EP0137352A2 - Fermeture de garantie en matière plastique - Google Patents

Fermeture de garantie en matière plastique Download PDFInfo

- Publication number

- EP0137352A2 EP0137352A2 EP84111027A EP84111027A EP0137352A2 EP 0137352 A2 EP0137352 A2 EP 0137352A2 EP 84111027 A EP84111027 A EP 84111027A EP 84111027 A EP84111027 A EP 84111027A EP 0137352 A2 EP0137352 A2 EP 0137352A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- tear

- overcap

- elements

- tamper

- screw cap

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D50/00—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures

- B65D50/02—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures openable or removable by the combination of plural actions

- B65D50/04—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures openable or removable by the combination of plural actions requiring the combination of simultaneous actions, e.g. depressing and turning, lifting and turning, maintaining a part and turning another one

- B65D50/041—Closures with means for discouraging unauthorised opening or removal thereof, with or without indicating means, e.g. child-proof closures openable or removable by the combination of plural actions requiring the combination of simultaneous actions, e.g. depressing and turning, lifting and turning, maintaining a part and turning another one the closure comprising nested inner and outer caps or an inner cap and an outer coaxial annular member, which can be brought into engagement to enable removal by rotation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D41/00—Caps, e.g. crown caps or crown seals, i.e. members having parts arranged for engagement with the external periphery of a neck or wall defining a pouring opening or discharge aperture; Protective cap-like covers for closure members, e.g. decorative covers of metal foil or paper

- B65D41/32—Caps or cap-like covers with lines of weakness, tearing-strips, tags, or like opening or removal devices, e.g. to facilitate formation of pouring openings

- B65D41/34—Threaded or like caps or cap-like covers provided with tamper elements formed in, or attached to, the closure skirt

- B65D41/3442—Threaded or like caps or cap-like covers provided with tamper elements formed in, or attached to, the closure skirt with rigid bead or projections formed on the tamper element and coacting with bead or projections on the container

- B65D41/3447—Threaded or like caps or cap-like covers provided with tamper elements formed in, or attached to, the closure skirt with rigid bead or projections formed on the tamper element and coacting with bead or projections on the container the tamper element being integrally connected to the closure by means of bridges

Definitions

- the invention relates to a tamper-evident closure with the features mentioned in the preamble of claim 1.

- the condition of the closure should show whether it was opened after the first closure or not.

- Tamper-evident closures made of sheet metal are known, in which a closure cap has a smooth, cylindrical jacket which is flanged over the thread of a mouth and under the retaining bead.

- the present invention is intended to design a tamper-evident closure made of plastic in such a way that it can be attached to threaded mouths with a retaining bead using normal closing machines.

- the closure should be able to be closed and opened as often as desired after opening for the first time, destroying its originality markings.

- the overcap is held captive on the screw cap. It is freely movable axially a certain distance, so that the projections or projections and recesses, which are necessary for the transmission of a torque from the overcap to the screw cap, can snap in and out.

- Such a closure can easily be screwed onto bottles by hand or by capping machines.

- the projections or projections and depressions lie against each other so that the screw cap is carried by the overcap.

- the tear-off elements are detached and thereby make it clearly recognizable that the closure has been opened. Since the user has to exert an axial force against the mouth and the container when the screw cap is first opened to take the screw cap with him, he must also press the tear-off elements against the mouth with the aid of the edge section of the overcap, so that its claws under the retaining bead of the mouth stay anchored. Since the screw cap now moves upwards relative to the mouth, the tear-off elements, which are stuck under the retaining bead of the mouth, must necessarily be torn off.

- top and bottom refer to the position of a closure z. B. on an upright bottle.

- the screw cap with the tear-off elements can be produced in one piece by injection molding.

- the tear-off elements including claws can be easily removed from the mold after injection molding and that when the closure is first applied to a mouth, tear-off webs which hold the tear-off elements remain undamaged.

