EP0100932A2 - Powder spray booth - Google Patents

Powder spray booth Download PDFInfo

- Publication number

- EP0100932A2 EP0100932A2 EP83107084A EP83107084A EP0100932A2 EP 0100932 A2 EP0100932 A2 EP 0100932A2 EP 83107084 A EP83107084 A EP 83107084A EP 83107084 A EP83107084 A EP 83107084A EP 0100932 A2 EP0100932 A2 EP 0100932A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- powder

- spray booth

- booth according

- powder spray

- cyclone

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 229940098458 powder spray Drugs 0.000 title claims abstract description 27

- 239000000843 powder Substances 0.000 claims abstract description 67

- 239000007921 spray Substances 0.000 claims abstract description 21

- 238000000576 coating method Methods 0.000 claims abstract description 16

- 239000011248 coating agent Substances 0.000 claims abstract description 15

- JTJMJGYZQZDUJJ-UHFFFAOYSA-N phencyclidine Chemical class C1CCCCN1C1(C=2C=CC=CC=2)CCCCC1 JTJMJGYZQZDUJJ-UHFFFAOYSA-N 0.000 claims description 13

- 238000005192 partition Methods 0.000 claims description 7

- 238000009795 derivation Methods 0.000 claims 1

- 238000004140 cleaning Methods 0.000 abstract description 9

- 230000000694 effects Effects 0.000 abstract description 2

- 230000005484 gravity Effects 0.000 abstract description 2

- 230000003247 decreasing effect Effects 0.000 abstract 1

- 239000002245 particle Substances 0.000 description 7

- 238000011084 recovery Methods 0.000 description 7

- 238000001556 precipitation Methods 0.000 description 3

- 230000001174 ascending effect Effects 0.000 description 2

- 238000005253 cladding Methods 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 230000000630 rising effect Effects 0.000 description 2

- 238000007790 scraping Methods 0.000 description 2

- 238000007789 sealing Methods 0.000 description 2

- 238000000926 separation method Methods 0.000 description 2

- 230000009471 action Effects 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 239000003086 colorant Substances 0.000 description 1

- 230000003670 easy-to-clean Effects 0.000 description 1

- 230000029142 excretion Effects 0.000 description 1

- 238000001914 filtration Methods 0.000 description 1

- 238000000227 grinding Methods 0.000 description 1

- 238000002347 injection Methods 0.000 description 1

- 239000007924 injection Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 238000004904 shortening Methods 0.000 description 1

- 238000007873 sieving Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B14/00—Arrangements for collecting, re-using or eliminating excess spraying material

- B05B14/40—Arrangements for collecting, re-using or eliminating excess spraying material for use in spray booths

- B05B14/45—Arrangements for collecting, re-using or eliminating excess spraying material for use in spray booths using cyclone separators

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05B—SPRAYING APPARATUS; ATOMISING APPARATUS; NOZZLES

- B05B14/00—Arrangements for collecting, re-using or eliminating excess spraying material

- B05B14/40—Arrangements for collecting, re-using or eliminating excess spraying material for use in spray booths

- B05B14/48—Arrangements for collecting, re-using or eliminating excess spraying material for use in spray booths specially adapted for particulate material

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S118/00—Coating apparatus

- Y10S118/07—Hoods

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S55/00—Gas separation

- Y10S55/46—Spray booths

Definitions

- the invention relates to a powder spray booth with a device for separating or recovering spray powder from its conveying gas, with an outlet opening arranged on an outlet side of the spray booth, through which the conveying gas with a residual portion of the spray powder not deposited on the workpiece passes through a plurality of cyclone separators integrated into the spray booth is sucked in.

- cyclone separators are also used to recover powder from the exhaust air from powder spray booths, to which the conveying air carrying the residual powder is usually fed in a rotating manner from above and centrally sucked up again, with a large proportion of the imported residual powder settling at the bottom of the cyclone and can be used there for further use.

- cyclone separators have the advantage of better cleaning, since practically no powder settles inside their housing.

- the lower degree of excretion is disadvantageous, especially with fine-grain powder. About 95% of powders with a particle size of 10 microns are recovered, ie only 5% are lost, but with powder dimensions of less than 10 microns, only 60% are recovered. For coarse powder, it is therefore very economical to operate the recovery exclusively with cyclones, but with finer powder types, post-filtering for further use is essential.

- the invention pursues the task of developing the powder spray booth defined at the outset in such a way that, when the coating process is made more uniform, the degree of precipitation on the workpiece increases, while the amount of powder supplied to the cyclone separators is reduced.

- the cabin outlet is designed according to the invention as a horizontal transverse slot arranged near the injection opening near the cabin ceiling, from which at least one suction channel of the cyclone separator originates.

- Cyclone separators of the same height are preferably arranged in a row next to one another, distributed over at least the major part of the cabin outlet side. It is relatively easy to equalize the cabin flow.

- the suction channel formed above the cyclone separators can directly connect to the transverse slot. It can have the same depth and be closed at the back by a flat wall if the individual cyclones are close together. However, if there is an intermediate distance, the cross-section of the suction channel can change over its length, in order to make room for other flow paths.

- the cyclone separators are expediently arranged at a vertical distance above the cabin floor in such a way that residual powder deposited on the cabin floor and the spray powder recovered in the cyclones can be fed to the same collecting space. Except for the inlet and outlet opening, the cyclone separators towards the coating room can also be shielded by a common, smooth surface and therefore easy to clean.

- the lock closure arranged at the lower end of a cyclone separator is characterized according to the invention by closure elements connected in series and alternately movable between the open and closed positions by means of a common motor-movable support.

- closure elements can then be relatively large and move largely perpendicular to the remaining opening gap. In this way, powder particles remaining in the gap are only exposed to a compressive force, but not to a grinding load, as occurs, for example, in cell locks.

- the pressure can be reduced as desired without the risk of leaks in the large sealing surfaces.

- both locking elements in particular resiliently adjustable relative to one another, are attached to one end of a double lever which can be pivoted about a horizontal axis, at the other end of which a periodically actuated actuator acts.

- Such training is not only simple, but also extremely reliable.

- a filter unit is connected downstream of the cyclone separators to increase the degree of recovery, this can be inserted directly into the spray booth on the outside of the cyclone separator, in particular integrated into it. It is also relatively easy to guide or provide funding for bringing together the amounts of powder separated by the cyclone separator and the filter unit.

- a switch device is particularly recommended for this. for optional merging or separate discharge of the residual powder quantities recovered by cyclones and filter units.

- a collecting space for recovered residual powder attached under the filter unit can be connected to a separate collecting space by a first switching element and to a common powder collecting space by a second switching element.

- Both switch elements can be connected in such a way that each can only be opened in the closed position of the other or that both switch elements, in particular together, can be actuated alternately in opposite directions.

- Significance here can be a sloping floor arranged under the post-filter unit, which is inclined towards the cyclones after a common partition wall and has a first outlet flap close to the partition wall to a separate collecting space, while a second outlet flap is attached to the common collecting space in the partition wall close to the sloping floor is.

- the first outlet flap is advantageously mounted at its lower end, the second at its upper end.

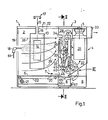

- the powder spray booth forms a linen coating space 2, to which two recovery units, a cyclone unit 3 and a filter unit 4 are connected, both of which are under the action of a suction fan 5.

- An effective scraping device 7 on the cabin floor 6 conveys into a powder carriage 8 which can be moved through the space 9 from the outside.

