EP0100932A2 - Cabine de pulvérisation de poudre - Google Patents

Cabine de pulvérisation de poudre Download PDFInfo

- Publication number

- EP0100932A2 EP0100932A2 EP83107084A EP83107084A EP0100932A2 EP 0100932 A2 EP0100932 A2 EP 0100932A2 EP 83107084 A EP83107084 A EP 83107084A EP 83107084 A EP83107084 A EP 83107084A EP 0100932 A2 EP0100932 A2 EP 0100932A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- powder

- spray booth

- booth according

- powder spray

- cyclone

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 229940098458 powder spray Drugs 0.000 title claims abstract description 27

- 239000000843 powder Substances 0.000 claims abstract description 67

- 239000007921 spray Substances 0.000 claims abstract description 21

- 238000000576 coating method Methods 0.000 claims abstract description 16

- 239000011248 coating agent Substances 0.000 claims abstract description 15

- JTJMJGYZQZDUJJ-UHFFFAOYSA-N phencyclidine Chemical class C1CCCCN1C1(C=2C=CC=CC=2)CCCCC1 JTJMJGYZQZDUJJ-UHFFFAOYSA-N 0.000 claims description 13

- 238000005192 partition Methods 0.000 claims description 7

- 238000009795 derivation Methods 0.000 claims 1

- 238000004140 cleaning Methods 0.000 abstract description 9

- 230000000694 effects Effects 0.000 abstract description 2

- 230000005484 gravity Effects 0.000 abstract description 2

- 230000003247 decreasing effect Effects 0.000 abstract 1

- 239000002245 particle Substances 0.000 description 7

- 238000011084 recovery Methods 0.000 description 7

- 238000001556 precipitation Methods 0.000 description 3

- 230000001174 ascending effect Effects 0.000 description 2

- 238000005253 cladding Methods 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 230000000630 rising effect Effects 0.000 description 2

- 238000007790 scraping Methods 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 230000009471 action Effects 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 230000003670 easy-to-clean Effects 0.000 description 1

- 230000029142 excretion Effects 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000004904 shortening Methods 0.000 description 1

- 238000007873 sieving Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B14/00—Arrangements for collecting, re-using or eliminating excess spraying material

- B05B14/40—Arrangements for collecting, re-using or eliminating excess spraying material for use in spray booths

- B05B14/45—Arrangements for collecting, re-using or eliminating excess spraying material for use in spray booths using cyclone separators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B14/00—Arrangements for collecting, re-using or eliminating excess spraying material

- B05B14/40—Arrangements for collecting, re-using or eliminating excess spraying material for use in spray booths

- B05B14/48—Arrangements for collecting, re-using or eliminating excess spraying material for use in spray booths specially adapted for particulate material

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S118/00—Coating apparatus

- Y10S118/07—Hoods

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S55/00—Gas separation

- Y10S55/46—Spray booths

Definitions

- the invention relates to a powder spray booth with a device for separating or recovering spray powder from its conveying gas, with an outlet opening arranged on an outlet side of the spray booth, through which the conveying gas with a residual portion of the spray powder not deposited on the workpiece passes through a plurality of cyclone separators integrated into the spray booth is sucked in.

- cyclone separators are also used to recover powder from the exhaust air from powder spray booths, to which the conveying air carrying the residual powder is usually fed in a rotating manner from above and centrally sucked up again, with a large proportion of the imported residual powder settling at the bottom of the cyclone and can be used there for further use.

- cyclone separators have the advantage of better cleaning, since practically no powder settles inside their housing.

- the lower degree of excretion is disadvantageous, especially with fine-grain powder. About 95% of powders with a particle size of 10 microns are recovered, ie only 5% are lost, but with powder dimensions of less than 10 microns, only 60% are recovered. For coarse powder, it is therefore very economical to operate the recovery exclusively with cyclones, but with finer powder types, post-filtering for further use is essential.

- the invention pursues the task of developing the powder spray booth defined at the outset in such a way that, when the coating process is made more uniform, the degree of precipitation on the workpiece increases, while the amount of powder supplied to the cyclone separators is reduced.

- the cabin outlet is designed according to the invention as a horizontal transverse slot arranged near the injection opening near the cabin ceiling, from which at least one suction channel of the cyclone separator originates.

- Cyclone separators of the same height are preferably arranged in a row next to one another, distributed over at least the major part of the cabin outlet side. It is relatively easy to equalize the cabin flow.

- the suction channel formed above the cyclone separators can directly connect to the transverse slot. It can have the same depth and be closed at the back by a flat wall if the individual cyclones are close together. However, if there is an intermediate distance, the cross-section of the suction channel can change over its length, in order to make room for other flow paths.

- the cyclone separators are expediently arranged at a vertical distance above the cabin floor in such a way that residual powder deposited on the cabin floor and the spray powder recovered in the cyclones can be fed to the same collecting space. Except for the inlet and outlet opening, the cyclone separators towards the coating room can also be shielded by a common, smooth surface and therefore easy to clean.

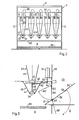

- the lock closure arranged at the lower end of a cyclone separator is characterized according to the invention by closure elements connected in series and alternately movable between the open and closed positions by means of a common motor-movable support.

- closure elements can then be relatively large and move largely perpendicular to the remaining opening gap. In this way, powder particles remaining in the gap are only exposed to a compressive force, but not to a grinding load, as occurs, for example, in cell locks.

- the pressure can be reduced as desired without the risk of leaks in the large sealing surfaces.

- both locking elements in particular resiliently adjustable relative to one another, are attached to one end of a double lever which can be pivoted about a horizontal axis, at the other end of which a periodically actuated actuator acts.

- Such training is not only simple, but also extremely reliable.

- a filter unit is connected downstream of the cyclone separators to increase the degree of recovery, this can be inserted directly into the spray booth on the outside of the cyclone separator, in particular integrated into it. It is also relatively easy to guide or provide funding for bringing together the amounts of powder separated by the cyclone separator and the filter unit.

- a switch device is particularly recommended for this. for optional merging or separate discharge of the residual powder quantities recovered by cyclones and filter units.

- a collecting space for recovered residual powder attached under the filter unit can be connected to a separate collecting space by a first switching element and to a common powder collecting space by a second switching element.

- Both switch elements can be connected in such a way that each can only be opened in the closed position of the other or that both switch elements, in particular together, can be actuated alternately in opposite directions.

- Significance here can be a sloping floor arranged under the post-filter unit, which is inclined towards the cyclones after a common partition wall and has a first outlet flap close to the partition wall to a separate collecting space, while a second outlet flap is attached to the common collecting space in the partition wall close to the sloping floor is.

- the first outlet flap is advantageously mounted at its lower end, the second at its upper end.

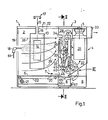

- the powder spray booth forms a linen coating space 2, to which two recovery units, a cyclone unit 3 and a filter unit 4 are connected, both of which are under the action of a suction fan 5.

- An effective scraping device 7 on the cabin floor 6 conveys into a powder carriage 8 which can be moved through the space 9 from the outside.

- Through openings 13 for workpieces 14 are formed in the cabin ceiling 11 and in the two end walls 12 of the coating room 2, to which tunnel attachments may also be connected on the outside, which are each suspended by means of a hanger 15 through a ceiling slot 16 on a circular conveyor 17 and so that they are automatically conveyed through the coating space 2 at a uniform speed.

- This scraper device 7 has a U-shaped scraper 20 which is moved back and forth over the cabin floor by means of a chain 22 driven by a motor 21 and is temporarily lifted off when moving to the left in FIG. 1.

