EP0048794B2 - Verwendung von kugelförmigen Füllkörpern für galvanische Bäder sowie Verfahren zur Herstellung dieser Füllkörper und von Anodenbehältern - Google Patents

Verwendung von kugelförmigen Füllkörpern für galvanische Bäder sowie Verfahren zur Herstellung dieser Füllkörper und von Anodenbehältern Download PDFInfo

- Publication number

- EP0048794B2 EP0048794B2 EP81104888A EP81104888A EP0048794B2 EP 0048794 B2 EP0048794 B2 EP 0048794B2 EP 81104888 A EP81104888 A EP 81104888A EP 81104888 A EP81104888 A EP 81104888A EP 0048794 B2 EP0048794 B2 EP 0048794B2

- Authority

- EP

- European Patent Office

- Prior art keywords

- anode

- balls

- packings

- diameter

- spherical

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 11

- 238000000034 method Methods 0.000 title claims abstract description 5

- 238000012856 packing Methods 0.000 title claims description 14

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical group [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims abstract description 10

- 229910052802 copper Inorganic materials 0.000 claims abstract description 9

- 239000010949 copper Substances 0.000 claims abstract description 9

- 238000003825 pressing Methods 0.000 claims abstract description 8

- 239000010405 anode material Substances 0.000 claims description 4

- OAICVXFJPJFONN-UHFFFAOYSA-N Phosphorus Chemical compound [P] OAICVXFJPJFONN-UHFFFAOYSA-N 0.000 claims description 3

- 239000000463 material Substances 0.000 claims description 3

- 229910052698 phosphorus Inorganic materials 0.000 claims description 3

- 239000011574 phosphorus Substances 0.000 claims description 3

- 238000009713 electroplating Methods 0.000 abstract description 4

- 229910052751 metal Inorganic materials 0.000 abstract description 4

- 239000002184 metal Substances 0.000 abstract description 4

- 230000001788 irregular Effects 0.000 abstract description 2

- 238000004070 electrodeposition Methods 0.000 abstract 1

- 238000007747 plating Methods 0.000 abstract 1

- 239000000945 filler Substances 0.000 description 6

- 230000008021 deposition Effects 0.000 description 3

- RTAQQCXQSZGOHL-UHFFFAOYSA-N Titanium Chemical compound [Ti] RTAQQCXQSZGOHL-UHFFFAOYSA-N 0.000 description 2

- 238000005266 casting Methods 0.000 description 2

- 239000008187 granular material Substances 0.000 description 2

- 229910001208 Crucible steel Inorganic materials 0.000 description 1

- 241000530268 Lycaena heteronea Species 0.000 description 1

- 230000002378 acidificating effect Effects 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 238000010924 continuous production Methods 0.000 description 1

- 230000003628 erosive effect Effects 0.000 description 1

- 230000003203 everyday effect Effects 0.000 description 1

- 238000005242 forging Methods 0.000 description 1

- 230000002045 lasting effect Effects 0.000 description 1

- 238000005096 rolling process Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000010936 titanium Substances 0.000 description 1

- 229910052719 titanium Inorganic materials 0.000 description 1

- 238000011282 treatment Methods 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25D—PROCESSES FOR THE ELECTROLYTIC OR ELECTROPHORETIC PRODUCTION OF COATINGS; ELECTROFORMING; APPARATUS THEREFOR

- C25D17/00—Constructional parts, or assemblies thereof, of cells for electrolytic coating

- C25D17/10—Electrodes, e.g. composition, counter electrode

- C25D17/12—Shape or form

Definitions

- the invention relates to a method according to the preamble of claim 1.

- anode metal fillers e.g. B. of copper

- acidic baths e.g. B. copper alloyed with phosphorus

- auxiliary anodes in the form of titanium baskets which are filled with the appropriate metal fillers, are often used for the electroplating of printing cylinders, printed circuit boards or other electronic device parts. It is important that these auxiliary anodes have the same filling over their entire area, so that the same possible deposition weight and the same deposition area are ensured during the whole operation, which are of crucial importance for exact support layers. These requirements are not met with the granules made of electrolytic copper scrap or sections of copper wires known in practice.

- the object of the invention is to provide a method for producing spherical fillers for anode containers of the aforementioned type to be used in electroplating baths, which enables the manufacture of such fillers with high throughput and low cost.

- Claim 2 specifies a method for producing an anode container filled with appropriately produced packing elements.

- the solution according to the invention makes it possible to produce spherical anode bodies on an industrial scale and quickly in a quasi-continuous process.

- the diameter of the packing balls is advantageously designed so that the balls roll individually through the loading opening of the anode container - and their diameter is somewhat smaller than the depth, but greater than half the depth of the anode container. If the balls are so large that only a single ball passes through the loading opening, there can be no blockages. The balls in the specified sizes also only form a stack layer. Optimal results are achieved if the balls of the filling of an anode container are the same size.

- the wire to be formed into balls can be produced in the usual way by rolling, casting or pressing. Depending on the intended use, it will consist of pure or alloyed metal.

- the wire diameter can be determined on a trial basis.

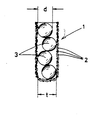

- the drawing shows part of an anode container in section with the packing elements according to the invention.

- Packing balls 3 are filled in an anode basket 1 made of a titanium wire mesh 2. Since the diameter d of the balls is slightly smaller than the depth f of the basket, the balls are stacked in one layer. Even if these balls are slightly offset or shifted, the contact surface is always the same due to the evenly rounded surface of the balls. Due to the spherical shape, the packing elements will always be arranged without gaps and without blocking, even when refilling, and thus enable a uniform filling level.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Electroplating Methods And Accessories (AREA)

- Electrolytic Production Of Metals (AREA)

- Physical Vapour Deposition (AREA)

- Manufacture And Refinement Of Metals (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT81104888T ATE15914T1 (de) | 1980-09-30 | 1981-06-24 | Verwendung von kugelfoermigen fuellkoerpern fuer galvanische baeder sowie verfahren zur herstellung dieser fuellkoerper und von anodenbehaeltern. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3036937 | 1980-09-30 | ||

| DE3036937A DE3036937C2 (de) | 1980-09-30 | 1980-09-30 | Verfahren zum Herstellen von Füllkörpern für Anodenbehälter sowie danach hergestellte Füllkörper |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0048794A1 EP0048794A1 (de) | 1982-04-07 |

| EP0048794B1 EP0048794B1 (de) | 1985-10-02 |

| EP0048794B2 true EP0048794B2 (de) | 1990-03-07 |

Family

ID=6113249

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP81104888A Expired - Lifetime EP0048794B2 (de) | 1980-09-30 | 1981-06-24 | Verwendung von kugelförmigen Füllkörpern für galvanische Bäder sowie Verfahren zur Herstellung dieser Füllkörper und von Anodenbehältern |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US4447298A (enExample) |

| EP (1) | EP0048794B2 (enExample) |

| AT (1) | ATE15914T1 (enExample) |

| CA (1) | CA1177779A (enExample) |

| DE (1) | DE3036937C2 (enExample) |

| ES (1) | ES269127Y (enExample) |

| GR (1) | GR75050B (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3835749A1 (de) * | 1987-10-20 | 1989-05-03 | Outokumpu Oy | Profilkoerper fuer elektrolysebehandlung und verfahren zum herstellen desselben |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5628887A (en) * | 1996-04-15 | 1997-05-13 | Patterson; James A. | Electrolytic system and cell |

| US5744013A (en) * | 1996-12-12 | 1998-04-28 | Mitsubishi Semiconductor America, Inc. | Anode basket for controlling plating thickness distribution |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE217938C (enExample) * | ||||

| US1204127A (en) * | 1915-02-23 | 1916-11-07 | Ferdinand Mora Canda | Process of and apparatus for forging balls. |

| US1765706A (en) * | 1927-08-13 | 1930-06-24 | Westinghouse Electric & Mfg Co | Dual anode |

| US1868052A (en) * | 1929-11-13 | 1932-07-19 | Udylite Process Company | Anode |

| FR697729A (fr) * | 1930-02-20 | 1931-01-21 | Udylite Process Company | Perfectionnements aux anodes |

| US2313876A (en) * | 1940-06-18 | 1943-03-16 | Westinghouse Electric & Mfg Co | Method of making balls |

| US2614317A (en) * | 1949-08-19 | 1952-10-21 | Deussen Emil | Method of making metal balls |

| US3300396A (en) * | 1965-11-24 | 1967-01-24 | Charles T Walker | Electroplating techniques and anode assemblies therefor |

-

1980

- 1980-09-30 DE DE3036937A patent/DE3036937C2/de not_active Expired

-

1981

- 1981-06-24 EP EP81104888A patent/EP0048794B2/de not_active Expired - Lifetime

- 1981-06-24 AT AT81104888T patent/ATE15914T1/de not_active IP Right Cessation

- 1981-09-22 US US06/304,373 patent/US4447298A/en not_active Expired - Lifetime

- 1981-09-22 CA CA000386405A patent/CA1177779A/en not_active Expired

- 1981-09-23 GR GR66118A patent/GR75050B/el unknown

- 1981-09-29 ES ES1981269127U patent/ES269127Y/es not_active Expired

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3835749A1 (de) * | 1987-10-20 | 1989-05-03 | Outokumpu Oy | Profilkoerper fuer elektrolysebehandlung und verfahren zum herstellen desselben |

Also Published As

| Publication number | Publication date |

|---|---|

| US4447298A (en) | 1984-05-08 |

| EP0048794A1 (de) | 1982-04-07 |

| ES269127U (es) | 1983-06-16 |

| EP0048794B1 (de) | 1985-10-02 |

| CA1177779A (en) | 1984-11-13 |

| ATE15914T1 (de) | 1985-10-15 |

| DE3036937A1 (de) | 1982-04-08 |

| ES269127Y (es) | 1984-01-01 |

| GR75050B (enExample) | 1984-07-12 |

| DE3036937C2 (de) | 1983-05-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE102007017754B4 (de) | Verfahren zur Herstellung eines Werkstücks mit mindestens einem Freiraum | |

| DE3542185A1 (de) | Waermeaustauscher unter verwendung einer wasserstoff-okklusion-legierung | |

| DE19883018C2 (de) | Verfahren zur Bearbeitung einer Oberfläche einer Form unter Verwendung einer elektrischen Entladung, bei einer derartigen Bearbeitung verwendete Elektrode, und Verfahren zur Herstellung einer derartigen Elektrode | |

| DE102007017762A1 (de) | Trägermaterial zur Herstellung von Werkstücken | |

| DE10296884T5 (de) | Herstellung festkörperelektronischer Bauteile | |

| EP0048794B2 (de) | Verwendung von kugelförmigen Füllkörpern für galvanische Bäder sowie Verfahren zur Herstellung dieser Füllkörper und von Anodenbehältern | |

| DE4108297A1 (de) | Verfahren und einrichtung zur oberflaechenbehandlung eines halbgleitlagers | |

| DE2124677A1 (de) | Wärmeröhre und Verfahren zu ihrer Herstellung | |

| DE3874106T2 (de) | Mechanisches plattierungsverfahren. | |

| AT148456B (de) | Aus mindestens zwei Metallen zusammengesetzter Werkstoff, wie Verbund- oder Formkörper, insbesondere für elektrische Zwecke, sowie Verfahren zu deren Herstellung. | |

| DE2234618A1 (de) | Kondensator und verfahren zur herstellung seiner elektroden | |

| DE1038193B (de) | Verfahren zur Herstellung von einzelnen Sinterelektroden fuer elektrolytische Kondensatoren | |

| CH621956A5 (enExample) | ||

| DE2166925C3 (de) | Verfahren zum Herstellen von Zweischichten-Kontaktstücken als Formteil | |

| DE2256739B2 (de) | Verfahren zur Herstellung eines Elektrolytkondensators | |

| DE8026170U1 (de) | Fuellkoerpern fuer in galvanische baeder einzusetzende anodenbehaelter | |

| EP1249518B1 (de) | Verwendung von im wesentlichen sauerstofffreiem, dendritischem und unbeschichtetem Kupfer zur galvanischen Beschichtung von Druckzylindern | |

| AT92527B (de) | Verfahren zur Herstellung von zur Auswalzung in Platten und Bleche dienenden Verbundmetallblöcken. | |

| DD277471A1 (de) | Verbundtarget | |

| DE1933455A1 (de) | Zellenartiger,starrer,dreidimensionaler Koerper,sein Herstellungsverfahren und Werkzeuge fuer elektrolytische Bearbeitung | |

| DE3049304C2 (enExample) | ||

| CH619739A5 (en) | Process and appliance for making a non-conductive porous grinding body electroconductive | |

| DE505966C (de) | Elektrolytisch hergestellter Metallblock und Verfahren zu dessen Herstellung | |

| DE1771612C3 (de) | Verfahren zur Herstellung eines aus metallbeschichteten Schleifpartikeln bestehenden porösen Formkörpers | |

| EP4605584A1 (de) | Metallkörper sowie verfahren zum herstellen des metallkörpers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH FR GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19820616 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH FR GB IT LI NL SE |

|

| REF | Corresponds to: |

Ref document number: 15914 Country of ref document: AT Date of ref document: 19851015 Kind code of ref document: T |

|

| ET | Fr: translation filed | ||

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: KABEL- UND METALLWERKE GUTEHOFFNUNGSHUETTE AKTIEN Effective date: 19860221 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: KABEL-UND METALLWERKE GUTEHOFFNUNGSHUETTE AG |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| 26 | Opposition filed |

Opponent name: CUIVRE ET ALLIAGES Effective date: 19860510 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: CUIVRE ET ALLIAGES |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: KABEL- UND METALLWERKE GUTEHOFFNUNGSHUETTE AKTIEN Effective date: 19860221 |

|

| PUAH | Patent maintained in amended form |

Free format text: ORIGINAL CODE: 0009272 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: PATENT MAINTAINED AS AMENDED |

|

| 27A | Patent maintained in amended form |

Effective date: 19900307 |

|

| AK | Designated contracting states |

Kind code of ref document: B2 Designated state(s): AT BE CH FR GB IT NL SE |

|

| ITF | It: translation for a ep patent filed | ||

| ET3 | Fr: translation filed ** decision concerning opposition | ||

| NLR2 | Nl: decision of opposition | ||

| NLR3 | Nl: receipt of modified translations in the netherlands language after an opposition procedure | ||

| ITTA | It: last paid annual fee | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 81104888.3 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20000511 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20000517 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20000519 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20000522 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20000523 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20000524 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20000615 Year of fee payment: 20 |

|

| BE20 | Be: patent expired |

Free format text: 20010624 *HOLL & CIE G.M.B.H. |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20010623 Ref country code: GB Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20010623 Ref country code: CH Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20010623 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20010624 Ref country code: AT Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20010624 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 20010629 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: PE20 Effective date: 20010623 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 81104888.3 |

|

| NLV7 | Nl: ceased due to reaching the maximum lifetime of a patent |

Effective date: 20010624 |