- Through openings 13 for workpieces 14 are formed in the cabin ceiling 11 and in the two end walls 12 of the coating room 2, to which tunnel attachments may also be connected on the outside, which are each suspended by means of a hanger 15 through a ceiling slot 16 on a circular conveyor 17 and so that they are automatically conveyed through the coating space 2 at a uniform speed.

- This scraper device 7 has a U-shaped scraper 20 which is moved back and forth over the cabin floor by means of a chain 22 driven by a motor 21 and is temporarily lifted off when moving to the left in FIG. 1.

- the cyclone unit 3 has, as can also be seen from FIGS. 2 and 5, five individual cyclone separators 23, that is to say in a known manner vertically arranged sheet metal container with a upper cylinder part 24 and a lower acute-angled cone part 25. From the middle of the cylinder part, a tube 26 leads upwards through a transverse suction channel 27 into an overlying connection space 28, from which the air according to arrows 29 into which the filter 31 of the filter r-aggregates 4 receiving filter space 32 and then sucked through the filter by the suction fan 5 and is expelled through filter mats 33 as shown by the arrow.

- the common suction channel 27 of all cyclone separators 23 is located directly under the cabin ceiling 11 and is connected directly to the coating space 2 by a transverse slot 34, possibly covered by a perforated plate.

- guide vanes 35 are inserted in the usual manner, which set the air sucked in downward in rotation according to the flow lines 36 before the direction of flow reverses toward the upper tube 26. Since the powder particles do not participate in this reversal movement because of their larger mass, they are removed downward and predominantly fall out of the cone part 25.

- All cyclone separators 23 are closed off by a common flat cladding wall 37 towards the coating space 2.

- the air sucked in by the suction fan 5 enters at least approximately horizontally through the spray opening 19 in a somewhat uniformly distributed manner according to the flow lines 38 drawn with solid lines. It should initially be disregarded that, depending on the arrangement and connection of the cabin, additional air quantities can also enter through the through openings 13 and the ceiling slot 16. These secondary flows are of no particular importance for the guidance of the powder on the workpiece. It can therefore be assumed that the powder sprayed by the powder spray gun is transported predominantly horizontally to the workpiece 14 by the sucked-in air and thereby ei ne even coating enables. The electrostatic guidance ends behind the workpiece.

- the sucked-in air now forms the predominant conveying medium and is sucked into the suction channel 27 through the high transverse slot 34, the trajectories 39 of the powder particles are still supported, ie they are raised a little. The vast majority of the powder hits the cladding wall 37 and falls from there to the floor.

- the filter 31 which can be designed as a pocket filter with a large surface area and in a known manner provided with a cleaning device.

- Lock closures 40 are attached to the lower intermediate wall 42, namely that a truncated cone-shaped funnel 44 is detachably flanged under each outlet opening 43 of the conical part 25 and forms a second outlet opening 54 with its lower end.

- Both outlet openings are conical valve elements 45 and 46 which are assigned to a common one Carrier rod 48 are attached, which in turn is seated at one end of a double lever 49, at the other end of which an actuator 51 such as a compressed air cylinder or the like is connected.

- This double lever 49 is sealed on an axle 52 fixed to the housing.

- At least one of the valve elements 45 and 46 is also provided to be resiliently adjustable over a limited distance in the direction of the rod 48. This ensures that when the support rod 48 is lifted, the valve element 45, for example, first comes into sealing contact with the first outlet opening 43 before the second valve element 46 lifts off the second outlet opening 54. In this way there is always an air seal in the inside of the cyclone preserve space.

- the amount of powder accumulated in the bottom region of the cone part 26 during the draining process is immediately entered into the funnel 44 when switching back to the operating position shown.

- the filter chamber 32 of the filter unit 4 is closed towards the cyclone unit 3 by a rear wall 55 covering all cyclone separators and down towards the chamber 9 by an inclined floor 56.

- a horizontal pivot axis 57 is provided, on which a first outlet flap 58 is attached, which closes a first outlet opening 59 in the inclined floor 56 in the closed position shown and in the opening position 59 'shown with broken lines that from Inclined floor 56 introduces powder sliding down into space 9, in which a further powder container 8 can optionally be attached.

- a second outlet opening 62 is attached above the pivot axis 57 and a gusset 61 which extends the inclined floor 56 at the lower end of the rear wall 55, which is closed in the manner drawn with solid lines by a second outlet flap 63, but which extends around its high pivot axis 64 to can be pivoted into the open position 64 'shown with broken lines.

- Both flaps 58 and 63 can also be mutually coupled in such a way that only one is always open but the other is closed.

- a filter unit 4 can be completely dispensed with. So you could place the suction fan 5 directly in the room 28. However, if the filter unit is present, it may be possible that can be driven without filter 31.

- Such a filter 31 is in any case necessary when working with fine-grained spray powder which, for example, only enables a cyclone recovery rate of 60 to 80%.

- the downstream filter separation is necessary and, above all, the powder can be separated into coarse-grained and fine-grained powder parts.

- powder booths provided with z y clone separators will generally be used in all work with coarse-grained powder, because this simplifies cleaning. Cleaning in the filter unit 4 is much more cumbersome. It is therefore possible, under certain circumstances, to give up the powder parts filtered out there and to drive different colors in succession, while in the cyclone unit 3 only the smooth surfaces outside the cyclone housing are cleaned. If this principle is used, several cyclone cabins can also be connected to a separate filter unit. Overall, the areas to be cleaned are in any case significantly reduced if the cyclone separators are arranged in the powder spray booth, which is otherwise closed.

- gusset spaces 71 also remain on the back between the guide plates 69, these gusset spaces can be used to convey the suction air from the high space 28 into the filter space 32.

- these gusset spaces can be used to convey the suction air from the high space 28 into the filter space 32.

- Zwikkel spaces 71 to the lower end by a preferably curved floor baffle / be closed. From the flat rear wall 55 of FIG. 3, only a flat rear strip 551 remains, to which the filter 31 can be moved closer.

Landscapes

- Details Or Accessories Of Spraying Plant Or Apparatus (AREA)

- Cyclones (AREA)

- Nozzles (AREA)

- Electrostatic Spraying Apparatus (AREA)

Abstract

Description

Die Erfindung betrifft eine Pulversprühkabine mit einer Vorrichtung zum Abscheiden bzw. RUckgewinnen von SprUhpulver aus dessen Fördergas, mit einer an einer Auslaßseite der Sprühkabine angeordneten Auslaßöffnung, durch welche hindurch das Fördergas mit einem Restanteil des nicht am Werkstück niedergeschlagenen Sprühpulvers durch mehrere in die Sprühkabine integrierte Zyklonabscheider eingesaugt wird.The invention relates to a powder spray booth with a device for separating or recovering spray powder from its conveying gas, with an outlet opening arranged on an outlet side of the spray booth, through which the conveying gas with a residual portion of the spray powder not deposited on the workpiece passes through a plurality of cyclone separators integrated into the spray booth is sucked in.

Neben verschiedenartigen Filteraggregaten werden zum Wiedergewinnen von Pulver aus der Abluft von Pulversprühkabinen auch Zyklonabscheider eingesetzt, welchen die das Restpulver führende Förderluft rotierend meist von oben zugeführt und zentrisch wiederum nach oben abgesaugt wird, wobei sich ein großer Anteil des eingeführten Restpulvers am Boden des Zyklons absetzt und dort einer weiteren Verwendung zugeführt werden kann. Gegenüber Filteraggregaten haben Zyklonabscheider den Vorteil der besseren Reinigung, da sich in ihrem Gehäuseinneren praktisch kein Pulver absetzt. Nachteilig ist dagegen der geringere Ausscheidungsgrad vor allem bei feinkörnigem Pulver. So werden zwar von Pulvern einer Partikelgröße von 10 mikron etwa 95 % zurückgewonnen, d.h. es gehen nur 5 % verloren, aber bei Pulverabmessungen von weniger als 10 mikron werden nur 60 % zurückgewonnen. Daher ist es bei grobem Pulver durchaus wirtschaftlich, die Rückgewinnung ausschließlich mit Zyklonen zu betreiben, aber bei feineren Pulverarten Ist eine Nachfilterung zur Weiterverwendung unerläßlich.In addition to various types of filter units, cyclone separators are also used to recover powder from the exhaust air from powder spray booths, to which the conveying air carrying the residual powder is usually fed in a rotating manner from above and centrally sucked up again, with a large proportion of the imported residual powder settling at the bottom of the cyclone and can be used there for further use. Compared to filter units, cyclone separators have the advantage of better cleaning, since practically no powder settles inside their housing. On the other hand, the lower degree of excretion is disadvantageous, especially with fine-grain powder. About 95% of powders with a particle size of 10 microns are recovered, ie only 5% are lost, but with powder dimensions of less than 10 microns, only 60% are recovered. For coarse powder, it is therefore very economical to operate the recovery exclusively with cyclones, but with finer powder types, post-filtering for further use is essential.

Durch die DE-OS 28 39 540-ist es bekannt, eine Reihe Zyklonabscheider fest einer Pulversprühkabine zuzuordnen und saugseitig unmittelbar an den Kabinenauslaß anzuschliessen. Dort ist aber der Auslaß im Kabinenboden angeordnet, wodurch das etwa waagrecht in die Kabine eingesprühte Pulver durch die Saugkraft nach unten abgelenkt wird, was zu einer Verkürzung der Flugbahn und einer Minderung des Niederschiagsgrades führt, während der den Zyklonabscheidern zugeführte Pulveranteil unverhältnismäßig groß ist.From DE-OS 28 39 540 it is known to permanently assign a series of cyclone separators to a powder spray booth and to connect them directly to the booth outlet on the suction side. There, however, the outlet is arranged in the cabin floor, whereby the powder sprayed approximately horizontally into the cabin is deflected downward by the suction force, which leads to a shortening of the trajectory and a reduction in the degree of precipitation, while the proportion of powder supplied to the cyclone separators is disproportionately large.

Die Erfindung verfolgt dagegen die Aufgabe, die eingangs definierte Pulversprühkabine so weiterzubilden, daß bei einer Vergleichmäßigung des Beschichtungsvorganges der Niederschlagsgrad am Werkstück vergrößert, die den Zyklonabscheidern zugeführte Pulvermenge dagegen verkleinert wird.The invention, on the other hand, pursues the task of developing the powder spray booth defined at the outset in such a way that, when the coating process is made more uniform, the degree of precipitation on the workpiece increases, while the amount of powder supplied to the cyclone separators is reduced.

Zur Lösung dieser Aufgabe wird erfindungsgemäß der Kabinenauslaß als gegenüber der EinsprUhöffnung nahe der Kabinendecke angeordneter waagrechter Querschlitz ausgebildet, von dem wenigstens ein Saugkanal der Zyklonabscheider ausgeht.To achieve this object, the cabin outlet is designed according to the invention as a horizontal transverse slot arranged near the injection opening near the cabin ceiling, from which at least one suction channel of the cyclone separator originates.

Selbst wenn man nur zwei kleine Zyklonabscheider-anschließt, wird dadurch der Saugstrom von der Einström- öffnung quer durch den ganzen Beschichtungsraum hindurch vergleichmäßigt und läuft auf der ganzen Kabinenbreite weitgehend ansteigend zum hochliegenden Querschlitz - Auslaß. Dadurch wird das Pulver auf einer verlängerten Flugbahn gehalten, was eine Steigerung des Niederschlags-Wirkungsgrades mit sich bringt. Das Fördergas strõmt dann auf der ganzen Breite des Beschichtungsraumes etwa keilförmig ansteigend durch den hochliegenden Querschlitz in den Saugkanal ein: Auch dabei ergibt sich eine dem Zykloneffekt vergleichbare Abscheidung dadurch, daß die Schwerkraft der Pulverpartikel der Hubkraft des Fördergases entgegenwirkt. Der größere Teil des Pulvers bewegt sich daher weniger ansteigend und mehr auf waagrechter Bahn. Die meisten Pulverpartikel sinken gegen den ansteigenden Fördergasstrom stärker werdend ab und gelangen zur Rückwand des Beschichtungsraumes, sofern sie nicht schon vorher zu Boden fallen.Da somit die den Zyklonen noch zugeführte Restmenge Sprühpulver erheblich vermindert wird und nur diese dem geringeren Rückgewinnungsgrad der Zyklonenabscheider unterliegt, steigert sich der effektive Rückgewinnungsanteil.Even if only two small cyclone separators are connected, the suction flow from the inflow opening is made uniform across the entire coating room and runs largely ascending across the entire width of the cabin to the high-lying cross slot - Outlet. This keeps the powder on an extended trajectory, which leads to an increase in the efficiency of precipitation. The conveying gas then flows over the entire width of the coating space, rising in a wedge shape through the high transverse slot into the suction channel: Here too, a separation comparable to the cyclone effect results from the fact that the gravity of the powder particles counteracts the lifting force of the conveying gas. The greater part of the powder therefore moves less ascending and more on a horizontal path. Most of the powder particles sink more and more against the rising flow of the conveying gas and reach the back wall of the coating room, provided they do not fall to the floor beforehand, so that the residual amount of spray powder still supplied to the cyclones is considerably reduced and only this is subject to the lower recovery rate of the cyclone separator the effective recovery share.

Vorzugsweise werden Zyklonabscheider gleicher Höhe in einer Reihe nebeneinander über wenigstens den größten Teil der Kabinen-Auslaßseite verteilt angeordnet. Die Vergleichmäßigung der Kabinenströmung läßt sich so relativ einfach erreichen.Cyclone separators of the same height are preferably arranged in a row next to one another, distributed over at least the major part of the cabin outlet side. It is relatively easy to equalize the cabin flow.

Der dabei über den Zyklonabscheidern gebildete Saugkanal kann sich unmittelbar an den Querschlitz anschließen. Er kann gleiche Tiefe haben und rückseitig durch eine ebene Wand abgeschlossen sein, wenn die einzelnen Zyklonen dicht aneinanderstehen. Bleibt jedoch Zwischenabstand, sd kann sich der Querschnitt des Saugkanals über seine Länge hinweg ändern, um dadurch Platz für andere Strömungswege zu schaffen.The suction channel formed above the cyclone separators can directly connect to the transverse slot. It can have the same depth and be closed at the back by a flat wall if the individual cyclones are close together. However, if there is an intermediate distance, the cross-section of the suction channel can change over its length, in order to make room for other flow paths.

Zweckmäßigerweise werden die Zyklonabscheider mit lotrechtem Abstand über dem Kabinenboden angebracht, derart, daß am Kabinenboden abgelagertes Restpulver und das in den Zyklonen wiedergewonnene Sprühpulver dem gleichen Sammelraum zugeführt werden können. Bis auf Ein- und Ausgabeöffnung lassen sich zudem die Zyklonabscheider zum Beschichtungsraum hin durch eine gemeinsame glattflächige und daher leicht zu reinigende Verkleidung abschirmen.The cyclone separators are expediently arranged at a vertical distance above the cabin floor in such a way that residual powder deposited on the cabin floor and the spray powder recovered in the cyclones can be fed to the same collecting space. Except for the inlet and outlet opening, the cyclone separators towards the coating room can also be shielded by a common, smooth surface and therefore easy to clean.

Der am Unterende eines Zyklonabscheiders angeordnete Schleusenverschluß ist erfindungsgemäß gekennzeichnet durch hintereinander geschaltete, mittels eines gemeinsamen motorisch bewegbaren Trägerswechselseitig zwischen Öffnungs- und Schließstellung bewegbare Verschlußelemente. Solche Verschlußelemente können dann verhältnismäßig großflächig sein und bewegen sich weitgehend senkrecht zum verbleibenden öffnungsspalt. Auf diese Weise werden im Spalt verbliebene Pulverpartikel nur einer Druckkraft ausgesetzt, nicht aber einer schleifenden Beanspruchung, wie sich diese beispielsweise bei Zellenschleusen einstellt. Zudem kann die Druckbeanspnchung nach Belieben vermindert werden, ohne daß bei den großen Abdichtungsflächen die Gefahr von Undichtheiten besteht.The lock closure arranged at the lower end of a cyclone separator is characterized according to the invention by closure elements connected in series and alternately movable between the open and closed positions by means of a common motor-movable support. Such closure elements can then be relatively large and move largely perpendicular to the remaining opening gap. In this way, powder particles remaining in the gap are only exposed to a compressive force, but not to a grinding load, as occurs, for example, in cell locks. In addition, the pressure can be reduced as desired without the risk of leaks in the large sealing surfaces.

Nach einem Erfindungsvorschlag sind beide Verschlußelemente, insbesondere nachgiebig gegeneinander verstellbar, an einem Ende eines um eine waagerechte Achse schwenkbaren Doppelhebels angebracht, an dessen anderem Ende ein periodisch betätigtes Stellorgan angreift. Eine solche Ausbildung ist nicht nur einfach, sondern auch außerordentlich betriebssicher.According to a proposal of the invention, both locking elements, in particular resiliently adjustable relative to one another, are attached to one end of a double lever which can be pivoted about a horizontal axis, at the other end of which a periodically actuated actuator acts. Such training is not only simple, but also extremely reliable.

Sofern den Zyklonabscheidern zur Steigerung des Ruckgewinnungsgrades ein Filteraggregat nachgeschaltet wird, kann sich dieses auf der Außenseite der Zyklonabscheider unmittelbar in die Sprühkabine einfügen, insbesondere in diese integriert werden. Dabei ist es zudem verhältnismäßig einfach, Leit-oder Fördermittel zum Zusammenführen der durch die Zyklonabscheider und das Filteraggregat ausgeschiedenen Pulvermengen vorzusehen.If a filter unit is connected downstream of the cyclone separators to increase the degree of recovery, this can be inserted directly into the spray booth on the outside of the cyclone separator, in particular integrated into it. It is also relatively easy to guide or provide funding for bringing together the amounts of powder separated by the cyclone separator and the filter unit.

Hierzu empfiehlt sich vor allem eine Weicheneinrichtung. zum wahlweisen Zusammenführen oder getrennten Ableiten der durch Zyklone und Filteraggregate wiedergewonnenen Restpulvermengen. So kann ein unter dem Filteraggregat angebrachter Auffangraum für wiedergewonnenes Restpulver durch ein erstes Weichenelement mit einem gesonderten Sammelraum und durch ein zweites Weichenelement mit einem gemeinsamen Pulver-Sammelraum verbindbar sein. Dabei lassen sich beide Weichenelemente derart zusammenschließen, daß jedes nur in der Schließstellung des anderen zu öffnen ist oder daß beide Weichenelemente, insbesondere gemeinsam, wechselweise gegensinnig zu betätigen sind.A switch device is particularly recommended for this. for optional merging or separate discharge of the residual powder quantities recovered by cyclones and filter units. For example, a collecting space for recovered residual powder attached under the filter unit can be connected to a separate collecting space by a first switching element and to a common powder collecting space by a second switching element. Both switch elements can be connected in such a way that each can only be opened in the closed position of the other or that both switch elements, in particular together, can be actuated alternately in opposite directions.

Bedeutung kann hier ein unter dem Nachfilteraggregat angeordneter Schrägboden haben, der nach einer gemeinsamen Zwischenwand zu den Zyklonen hin geneigt ist und dicht an der Zwischenwand eine erste Auslaßklappe zu einem gesonderten Sammelraum aufweist, während in der Zwischenwand dicht am Schrägboden eine zweite Auslaßklappe zum gemeinsamen Sammelraum angebracht ist. Vorteilhafterweise wird hier die erste Auslaßklappe an ihrem unteren Ende, die zweite an ihrem oberen Ende gelagert.Significance here can be a sloping floor arranged under the post-filter unit, which is inclined towards the cyclones after a common partition wall and has a first outlet flap close to the partition wall to a separate collecting space, while a second outlet flap is attached to the common collecting space in the partition wall close to the sloping floor is. The first outlet flap is advantageously mounted at its lower end, the second at its upper end.

Die Zeichnung gibt die Erfindung beispielsweise wieder. Es zeigen

- Fig. 1 einen Querschnitt durch eine erfindungsgemäße Pulversprühkabine,

- Fig. 2 einen Schnitt durch diese Kabine nach der Linie II-II in Fig. 1,

- Fig. 3 in vergrößerter Darstellung die Stelle III in Fig. 1,

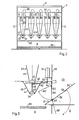

- Fig. 4 einen Teilschnitt durch eine abgewandelte Kabinenausführung nach der Linie IV-IV in Fig. 5 und

- Fig. 5 einen Teilschnitt durch diese Kabine nach der Linie V-V in Fig. 4.

- 1 shows a cross section through a powder spray booth according to the invention,

- 2 shows a section through this cabin along the line II-II in Fig. 1,

- 3 is an enlarged view of the point III in Fig. 1,

- Fig. 4 shows a partial section through a modified cabin execution along the line IV-IV in Fig. 5 and

- 5 shows a partial section through this cabin along the line VV in FIG. 4th

Nach der Zeichnung bildet die Pulversprühkabine leinen Beschichtungsraum 2, an den sich zwei Rückgewinnungsaggregate, ein Zyklonaggregat 3 und ein Filteraggregat 4 anschließen, die beide unter der Wirkung eines Sauggebläses 5 stehen. Eine auf dem Kabinenboden 6 wirksame Schabevorrichtung 7 fördert dabei in einen Pulverwagen 8, der durch den Raum 9 hindurch von außen verfahrbar ist.According to the drawing, the powder spray booth forms a

In der Kabinendecke 11 und in den beiden Stirnwänden 12 des Beschichtungsraumes 2, an die sich außen ggf. noch Tunnelansätze anschließen, sind Durchlauföffnungen 13 für Werkstücke 14 eingeformt, die jeweils mittels eines Gehänges 15 durch einen Deckenschlitz 16 hindurch an einem Kreisförderer 17 aufgehängt sind und damit automatisch mit gleichförmiger Geschwindigkeit durch den Beschichtungsraum 2 hindurchgefördert werden.Through

Mittels einer oder mehrerer Pulversprühpistolen 18 wird Sprühpulver zum Beschichten der Werkstücke 14 durch die Einsprühöffnung 19 eingesprüht und durch elektrostatische Kräfte zum jeweiligen Werkstück 5 geführt. Ein Teil der nicht am Werkstück haften gebliebenen Pulverpartikel fällt unmittelbar auf den Kabinenboden 6 und wird durch die Schabevorrichtung 7 dem Pulverwagen 8 zugeführt. Diese Schabevorrichtung 7 weist einen U-förmigen Schaber 20 auf, der mittels einer von einem Motor 21 angetriebenen Kette 22 hin- und hergehend über dem Kabinenboden verschoben und bei der Bewegung nach links in Fig. 1 vorübergehend abgehoben wird.Using one or more

Das Zyklonaggregat 3 weist, wie u.a. auch aus Figi.-2 zu ersehen, fünf einzelne Zyklonabscheider 23 auf, d.h. in bekannter Weise lotrecht angeordnete Blechbehälter mit einem oberen Zylinderteil 24 und einem unteren spitzwinkligen Kegelteil 25. Aus der Mitte des Zylinderteiles führt nach oben ein Rohr 26 durch einen querliegenden Saugkanal 27 hindurch in einen darüberliegenden Anschlußraum 28, aus dem heraus die Luft gemäß den Pfeilen 29 in den das Filter 31 des Fille-r-aggregates 4 aufnehmenden Filterraum 32 und dann durch das Filter hindurch vom Sauggebläse 5 angesaugt und durch Filtermatten 33 hindurch gemäß Pfeil wieder ausgestoßen wird.The

Der gemeinsame Saugkanal 27 aller Zyklonabscheider 23 liegt dicht unter der Kabinendecke 11 und ist durch einen, evtl. noch durch ein Lochblech überdeckten Querschlitz 34 direkt mit dem Beschichtungsraum 2 verbunden. Zwischen der oberen Wandung des Zylinderteiles 24 und dem Rohr 26 sind in der üblichen Weise Leitschaufeln 35 eingefügt, welche die nach unten eingesaugte Luft gemäß den Strömungslinien 36 in Rotation versetzen, bevor sich die Strömungsrichtung zum oberen Rohr 26 hin umkehrt. Da die Pulverpartikel diese Umkehrbewegung wegen ihrer größeren Masse nicht mitmachen, werden sie nach unten abgetragen und fallen überwiegend aus dem Kegelteil 25 heraus.The

Alle Zyklonabscheider 23 sind durch eine gemeinsame ebene Verkleidungswand 37 zum Beschichtungsraum 2 hin abgeschlossen. Die vom Sauggebläse 5 angesaugte Luft tritt einigermaßen gleichmäßig verteilt gemäß den mit vollen Linien gezeichneten Strömungslinien 38 wenigstens annähernd waagerecht durch die Einsprühöffnung 19 ein. Dabei soll zunächst unberücksichtigt bleiben, daß weitere Luftmengen je nach Anordnung und Anschluß der Kabine auch durch die Durchlauföffnungen 13 und den Deckenschlitz 16 eintreten können. Für die Führung des Pulvers am Werkstück haben diese Nebenströmungen jedoch keine sonderliche Bedeutung. Es darf also davon ausgegangen werden, daß das von der Pulversprühpistole versprühte Pulver von der angesaugten Luft überwiegend waagerecht bis zum Werkstück 14 transportiert wird und dadurch eine gleichmäßige Beschichtung ermöglicht. Hinter dem Werkstück endet zunächst die elektrostatische Führung. Da die angesaugte Luft jetzt das überwiegende Fördermedium bildet und durch den hochliegenden Querschlitz 34 in den Saugkanal 27 eingesaugt wird, werdenzwar die Flugbahnen-39 der Pulverpartikel noch gestützt, d.h. sie werden noch etwas angehoben. Der weitaus überwiegende Teil des Pulvers stößt aber gegen die Verkleidungswand 37 und fällt von dort zu Boden.All

Nur ein sehr geringer Anteil des gesamten versprühten Pulvers gelangt in die Zyklonabscheider, und der Rest wird wiederum im Filter 31 aufgefangen, das als großflächiges und in bekannter Weise mit einer Abreinigungsvorrichtung versehenes Taschenfilter ausgebildet sein kann.Only a very small proportion of the total sprayed powder gets into the cyclone separator, and the rest is again collected in the

Die oberen und unteren Enden der einzelnen Zyklonabscheider sind in gemeinsamen Zwischenwänden 41, 42 gefaßt. An der unteren Zwischenwand 42 sind Schleusenverschlüsse 40 angebracht und zwar ist unter jeder Auslaßöffnung 43 des Kegelteils 25 ein kegelstumpfförmiger Trichter 44 lösbar angeflanscht und bildet mit seinem unteren Ende eine zweite Auslaßöffnung 54. Beiden Auslaßöffnungen sind kegelförmige Ventilelemente 45 und 46 zugeordnet, die an einem gemeinsamen Trägerstab 48 angebracht sind, der wiederum an einem Ende eines Doppelhebels 49 sitzt, an dessen anderem Ende ein Betätigungsorgan 51 wie ein Druckluftzylinder o. dgl. angeschlossen ist. Dieser Doppelhebel 49 ist abgedichtet auf einer gehäusefesten Achse 52 gelagert. Wenigstens eines der Ventilelemente 45 und 46 ist auch über eine begrenzte Strecke in Richtung des Stabes 48 nachgiebig verstellbar vorgesehen. Dadurch wird gewährleistet, daß beim Anheben des Trägerstabes 48 zunächst beispielsweise das Ventilelement 45 abdichtend in der ersten Auslaßöffnung 43 zur Anlage kommt, bevor das zweite Ventilelement 46 von der zweiten Auslaßöffnung-:54 abhebt. Auf diese Weise bleibt ständig ein Luftabschluß des Zyklon-Innenraumes erhalten. Die während des Ablaßvorganges im Bodenbereich des Kegelteiles 26 angesammelte Pulvermenge wird beim Rückschalten in die gezeigte Betriebsstellung unverzüglich in den Trichter 44 eingegeben. Der Filterraum 32 des-Filteraggregates 4 wind zum Zyklonaggregat 3 hin durch eine alle Zyklonabscheider hinterfassende Rückwand 55 und nach unten zum Raum 9 hin durch einen Schrägboden 56 abgeschlossen. Im Bereich von dessen Schnittkante mit der Rückwand 55 ist eine waagerechte Schwenkachse 57 vorgesehen, auf der eine erste Auslaßklappe 58 angebracht ist, die in der gezeigten Schließstellung eine erste Auslaßöffnung 59 im Schrägboden 56 abschließt und in der mit unterbrochenen Linien eingezeichneten Öffnungsstellung 59' das vom Schrägboden 56 herabgleitende Pulver in den Raum 9 einleitet, in dem ggf. ein weiterer Pulverbehälter 8 angebracht sein kann.The upper and lower ends of the individual cyclone separators are contained in

Ferner ist oberhalb der Schwenkachse 57 und eines den Schrägboden 56 verlängernden Zwickels 61 am unteren Ende der Rückwand 55 eine zweite Auslaßöffnung 62 angebracht, die in der mit vollen Linien gezeichneten Weise durch eine zweite Auslaßklappe 63 verschlossen ist, die aber um ihre hochliegende Schwenkachse 64 bis in die mit unterbrochenen Linien eingezeichnete öffnungsstellung 64' geschwenkt werden kann. Beide Klappen 58 und 63 können auch wechselseitig derart gekuppelt sein, daß nur immer eine geöffnet, die andere aber geschlossen ist.Furthermore, a second outlet opening 62 is attached above the

Ist die Auslaßklappe 63 geöffnet, dann gelangen die Pulvermengen des Zyklonaggregates und des Filteraggregates in den Pulverbehälter'8, wo sie der gemeinsamen Aufbereitung durch eine Siebmaschine 65 unterzogen, mittels Luftboden 66-aufgelockert und direkt durch einen Injektor 67 und Schlauch 68 der Pulversprühpistole 18 zugeführt werden. öffnet man je- doch die Auslaßklappe 58, dann wird das vom Filteraggregat 4 durch Abreinigung des Filters 31 rückgewonnene Pulver durch die Auslaßöffnung 59 getrennt einem nicht dargestellten und im Raum 9 anzuordnenden Pulverwagen 8 zugeführt.If the

Arbeitet man mit grobkörnigem Pulver, das einen ungewöhnlich hohen Rückgewinnungsgrad ermöglicht, dann kann u.U. auf ein Filteraggregat 4 ganz verzichtet werden. Man könnte also das Sauggebläse 5 direkt im Raum 28 unterbringen. Ist jedoch das Filteraggregat vorhanden, dann kann u.U. ohne Filter 31 gefahren werden.If you work with coarse-grained powder, which enables an unusually high degree of recovery, you may a filter unit 4 can be completely dispensed with. So you could place the

Ein solches Filter 31 ist jedenfalls notwendig, wenn mit feinkörnigem Sprühpulver gearbeitet wird, das beispielsweise nur einen Zyklon-Rückgewinnungsgrad von 60 bis 80 % ermöglicht. In diesem Fall ist die nachgeschaltete Filterausscheidung notwendig, und man kann vor allem das Pulver trennen in grobkörnige und feinkörnige Pulverteile. Im übrigen wird man mit Zyklonabscheidern versehene Pulverkabinen in der Regel bei allen Arbeiten mit grobkörnigem Pulver einsetzen, weil auf diese Weise die Reinigung vereinfacht wird. Eine Reinigung im Filteraggregat 4 ist wesentlich umständlicher. Man kann daher u.U. die dort ausgefilterten Pulverteile verloren geben und aufeinanderfolgend verschiedene Farben fahren, während im Zyklonaggregat 3 nur die glatten Flächen ausserhalb der Zyklongehäuse gereinigt werden. Wird grundsätzlich nach diesem Prinzip gearbeitet, dann lassen sich auch mehrere Zyklonkabinen an ein gesondertes Filteraggregat anschließen. Insgesamt sind jedenfalls die zu reinigenden Flächen wesentlich herabgesetzt, wenn die Zyklonabscheider in der im übrigen geschlossenen Pulversprühkabine angeordnet sind.Such a

Der Herstellungsaufwand der hier eingesetzten kleinen Zyklonabscheider ist außergewöhnlich klein. Trotzdem kann es irgendwann interessant sein, die Anzahl der verwendeten Zyklone zu verringern. So ist nach Fig. 4 der Zwischenabstand zwischen den Zyklonabscheidern 23 nahezu verdoppelt, und der Saugraum 271 ist durch die Zyklone bzw. die Rohre 26 umgebende Leitbleche 69, die sich zur Anströmrichtung gemäß den Strömungslinien 38 schneidenförmig zusammenschließen, in einzelne Bereiche unterteilt, die eine gleichmäßige Anströmung ermöglichen, ob nun die Leitwände nach beiden Seiten gleichmäßig gekrümmt oder dem Rotationswirbel entsprechend spiralenförmig ausgebildet sind. Auf diese Weise können mit kleinerer Anzahl Zyklonen etwa gleiche Anströmverhältnisse geschaffen werden.The manufacturing costs of the small cyclone separators used here are exceptionally small. Nevertheless, it can be interesting at some point to reduce the number of cyclones used. 4, the intermediate distance between the

Da zudem rückseitig zwischen den Leitblechen 69 Zwickelräume 71 verbleiben, kann man diese Zwickelräume dazu verwenden, die Saugluft aus dem hochliegenden Raum 28 in den Filterraum 32 zu fördern. Hierzu müssen lediglich die Zwikkelräume 71 zum unteren Ende hin durch ein vorzugsweise gekrümmtes Boden-Leitblech/abgeschlossen werden. Von der ebenen Rückwand 55 der Fig. 3 bleibt dann nur ein ebener Rückstreifen 551, an welchen das Filter 31 dichter herangerückt werden kann.Since 69

Da normalerweise die Reinigung des Filterraumes entfällt, wird die Reinigung nur an der zum Beschichtungsraum 2 hin liegenden Seite durch die Form der Leitbleche 69 etwas erschwert. Gegenüber den Fig. 1 bis 3 fällt dies aber nicht sonderlich ins Gewicht, da man dort die freistehenden Rohre 26 abreinigen muß.Since the cleaning of the filter space is normally not required, the shape of the

Claims (15)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT83107084T ATE30125T1 (en) | 1982-08-10 | 1983-07-20 | POWDER SPRAY CABIN. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3229756 | 1982-08-10 | ||

| DE19823229756 DE3229756A1 (en) | 1982-08-10 | 1982-08-10 | POWDER SPRAYING CAB |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0100932A2 true EP0100932A2 (en) | 1984-02-22 |

| EP0100932A3 EP0100932A3 (en) | 1985-05-29 |

| EP0100932B1 EP0100932B1 (en) | 1987-10-07 |

Family

ID=6170531

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83107084A Expired EP0100932B1 (en) | 1982-08-10 | 1983-07-20 | Powder spray booth |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4504292A (en) |

| EP (1) | EP0100932B1 (en) |

| AT (1) | ATE30125T1 (en) |

| DE (2) | DE3229756A1 (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO1986003994A1 (en) * | 1985-01-02 | 1986-07-17 | Esb Elektrostatische Sprüh- Und Beschichtungsanlag | Booth for applying a powdered coating to the surface of workpieces |

| FR2588780A1 (en) * | 1985-10-17 | 1987-04-24 | Sames Sa | POWDER INSTALLATION FOR POWDER CABLES MADE IN LOW PRESSURE |

| DE4203948A1 (en) * | 1992-02-11 | 1993-08-12 | Sfb Spezial Filter Anlagen | Installation for spraying workpieces with powder to form surface coating - has cyclone type separators mounted horizontally to separate excess powder from carrier gas, such as air |

| EP0698421A1 (en) * | 1994-08-22 | 1996-02-28 | Erich Bauer | Powder recovery using a cyclone or a filter and powder transfer using a rotary element in the operation with a cyclone |

| WO2014169992A1 (en) * | 2013-04-18 | 2014-10-23 | Eisenmann Ag | Device for conducting process air loaded with overspray, and coating system with such a device |

| IT201900024985A1 (en) * | 2019-12-20 | 2021-06-20 | Geico Spa | Spray booth with improved filter replacement system |

Families Citing this family (38)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4723505A (en) * | 1986-03-17 | 1988-02-09 | Nordson Corporation | Powder booth |

| DE3611700A1 (en) * | 1986-04-08 | 1987-10-15 | Hoelter Heinz | Process for cleaning off a hot gas filter |

| US4718924A (en) * | 1986-05-30 | 1988-01-12 | Demarco Thomas M | Two compartment four stage industrial dust collector |

| US4790865A (en) * | 1986-05-30 | 1988-12-13 | Demarco Thomas | Two compartment industrial dust collector |

| US4704953A (en) * | 1986-11-12 | 1987-11-10 | Nordson Corporation | Powder spray system |

| DE8907540U1 (en) * | 1989-06-16 | 1990-10-18 | Farb-Tec Gesellschaft für Beschichtungskabinen-Systeme mbH, 2000 Hamburg | Booth for spray coating objects with powder coating material |

| FI85764C (en) * | 1990-03-30 | 1992-05-25 | Jeven Oy | Avluftsanordning |

| DE4025006C2 (en) * | 1990-08-07 | 2002-12-05 | Werner Durst | fan unit |

| DE4037459C2 (en) * | 1990-11-24 | 1994-02-24 | Eisenmann Kg Maschbau | Cyclone separator |

| US5306332A (en) * | 1991-05-14 | 1994-04-26 | Air-Gonomics, Inc. | Columnar filtering unit for spray painting |

| DE4134701C2 (en) * | 1991-10-21 | 1996-06-05 | Gema Volstatic Ag | Powder spray coating device with alternatively exchangeable filter and cyclone units |

| DE4239496A1 (en) * | 1992-11-25 | 1994-05-26 | Gema Volstatic Ag St Gallen | Electrostatic powder spray coating appts. - uses powder delivery container as powder supply and recovers excess sprayed powder |

| DE4300832A1 (en) * | 1993-01-14 | 1994-07-21 | Gema Volstatic Ag St Gallen | Powder spray coater |

| DE4417728A1 (en) * | 1994-05-20 | 1995-11-23 | Gema Volstatic Ag | Brush device for cleaning channels |

| CN1185123A (en) * | 1995-05-22 | 1998-06-17 | 诺德森公司 | Cyclone recovery system and cyclone separator with perferated thimble |

| US5788728A (en) * | 1996-12-03 | 1998-08-04 | Nordson Corporation | Powder coating booth with improved cyclone separator |

| DE19720005C1 (en) * | 1997-05-13 | 1998-11-19 | Wagner Int | Device for separating excess powder, which is obtained during the powder coating of workpieces |

| GB9718944D0 (en) | 1997-09-05 | 1997-11-12 | Nordson Corp | Improvements relating to powder spray coating |

| US5906676A (en) * | 1997-10-01 | 1999-05-25 | Nordson Corporation | Ejector-augmented overspray reclaim system |

| EP1328352A2 (en) | 1999-09-17 | 2003-07-23 | Nordson Corporation | Quick color change powder coating system |

| EP1138394A1 (en) * | 2000-03-31 | 2001-10-04 | Nordson Corporation | Improvements in and relating to powder coating system |

| US6569217B1 (en) | 2000-05-10 | 2003-05-27 | Thomas M. DeMarco | Industrial dust collector with multiple filter compartments |

| US6730169B2 (en) | 2000-08-22 | 2004-05-04 | Nordson Corporation | Electrostatic power coating system |

| US6432173B1 (en) * | 2000-10-27 | 2002-08-13 | Donaldson Company, Inc. | Centrifugal separator arrangement for powder coating recovery system and methods |

| NL1017818C2 (en) * | 2001-04-10 | 2002-10-15 | Cfs Bakel Bv | Air unit for removing particulate material. |

| US20050274094A1 (en) * | 2003-03-17 | 2005-12-15 | Demarco Thomas M | Vacuum loader |

| US20060207230A1 (en) * | 2003-03-17 | 2006-09-21 | Demarco Maxvac Corporation | Vacuum loader with filter doors |

| US7716947B2 (en) * | 2005-10-07 | 2010-05-18 | Gas-Chill, Inc. | Apparatus and method for condensing hydrocarbons from natural gas |

| NO326078B1 (en) * | 2006-07-07 | 2008-09-15 | Shell Int Research | The fluid separation vessel |

| DE102006032184B4 (en) * | 2006-07-12 | 2010-06-17 | Eisenmann Anlagenbau Gmbh & Co. Kg | Device for conveying powdered fluidized media |

| US7931718B2 (en) * | 2009-04-09 | 2011-04-26 | San Ford Machinery Co., Ltd. | Oil mist separator |

| US20120260521A1 (en) * | 2009-10-22 | 2012-10-18 | Bunnell Michael H | Paint spray booth system |

| DE102013007482A1 (en) * | 2013-04-29 | 2014-10-30 | Georg Schneider | Device for applying material |

| US20150157972A1 (en) * | 2013-12-09 | 2015-06-11 | Keith Bratten | Demister Apparatus and Method |

| CN104289335B (en) * | 2014-10-16 | 2016-07-20 | 浙江德立涂装机械有限公司 | Electrostatic powder spraying system |

| CN104289336B (en) * | 2014-10-16 | 2016-07-20 | 浙江德立涂装机械有限公司 | Automatic powder spraying system |

| CN110420790B (en) * | 2019-08-01 | 2021-01-12 | 张家港市宏基精密铝材科技有限公司 | Environment-friendly spraying device for aluminum profile machining |

| US11878316B2 (en) * | 2020-12-15 | 2024-01-23 | Gallagher-Kaiser Corporation | Sliding drawer dry filtration system for a paint booth |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2259626A (en) * | 1939-04-06 | 1941-10-21 | Binks Mfg Co | Means for and method of eliminating splash in wash type spray booths |

| DE918193C (en) * | 1950-02-09 | 1954-09-20 | Heinrich Ausserehl | Paint spray booth |

| US3473561A (en) * | 1966-03-29 | 1969-10-21 | Bert N Svenson | Check valve with supported closure member |

| DE2839540A1 (en) * | 1978-09-12 | 1980-03-20 | Hans J Schaad | powder coating chamber powder recovery system - has bottom of chamber formed as entry to cyclone separator with suction tube |

| US4277260A (en) * | 1979-08-14 | 1981-07-07 | Browning Jesse H | Powder collectors |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US940076A (en) * | 1908-08-18 | 1909-11-16 | Jonathan M Seaver | Separator. |

| GB737457A (en) * | 1952-01-28 | 1955-09-28 | Pneumatic Conveyors Huddersfie | Improvements in or relating to separating dust from air |

| DE1753411U (en) * | 1957-08-03 | 1957-10-03 | Metallgesellschaft Ag | MOVING LOCKING DEVICE IN THE DUST SPOUT OF MULTIPLE CENTRIFUGAL SEPARATORS. |

| FR1226122A (en) * | 1959-05-30 | 1960-07-08 | Applic De La Ventilation Soc D | Dedusting device by vacuum fan with prior recovery and automatic dust evacuation |

| GB1014934A (en) * | 1962-12-19 | 1965-12-31 | Rotalectors | Improvements in or relating to apparatus for the separation of particles from fluids |

| US3618302A (en) * | 1969-10-17 | 1971-11-09 | Milan S Cornett | Unitary portable air cleaner |

| BE789579A (en) * | 1971-10-06 | 1973-02-01 | Masuda Senichi | ENCLOSURE FOR THE APPLICATION, BY MEANS OF A CURTAIN OF ELECTRICAL FIELDS OF THE CONTACT TYPE, OF COATINGS FORMED BY ELECTROSTATIC CHARGED POWDERS |

| CH562639A5 (en) * | 1973-07-19 | 1975-06-13 | Gema Ag | |

| DE2809020B2 (en) * | 1978-03-02 | 1980-08-28 | Adolf 7251 Weissach Berkmann | Coating booth for the electrostatic application of powdery substances |

| DE2813854A1 (en) * | 1978-03-31 | 1979-10-11 | Interesco Int Res | DEVICE FOR RECOVERING POWDER, IN PARTICULAR FROM POWDER SPRAYING CABINS |

| US4224043A (en) * | 1978-04-20 | 1980-09-23 | Nfe International, Ltd. | Compact multistage particle separator |

| DE3003158A1 (en) * | 1980-01-30 | 1982-03-04 | ESB Elektrostatische Sprüh- und Beschichtungsanlagen G.F. Vöhringer GmbH, 7758 Meersburg | DEVICE FOR THE POWDER COATING OF WORKPIECES WITH A SPRAYING CABIN TEMPORARY FROM THE WORKPIECE |

| DE3012877A1 (en) * | 1980-04-02 | 1981-10-08 | J. Wagner AG, 9450 Altstätten | POWDER COATING SYSTEM FOR WORKPIECES |

| US4303417A (en) * | 1980-10-03 | 1981-12-01 | George Koch Sons, Inc. | Spray booth with reconditioning filter system |

| US4401445A (en) * | 1981-03-17 | 1983-08-30 | Jesse Browning | Method for converting a liquid paint spray booth to a powder paint spray booth |

-

1982

- 1982-08-10 DE DE19823229756 patent/DE3229756A1/en not_active Withdrawn

-

1983

- 1983-07-20 DE DE8383107084T patent/DE3373985D1/en not_active Expired

- 1983-07-20 AT AT83107084T patent/ATE30125T1/en not_active IP Right Cessation

- 1983-07-20 EP EP83107084A patent/EP0100932B1/en not_active Expired

- 1983-08-04 US US06/520,195 patent/US4504292A/en not_active Expired - Lifetime

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2259626A (en) * | 1939-04-06 | 1941-10-21 | Binks Mfg Co | Means for and method of eliminating splash in wash type spray booths |

| DE918193C (en) * | 1950-02-09 | 1954-09-20 | Heinrich Ausserehl | Paint spray booth |

| US3473561A (en) * | 1966-03-29 | 1969-10-21 | Bert N Svenson | Check valve with supported closure member |

| DE2839540A1 (en) * | 1978-09-12 | 1980-03-20 | Hans J Schaad | powder coating chamber powder recovery system - has bottom of chamber formed as entry to cyclone separator with suction tube |

| US4277260A (en) * | 1979-08-14 | 1981-07-07 | Browning Jesse H | Powder collectors |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4913085A (en) * | 1985-01-01 | 1990-04-03 | Esb Elektorstatische Spruh-Und Beschichtungsanlagen G.F. Vohringer Gmbh | Coating booth for applying a coating powder to the surface of workpieces |

| WO1986003994A1 (en) * | 1985-01-02 | 1986-07-17 | Esb Elektrostatische Sprüh- Und Beschichtungsanlag | Booth for applying a powdered coating to the surface of workpieces |

| US4770118A (en) * | 1985-01-02 | 1988-09-13 | Esb Elektrostatische Spruh- Und Beschichtungsanlagen G. F. Vohringer Gmbh | Coating booth for applying a coating powder to the surface of workpieces |

| FR2588780A1 (en) * | 1985-10-17 | 1987-04-24 | Sames Sa | POWDER INSTALLATION FOR POWDER CABLES MADE IN LOW PRESSURE |

| EP0223660A1 (en) * | 1985-10-17 | 1987-05-27 | Sames S.A. | Powder coating installation with a spray booth kept at sub-atmospheric pressure |

| DE4203948A1 (en) * | 1992-02-11 | 1993-08-12 | Sfb Spezial Filter Anlagen | Installation for spraying workpieces with powder to form surface coating - has cyclone type separators mounted horizontally to separate excess powder from carrier gas, such as air |

| EP0698421A1 (en) * | 1994-08-22 | 1996-02-28 | Erich Bauer | Powder recovery using a cyclone or a filter and powder transfer using a rotary element in the operation with a cyclone |

| WO2014169992A1 (en) * | 2013-04-18 | 2014-10-23 | Eisenmann Ag | Device for conducting process air loaded with overspray, and coating system with such a device |

| IT201900024985A1 (en) * | 2019-12-20 | 2021-06-20 | Geico Spa | Spray booth with improved filter replacement system |

| WO2021124183A1 (en) * | 2019-12-20 | 2021-06-24 | Geico Spa | Painting booth with improved system for replacement of the filters |

Also Published As

| Publication number | Publication date |

|---|---|

| US4504292A (en) | 1985-03-12 |

| EP0100932A3 (en) | 1985-05-29 |

| DE3373985D1 (en) | 1987-11-12 |

| ATE30125T1 (en) | 1987-10-15 |

| DE3229756A1 (en) | 1984-02-16 |

| EP0100932B1 (en) | 1987-10-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0100932B1 (en) | Powder spray booth | |

| EP2258485B2 (en) | Device for separating liquid coating overspray | |

| CH638698A5 (en) | COATING DEVICE FOR THE ELECTROSTATIC APPLICATION OF POWDER-SHAPED SUBSTANCES. | |

| DE4119216C2 (en) | Droplet separator | |

| DE4134701C2 (en) | Powder spray coating device with alternatively exchangeable filter and cyclone units | |

| DE3131565C2 (en) | Booth for spray coating objects with powder | |

| DE2419925A1 (en) | Powder spray booth | |

| EP0384236B1 (en) | Powder spraying booth with a device for leading crude gas to a suction flow of a separator | |

| EP3457033A1 (en) | Extractor for removing exhaust generated by a cooking hob in a vertical direction beneath a cooking hob level | |

| DE2640219A1 (en) | CAB FOR AN ELECTROSTATIC POWDER COATING PLANT | |

| DE2630646A1 (en) | ROAD SWEEPING MACHINE | |

| DE3933405C2 (en) | ||

| DE3731591C2 (en) | ||

| DE19851111C1 (en) | Suction dredger handling mining paydirt or slurry from drains | |

| EP0014782A1 (en) | Dust separation device | |

| DE1421310A1 (en) | Wet dust separator | |

| DE3408474C2 (en) | ||

| EP1342506A1 (en) | Powder coating booth | |

| DE3042659A1 (en) | Electrostatic solvent-free pigment coating - guiding air flow over workpiece vertically downwards, with acceleration below working zone | |

| DE3018162C2 (en) | Cyclone dust collector | |

| DE3318797C2 (en) | Rotary valve | |

| DE1546677B2 (en) | DEVICE FOR CLEANING A GAS FLOW | |

| DE4212270C2 (en) | ||

| EP2332626B1 (en) | Device for separating impurities out of an air flow | |

| DE3248098C1 (en) | Outlet and filter arrangement |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| RHK1 | Main classification (correction) |

Ipc: B05B 15/12 |

|

| 17P | Request for examination filed |

Effective date: 19850827 |

|

| 17Q | First examination report despatched |

Effective date: 19861106 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: BE Effective date: 19871007 |

|

| REF | Corresponds to: |

Ref document number: 30125 Country of ref document: AT Date of ref document: 19871015 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3373985 Country of ref document: DE Date of ref document: 19871112 |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 83107084.2 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19960619 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19960624 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19960710 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19960723 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19960729 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19960731 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19960919 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970720 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970720 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19970721 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970731 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19970731 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980201 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19970720 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980331 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19980201 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980401 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 83107084.2 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |