A (en) * | 1986-05-02 | 1988-07-19 | Sakase Kagaku Kogyo Kabushiki Kaisha | Web feed tractor for printer |

| JPS6399969A (en) * | 1986-10-17 | 1988-05-02 | Canon Inc | Pin feeder of recorder |

| DE8711771U1 (en) * | 1987-08-31 | 1987-10-29 | Nixdorf Computer Ag, 4790 Paderborn | Transport device for transporting a recording medium through a printer |

| US4817842A (en) * | 1988-01-29 | 1989-04-04 | International Business Machines Corporation | Door and spring assembly for a paper feed mechanism |

| ATE84387T1 (en) * | 1988-07-26 | 1993-01-15 | Mannesmann Ag | DEVICE FOR CONTROLLING THE SPEED OF PULSE WIDTH MODULATED ELECTRIC MOTORS, ESPECIALLY D.C. MOTORS. |

| US4955520A (en) * | 1989-03-24 | 1990-09-11 | Precision Handling Devices, Inc. | Web feed device having an improved lid mechanism |

| US5488467A (en) * | 1994-06-24 | 1996-01-30 | Rjs, Inc. | Laser printer paper handling system |

| SI2537900T1 (en) | 2011-06-21 | 2015-11-30 | Omya International Ag | Process for the production of precipitated calcium carbonate |

| CN109262070B (en) * | 2018-11-08 | 2020-04-17 | 温州普睿达机械科技有限公司 | Pipeline processing cutting spouts a yard all-in-one |

| CN114715707B (en) * | 2022-03-31 | 2023-01-03 | 先之科半导体科技(东莞)有限公司 | Wafer material belt transmission structure convenient to adjust |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1524445A1 (en) * | 1966-12-24 | 1969-11-20 | Ibm Deutschland | Transport device for paper webs |

| FR2499618A1 (en) * | 1981-02-06 | 1982-08-13 | Lucas Noel | Settable hinge for door - incorporates spring biassed cam which holds door open in predetermined positions |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2342477A (en) * | 1941-08-08 | 1944-02-22 | Waterbury Button Company | Plastic hinge cap |

| US2442873A (en) * | 1944-04-28 | 1948-06-08 | Trig Corp | Molded plastic receptacle hinge |

| US2797434A (en) * | 1953-12-23 | 1957-07-02 | Chrysler Corp | Hood or deck lid hinge |

| US2707800A (en) * | 1954-08-16 | 1955-05-10 | Popper Emil | Spring hinge for bracelets, watch bands, and the like |

| US2987332A (en) * | 1958-11-17 | 1961-06-06 | Bonmartini Glovanni | Resilient torque-transmitting hinge structure |

| US3388420A (en) * | 1966-09-15 | 1968-06-18 | Gen Motors Corp | Integral hinge and hinge bias structure |

| US3545034A (en) * | 1969-01-31 | 1970-12-08 | Gen Motors Corp | Over-center door hinge |

| JPS552043A (en) * | 1978-06-22 | 1980-01-09 | Oki Electric Ind Co Ltd | Fixing system for continuous supply device |

| DE3036642A1 (en) * | 1980-09-29 | 1982-05-13 | Philips Patentverwaltung Gmbh, 2000 Hamburg | TRANSPORT DEVICE FOR PAPER RAILS IN BOOKING MACHINES |

| IT1135127B (en) * | 1981-01-22 | 1986-08-20 | Honeywell Inf Systems | PAPER TRANSPORTATION MECHANISM FOR PRINTER |

| US4390002A (en) * | 1981-08-14 | 1983-06-28 | Unarco Industries, Inc. | Hinge for cover of kettle cooker |

| US4493680A (en) * | 1982-12-02 | 1985-01-15 | Florkey's Conveyor Service, Inc. | Wear compensating link pin |

-

1984

- 1984-04-03 DE DE3412852A patent/DE3412852C2/en not_active Expired

-

1985

- 1985-02-06 EP EP85730019A patent/EP0157724B1/en not_active Expired - Lifetime

- 1985-02-06 DE DE8585730019T patent/DE3582511D1/en not_active Expired - Fee Related