- the cyclone unit 3 has, as can also be seen from FIGS. 2 and 5, five individual cyclone separators 23, that is to say in a known manner vertically arranged sheet metal container with a upper cylinder part 24 and a lower acute-angled cone part 25. From the middle of the cylinder part, a tube 26 leads upwards through a transverse suction channel 27 into an overlying connection space 28, from which the air according to arrows 29 into which the filter 31 of the filter r-aggregates 4 receiving filter space 32 and then sucked through the filter by the suction fan 5 and is expelled through filter mats 33 as shown by the arrow.

- the common suction channel 27 of all cyclone separators 23 is located directly under the cabin ceiling 11 and is connected directly to the coating space 2 by a transverse slot 34, possibly covered by a perforated plate.

- guide vanes 35 are inserted in the usual manner, which set the air sucked in downward in rotation according to the flow lines 36 before the direction of flow reverses toward the upper tube 26. Since the powder particles do not participate in this reversal movement because of their larger mass, they are removed downward and predominantly fall out of the cone part 25.

- All cyclone separators 23 are closed off by a common flat cladding wall 37 towards the coating space 2.

- the air sucked in by the suction fan 5 enters at least approximately horizontally through the spray opening 19 in a somewhat uniformly distributed manner according to the flow lines 38 drawn with solid lines. It should initially be disregarded that, depending on the arrangement and connection of the cabin, additional air quantities can also enter through the through openings 13 and the ceiling slot 16. These secondary flows are of no particular importance for the guidance of the powder on the workpiece. It can therefore be assumed that the powder sprayed by the powder spray gun is transported predominantly horizontally to the workpiece 14 by the sucked-in air and thereby ei ne even coating enables. The electrostatic guidance ends behind the workpiece.

- the sucked-in air now forms the predominant conveying medium and is sucked into the suction channel 27 through the high transverse slot 34, the trajectories 39 of the powder particles are still supported, ie they are raised a little. The vast majority of the powder hits the cladding wall 37 and falls from there to the floor.

- the filter 31 which can be designed as a pocket filter with a large surface area and in a known manner provided with a cleaning device.

- Lock closures 40 are attached to the lower intermediate wall 42, namely that a truncated cone-shaped funnel 44 is detachably flanged under each outlet opening 43 of the conical part 25 and forms a second outlet opening 54 with its lower end.

- Both outlet openings are conical valve elements 45 and 46 which are assigned to a common one Carrier rod 48 are attached, which in turn is seated at one end of a double lever 49, at the other end of which an actuator 51 such as a compressed air cylinder or the like is connected.

- This double lever 49 is sealed on an axle 52 fixed to the housing.

- At least one of the valve elements 45 and 46 is also provided to be resiliently adjustable over a limited distance in the direction of the rod 48. This ensures that when the support rod 48 is lifted, the valve element 45, for example, first comes into sealing contact with the first outlet opening 43 before the second valve element 46 lifts off the second outlet opening 54. In this way there is always an air seal in the inside of the cyclone preserve space.

- the amount of powder accumulated in the bottom region of the cone part 26 during the draining process is immediately entered into the funnel 44 when switching back to the operating position shown.

- the filter chamber 32 of the filter unit 4 is closed towards the cyclone unit 3 by a rear wall 55 covering all cyclone separators and down towards the chamber 9 by an inclined floor 56.

- a horizontal pivot axis 57 is provided, on which a first outlet flap 58 is attached, which closes a first outlet opening 59 in the inclined floor 56 in the closed position shown and in the opening position 59 'shown with broken lines that from Inclined floor 56 introduces powder sliding down into space 9, in which a further powder container 8 can optionally be attached.

- a second outlet opening 62 is attached above the pivot axis 57 and a gusset 61 which extends the inclined floor 56 at the lower end of the rear wall 55, which is closed in the manner drawn with solid lines by a second outlet flap 63, but which extends around its high pivot axis 64 to can be pivoted into the open position 64 'shown with broken lines.

- Both flaps 58 and 63 can also be mutually coupled in such a way that only one is always open but the other is closed.

- a filter unit 4 can be completely dispensed with. So you could place the suction fan 5 directly in the room 28. However, if the filter unit is present, it may be possible that can be driven without filter 31.

- Such a filter 31 is in any case necessary when working with fine-grained spray powder which, for example, only enables a cyclone recovery rate of 60 to 80%.

- the downstream filter separation is necessary and, above all, the powder can be separated into coarse-grained and fine-grained powder parts.

- powder booths provided with z y clone separators will generally be used in all work with coarse-grained powder, because this simplifies cleaning. Cleaning in the filter unit 4 is much more cumbersome. It is therefore possible, under certain circumstances, to give up the powder parts filtered out there and to drive different colors in succession, while in the cyclone unit 3 only the smooth surfaces outside the cyclone housing are cleaned. If this principle is used, several cyclone cabins can also be connected to a separate filter unit. Overall, the areas to be cleaned are in any case significantly reduced if the cyclone separators are arranged in the powder spray booth, which is otherwise closed.

- gusset spaces 71 also remain on the back between the guide plates 69, these gusset spaces can be used to convey the suction air from the high space 28 into the filter space 32.

- these gusset spaces can be used to convey the suction air from the high space 28 into the filter space 32.

- Zwikkel spaces 71 to the lower end by a preferably curved floor baffle / be closed. From the flat rear wall 55 of FIG. 3, only a flat rear strip 551 remains, to which the filter 31 can be moved closer.

Landscapes

- Details Or Accessories Of Spraying Plant Or Apparatus (AREA)

- Cyclones (AREA)

- Electrostatic Spraying Apparatus (AREA)

- Nozzles (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT83107084T ATE30125T1 (de) | 1982-08-10 | 1983-07-20 | Pulverspruehkabine. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19823229756 DE3229756A1 (de) | 1982-08-10 | 1982-08-10 | Pulverspruehkabine |

| DE3229756 | 1982-08-10 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0100932A2 true EP0100932A2 (fr) | 1984-02-22 |

| EP0100932A3 EP0100932A3 (en) | 1985-05-29 |

| EP0100932B1 EP0100932B1 (fr) | 1987-10-07 |

Family

ID=6170531

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83107084A Expired EP0100932B1 (fr) | 1982-08-10 | 1983-07-20 | Cabine de pulvérisation de poudre |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4504292A (fr) |

| EP (1) | EP0100932B1 (fr) |

| AT (1) | ATE30125T1 (fr) |

| DE (2) | DE3229756A1 (fr) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1986003994A1 (fr) * | 1985-01-02 | 1986-07-17 | Esb Elektrostatische Sprüh- Und Beschichtungsanlag | Cabine pour appliquer une couche de poudre sur la surface de pieces |

| FR2588780A1 (fr) * | 1985-10-17 | 1987-04-24 | Sames Sa | Installation de poudrage de pieces a cabine de poudrage maintenue en depression |

| DE4203948A1 (de) * | 1992-02-11 | 1993-08-12 | Sfb Spezial Filter Anlagen | Zyklonabscheider und pulverbeschichtungsanlage mit integriertem zyklonabscheider |

| EP0698421A1 (fr) * | 1994-08-22 | 1996-02-28 | Erich Bauer | Récupération de poudre par cyclone ou filtre et transfert de poudre par organe rotatif lors du fonctionnement avec cyclone |

| WO2014169992A1 (fr) * | 2013-04-18 | 2014-10-23 | Eisenmann Ag | Dispositif de guidage d'air de traitement chargé d'un excès de peinture pulvérisée, et installation de revêtement présentant un tel dispositif |

| IT201900024985A1 (it) * | 2019-12-20 | 2021-06-20 | Geico Spa | Cabina di verniciatura con sistema perfezionato per la sostituzione dei filtri |

Families Citing this family (38)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4723505A (en) * | 1986-03-17 | 1988-02-09 | Nordson Corporation | Powder booth |

| DE3611700A1 (de) * | 1986-04-08 | 1987-10-15 | Hoelter Heinz | Verfahren zur abreinigung eines heissgasfilters |

| US4718924A (en) * | 1986-05-30 | 1988-01-12 | Demarco Thomas M | Two compartment four stage industrial dust collector |

| US4790865A (en) * | 1986-05-30 | 1988-12-13 | Demarco Thomas | Two compartment industrial dust collector |

| US4704953A (en) * | 1986-11-12 | 1987-11-10 | Nordson Corporation | Powder spray system |

| DE8907540U1 (de) * | 1989-06-16 | 1990-10-18 | Farb-Tec Gesellschaft für Beschichtungskabinen-Systeme mbH, 2000 Hamburg | Kabine zum Sprühbeschichten von Gegenständen mit pulverförmigem Beschichtungsmaterial |

| FI85764C (fi) * | 1990-03-30 | 1992-05-25 | Jeven Oy | Avluftsanordning. |

| DE4025006C2 (de) * | 1990-08-07 | 2002-12-05 | Werner Durst | Ventilatoreinheit |

| DE4037459C2 (de) * | 1990-11-24 | 1994-02-24 | Eisenmann Kg Maschbau | Zyklonabscheider |

| US5306332A (en) * | 1991-05-14 | 1994-04-26 | Air-Gonomics, Inc. | Columnar filtering unit for spray painting |

| DE4134701C2 (de) * | 1991-10-21 | 1996-06-05 | Gema Volstatic Ag | Pulver-Sprühbeschichtungseinrichtung mit alternativ austauschbaren Filter- und Zykloneinheiten |

| DE4239496A1 (de) * | 1992-11-25 | 1994-05-26 | Gema Volstatic Ag St Gallen | Pulver-Sprühbeschichtungsvorrichtung |

| DE4300832A1 (de) * | 1993-01-14 | 1994-07-21 | Gema Volstatic Ag St Gallen | Pulver-Sprühbeschichtungsvorrichtung |

| DE4417728A1 (de) * | 1994-05-20 | 1995-11-23 | Gema Volstatic Ag | Bürstenvorrichtung zum Reinigen von Kanälen |

| EP0827428A1 (fr) * | 1995-05-22 | 1998-03-11 | Nordson Corporation | Systeme de recuperation a cyclone et separateur cyclone a manchon perfore |

| US5788728A (en) * | 1996-12-03 | 1998-08-04 | Nordson Corporation | Powder coating booth with improved cyclone separator |

| DE19720005C1 (de) * | 1997-05-13 | 1998-11-19 | Wagner Int | Einrichtung zum Abscheiden von Überschußpulver, das bei der Pulverbeschichtung von Werkstücken anfällt |

| GB9718944D0 (en) | 1997-09-05 | 1997-11-12 | Nordson Corp | Improvements relating to powder spray coating |

| US5906676A (en) * | 1997-10-01 | 1999-05-25 | Nordson Corporation | Ejector-augmented overspray reclaim system |

| WO2001019529A2 (fr) * | 1999-09-17 | 2001-03-22 | Nordson Corporation | Systeme d'application de poudre a changement de couleur rapide |

| EP1138394A1 (fr) * | 2000-03-31 | 2001-10-04 | Nordson Corporation | Améliorations concernant un système de revêtement en poudre |

| US6569217B1 (en) | 2000-05-10 | 2003-05-27 | Thomas M. DeMarco | Industrial dust collector with multiple filter compartments |

| US6730169B2 (en) | 2000-08-22 | 2004-05-04 | Nordson Corporation | Electrostatic power coating system |

| US6432173B1 (en) * | 2000-10-27 | 2002-08-13 | Donaldson Company, Inc. | Centrifugal separator arrangement for powder coating recovery system and methods |

| NL1017818C2 (nl) * | 2001-04-10 | 2002-10-15 | Cfs Bakel Bv | Luchteenheid voor het verwijderen van deeltjesvormig materiaal. |

| US20060207230A1 (en) * | 2003-03-17 | 2006-09-21 | Demarco Maxvac Corporation | Vacuum loader with filter doors |

| US20050274094A1 (en) * | 2003-03-17 | 2005-12-15 | Demarco Thomas M | Vacuum loader |

| US7716947B2 (en) * | 2005-10-07 | 2010-05-18 | Gas-Chill, Inc. | Apparatus and method for condensing hydrocarbons from natural gas |

| NO326078B1 (no) * | 2006-07-07 | 2008-09-15 | Shell Int Research | Fluidseparasjonskar |

| DE102006032184B4 (de) * | 2006-07-12 | 2010-06-17 | Eisenmann Anlagenbau Gmbh & Co. Kg | Vorrichtung zum Fördern pulverförmiger fluidisierter Medien |

| US7931718B2 (en) * | 2009-04-09 | 2011-04-26 | San Ford Machinery Co., Ltd. | Oil mist separator |

| CA2750586A1 (fr) * | 2009-10-22 | 2011-04-28 | Michael H. Bunnell | Systeme de cabine de pulverisation de peinture |

| DE102013007482A1 (de) * | 2013-04-29 | 2014-10-30 | Georg Schneider | Vorrichtung zum Auftragen von Material |

| US20150157972A1 (en) * | 2013-12-09 | 2015-06-11 | Keith Bratten | Demister Apparatus and Method |

| CN104289335B (zh) * | 2014-10-16 | 2016-07-20 | 浙江德立涂装机械有限公司 | 粉末静电喷涂系统 |

| CN104289336B (zh) * | 2014-10-16 | 2016-07-20 | 浙江德立涂装机械有限公司 | 自动喷粉系统 |

| CN110420790B (zh) * | 2019-08-01 | 2021-01-12 | 张家港市宏基精密铝材科技有限公司 | 一种环保型铝型材加工用喷涂装置 |

| US11878316B2 (en) * | 2020-12-15 | 2024-01-23 | Gallagher-Kaiser Corporation | Sliding drawer dry filtration system for a paint booth |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2259626A (en) * | 1939-04-06 | 1941-10-21 | Binks Mfg Co | Means for and method of eliminating splash in wash type spray booths |

| DE918193C (de) * | 1950-02-09 | 1954-09-20 | Heinrich Ausserehl | Farbspritzstand |

| US3473561A (en) * | 1966-03-29 | 1969-10-21 | Bert N Svenson | Check valve with supported closure member |

| DE2839540A1 (de) * | 1978-09-12 | 1980-03-20 | Hans J Schaad | Pulverspruehkabine |

| US4277260A (en) * | 1979-08-14 | 1981-07-07 | Browning Jesse H | Powder collectors |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US940076A (en) * | 1908-08-18 | 1909-11-16 | Jonathan M Seaver | Separator. |

| GB737457A (en) * | 1952-01-28 | 1955-09-28 | Pneumatic Conveyors Huddersfie | Improvements in or relating to separating dust from air |

| DE1753411U (de) * | 1957-08-03 | 1957-10-03 | Metallgesellschaft Ag | Bewegliche sperrvorrichtung im staubauslauf von mehrfach-fliehkraftabscheidern. |

| FR1226122A (fr) * | 1959-05-30 | 1960-07-08 | Applic De La Ventilation Soc D | Appareil de dépoussiérage par ventilateur de dépression avec récupération préalable et évacuation automatique des poussières |

| GB1014934A (en) * | 1962-12-19 | 1965-12-31 | Rotalectors | Improvements in or relating to apparatus for the separation of particles from fluids |

| US3618302A (en) * | 1969-10-17 | 1971-11-09 | Milan S Cornett | Unitary portable air cleaner |

| BE789579A (fr) * | 1971-10-06 | 1973-02-01 | Masuda Senichi | Enceinte pour l'application, au moyen d'un rideau de champs electriquesdu type contact, de revetements formes par des poudres chargees electrostatiquement |

| CH562639A5 (fr) * | 1973-07-19 | 1975-06-13 | Gema Ag | |

| DE2809020B2 (de) * | 1978-03-02 | 1980-08-28 | Adolf 7251 Weissach Berkmann | Beschichtungskabine für das elektrostatische Auftragen von pulverförmigen Stoffen |

| DE2813854A1 (de) * | 1978-03-31 | 1979-10-11 | Interesco Int Res | Vorrichtung zum rueckgewinnen von pulver, insbesondere aus pulver-spruehkabinen |

| US4224043A (en) * | 1978-04-20 | 1980-09-23 | Nfe International, Ltd. | Compact multistage particle separator |

| DE3003158A1 (de) * | 1980-01-30 | 1982-03-04 | ESB Elektrostatische Sprüh- und Beschichtungsanlagen G.F. Vöhringer GmbH, 7758 Meersburg | Vorrichtung zum pulverbeschichten von werkstuecken mit einer das werkstueck zeitweise aufnehmenden spruehkabine |

| DE3012877A1 (de) * | 1980-04-02 | 1981-10-08 | J. Wagner AG, 9450 Altstätten | Anlage zum pulverbeschichten von werkstuecken |

| US4303417A (en) * | 1980-10-03 | 1981-12-01 | George Koch Sons, Inc. | Spray booth with reconditioning filter system |

| US4401445A (en) * | 1981-03-17 | 1983-08-30 | Jesse Browning | Method for converting a liquid paint spray booth to a powder paint spray booth |

-

1982

- 1982-08-10 DE DE19823229756 patent/DE3229756A1/de not_active Withdrawn

-

1983

- 1983-07-20 DE DE8383107084T patent/DE3373985D1/de not_active Expired

- 1983-07-20 EP EP83107084A patent/EP0100932B1/fr not_active Expired

- 1983-07-20 AT AT83107084T patent/ATE30125T1/de not_active IP Right Cessation

- 1983-08-04 US US06/520,195 patent/US4504292A/en not_active Expired - Lifetime

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2259626A (en) * | 1939-04-06 | 1941-10-21 | Binks Mfg Co | Means for and method of eliminating splash in wash type spray booths |

| DE918193C (de) * | 1950-02-09 | 1954-09-20 | Heinrich Ausserehl | Farbspritzstand |

| US3473561A (en) * | 1966-03-29 | 1969-10-21 | Bert N Svenson | Check valve with supported closure member |

| DE2839540A1 (de) * | 1978-09-12 | 1980-03-20 | Hans J Schaad | Pulverspruehkabine |

| US4277260A (en) * | 1979-08-14 | 1981-07-07 | Browning Jesse H | Powder collectors |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4913085A (en) * | 1985-01-01 | 1990-04-03 | Esb Elektorstatische Spruh-Und Beschichtungsanlagen G.F. Vohringer Gmbh | Coating booth for applying a coating powder to the surface of workpieces |

| WO1986003994A1 (fr) * | 1985-01-02 | 1986-07-17 | Esb Elektrostatische Sprüh- Und Beschichtungsanlag | Cabine pour appliquer une couche de poudre sur la surface de pieces |

| US4770118A (en) * | 1985-01-02 | 1988-09-13 | Esb Elektrostatische Spruh- Und Beschichtungsanlagen G. F. Vohringer Gmbh | Coating booth for applying a coating powder to the surface of workpieces |

| FR2588780A1 (fr) * | 1985-10-17 | 1987-04-24 | Sames Sa | Installation de poudrage de pieces a cabine de poudrage maintenue en depression |

| EP0223660A1 (fr) * | 1985-10-17 | 1987-05-27 | Sames S.A. | Installation de poudrage de pièces à cabine de poudrage maintenue en dépression |

| DE4203948A1 (de) * | 1992-02-11 | 1993-08-12 | Sfb Spezial Filter Anlagen | Zyklonabscheider und pulverbeschichtungsanlage mit integriertem zyklonabscheider |

| EP0698421A1 (fr) * | 1994-08-22 | 1996-02-28 | Erich Bauer | Récupération de poudre par cyclone ou filtre et transfert de poudre par organe rotatif lors du fonctionnement avec cyclone |

| WO2014169992A1 (fr) * | 2013-04-18 | 2014-10-23 | Eisenmann Ag | Dispositif de guidage d'air de traitement chargé d'un excès de peinture pulvérisée, et installation de revêtement présentant un tel dispositif |

| IT201900024985A1 (it) * | 2019-12-20 | 2021-06-20 | Geico Spa | Cabina di verniciatura con sistema perfezionato per la sostituzione dei filtri |

| WO2021124183A1 (fr) * | 2019-12-20 | 2021-06-24 | Geico Spa | Cabine de peinture avec système amélioré de remplacement des filtres |

Also Published As

| Publication number | Publication date |

|---|---|

| ATE30125T1 (de) | 1987-10-15 |

| EP0100932A3 (en) | 1985-05-29 |

| DE3373985D1 (en) | 1987-11-12 |

| EP0100932B1 (fr) | 1987-10-07 |

| US4504292A (en) | 1985-03-12 |

| DE3229756A1 (de) | 1984-02-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0100932B1 (fr) | Cabine de pulvérisation de poudre | |

| EP2258485B2 (fr) | Dispositif de séparation de pulvérisations de laque humide | |

| CH638698A5 (de) | Beschichtungsvorrichtung fuer das elektrostatische auftragen von pulverfoermigen stoffen. | |

| DE4119216C2 (de) | Tropfenabscheider | |

| DE4134701C2 (de) | Pulver-Sprühbeschichtungseinrichtung mit alternativ austauschbaren Filter- und Zykloneinheiten | |

| DE3131565C2 (de) | Kabine zum Sprühbeschichten von Gegenständen mit Pulver | |

| DE2419925A1 (de) | Pulverspritzkabine | |

| EP0384236B1 (fr) | Cabine d'atomisation à poudre avec dispositif pour guider le gaz brut dans un courant aspirateur d'un séparateur | |

| EP3457033A1 (fr) | Dispositif aspirante destinée à aspirer l'air d'évacuation produit sur une plaque de cuisson en vertical en dessous d'une direction orientée vers le plan de plaque de cuisson | |

| DE2640219A1 (de) | Kabine fuer eine elektrostatische pulver-beschichtungsanlage | |

| DE2630646A1 (de) | Strassenkehrmaschine | |

| DE3731591C2 (fr) | ||

| DE3933405C2 (fr) | ||

| DE19851111C1 (de) | Saugbagger zum Aufnehmen von Sauggut, wie Erdreich oder Schlämme | |

| EP0014782A1 (fr) | Dispositif de dépoussiérage | |

| DE1421310A1 (de) | Nassstaubabscheider | |

| DE3408474C2 (fr) | ||

| EP1342506A1 (fr) | Cabine de poudrage | |

| DE2134775B2 (de) | Kabine zum elektrostatischen Aufbringen von Pulver | |

| DE3018162C2 (de) | Zyklon-Staubabscheider | |

| DE3318797C2 (de) | Zellenradschleuse | |

| DE1546677B2 (de) | Vorrichtung zur reinigung eines gasstromes | |

| DE4212270C2 (fr) | ||

| EP2332626B1 (fr) | Dispositif de séparation d'impuretés à partir d'un flux d'air | |

| DE3248098C1 (de) | Abzugs- und Filtereinrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| RHK1 | Main classification (correction) |

Ipc: B05B 15/12 |

|

| 17P | Request for examination filed |

Effective date: 19850827 |

|

| 17Q | First examination report despatched |

Effective date: 19861106 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19871007 |

|

| REF | Corresponds to: |

Ref document number: 30125 Country of ref document: AT Date of ref document: 19871015 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3373985 Country of ref document: DE Date of ref document: 19871112 |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 83107084.2 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19960619 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19960624 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19960710 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19960723 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19960729 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19960731 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19960919 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970720 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970720 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19970721 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970731 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980201 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19970720 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980331 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19980201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980401 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 83107084.2 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |