EP0062030B1 - Moteur à combustion interne à piston alternatif - Google Patents

Moteur à combustion interne à piston alternatif Download PDFInfo

- Publication number

- EP0062030B1 EP0062030B1 EP82890045A EP82890045A EP0062030B1 EP 0062030 B1 EP0062030 B1 EP 0062030B1 EP 82890045 A EP82890045 A EP 82890045A EP 82890045 A EP82890045 A EP 82890045A EP 0062030 B1 EP0062030 B1 EP 0062030B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- housing

- combustion engine

- enclosure

- internal combustion

- engine block

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02B—INTERNAL-COMBUSTION PISTON ENGINES; COMBUSTION ENGINES IN GENERAL

- F02B77/00—Component parts, details or accessories, not otherwise provided for

- F02B77/11—Thermal or acoustic insulation

- F02B77/13—Acoustic insulation

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S277/00—Seal for a joint or juncture

- Y10S277/916—Seal including vibration dampening feature

Definitions

- the invention relates to a reciprocating internal combustion engine with an engine block consisting of cylinders, cylinder heads, crankshaft together with engine, camshaft with control wheels and intake and exhaust manifold, which has an at least partially enclosing, multi-part, a common oil chamber formwork, the structure-borne soundproofing sealing elements on Engine block is attached, wherein the engine block, the flywheel housing and possibly the gearbox are rigidly connected to one another.

- the object of the invention is to eliminate these deficiencies and to provide a reciprocating piston internal combustion engine of the type described at the outset, which ensures the greatest possible sound insulation with reduced technical outlay.

- the invention solves this problem in that the unit is suspended on the end facing away from the flywheel with the interposition of an elastic and structure-borne sound-absorbing element on a cross member and has lateral eyes in the rocker-wheel housing with elastic and sound-absorbing lining for trunnions, the formwork as a unit by means of a ring designed sealing elements in the area of the end faces of the engine block is supported on this.

- the formwork forms a unit in itself, it only needs to be attached to the engine block as a whole to reduce structure-borne noise and oil-seal in order to achieve effective sound insulation even if the formwork itself consists of parts that are only oil-tight but not sound-proof connected, because of the formwork as a whole is no longer transmitted structure-borne noise. It is therefore sufficient to connect the individual parts of the formwork in a simple manner without special insulation measures, so that there is a corresponding reduction in the technical outlay and the costs.

- the support of the unitary formwork on the front sides of the engine block offers the possibility of using the ring-shaped sealing elements, which ensure secure mounting without the use of the necessary sound-transmitting fastening screws or the like.

- the auxiliary devices such as alternator, water pump, filter, oil cooler, compressor and / or. Like., attached. This avoids stressing the formwork by these auxiliary devices, and the wall thickness of the formwork can be kept very small. In addition, the vibrating mass of the formwork is of course also reduced, so that there are, if at all, only very small vibration amplitudes with respect to the engine block.

- a bearing plate which is coaxial with the crankshaft and serves as a cover, is fastened to the crossmember with a bearing for the shaft of the drive of the auxiliary devices, and this shaft is connected to the crankshaft via an elastic coupling which isolates structure-borne noise. Since the drive shaft of the auxiliary devices is mounted in the bearing plate attached to the cross member, there are no relative movements between the auxiliary devices and the drive shaft. On the other hand, the radial relative movements between the crankshaft and the drive shaft for the auxiliary devices resulting from the elastic mounting of the unit formed in the cross member can take place unhindered and without harmful effects.

- the end shield has the further advantage that it covers the crankshaft end together with the vibration damper that is usually present in a noise-absorbing manner.

- the casing has an elongated opening in the area of the exhaust manifold, which is closed by a housing enclosing the exhaust manifold with the interposition of an elastic and structure-borne sound-absorbing seal, so that the exhaust manifold is also soundproofed.

- the housing is attached to the cylinder heads with the interposition of a structure-borne sound-absorbing seal, and the edge of the formwork opening nestles against the housing with the interposition of an elastic seal, which in the edge region of the opening consists of layers separated from one another by heat-resistant and structure-borne sound-insulating flat seals.

- an elastic seal which in the edge region of the opening consists of layers separated from one another by heat-resistant and structure-borne sound-insulating flat seals.

- the flywheel housing can have its own formwork supported on it or on the trunnion under structure-borne sound insulation, optionally enclosing the starter, to which a gearbox formwork can then be connected.

- the starter is attached to the flywheel housing in the usual way and thus does not perform any relative movements with respect to the flywheel.

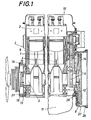

- the engine block is enclosed on all sides by a casing 9, the u a removable cover 10 to make the valve rocker arms accessible. Like. And has an oil pan 11 and forms an oil space.

- the casing 9 is fastened to the engine block I via structure-borne noise-isolating sealing elements 12, 13, the sealing elements 12, 13 being arranged on the end faces of the engine block I and being designed in a ring shape.

- a cross member 15 with the interposition of an elastic and structure-borne sound-absorbing ring 16, auxiliary devices such as alternator 18, water pump 19 and compressor being attached to the cross member 15, which in turn is supported on longitudinal members 17 of a chassis 20 (Fig. 3) are attached.

- a bearing plate 21 which is coaxial with the crankshaft 3 and serves as cover, is screwed to the cross member 15 and is provided with a bearing 22 for the shaft 23 of the drive pulley 24 for the auxiliary devices 18, 19, 20.

- the shaft 23 is connected to the crankshaft 3 via an elastic coupling 25 which isolates structure-borne noise.

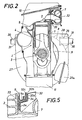

- the flywheel housing 8 has its own formwork 27 supported on it with the interposition of structure-borne sound-absorbing rings 26, which part 27a also encloses the starter. 2 eyes 28 are provided in the flywheel housing 8, which have a rubber lining 29 and are used to support trunnions 30 for the unit formed.

- the cladding 27 of the flywheel housing 8 is supported on the trunnion 30 also by means of structure-borne rings 31.

- the casing 9 has an elongated opening in the area of the exhaust manifold 7, which opening is closed by a housing 32 surrounding the exhaust manifold 7.

- the edge 9a of the opening of the casing 9 nestles against the housing 32 with the interposition of an elastic seal 33 (see in particular FIG. 5), which in this edge region of the opening consists of layers 32a, 32b, 32c separated by heat-resistant and structure-borne sound insulation 34 consists.

Claims (6)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT1487/81 | 1981-03-31 | ||

| AT0148781A AT387624B (de) | 1981-03-31 | 1981-03-31 | Hubkolben-brennkraftmaschine |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0062030A1 EP0062030A1 (fr) | 1982-10-06 |

| EP0062030B1 true EP0062030B1 (fr) | 1985-07-10 |

Family

ID=3514955

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82890045A Expired EP0062030B1 (fr) | 1981-03-31 | 1982-03-24 | Moteur à combustion interne à piston alternatif |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US4480608A (fr) |

| EP (1) | EP0062030B1 (fr) |

| JP (1) | JPS57176345A (fr) |

| AT (1) | AT387624B (fr) |

| CA (1) | CA1189454A (fr) |

| DE (1) | DE3264630D1 (fr) |

| YU (1) | YU43512B (fr) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3408011A1 (de) * | 1984-03-03 | 1985-09-05 | Klein, Schanzlin & Becker Ag, 6710 Frankenthal | Abdichtung fuer teilflansch und dichtungsgehaeuse von laengsgeteilten maschinengehaeusen |

| US4669432A (en) * | 1986-05-16 | 1987-06-02 | Kabushiki Kaisha Komatsu Seisakusho | Sealing device for an oil pan adapter in an internal combustion engine |

| EP0252178B2 (fr) * | 1986-07-10 | 1993-06-09 | MAN Nutzfahrzeuge Aktiengesellschaft | Enveloppe pour moteur de propulsion dans les automobiles |

| AT389744B (de) * | 1987-09-09 | 1990-01-25 | Steyr Daimler Puch Ag | Schalldaemmende verschalung fuer brennkraftmaschinen |

| AT392132B (de) * | 1987-11-03 | 1991-01-25 | Steyr Daimler Puch Ag | Verbindung der kurbelwelle einer schalldicht gekapselten brennkraftmaschine mit der koaxialen antriebswelle der ausserhalb der kapsel angeordneten hilfseinrichtungen |

| ATA108690A (de) * | 1990-05-16 | 1994-12-15 | Laimboeck Franz | Flüssigkeitsgekühlte brennkraftmaschine |

| US5665019A (en) * | 1996-02-05 | 1997-09-09 | Ford Global Technologies, Inc. | Chain guide mounting assembly for the reduction of chain induced noise and vibration in a chain driven overhead cam internal combustion engine |

| US6178939B1 (en) * | 1998-06-24 | 2001-01-30 | Siemens Canada Limited | Housing system |

| DE10358117A1 (de) * | 2003-12-12 | 2005-07-14 | Man Nutzfahrzeuge Ag | Flachdichtung |

| AT503764B1 (de) * | 2007-09-06 | 2009-01-15 | Avl List Gmbh | Schwungradgehäuse |

| CN112682621B (zh) * | 2020-12-21 | 2023-01-20 | 中国北方发动机研究所(天津) | 一种集成油路的分体式飞轮壳结构 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT308475B (de) * | 1969-09-08 | 1973-07-10 | List Hans | Schalldämmende Verschalung für Brennkraftmaschinen |

| DE2612182A1 (de) * | 1975-04-18 | 1976-10-28 | List Hans | Geraeuscharmer verbrennungsmotor |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE306982C (fr) * | 1915-12-18 | |||

| US2875746A (en) * | 1956-05-09 | 1959-03-03 | Gen Motors Corp | Engine accessory support means |

| US3263663A (en) * | 1963-09-09 | 1966-08-02 | Crusader Marine Corp | Engine |

| AT278448B (de) * | 1967-08-21 | 1970-01-26 | H C Hans Dipl Ing Dr Dr List | Brennkraftmaschine mit geräuschdämmender Verschalung |

| US3863936A (en) * | 1973-03-27 | 1975-02-04 | Farnam Co F D | High temperature gasket structure and method of producing same |

| GB1451707A (en) * | 1974-07-26 | 1976-10-06 | British Uralite Ltd | Noise control materials |

| JPS5516090Y2 (fr) * | 1976-03-26 | 1980-04-15 | ||

| US4137888A (en) * | 1976-11-24 | 1979-02-06 | Allis-Chalmers Corporation | Sound abatement device for internal combustion engine |

| DE2804833A1 (de) * | 1977-02-24 | 1978-08-31 | List Hans | Geraeuscharmer verbrennungsmotor |

| DE2736378C2 (de) * | 1977-08-12 | 1985-12-19 | Klöckner-Humboldt-Deutz AG, 5000 Köln | Hilfsmaschinen für die luftgekühlte Brennkraftmaschine eines Schleppers |

| AT365309B (de) * | 1977-08-18 | 1982-01-11 | List Hans | Brennkraftmaschine mit schalldaemmender verschalung |

| AT375444B (de) * | 1977-12-07 | 1984-08-10 | Steyr Daimler Puch Ag | Hubkolben-brennkraftmaschine |

| AT374569B (de) * | 1979-02-07 | 1984-05-10 | List Hans | Brennkraftmaschine |

-

1981

- 1981-03-31 AT AT0148781A patent/AT387624B/de not_active IP Right Cessation

-

1982

- 1982-03-18 US US06/359,279 patent/US4480608A/en not_active Expired - Fee Related

- 1982-03-24 EP EP82890045A patent/EP0062030B1/fr not_active Expired

- 1982-03-24 DE DE8282890045T patent/DE3264630D1/de not_active Expired

- 1982-03-30 JP JP57050258A patent/JPS57176345A/ja active Granted

- 1982-03-30 CA CA000399768A patent/CA1189454A/fr not_active Expired

- 1982-03-31 YU YU718/82A patent/YU43512B/xx unknown

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT308475B (de) * | 1969-09-08 | 1973-07-10 | List Hans | Schalldämmende Verschalung für Brennkraftmaschinen |

| DE2612182A1 (de) * | 1975-04-18 | 1976-10-28 | List Hans | Geraeuscharmer verbrennungsmotor |

Also Published As

| Publication number | Publication date |

|---|---|

| YU71882A (en) | 1985-03-20 |

| EP0062030A1 (fr) | 1982-10-06 |

| US4480608A (en) | 1984-11-06 |

| CA1189454A (fr) | 1985-06-25 |

| YU43512B (en) | 1989-08-31 |

| ATA148781A (de) | 1988-07-15 |

| AT387624B (de) | 1989-02-27 |

| JPS6315471B2 (fr) | 1988-04-05 |

| DE3264630D1 (en) | 1985-08-14 |

| JPS57176345A (en) | 1982-10-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE1775468C3 (de) | Brennkraftmaschine mit geräuschdämmender Verschalung | |

| EP0062030B1 (fr) | Moteur à combustion interne à piston alternatif | |

| DE1914162C3 (de) | Luftgekühlte Einzylinderbrennkraftm aschine | |

| US3684053A (en) | Internal combustion engine with sound-absorbing casing | |

| DE1576775C3 (de) | Brennkraftmaschine mit schallisolierender Verschalung | |

| DE2839885C2 (fr) | ||

| US3464398A (en) | Soundproofed internal combustion engine | |

| DE2612182A1 (de) | Geraeuscharmer verbrennungsmotor | |

| DE2922030A1 (de) | Brennkraftmaschine | |

| DE2920082C2 (de) | Brennkraftmaschine mit körperschallisolierendem Element zwischen Triebwerksträger und Kurbelgehäuse | |

| DE3050893C2 (fr) | ||

| DE2065889A1 (de) | Brennkraftmaschine mit schalldaemmender verschalung | |

| DE2801431A1 (de) | Hubkolben-brennkraftmaschine | |

| DE3831334C2 (fr) | ||

| DE4041388C2 (de) | Brennkraftmaschine mit Akustikhaube | |

| DE3016673A1 (de) | Geraeuscharme brennkraftmaschine | |

| DE3532599C2 (fr) | ||

| DE4141881C2 (de) | Schallgedämpfte Hubkolbenbrennkraftmaschine | |

| EP0435847A1 (fr) | Moteur alternatif à combustion interne | |

| DE19622678C1 (de) | Mehrzylindrige Brennkraftmaschine in Kapselbauweise | |

| AT394758B (de) | Brennkraftmaschine | |

| EP0457750B1 (fr) | Moteur à combustion interne à refroidissement liquide | |

| AT400742B (de) | Brennkraftmaschine mit hin- und hergehenden kolben | |

| EP0252178B1 (fr) | Enveloppe pour moteur de propulsion dans les automobiles | |

| AT399916B (de) | Brennkraftmaschine mit schalldämmender verschalung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19821016 |

|

| ITF | It: translation for a ep patent filed |

Owner name: MODIANO & ASSOCIATI S.R.L. |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB IT NL SE |

|

| REF | Corresponds to: |

Ref document number: 3264630 Country of ref document: DE Date of ref document: 19850814 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19940215 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19940218 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19940223 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19940331 Year of fee payment: 13 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 82890045.6 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19950324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19950325 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19951001 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19950324 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19951130 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19951001 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 82890045.6 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20010313 Year of fee payment: 20 |