- 1985-02-06 AT AT85730019T patent/ATE62627T1/en not_active IP Right Cessation

- 1985-02-26 JP JP60037346A patent/JPS60212366A/en active Granted

- 1985-04-02 US US06/719,241 patent/US4650358A/en not_active Expired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1524445A1 (en) * | 1966-12-24 | 1969-11-20 | Ibm Deutschland | Transport device for paper webs |

| FR2499618A1 (en) * | 1981-02-06 | 1982-08-13 | Lucas Noel | Settable hinge for door - incorporates spring biassed cam which holds door open in predetermined positions |

Also Published As

| Publication number | Publication date |

|---|---|

| JPH0431314B2 (en) | 1992-05-26 |

| EP0157724B1 (en) | 1991-04-17 |

| DE3582511D1 (en) | 1991-05-23 |

| US4650358A (en) | 1987-03-17 |

| DE3412852C2 (en) | 1986-07-17 |

| DE3412852A1 (en) | 1985-10-03 |

| ATE62627T1 (en) | 1991-05-15 |

| JPS60212366A (en) | 1985-10-24 |

| EP0157724A3 (en) | 1988-06-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2913186C2 (en) | Tiltable roller bearing | |

| DE3044806C2 (en) | ||

| DE60218365T2 (en) | Articulating device for an aircraft door leaf and aircraft door with such a device | |

| DE2840053C2 (en) | Hinge for a hood of a motor vehicle | |

| DE3712114A1 (en) | (THERMO) PRINTER WITH HOUSING | |

| DE102020110154A1 (en) | Connection structure to prevent swaying of opposing sliding doors | |

| EP0157724A2 (en) | Transport device for a printer, especially for a matrix printer | |

| DE3402067C2 (en) | Direct writing paper writer | |

| DE3314628A1 (en) | FRICTION FEED PAPER HANDLING DEVICE | |

| DE3128169C2 (en) | Removable handle | |

| EP0243795A2 (en) | Device for guiding rounded borders through a welding zone | |

| DE2447472B2 (en) | Original holder for a copier | |

| DE3876236T2 (en) | TRACTOR HATCHES FOR A PAPER FEED MECHANISM. | |

| DE1179349B (en) | Remote handling device (manipulator) | |

| DE2601152C2 (en) | Electric dry shaver | |

| DE3008540C2 (en) | Device on the platen bearing frame of writing or similar machines for adjusting the platen in the direction of the print | |

| DE4190357C2 (en) | Filing template for filing saw chains | |

| DE102019200066A1 (en) | Hatch arrangement for a recreational vehicle | |

| DE1225988B (en) | Opening device for tilt and turn windows, doors or the like. | |

| EP0292683A2 (en) | Check for vehicle door | |

| DE3136192C2 (en) | Paper guide for printer | |

| DE2559494C3 (en) | Ribbon cassette for typewriters and similar machines | |

| DE3537240C2 (en) | ||

| DE2827133C2 (en) | Support arrangement for securing a raised folding part against falling, in particular for securing a truck driver's cab in the tilted position | |

| DE2637870C3 (en) | Safety ski bindings |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI NL |

|

| 17P | Request for examination filed |

Effective date: 19850907 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB IT LI NL |

|

| 17Q | First examination report despatched |

Effective date: 19891013 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI NL |

|

| REF | Corresponds to: |

Ref document number: 62627 Country of ref document: AT Date of ref document: 19910515 Kind code of ref document: T |

|

| ITF | It: translation for a ep patent filed | ||

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 3582511 Country of ref document: DE Date of ref document: 19910523 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19920206 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19920228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19920229 Ref country code: CH Effective date: 19920229 |

|

| 26N | No opposition filed | ||

| BERE | Be: lapsed |

Owner name: MANNESMANN A.G. Effective date: 19920228 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19920901 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19930113 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19930120 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19930322 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19940206 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19940206 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19941031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19941101 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |