DE102015114673A1 - Stahl-Reiblamelle und Reibungskupplung mit solchen Reiblamellen und Verfahren zur Herstellung einer solchen Reiblamelle - Google Patents

Stahl-Reiblamelle und Reibungskupplung mit solchen Reiblamellen und Verfahren zur Herstellung einer solchen Reiblamelle Download PDFInfo

- Publication number

- DE102015114673A1 DE102015114673A1 DE102015114673.8A DE102015114673A DE102015114673A1 DE 102015114673 A1 DE102015114673 A1 DE 102015114673A1 DE 102015114673 A DE102015114673 A DE 102015114673A DE 102015114673 A1 DE102015114673 A1 DE 102015114673A1

- Authority

- DE

- Germany

- Prior art keywords

- friction

- friction plate

- slot

- range

- peripheral edge

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 229910000831 Steel Inorganic materials 0.000 title claims abstract description 19

- 239000010959 steel Substances 0.000 title claims abstract description 19

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 9

- 230000002093 peripheral effect Effects 0.000 claims abstract description 26

- 239000000463 material Substances 0.000 claims abstract description 3

- 235000012773 waffles Nutrition 0.000 claims description 3

- 238000000034 method Methods 0.000 claims description 2

- 238000000576 coating method Methods 0.000 description 6

- 239000000314 lubricant Substances 0.000 description 6

- 239000011248 coating agent Substances 0.000 description 5

- 241000446313 Lamella Species 0.000 description 3

- 238000005520 cutting process Methods 0.000 description 2

- 238000003698 laser cutting Methods 0.000 description 2

- 238000005121 nitriding Methods 0.000 description 2

- 238000012805 post-processing Methods 0.000 description 2

- 238000004080 punching Methods 0.000 description 2

- 230000003746 surface roughness Effects 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 description 1

- 230000005540 biological transmission Effects 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000001627 detrimental effect Effects 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 230000001050 lubricating effect Effects 0.000 description 1

- 238000005461 lubrication Methods 0.000 description 1

- 229910052750 molybdenum Inorganic materials 0.000 description 1

- 239000011733 molybdenum Substances 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 230000008646 thermal stress Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21B—ROLLING OF METAL

- B21B1/00—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations

- B21B1/22—Metal-rolling methods or mills for making semi-finished products of solid or profiled cross-section; Sequence of operations in milling trains; Layout of rolling-mill plant, e.g. grouping of stands; Succession of passes or of sectional pass alternations for rolling plates, strips, bands or sheets of indefinite length

- B21B1/227—Surface roughening or texturing

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D65/00—Parts or details

- F16D65/02—Braking members; Mounting thereof

- F16D65/04—Bands, shoes or pads; Pivots or supporting members therefor

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

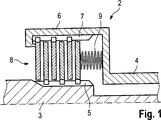

- F16D13/00—Friction clutches

- F16D13/22—Friction clutches with axially-movable clutching members

- F16D13/38—Friction clutches with axially-movable clutching members with flat clutching surfaces, e.g. discs

- F16D13/52—Clutches with multiple lamellae ; Clutches in which three or more axially moveable members are fixed alternately to the shafts to be coupled and are pressed from one side towards an axially-located member

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D28/00—Shaping by press-cutting; Perforating

- B21D28/02—Punching blanks or articles with or without obtaining scrap; Notching

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D53/00—Making other particular articles

- B21D53/84—Making other particular articles other parts for engines, e.g. connecting-rods

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21H—MAKING PARTICULAR METAL OBJECTS BY ROLLING, e.g. SCREWS, WHEELS, RINGS, BARRELS, BALLS

- B21H8/00—Rolling metal of indefinite length in repetitive shapes specially designed for the manufacture of particular objects, e.g. checkered sheets

- B21H8/005—Embossing sheets or rolls

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21K—MAKING FORGED OR PRESSED METAL PRODUCTS, e.g. HORSE-SHOES, RIVETS, BOLTS OR WHEELS

- B21K23/00—Making other articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23P—METAL-WORKING NOT OTHERWISE PROVIDED FOR; COMBINED OPERATIONS; UNIVERSAL MACHINE TOOLS

- B23P15/00—Making specific metal objects by operations not covered by a single other subclass or a group in this subclass

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D13/00—Friction clutches

- F16D13/58—Details

- F16D13/74—Features relating to lubrication

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D69/00—Friction linings; Attachment thereof; Selection of coacting friction substances or surfaces

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D13/00—Friction clutches

- F16D13/58—Details

- F16D13/60—Clutching elements

- F16D13/64—Clutch-plates; Clutch-lamellae

- F16D13/648—Clutch-plates; Clutch-lamellae for clutches with multiple lamellae

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D69/00—Friction linings; Attachment thereof; Selection of coacting friction substances or surfaces

- F16D2069/004—Profiled friction surfaces, e.g. grooves, dimples

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D2200/00—Materials; Production methods therefor

- F16D2200/0004—Materials; Production methods therefor metallic

- F16D2200/0008—Ferro

- F16D2200/0021—Steel

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D2250/00—Manufacturing; Assembly

- F16D2250/0023—Shaping by pressure

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D2250/00—Manufacturing; Assembly

- F16D2250/0038—Surface treatment

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D2300/00—Special features for couplings or clutches

- F16D2300/06—Lubrication details not provided for in group F16D13/74

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D2300/00—Special features for couplings or clutches

- F16D2300/10—Surface characteristics; Details related to material surfaces

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D2300/00—Special features for couplings or clutches

- F16D2300/12—Mounting or assembling

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16D—COUPLINGS FOR TRANSMITTING ROTATION; CLUTCHES; BRAKES

- F16D35/00—Fluid clutches in which the clutching is predominantly obtained by fluid adhesion

- F16D35/005—Fluid clutches in which the clutching is predominantly obtained by fluid adhesion with multiple lamellae

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Braking Arrangements (AREA)

- Mechanical Operated Clutches (AREA)

Priority Applications (6)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102015114673.8A DE102015114673A1 (de) | 2015-09-02 | 2015-09-02 | Stahl-Reiblamelle und Reibungskupplung mit solchen Reiblamellen und Verfahren zur Herstellung einer solchen Reiblamelle |

| FR1658142A FR3040453A1 (enExample) | 2015-09-02 | 2016-09-01 | |

| JP2016171228A JP2017083007A (ja) | 2015-09-02 | 2016-09-01 | 摩擦継手のための鋼製摩擦層板を製造する方法 |

| US15/255,190 US20170056943A1 (en) | 2015-09-02 | 2016-09-02 | Method for manufacturing a steel friction lamella for a friction coupling |

| CN201610801028.4A CN107246448A (zh) | 2015-09-02 | 2016-09-02 | 用于制造用于摩擦联轴器的钢摩擦片的方法 |

| ATA50779/2016A AT517814A3 (de) | 2015-09-02 | 2016-09-02 | Verfahren zur Herstellung einer Stahl- Reiblamelle für eine Reibungskupplung |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102015114673.8A DE102015114673A1 (de) | 2015-09-02 | 2015-09-02 | Stahl-Reiblamelle und Reibungskupplung mit solchen Reiblamellen und Verfahren zur Herstellung einer solchen Reiblamelle |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| DE102015114673A1 true DE102015114673A1 (de) | 2017-03-02 |

Family

ID=58011057

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| DE102015114673.8A Withdrawn DE102015114673A1 (de) | 2015-09-02 | 2015-09-02 | Stahl-Reiblamelle und Reibungskupplung mit solchen Reiblamellen und Verfahren zur Herstellung einer solchen Reiblamelle |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20170056943A1 (enExample) |

| JP (1) | JP2017083007A (enExample) |

| CN (1) | CN107246448A (enExample) |

| AT (1) | AT517814A3 (enExample) |

| DE (1) | DE102015114673A1 (enExample) |

| FR (1) | FR3040453A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102019204988A1 (de) * | 2019-04-08 | 2020-10-08 | Zf Friedrichshafen Ag | Lamelle für eine Lamellenkupplung, Lamellenkupplung mit der Lamelle sowie Verfahren zur Herstellung der Lamelle |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10975919B2 (en) * | 2018-03-06 | 2021-04-13 | Schaeffler Technologies AG & Co. KG | Laser etching of patterns on a surface for friction material adhesion |

| DE102018003829A1 (de) * | 2018-05-11 | 2019-11-14 | Borgwarner Inc. | Reiblamelle und reibschlüssig arbeitende Einrichtung mit einer solchen Reiblamelle |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3025686A (en) * | 1961-05-24 | 1962-03-20 | Robert P Lewis | Clutch discs |

| DE1173740B (de) * | 1960-12-14 | 1964-07-09 | Held Ag Maschf | Reibungskupplung mit in OEl laufenden Lamellen |

| DE1208127B (de) * | 1961-09-27 | 1965-12-30 | Pulsgetriebe Erich Friedrich P | Lamellenkupplung fuer hohe Belastungen |

| AT408478B (de) * | 1991-07-02 | 2001-12-27 | Hoerbiger & Co | Reibring |

| US20080314713A1 (en) * | 2005-11-01 | 2008-12-25 | Richard Vogele | Segmented and Laminated Core Steel Plate for Single and/or Double Sided Wet Clutch Friction Plates or Separator Plates |

| DE102011013936A1 (de) * | 2011-03-14 | 2012-09-20 | Friedrich Henkel Feinmechanik KG | Werkstücksegmentierung mittels Feinschneiden |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB341243A (en) * | 1929-12-23 | 1931-01-15 | Hermann Schoening | Improvements in and relating to multiple plate clutches |

| GB743192A (en) * | 1952-11-10 | 1956-01-11 | Geoffrey Robert Greenbergh Gat | Improvements in or relating to clutch plates |

| US3073424A (en) * | 1959-06-15 | 1963-01-15 | Eaton Mfg Co | Friction device |

| GB1276197A (en) * | 1969-10-08 | 1972-06-01 | Girling Ltd | Improvements in multiple disc brakes and stator discs for such brakes |

| JPS548144A (en) * | 1977-06-21 | 1979-01-22 | Mitsubishi Electric Corp | Manufacture of friction plate |

| US4260047A (en) * | 1979-12-03 | 1981-04-07 | General Motors Corporation | Friction disc and method of making same |

| AU550746B2 (en) * | 1980-11-26 | 1986-04-10 | Massey-Ferguson Services N.V. | Disc brake |

| JPS61130634A (ja) * | 1984-11-29 | 1986-06-18 | Sunstar Giken Kk | ディスクブレーキ用ディスク |

| DE3605558C5 (de) * | 1985-04-12 | 2004-10-14 | Volkswagen Ag | Kupplungsscheiben für eine Flüssigkeitsreibungskupplung und Verfahren zu deren Herstellung |

| JPH0772574B2 (ja) * | 1986-08-07 | 1995-08-02 | 愛知製鋼株式会社 | 差動制限装置の溝付きクラツチ板 |

| JPH0818092B2 (ja) * | 1986-08-08 | 1996-02-28 | 愛知製鋼株式会社 | 溝付きクラツチ板の製造方法 |

| JPS6349303A (ja) * | 1986-08-13 | 1988-03-02 | Aichi Steel Works Ltd | 溝付きクラツチ板の製造方法 |

| JPS62297549A (ja) * | 1987-06-12 | 1987-12-24 | Honda Motor Co Ltd | ブレ−キデイスク |

| EP0308048B1 (en) * | 1987-07-28 | 1991-05-15 | LUCAS INDUSTRIES public limited company | Rotatable member for a vehicle disc brake of the liquid cooled type |

| DE59005109D1 (de) * | 1990-01-17 | 1994-04-28 | Hjl Projects & Dev | Verfahren zur Bearbeitung von Oberflächen auf Gebilden und nach diesem Verfahren hergestellte Gebilde. |

| JP2003130084A (ja) * | 2001-10-23 | 2003-05-08 | Tochigi Fuji Ind Co Ltd | 湿式摩擦クラッチ板 |

| EP1858295B1 (en) * | 2006-05-19 | 2013-06-26 | Nuance Communications, Inc. | Equalization in acoustic signal processing |

| DE102011120811A1 (de) * | 2011-12-10 | 2013-06-13 | Volkswagen Aktiengesellschaft | Reiblamellen, Lamellenkupplung und Verfahren zur Herstellung von Reiblamellen |

| JP6044754B2 (ja) * | 2012-01-19 | 2016-12-14 | 株式会社ジェイテクト | クラッチプレートおよびその製造方法 |

-

2015

- 2015-09-02 DE DE102015114673.8A patent/DE102015114673A1/de not_active Withdrawn

-

2016

- 2016-09-01 FR FR1658142A patent/FR3040453A1/fr not_active Ceased

- 2016-09-01 JP JP2016171228A patent/JP2017083007A/ja active Pending

- 2016-09-02 AT ATA50779/2016A patent/AT517814A3/de not_active Application Discontinuation

- 2016-09-02 US US15/255,190 patent/US20170056943A1/en not_active Abandoned

- 2016-09-02 CN CN201610801028.4A patent/CN107246448A/zh active Pending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1173740B (de) * | 1960-12-14 | 1964-07-09 | Held Ag Maschf | Reibungskupplung mit in OEl laufenden Lamellen |

| US3025686A (en) * | 1961-05-24 | 1962-03-20 | Robert P Lewis | Clutch discs |

| DE1208127B (de) * | 1961-09-27 | 1965-12-30 | Pulsgetriebe Erich Friedrich P | Lamellenkupplung fuer hohe Belastungen |

| AT408478B (de) * | 1991-07-02 | 2001-12-27 | Hoerbiger & Co | Reibring |

| US20080314713A1 (en) * | 2005-11-01 | 2008-12-25 | Richard Vogele | Segmented and Laminated Core Steel Plate for Single and/or Double Sided Wet Clutch Friction Plates or Separator Plates |

| DE102011013936A1 (de) * | 2011-03-14 | 2012-09-20 | Friedrich Henkel Feinmechanik KG | Werkstücksegmentierung mittels Feinschneiden |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102019204988A1 (de) * | 2019-04-08 | 2020-10-08 | Zf Friedrichshafen Ag | Lamelle für eine Lamellenkupplung, Lamellenkupplung mit der Lamelle sowie Verfahren zur Herstellung der Lamelle |

| WO2020207878A1 (de) | 2019-04-08 | 2020-10-15 | Zf Friedrichshafen Ag | Lamelle für eine lamellenkupplung, lamellenkupplung mit der lamelle sowie verfahren zur herstellung der lamelle |

Also Published As

| Publication number | Publication date |

|---|---|

| FR3040453A1 (enExample) | 2017-03-03 |

| AT517814A2 (de) | 2017-04-15 |

| CN107246448A (zh) | 2017-10-13 |

| US20170056943A1 (en) | 2017-03-02 |

| AT517814A3 (de) | 2020-01-15 |

| JP2017083007A (ja) | 2017-05-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1988310B1 (de) | Zahnriemenrad | |

| EP2210005B1 (de) | Axiallager, insbesondere für einen turbolader | |

| EP2894363B1 (de) | Reibring, Synchronring, Synchronisierungseinheit, sowie ein Zahnräderwechselgetriebe für ein Fahrzeug | |

| DE102006045456A1 (de) | Reibteil für eine reibschlüssig arbeitende Einrichtung und reibschlüssig arbeitende Einrichtung mit einem solchen Reibteil | |

| DE102012218357A1 (de) | Verfahren zum Herstellen eines Kombinationszahnrads für einen gestapelten Planetenradsatz | |

| DE102008063662A1 (de) | Lamelle für eine reibschlüssig arbeitende Einrichtung und reibschlüssig arbeitende Einrichtung mit einer solchen Lamelle | |

| EP3374652A1 (de) | Lamelle für ein kraftschlüssiges schaltelement | |

| DE102007010764A1 (de) | Kupplungskörper und Synchronring für eine Synchronisierungseinrichtung | |

| DE112009002345T5 (de) | Verarbeitung von Videodaten in Geräten mit eingeschränkten Ressourcen | |

| DE102014226644A1 (de) | Verfahren zum Herstellen einer Differentialvorrichtung | |

| WO2016007980A1 (de) | Reiblamelle | |

| WO2018171835A1 (de) | Reibteil | |

| DE102013200039A1 (de) | Wellenanordnung mit umgekehrten Fasen an Keilnuten | |

| WO2015124154A2 (de) | Kupplung mit flanschverbindung | |

| EP2495468A2 (de) | Planetengetriebe mit Wellen-Naben-Verbindung | |

| DE102015100869A1 (de) | Verfahren zur Herstellung eines Synchronrings sowie Synchronring für synchronisierte Schaltgetriebe | |

| DE102017222891A1 (de) | Blech-Lamellenträger sowie Verfahren zu dessen Drehzahlfestigkeitserhöhung | |

| DE102015114673A1 (de) | Stahl-Reiblamelle und Reibungskupplung mit solchen Reiblamellen und Verfahren zur Herstellung einer solchen Reiblamelle | |

| DE102015212662A1 (de) | Reibschaltelement für ein Getriebe eines Fahrzeuges | |

| DE102014007270A1 (de) | Lamelle mit einem segmentierten Grundkörper und Verfahren zur Herstellung einer Lamelle oder eines segmentierten Grundkörpers für eine Lamelle | |

| DE102011120343B4 (de) | Verfahren zur Herstellung eines Kupplungskörpers sowie Kupplungskörper für eine Synchronisiereinrichtung | |

| DE102006034736A1 (de) | Lagerschale und Lager für Pleuel | |

| DE102015013215A1 (de) | Mehrteiliges Hochleistungskettenrad | |

| AT513583A1 (de) | Kupplungslamelle | |

| DE102017107209B4 (de) | Reiblamelle aus mehreren miteinander verbundenen Segmenten |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| R012 | Request for examination validly filed | ||

| R016 | Response to examination communication | ||

| R016 | Response to examination communication | ||

| R016 | Response to examination communication | ||

| R120 | Application withdrawn or ip right abandoned |