- the tear-off elements can be connected to one another by easily tearable connecting webs for better grip when demolding after injection molding and when the mouth is closed for the first time.

- Different embodiments allow different methods of attaching the closure to a mouth for the first time.

- a closure designed according to claim 10 can be bounced after the threaded cap has been screwed on, as a result of which the tear-off elements come into their position required for tamper-evident securing, in which the claws engage behind the retaining bead of the mouth.

- this bouncing can be replaced by a screwing operation.

- an internal thread is provided on the overcap and an associated external thread is provided on the screw cap.

- the tamper-evident closure can also be used as a child-resistant closure.

- Some of the protrusions or depressions have sloping surfaces. When unscrewing these inclined surfaces have the effect that an overcap which is only slightly pressed against the screw cap performs a ratchet movement, so that a tight screw cap is not taken along. The screw cap can only be taken along if a considerable axial force is exerted that a small child cannot exert.

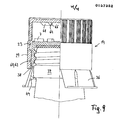

- FIGS. 6 to 9 show a second embodiment with an overcap to be screwed on.

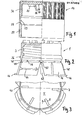

- the screw cap 1 has an internal thread 3 for the threaded mouth 2 of a bottle.

- Six approximately radially directed, rib-shaped projections 7 are provided on the end face 5 of the screw cap.

- Similar projections 18 are present on the inner end face of the overcap 14.

- the projections have mutually parallel flanks 9 and 20, which lie in axial or axially parallel planes.

- the overcap 14 has a relatively large annular groove 23 above its edge, while the screw cap has an annular bead 26 on its outside, which is arranged at some distance from the open end of the screw cap. After the screw cap has been impacted onto the overcap, the annular bead 26 can move axially within the annular groove 23. The screw cap is thus held captive within the overcap with axial play. In one extreme position, the projections 7 of the screw cap touch the end face 16 of the overcap, in the other extreme position the annular bead 26 abuts a shoulder 28 on the lower edge of the annular groove 23.

- Threaded mouths 2 on containers or bottles which are suitable for receiving a screw cap with tamper-evident protection have a retaining bead 32 (FIG. 4), generally just below an external thread 34.

- Tear-off elements 36 which are held on the edge of the screw cap 1 by tear-off webs 38, serve to ensure tamper evidence.

- four tear-off elements 36 are provided, and each is held by three tear-off webs 38.

- the tear-off elements 36 are connected to one another by connecting webs 40 connected.

- the tear-off elements 36 are parts of a hollow cone surface with a central angle of approximately 30 °. Except for the connecting webs 40, they are separated from one another by V-shaped cutouts 42. The opening angle of each section is also approx. 30 °.

- a claw 44 in the form of an annular rib is provided on the inner wall of each of the tear-off elements.

- each tear-off element On the outer wall, namely at the lower edge, each tear-off element has an annular flange 46. As FIG. 5 shows, this annular flange, which projects under the edge of the overcap after the first closure, shows that the closure has not yet been opened.

- each tear-off element 36 has two outer ribs 48, which run approximately parallel to the generatrix of the tapered surface of the tear-off elements.

- the screw cap is produced together with the tear-off elements in the position shown in FIGS. 2 and 3 by injection molding.

- the screw cap is first turned, for example by a capping machine, onto the mouth of the bottle, the tear-off elements 36 and their claws 44 easily gripping over the external thread 34 and the holding bead 32 of the mouth.

- the overcap 14 is chipped in the axial direction over the screw cap 1, so that the situation according to FIG. 5 then results, in which the annular bead 26 of the screw cap 1 engages in the annular groove 23 of the overcap 14.

- the overcap is thus held captive on the screw cap.

- the edge section 29 of the overcap has pressed the tear-off elements 36 inwards, so that their claws 44 engage behind, ie under the retaining bead 32 of the mouth.

- the V-shaped cutouts 42 between the tear-offs elements have narrowed into a slit.

- the lower edges 50 of the tear-off elements now form arches while they were in a radial plane in the production state.

- the closure can be screwed even more tightly, the projections 18 of the overcap taking the projections 7 of the screw cap with them.

- the overcap For the first unscrewing, the overcap must be pressed against the screw cap so that the projections 18 of the overcap can take the projections 7 and with them the screw cap in the direction of rotation.

- the edge section 29 inevitably holds the tear-off elements 36 inward and thus the claws 44 firmly below the holding bead 32 of the mouth, so that the tear-off elements 36 cannot move upward.

- the tear-off webs 38 must be torn through. The tear-off elements 36 are thus separated from the inner cap 1, whereby it can be seen that the closure has been opened.

- the second exemplary embodiment, shown in FIGS. 6 to 9, differs from the first in that the overcap 14 can be screwed onto the screw cap 1.

- a multiple-thread, here three-thread, external thread 60 is provided on the outer wall of the screw cap, near its lower edge, and a corresponding internal thread 62 is provided on the overcap 14 at the lower edge of its edge portion 29.

- the cap has 16 projections 64 with flanks 66 and 68 on its inner end face. While the flanks 66 lie in axially parallel or axial planes, the flanks 68 have an inclination with respect to the end face 16 which is between 30 and 60 °, in particular approximately 45 ° is. This results in a child lock, which is described below.

- the overcap 14 is screwed onto the inner cap 1 in a position according to FIG.

- the tear-off elements 36 stand out unhindered, as in FIGS. 7 and 8.

- the screwing of the overcap onto the screw cap is first ended by the beginnings of the external thread 60 of the screw cap 1 abutting the ends of the internal thread 62 of the overcap. If the closure is turned onto the mouth 2 in this way, the torque that can be transmitted between the two caps is sufficient to screw the screw cap 1 onto the external thread 34 of the mouth. If rotation is then continued with increased torque and / or the overcap is bounced open, the edge section 29 widens and slides over the external thread 60 until it comes into the annular groove 23. As a result, both closure parts are in turn held captive.

- the projections 64 and 7 now engage one behind the other in the direction of rotation. If necessary, the closure can now be screwed tight.

- the edge section 29 presses the tear-off elements 36 inward, so that the claws 44 engage under the retaining bead 32 of the mouth.

- the edge section 29 in turn holds the tear-off elements 36 against the mouth during the unscrewing process and the claws 44 firmly below the retaining bead 32 of the mouth, so that the tear-off webs 38 have to be torn through.

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19833336908 DE3336908A1 (de) | 1983-10-11 | 1983-10-11 | Originalitaetsverschluss aus kunststoff |

| DE3336908 | 1983-10-11 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0137352A2 true EP0137352A2 (fr) | 1985-04-17 |

| EP0137352A3 EP0137352A3 (fr) | 1986-01-08 |

Family

ID=6211514

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84111027A Withdrawn EP0137352A3 (fr) | 1983-10-11 | 1984-09-15 | Fermeture de garantie en matière plastique |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4562931A (fr) |

| EP (1) | EP0137352A3 (fr) |

| JP (1) | JPS6099860A (fr) |

| DE (1) | DE3336908A1 (fr) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1987002009A1 (fr) * | 1985-10-03 | 1987-04-09 | Dawson Electrics Pty. Ltd. | Perfectionnements de fermetures mettant en evidence toute tentative d'ouverture |

| EP0343534A2 (fr) * | 1988-05-27 | 1989-11-29 | Walter Sarstedt Geräte und Verbrauchsmaterial für Medizin und Wissenschaft | Récipient pour conserver des liquides, en particulier des liquides corporels |

| EP0214711B1 (fr) * | 1985-08-29 | 1992-01-22 | Kerr Glass Manufacturing Corporation | Fermeture de protection à l'épreuve des enfants avec moyens pour indiquer l'ouverture |

| GB2454511A (en) * | 2007-11-09 | 2009-05-13 | Beeson & Sons Ltd | Tamper evident container closure with overcap |

| CN102482006A (zh) * | 2009-08-25 | 2012-05-30 | 超力公司 | 在内部件和外部件上具有斜角的凸轮表面的瓶盖 |

| EP3476760A4 (fr) * | 2016-06-28 | 2020-03-18 | Gomez Cao Innovations & Inventions, S.L. | Bouchon |

Families Citing this family (32)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE8805665U1 (fr) * | 1988-04-29 | 1988-07-07 | Rohe, Karl-Heinz, 3490 Bad Driburg, De | |

| US4805791A (en) * | 1988-05-04 | 1989-02-21 | Continental White Cap, Inc. | Band with lock ring for tamper-evident cap |

| GB2257693B (en) * | 1991-07-10 | 1995-08-02 | Beeson & Sons Ltd | A container and closure |

| US5411157A (en) * | 1990-05-30 | 1995-05-02 | Beeson And Sons Limited | Container and the manufacture thereof |

| GB2262280B (en) * | 1991-12-11 | 1995-09-20 | Beeson & Sons Ltd | A container neck and a closure therefor |

| US5100011A (en) * | 1991-04-05 | 1992-03-31 | The West Company, Incorporated | Tamper evident closure |

| US5588545A (en) * | 1991-09-23 | 1996-12-31 | Beeson And Sons Limited | Child-resistant and elderly friendly closure for containers |

| ES2103502T3 (es) * | 1992-11-13 | 1997-09-16 | Beeson & Sons Ltd | Cierre de envase con anillo a prueba de manipulacion. |

| GB9320389D0 (en) * | 1993-10-04 | 1993-11-24 | Beeson & Sons Ltd | Improvements relating to container closures |

| US5477972A (en) * | 1994-06-02 | 1995-12-26 | Lester; William M. | Tamper evident closure device for bottles and the like |

| US5456374A (en) * | 1994-09-19 | 1995-10-10 | Beck; Matthew R. | Tamper evident container closure |

| US5680965A (en) * | 1996-01-29 | 1997-10-28 | Beck; Matthew R. | Tamper evident container closure |

| DE29807243U1 (de) * | 1998-04-22 | 1999-08-26 | Sanner Friedr Gmbh Co Kg | Kindersicherer und originalitätsgesicherter Behälter-Verschluß |

| US6382444B1 (en) * | 1999-03-17 | 2002-05-07 | Sentinel Packaging Systems, Inc. | Tamper-evident plastic closure system with snap-on band |

| ITTV20020025A1 (it) * | 2002-03-06 | 2003-09-08 | Alessandro Tomasella | Dispositivo di chiusura, particolarmente per bottiglie e/o contenitori |

| CA2534786C (fr) * | 2003-08-01 | 2012-03-20 | Liqui-Box Canada Inc. | Ensemble fermeture inviolable |

| GB0503623D0 (en) * | 2005-02-22 | 2005-03-30 | Camlab Ltd | Secure sample collection |

| ATE499309T1 (de) * | 2005-02-28 | 2011-03-15 | Stanpac Inc | Verbundverschlüsse für behälter |

| US7549547B2 (en) * | 2005-06-06 | 2009-06-23 | Berry Plastics Corporation | Composite two-piece tamper-evident closure with a seal-delay-release feature and a method therefor |

| US20070272647A1 (en) * | 2006-03-31 | 2007-11-29 | Long Charles J | Closure with vertical tear bands |

| US20090014404A1 (en) * | 2007-07-10 | 2009-01-15 | Berry Plastics Corporation | Convertible container closure |

| ES2682462T3 (es) * | 2008-04-30 | 2018-09-20 | Closure Systems International Inc. | Envase a prueba de manipulación con rendimiento de apertura mejorado |

| US20090277861A1 (en) * | 2008-05-08 | 2009-11-12 | Long Jr Charles J | Closure with tamper evident strip |

| US9790005B2 (en) * | 2010-10-15 | 2017-10-17 | Closure Systems International Inc. | Plastic closure with enhanced performance |

| CN104309919B (zh) * | 2013-09-30 | 2017-02-22 | 青海春天药用资源科技利用有限公司 | 防盗瓶盖和防盗瓶 |

| US11273962B2 (en) | 2014-02-14 | 2022-03-15 | Closure Systems International Inc. | Tamper-evident closure |

| US10407225B2 (en) | 2017-11-07 | 2019-09-10 | Closure Systems International Inc. | Closure and package that vents at high pressure |

| JP2022551480A (ja) | 2019-10-07 | 2022-12-09 | クロージャー・システムズ・インターナショナル・インコーポレーテッド | フリップトップ式クロージャ |

| USD996968S1 (en) | 2021-05-17 | 2023-08-29 | Closure Systems International Inc. | Closure |

| USD996967S1 (en) | 2021-05-17 | 2023-08-29 | Closure Systems International Inc. | Closure |

| US11945625B2 (en) | 2022-06-24 | 2024-04-02 | Closure Systems International Inc. | Package with closure |

| US11801977B1 (en) | 2022-12-02 | 2023-10-31 | Closure Systems International Inc. | Package with one-piece closure |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2307205A1 (de) * | 1973-02-14 | 1974-08-22 | Neuro Plast Gmbh & Co Kg | Sicherheits-flaschenverschluss |

| EP0021985A1 (fr) * | 1979-06-22 | 1981-01-07 | André Chazeau | Dispositif de bouchage garantissant la non ouverture d'un récipient |

| FR2464199A1 (fr) * | 1979-09-05 | 1981-03-06 | Giraud Gallaire Sa Ets | Dispositif d'obturation inviolable |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1959264A1 (de) * | 1969-11-26 | 1971-06-16 | Gerhard Mueller | Sicherheitsschraubverschluss fuer Flaschen und aehnliche Behaelter |

| US3926326A (en) * | 1971-03-31 | 1975-12-16 | Hermann Grau | Safety closure |

| DE2115741B1 (de) * | 1971-03-31 | 1972-06-29 | Grau, Hermann, 7071 Lindach | Sicherheitsverschluß |

| DE2216343B2 (de) * | 1972-04-05 | 1975-05-15 | Hermann 7071 Lindach Grau | SicherheitsschraubverschluB |

| DE2943548A1 (de) * | 1979-10-27 | 1981-05-07 | Alcoa Deutschland Gmbh Verpackungswerke, 6520 Worms | Bausatz fuer einen kappenverschluss fuer behaelter mit gewindehals |

| GB2066792B (en) * | 1979-11-19 | 1983-10-26 | Deussen Stella Kg | Container closure with childproof lock and original package seal |

| US4474301A (en) * | 1983-03-14 | 1984-10-02 | Johnsen & Jorgensen (Plastics) Ltd. | Tamper-resistant and childproof closure |

-

1983

- 1983-10-11 DE DE19833336908 patent/DE3336908A1/de not_active Withdrawn

-

1984

- 1984-09-15 EP EP84111027A patent/EP0137352A3/fr not_active Withdrawn

- 1984-10-09 US US06/658,750 patent/US4562931A/en not_active Expired - Fee Related

- 1984-10-11 JP JP59211574A patent/JPS6099860A/ja active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2307205A1 (de) * | 1973-02-14 | 1974-08-22 | Neuro Plast Gmbh & Co Kg | Sicherheits-flaschenverschluss |

| EP0021985A1 (fr) * | 1979-06-22 | 1981-01-07 | André Chazeau | Dispositif de bouchage garantissant la non ouverture d'un récipient |

| FR2464199A1 (fr) * | 1979-09-05 | 1981-03-06 | Giraud Gallaire Sa Ets | Dispositif d'obturation inviolable |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0214711B1 (fr) * | 1985-08-29 | 1992-01-22 | Kerr Glass Manufacturing Corporation | Fermeture de protection à l'épreuve des enfants avec moyens pour indiquer l'ouverture |

| WO1987002009A1 (fr) * | 1985-10-03 | 1987-04-09 | Dawson Electrics Pty. Ltd. | Perfectionnements de fermetures mettant en evidence toute tentative d'ouverture |

| EP0343534A2 (fr) * | 1988-05-27 | 1989-11-29 | Walter Sarstedt Geräte und Verbrauchsmaterial für Medizin und Wissenschaft | Récipient pour conserver des liquides, en particulier des liquides corporels |

| EP0343534A3 (en) * | 1988-05-27 | 1990-11-28 | Sarstedt Walter Geraete | Container for preserving liquids, in particular bodily liquids |

| GB2454511A (en) * | 2007-11-09 | 2009-05-13 | Beeson & Sons Ltd | Tamper evident container closure with overcap |

| GB2454511B (en) * | 2007-11-09 | 2012-03-07 | Beeson & Sons Ltd | Container closure with overcap |

| CN102482006A (zh) * | 2009-08-25 | 2012-05-30 | 超力公司 | 在内部件和外部件上具有斜角的凸轮表面的瓶盖 |

| CN102482006B (zh) * | 2009-08-25 | 2014-07-16 | 超力公司 | 在内部件和外部件上具有斜角的凸轮表面的瓶盖 |

| EP3476760A4 (fr) * | 2016-06-28 | 2020-03-18 | Gomez Cao Innovations & Inventions, S.L. | Bouchon |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0137352A3 (fr) | 1986-01-08 |

| US4562931A (en) | 1986-01-07 |

| JPS6099860A (ja) | 1985-06-03 |

| DE3336908A1 (de) | 1985-04-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0137352A2 (fr) | Fermeture de garantie en matière plastique | |

| EP0049876A1 (fr) | Bouchon à vis inviolable | |

| DE3233805C2 (fr) | ||

| DE3319709A1 (de) | Eingriffe anzeigender verschluss | |

| EP0225394A1 (fr) | Fermeture inviolable | |

| DE2421292B2 (de) | Kindersicherer verschluss fuer einen behaelter | |

| DE2226906B2 (de) | Behälterverschlußkappe | |

| DE2753080C2 (de) | Verschlußkappe mit Originalitätssicherung | |

| EP0623522A1 (fr) | Capuchon à vis avec sécurité pour enfant | |

| DE1804099B2 (de) | Behälter mit Schraubverschlußkappe | |

| EP0123810A1 (fr) | Fermeture de sécurité | |

| DE2515565A1 (de) | Verschluss fuer behaelter, insbesondere fuer medizinische flaschen | |

| DE2638351C3 (de) | Garantieverschluß für Flaschen | |

| EP0297160B1 (fr) | Capuchon à vis de sécurité | |

| DE1914313A1 (de) | Unverletzlicher Verschluss | |

| DE3233806A1 (de) | Verschlusskappe, vorzugsweise mit originalitaetssicherung | |

| DE3108518C2 (fr) | ||

| DE3144924C2 (fr) | ||

| EP0090143A1 (fr) | Fermeture de sécurité à pression et à vissage interdisant aux jeunes enfants l'accès au contenu des récipients | |

| EP0060983B1 (fr) | Récipient avec fermeture de sécurité | |

| EP0052260B1 (fr) | Bouchon de sécurité | |

| DE102005040745A1 (de) | Originalitätsverschluss für Behälter | |

| EP0570760B1 (fr) | Capuchon de fermeture muni d'un élément de garantie | |

| DE3715862C2 (fr) | ||

| EP0498954B1 (fr) | Capuchon de fermeture pour fermeture en matière plastique |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19860909 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: BRACH, ULRICH Inventor name: PERSCH, ALOIS |