WO2020204167A1 - アルミニウム合金ブレージングシート及びその製造方法 - Google Patents

アルミニウム合金ブレージングシート及びその製造方法 Download PDFInfo

- Publication number

- WO2020204167A1 WO2020204167A1 PCT/JP2020/015339 JP2020015339W WO2020204167A1 WO 2020204167 A1 WO2020204167 A1 WO 2020204167A1 JP 2020015339 W JP2020015339 W JP 2020015339W WO 2020204167 A1 WO2020204167 A1 WO 2020204167A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- mass

- less

- brazing

- aluminum alloy

- brazing sheet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C21/00—Alloys based on aluminium

- C22C21/06—Alloys based on aluminium with magnesium as the next major constituent

- C22C21/08—Alloys based on aluminium with magnesium as the next major constituent with silicon

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K35/00—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting

- B23K35/22—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by the composition or nature of the material

- B23K35/24—Selection of soldering or welding materials proper

- B23K35/28—Selection of soldering or welding materials proper with the principal constituent melting at less than 950 degrees C

- B23K35/286—Al as the principal constituent

- B23K35/288—Al as the principal constituent with Sn or Zn

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K35/00—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting

- B23K35/02—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by mechanical features, e.g. shape

- B23K35/0222—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by mechanical features, e.g. shape for use in soldering, brazing

- B23K35/0233—Sheets, foils

- B23K35/0238—Sheets, foils layered

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K35/00—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting

- B23K35/22—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by the composition or nature of the material

- B23K35/24—Selection of soldering or welding materials proper

- B23K35/28—Selection of soldering or welding materials proper with the principal constituent melting at less than 950 degrees C

- B23K35/286—Al as the principal constituent

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/01—Layered products comprising a layer of metal all layers being exclusively metallic

- B32B15/016—Layered products comprising a layer of metal all layers being exclusively metallic all layers being formed of aluminium or aluminium alloys

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C21/00—Alloys based on aluminium

- C22C21/02—Alloys based on aluminium with silicon as the next major constituent

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C21/00—Alloys based on aluminium

- C22C21/10—Alloys based on aluminium with zinc as the next major constituent

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

- C22F1/04—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of aluminium or alloys based thereon

- C22F1/043—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of aluminium or alloys based thereon of alloys with silicon as the next major constituent

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

- C22F1/04—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of aluminium or alloys based thereon

- C22F1/047—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of aluminium or alloys based thereon of alloys with magnesium as the next major constituent

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

- C22F1/04—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of aluminium or alloys based thereon

- C22F1/053—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working of aluminium or alloys based thereon of alloys with zinc as the next major constituent

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K1/00—Soldering, e.g. brazing, or unsoldering

- B23K1/0008—Soldering, e.g. brazing, or unsoldering specially adapted for particular articles or work

- B23K1/0012—Brazing heat exchangers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K1/00—Soldering, e.g. brazing, or unsoldering

- B23K1/008—Soldering within a furnace

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2101/00—Articles made by soldering, welding or cutting

- B23K2101/04—Tubular or hollow articles

- B23K2101/14—Heat exchangers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K2103/00—Materials to be soldered, welded or cut

- B23K2103/08—Non-ferrous metals or alloys

- B23K2103/10—Aluminium or alloys thereof

Definitions

- the present invention relates to an aluminum alloy brazing sheet used for brazing aluminum or an aluminum alloy in an inert gas atmosphere that does not use flux, and a method for producing the same.

- Brazing joining is widely used as a joining method for aluminum products that have many fine joints, such as aluminum heat exchangers and mechanical parts.

- it is essential to break the oxide film covering the surface to expose the molten brazing material and wet it with the base material or the similarly molten brazing material.

- the flux reacts with the oxide film during waxing heat and destroys the oxide film.

- the cost of the flux and the cost of the process of applying the flux increase. Further, if the flux is applied non-uniformly, there is a risk that brazing defects will occur.

- a brazing material made of an Al—Si—Mg based alloy is used, and Mg evaporates in the brazing material by heating in a vacuum, destroying the oxide film on the surface of the material. To do.

- expensive vacuum heating equipment is required.

- the evaporated Mg adheres to the inside of the furnace, there is a problem that the maintenance cost for removing the adhered Mg is high. Therefore, there is an increasing need for joining in a nitrogen gas furnace without using flux.

- Patent Document 1 proposes that surface bonding becomes possible by containing Mg in the brazing material.

- Patent Document 2 proposes that a fillet can be formed with a simple fin / tube joint by containing Mg in the core material and diffusing Mg into the brazing material during brazing addition heat.

- good flux-free brazing property can be obtained by limiting the equivalent circle diameter and the number of Si particles contained in the brazing material and by contacting and adhering the brazing material and the brazing target member. Is disclosed. However, with these methods, it is not possible to form a sufficient fillet in a joint having a gap without applying flux.

- Patent Document 3 proposes that it is effective to suppress the thickness of the MgO film existing on the oxide film before brazing heat addition.

- the brazing material contains 0.1% by mass or more of Mg

- an MgO-based film is partially formed during the brazing heat addition, which inhibits the formation of fillets. , The fillet will run out.

- Patent Document 4 in a material containing 0.05% by mass or more of Mg in a brazing material, the MgO-based film can be removed by performing a pickling treatment before brazing heat addition, and brazing can be performed without flux.

- Patent Document 1 the formation of the MgO-based film during the heat addition of wax cannot be sufficiently suppressed.

- Patent Document 5 the X element having a volume change rate of 0.99 or less with respect to the oxide film before brazing heat is added (X is Mg, Li, Be, Ca, Ce, La, Y and Zr). Oxide particles containing zirconium have been proposed to form a brazing sheet on the surface, which enhances brazing for more practical joints with gaps, but because the gaps in the actual heat exchanger are larger. In addition, the brazing property may not be sufficient.

- An object of the present invention is an aluminum alloy having excellent brazing property not only in the contact contact portion between each member of the heat exchanger but also in the case of a large gap in brazing in an inert gas atmosphere without using flux.

- the present invention is to provide a brazing sheet and a method for producing the same.

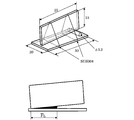

- the present invention (1) is an aluminum alloy brazing sheet used for brazing in an inert gas atmosphere that does not use flux.

- Wax is clad on at least one side of the heartwood

- the core material is aluminum or Fe of 1.50% by mass or less, Si of 1.50% by mass or less, Cu of 2.00% by mass or less, Mn of 2.00% by mass or less, and 3.00% by mass or less. Any of Zn, Cr of 0.30% by mass or less, Ti of 0.30% by mass or less, Zr of 0.30% by mass or less, In of 0.10% by mass or less, and Sn of 0.10% by mass or less.

- the brazing materials include 4.00 to 13.00% by mass of Si, Mg of more than 0.03% by mass and 3.00% by mass or less, Li of more than 0.03% by mass and 3.00% by mass or less.

- Aluminum alloy brazing sheet The atomic molar ratio of Mg, Li and Ca to Al in the oxide formed on the surface of the aluminum alloy brazing sheet before brazing heat is 0.5 or less. Provided is an aluminum alloy brazing sheet characterized by the above.

- the present invention (2) also provides the aluminum alloy brazing sheet of (1), wherein the aluminum alloy brazing sheet is a two-layer material in which the brazing material is clad on one side of the core material. It is a thing.

- the present invention (3) also provides the aluminum alloy brazing sheet of (1), wherein the aluminum alloy brazing sheet is a three-layer material in which the brazing material is clad on both sides of the core material. It is a thing.

- the aluminum alloy brazing sheet has three layers in which the brazing material is clad on one surface of the core material and the skin material is clad on the other surface of the core material. It is a material

- the skin material is an aluminum alloy skin material containing aluminum or an aluminum alloy containing 6.00% by mass or less of Zn and composed of the balance aluminum and unavoidable impurities.

- the present invention provides the aluminum alloy brazing sheet according to (1).

- the core material is further any one or 2 of Mg of 3.00% by mass or less, Li of 3.00% by mass or less and Ca of 3.00% by mass or less. It provides an aluminum alloy brazing sheet according to any one of (1) to (4) containing seeds or more.

- the present invention (6) provides an aluminum alloy brazing sheet according to any one of (1) to (5), wherein the core material further contains 1.00% by mass or less of Bi. is there.

- the present invention (7) provides an aluminum alloy brazing sheet according to any one of (1) to (6), wherein the brazing material further contains 1.00% by mass or less of Bi. Is.

- the brazing material further contains 0.05% by mass or less of Na, 0.05% by mass or less of Sr, 0.05% by mass or less of Sb, and 8.00% by mass or less.

- the aluminum alloy brazing sheet is provided.

- the skin material is further Mn of 2.00% by mass or less, Mg of 3.00% by mass or less, Si of 5.00% by mass or less, and 1.50% by mass or less.

- Fe Cu of 1.00% by mass or less, Ti of 0.30% by mass or less, Zr of 0.30% by mass or less, Cr of 0.30% by mass or less, In of 0.10% by mass or less and 0.10

- an aluminum alloy brazing sheet according to any one of (4) to (8), which contains any one or more of Sn of mass% or less.

- the present invention (10) is characterized in that the thickness of the oxide formed on the brazing material surface of the aluminum alloy brazing sheet is 50 nm or less, which is any of the aluminum alloys (1) to (9). It provides a brazing sheet.

- a laminate in which a brazing ingot / a core ingot is laminated in this order and (2) a brazing ingot / a core ingot / a brazing ingot in that order.

- An aluminum alloy brazing sheet is subjected to at least hot working and cold working on the laminated laminate or the laminate in which (3) brazing ingot / core material ingot / skin material ingot are laminated in this order.

- the ingot for the core material is aluminum or Fe of 1.50% by mass or less, Si of 1.50% by mass or less, Cu of 2.00% by mass or less, Mn of 2.00% by mass or less, 3.00% by mass.

- the ingots for brazing materials include 4.00 to 13.00% by mass of Si, Mg of more than 0.03% by mass and 3.00% by mass or less, and more than 0.03% by mass and 3.00% by mass or less. It is an aluminum alloy containing Li and any one or more of Ca of more than 0.03% by mass and 3.00% by mass or less, and composed of the balance aluminum and unavoidable impurities.

- the ingot for skin material is an aluminum alloy containing aluminum or an aluminum alloy containing 6.00% by mass or less of Zn, the balance of aluminum, and unavoidable impurities.

- intermediate annealing is performed by heating at 250-450 ° C for 1 hour or more in an atmosphere where the oxygen concentration is 10000 ppm or less and the dew point is controlled at 20 ° C or less, or the final After the cold working pass, final annealing is performed by heating at 250 to 450 ° C. for 1 hour or more in an atmosphere where the oxygen concentration is 10000 ppm or less and the dew point is controlled to 20 ° C., or rolling by cold working. Annealing is performed by heating at 250 to 450 ° C.

- the present invention provides a method for producing an aluminum alloy brazing sheet.

- the ingot for the core material is further any one of Mg of 3.00% by mass or less, Li of 3.00% by mass or less, and Ca of 3.00% by mass or less. It provides a method for producing the aluminum alloy brazing sheet of (11) containing a seed or two or more kinds.

- the present invention (13) is characterized in that any one of the core material ingot and the brazing material ingot further contains 1.00% by mass or less of Bi (11) or. It provides the method of manufacturing the aluminum alloy brazing sheet of (12).

- the ingot for brazing material further contains 0.05% by mass or less of Na, 0.05% by mass or less of Sr, 0.05% by mass or less of Sb, and 8.00% by mass.

- the ingot for the skin material further contains 2.00% by mass or less of Mn, 3.00% by mass or less of Mg, 5.00% by mass or less of Si, and 1.50% by mass. % Or less Fe, 1.00% by mass or less Cu, 0.30% by mass or less Ti, 0.30% by mass or less Zr, 0.30% by mass or less Cr, 0.10% by mass or less.

- the present invention provides a method for producing an aluminum alloy brazing sheet according to any one of (11) to (14), which contains any one or more of Sn of 0.10% by mass or less. ..

- the present invention when the intermediate annealing is performed, the intermediate annealing is performed, when the final annealing is performed, the final annealing is performed, and then both the intermediate annealing and the final annealing are performed.

- either one of the acidic aqueous solution and the alkaline aqueous solution or both the acidic aqueous solution and the alkaline aqueous solution are used to braze the clad material.

- the present invention provides a method for producing an aluminum alloy brazing sheet according to any one of (11) to (15), which comprises etching the surface of a material.

- an aluminum alloy brazing sheet having excellent brazing properties and a method for producing the same in brazing in an inert gas atmosphere that does not use flux.

- Mg, Li and Ca destroy the film-like oxide formed on the surface of the brazing filler metal during the heat addition of the brazing filler metal, effectively exposing the new surface of the molten brazing filler metal. Since Mg, Li and Ca have smaller oxide formation energies than Al, the film-like oxide containing Al as a main component is reduced during the wax addition heat to contain particulate Mg, Li and Ca. Form oxides.

- the brazing material of the brazing sheet contains any one or more of Mg, Li and Ca in an amount of more than 0.03% by mass, the mating material to which the brazing sheet is bonded (for example, 3003 material).

- Mg, Li and Ca are sufficiently diffused on the surface layer, and oxide particles containing any one or more of Mg, Li and Ca are formed in the mating material 3003.

- the volume of the oxide on the surface of the mating material changes, and good brazing property can be obtained even in a joint having a large gap.

- the aluminum alloy brazing sheet of the present invention is an aluminum alloy brazing sheet used for brazing in an inert gas atmosphere that does not use flux.

- Wax is clad on at least one side of the heartwood

- the core material is aluminum or Fe of 1.50% by mass or less, Si of 1.50% by mass or less, Cu of 2.00% by mass or less, Mn of 2.00% by mass or less, and 3.00% by mass or less. Any of Zn, Cr of 0.30% by mass or less, Ti of 0.30% by mass or less, Zr of 0.30% by mass or less, In of 0.10% by mass or less, and Sn of 0.10% by mass or less.

- An aluminum alloy core material containing one or more types and composed of the balance aluminum and unavoidable impurities.

- the brazing materials include 4.00 to 13.00% by mass of Si, Mg of more than 0.03% by mass and 3.00% by mass or less, Li of more than 0.03% by mass and 3.00% by mass or less.

- Aluminum alloy brazing sheet The atomic molar ratio of Mg, Li and Ca to Al in the oxide formed on the surface of the aluminum alloy brazing sheet before brazing heat is 0.5 or less. It is an aluminum alloy brazing sheet characterized by.

- the aluminum alloy brazing sheet of the present invention is an aluminum alloy brazing sheet used for brazing in an inert gas atmosphere that does not use flux.

- the aluminum alloy brazing sheet of the present invention is a clad material in which a brazing material having the chemical composition shown below is clad on at least one surface of a core material having the chemical composition shown below.

- the aluminum alloy brazing sheet of the present invention has (1) a two-layer material in which a brazing material is clad on one side of the core material, (2) a three-layer material in which a brazing material is clad on both sides of the core material, or (3) a core material. It is a three-layer material in which a brazing material is clad on one surface and a skin material is clad on the other surface of the core material.

- the core material according to the aluminum alloy brazing sheet of the present invention is aluminum or Fe of 1.50% by mass or less, Si of 1.50% by mass or less, Cu of 2.00% by mass or less, and Mn of 2.00% by mass or less. , Zn of 3.00 mass% or less, Cr of 0.30 mass% or less, Ti of 0.30 mass% or less, Zr of 0.30 mass% or less, In of 0.10 mass% or less and 0.10 mass It is an aluminum alloy core material containing any one or more of Sn of% or less and consisting of the balance aluminum and unavoidable impurities.

- the purity of aluminum is not particularly limited, but is preferably 99.0% by mass or more, and particularly preferably 99.5% by mass or more.

- Fe contributes to the improvement of strength in the aluminum alloy forming the core material.

- the Fe content in the core material is 1.50% by mass or less, preferably 0.10 to 0.70% by mass, and particularly preferably 0.20 to 0.60% by mass.

- the strength of the core material is increased.

- the Fe content in the core material exceeds the above range, the corrosion resistance is lowered and huge precipitates are likely to be generated.

- Si contributes to the improvement of strength in the aluminum alloy that forms the core material.

- the Si content in the core material is 1.50% by mass or less, preferably 0.10 to 1.00% by mass, and particularly preferably 0.30 to 0.75% by mass.

- the Si content in the core material is within the above range, the strength of the core material is increased.

- the Si content in the core material exceeds the above range, the melting point becomes too low, local melting occurs at the time of brazing, the core material is deformed, and the corrosion resistance is lowered.

- Cu contributes to strength improvement and potential adjustment.

- the Cu content in the core material is 2.00% by mass or less, preferably 0.10 to 1.00% by mass, and particularly preferably 0.15 to 0.80% by mass.

- the strength of the core material is increased.

- the Cu content in the core material exceeds the above range, intergranular corrosion is likely to occur and the melting point becomes too low.

- Mn contributes to strength improvement and potential adjustment.

- the Mn content in the core material is 2.00% by mass or less, preferably 0.30 to 1.80% by mass, and particularly preferably 0.30 to 1.50% by mass.

- the Mn content in the core material is within the above range, the strength of the core material is increased and the potential adjusting effect can be obtained. If the Mn content in the core material exceeds the above range, cracks are likely to occur during material rolling.

- Zn contributes to potential adjustment.

- the Zn content in the core material is 3.00% by mass or less, preferably 0.50 to 3.00% by mass, and particularly preferably 1.50 to 3.00% by mass.

- the Zn content in the core material is within the above range, the potential adjusting effect can be obtained.

- the Zn content in the core material exceeds the above range, the natural electrode potential becomes too low and the corrosion resistance deteriorates.

- Cr improves the strength by solid solution strengthening, and also precipitates Al—Cr-based fine compounds, which acts on the coarsening of crystal grains after brazing.

- the Cr content in the core material is 0.30% by mass or less, preferably 0.10 to 0.20% by mass. When the Cr content in the core material is within the above range, the strength of the core material is increased. On the other hand, if the Cr content in the core material exceeds the above range, a giant intermetallic compound is likely to be formed during casting, and the plastic workability is lowered.

- Ti improves its strength by strengthening the solid solution, and by forming layers with high and low potentials in the core material, the corrosion form changes from pitting corrosion to layers. It has the effect of improving corrosion resistance.

- the Ti content in the core material is 0.30% by mass or less, preferably 0.10 to 0.20% by mass, and particularly preferably 0.12 to 0.18% by mass. When the Ti content in the core material is within the above range, the strength of the core material is increased and the corrosion resistance is increased. On the other hand, if the Ti content in the core material exceeds the above range, a giant intermetallic compound is likely to be formed during casting, and the plastic workability is lowered.

- Zr improves the strength by solid solution strengthening, and also precipitates Al—Zr-based fine compounds, which acts on the coarsening of crystal grains after brazing.

- the Zr content in the core material is 0.30% by mass or less, preferably 0.10 to 0.20% by mass.

- the strength of the core material is increased, and the effect of coarsening the crystal grains after brazing can be obtained.

- the Zr content in the core material exceeds the above range, a giant intermetallic compound is likely to be formed during casting, and the plastic workability is lowered.

- In contributes to potential adjustment.

- the core material contains In

- the In content in the core material is 0.10% by mass or less, preferably 0.01 to 0.03% by mass.

- the potential adjusting effect can be obtained.

- the In content in the core material exceeds the above range, the natural electrode potential becomes too low and the corrosion resistance deteriorates.

- Sn contributes to potential adjustment.

- the Sn content in the core material is 0.10% by mass or less, preferably 0.01 to 0.10% by mass.

- the potential adjusting effect can be obtained.

- the Sn content in the core material exceeds the above range, the natural electrode potential becomes too low and the corrosion resistance becomes low.

- the heartwood can contain Bi.

- Bi acts to suppress a decrease in the Bi concentration of the brazing material when the brazing material melts during the brazing heat and melts a part of the core material, and Al—Si melts. It has the effect of reducing the surface tension of wax.

- the core material contains Bi

- the Bi content in the core material is 1.00% by mass or less, preferably 0.10 to 1.00% by mass.

- the Bi content in the core material is within the above range, the effect of melting in the brazing material to reduce the surface tension can be obtained.

- the Bi content in the core material exceeds the above range, it becomes difficult to roll the material.

- the core material can contain any one or more of Mg, Li and Ca.

- the Mg content in the core material is 3.00% by mass or less, preferably 0.10 to 1.80% by mass.

- the core material contains Li the Li content in the core material is 3.00% by mass or less, preferably 0.10 to 1.80% by mass.

- the core material contains Ca the Ca content in the core material is 3.00% by mass or less, preferably 0.10 to 1.80% by mass.

- the concentration of Mg, Li or Ca in the brazing material when the brazing material is melted during the heat addition heat and a part of the core material is melted.

- the volume change rate of the oxide formed by oxidizing Mg, Li or Ca on the surface of the brazing material becomes 0.990 or less, and the brazing sheet and partner by Mg, Li or Ca act to suppress the decrease of The destructive effect of the oxide film of the material is enhanced, and excellent brazing property can be obtained.

- the content of Mg, Li or Ca in the core material exceeds the above range, the melting point of the core material drops too much, so that local melting occurs in the core material during brazing heat, the core material is deformed, and the core material due to molten brazing. Erosion occurs, and brazing bondability and corrosion resistance are reduced.

- the core material contains 0.05% by mass or less of Ag, B, Be, Cd, Co, Ga, Ge, Mo, Na, Ni, P, Pb, Sr, V, Hg, and Y as unavoidable impurities. May be good.

- the brazing material according to the aluminum alloy brazing sheet of the present invention is (I) 4.0 to 13.0% by mass of Si and (Ii) Mg exceeding 0.03% by mass and 3.00% by mass or less, Li exceeding 0.03% by mass and 3.00% by mass or less and Ca exceeding 0.03% by mass and 3.00% by mass or less With any one or more of the It is an aluminum alloy brazing material containing the balance of aluminum and unavoidable impurities.

- the brazing material contains Si as an essential element.

- the Si content in the brazing filler metal is 4.00 to 13.00% by mass, particularly preferably 4.50 to 12.00% by mass.

- a sufficient liquid phase necessary for brazing bonding can be obtained.

- the Si content in the core material is less than the above range, the liquid phase amount is insufficient, and if it exceeds the above range, cracks are likely to occur during material production, which makes it difficult to produce a brazing sheet.

- the brazing material contains any one or more of Mg, Li and Ca.

- the Mg content in the brazing material exceeds 0.03% by mass and 3.00% by mass or less, preferably 0.10 to 1.80% by mass, and particularly preferably 0.60. It is ⁇ 1.20% by mass.

- the brazing material contains Li

- the Li content in the brazing material exceeds 0.03% by mass and 3.00% by mass or less, preferably 0.04 to 1.80% by mass, and particularly preferably 0.10. It is about 1.80% by mass.

- the brazing material contains Ca

- the Ca content in the brazing material is more than 0.03% by mass and 3.00% by mass or less, preferably 0.05 to 1.80% by mass, and particularly preferably 0.10. It is about 1.80% by mass.

- the volume change rate of the oxide formed by oxidizing Mg, Li or Ca during the heat of brazing is 0.990 or less.

- the effect of destroying the oxide film of the brazing sheet and the mating material by Mg, Li or Ca is enhanced, and excellent brazing property can be obtained.

- the content of Mg, Li and Ca in the core material is less than the above range, the effect of Mg, Li and Ca to destroy the oxide film of the brazing sheet and the mating material becomes poor, and if it exceeds the above range. Oxidation of Mg, Li and Ca proceeds during the heat of wax addition, and an oxide having a volume change rate of more than 0.990 is formed.

- the brazing material can contain Bi.

- Bi exerts the effect of lowering the surface tension of the Al—Si molten brazing material.

- the Bi content in the brazing material is 1.00% by mass or less, preferably 0.50% by mass or less, more preferably 0.05 to 0.40% by mass, and particularly preferably. It is 0.10 to 0.30% by mass.

- the Bi content in the brazing material is within the above range, the effect of lowering the surface tension can be easily obtained.

- the Bi content in the brazing material exceeds the above range, the surface of the brazing material after brazing turns black and the brazing property becomes low.

- the brazing material can contain any one or more of Na, Sr and Sb.

- Na, Sr, and Sb have the effect of refining the Si particles in the brazing material and increasing the fluidity of the brazing material.

- the brazing material contains Na

- the Na content in the brazing material is 0.05% by mass or less, preferably 0.005 to 0.04% by mass, and particularly preferably 0.007 to 0.04% by mass. is there.

- the brazing material contains Sr the Sr content in the brazing material is 0.05% by mass or less, preferably 0.005 to 0.04% by mass, and particularly preferably 0.005 to 0.02% by mass. is there.

- the brazing material contains Sb

- the Sb content in the brazing material is 0.05% by mass or less, preferably 0.005 to 0.04% by mass.

- the brazing material can contain any one or two of Zn and Cu.

- Zn and Cu lower the melting point of the brazing material and enable brazing at a temperature lower than the general brazing temperature of 600 ° C.

- the Zn content in the brazing material is preferably 8.00% by mass or less, preferably 1.00 to 8.00, in that the effect of lowering the melting point of the brazing material can be easily obtained.

- the mass% is more preferable, 2.00 to 8.00 mass% is particularly preferable, and 3.00 to 5.00 mass% is further preferable.

- the brazing material if the Zn content in the brazing material exceeds 8.00% by mass, the brazing material cracks during cold rolling, and a sound plate material cannot be obtained. Further, when the brazing material contains Zn, the potential of the brazing material is made low, and the core material is preferentially corroded, so that the effect of preventing corrosion of the core material can be easily obtained.

- the amount is preferably 3.00% by mass or less.

- the brazing material contains Cu

- the Cu content in the brazing material is 4.00% by mass or less, preferably 0.50 to 4.00% by mass, and particularly preferably 1.00 to 2.50% by mass. %. When the Cu content in the brazing material is in the above range, the effect of lowering the melting point of the brazing material is enhanced. On the other hand, if the Cu content in the brazing material exceeds the above range, the brazing material cracks during cold rolling, and a sound plate material cannot be obtained.

- the brazing material can contain Fe.

- Fe crystallizes a relatively coarse Al—Fe-based compound and acts on the grain refinement of the brazing material after brazing.

- the brazing material contains Fe

- the Fe content in the brazing material is 1.00% by mass or less, preferably 0.10 to 0.50% by mass, and particularly preferably 0.20 to 0.50% by mass. is there.

- the Fe content in the brazing material is in the above range, the effect of grain refinement can be easily obtained.

- the Fe content in the brazing material exceeds the above range, a giant intermetallic compound is likely to be formed during casting, and the plastic workability is lowered.

- the brazing material can contain any one or more of Mn, Cr, Ti and Zr.

- Mn, Cr, Ti, and Zr precipitate Al—Mn-based, Al—Cr, Al—Ti, and Al—Zr-based fine compounds, respectively, after brazing. It acts on the coarsening of crystal grains.

- the brazing material contains Mn

- the content of Mn in the brazing material is 1.00% by mass or less, preferably 0.10 to 0.60% by mass.

- the Mn content in the brazing material is in the above range, the effect of coarsening the crystal grains can be easily obtained.

- the Mn content in the brazing material exceeds the above range, a giant intermetallic compound is likely to be formed during casting, and the plastic workability is lowered.

- the brazing material contains Cr

- the content of Cr in the brazing material is 0.30% by mass or less, preferably 0.01 to 0.03% by mass.

- the Cr content in the brazing material is within the above range, the effect of coarsening the crystal grains can be easily obtained.

- the Cr content in the brazing material exceeds the above range, a giant intermetallic compound is likely to be formed during casting, and the plastic workability is lowered.

- the content of Ti in the brazing material is 0.30% by mass or less, preferably 0.10% by mass or less, and particularly preferably 0.01 to 0.03% by mass.

- the Ti content in the brazing material is within the above range, the effect of coarsening the crystal grains can be easily obtained.

- the Ti content in the brazing material exceeds the above range, a giant intermetallic compound is likely to be formed during casting, and the plastic workability is lowered.

- the brazing material contains Zr

- the content of Zr in the brazing material is 0.30% by mass or less, preferably 0.01 to 0.03% by mass. When the Zr content in the brazing material is within the above range, the effect of coarsening the crystal grains can be easily obtained.

- the brazing material can contain In.

- In makes the potential of the brazing material low and preferentially corrodes the core material, thereby exerting an effect of preventing corrosion of the core material.

- the brazing material contains In the In content in the brazing material is 0.10% by mass or less, preferably 0.01 to 0.03% by mass, and particularly preferably 0.02 to 0.03% by mass. is there.

- the In content in the brazing material is within the above range, the effect of potential adjustment can be easily obtained.

- the In content in the brazing material exceeds the above range, the natural electrode potential becomes too low and the corrosion resistance deteriorates.

- the brazing material can contain Sn.

- Sn exerts an effect of preventing the core material from corroding by lowering the potential of the brazing material and preferentially corroding the core material.

- the Sn content in the brazing material is 0.10% by mass or less, preferably 0.01 to 0.05% by mass.

- the Sn content in the brazing material is in the above range, the effect of potential adjustment can be easily obtained.

- the Sn content in the brazing material exceeds the above range, the natural electrode potential becomes too low and the corrosion resistance is lowered.

- the brazing material may contain Ag, B, Be, Cd, Co, Ga, Ge, Mo, Ni, P, Pb, V, Hg, and Y as unavoidable impurities in an amount of 0.05% by mass or less.

- the skin material according to the aluminum alloy brazing sheet of the present invention is an aluminum alloy skin material containing aluminum or an aluminum alloy containing 6.00% by mass or less of Zn and consisting of the balance aluminum and unavoidable impurities.

- the aluminum alloy brazing sheet of the present invention since the skin material is clad, the corrosion resistance of the aluminum product after brazing can be further improved by the sacrificial anticorrosion effect of the skin material.

- the aluminum alloy brazing sheet of the present invention has a volume change rate of 0.990 or less, preferably 0.700 or more, on the surface on the brazing material side during brazing heat, with respect to the surface oxide film before brazing heat.

- the aluminum alloy brazing sheet of the present invention exerts the above-mentioned effect of the present invention regardless of whether the skin material is clad on the surface of the core material opposite to the brazing material or the skin material is not clad.

- the purity of aluminum is not particularly limited, but is preferably 99.0% by mass or more, and particularly preferably 99.5% by mass or more.

- the Zn content in the skin material is 6.00% by mass or less, preferably 3.00% by mass or less.

- the sacrificial anticorrosion effect is enhanced.

- the potential of the skin material may be excessively lowered, and the progress of corrosion may be accelerated.

- the skin material can contain Mn.

- Mn contributes to the improvement of strength.

- the Mn content in the skin material is 2.00% by mass or less, preferably 0.30 to 1.80% by mass.

- the Mn content in the skin material is within the above range, the effect of improving the strength can be easily obtained.

- the Mn content in the skin material exceeds the above range, cracks are likely to occur during material rolling.

- the skin material can contain Mg.

- Mg contributes to the improvement of strength.

- the Mg content in the skin material is 3.00% by mass or less, preferably 0.30 to 1.80% by mass, and particularly preferably 0.40 to 1.80% by mass. is there.

- the Mg content in the skin material is within the above range, the effect of improving the strength can be easily obtained.

- the Mg content in the skin material exceeds the above range, cracks are likely to occur during material rolling.

- the skin material can contain Si.

- Si contributes to the improvement of strength.

- the Si content in the skin material is 5.00% by mass or less, preferably 0.10 to 1.50% by mass, and more preferably 0.10 to 1.00% by mass. Particularly preferably, it is 0.20 to 1.00% by mass.

- the Si content in the skin material is in the above range, the strength of the skin material is increased.

- the Si content in the skin material is 1.50 to 5.00% by mass, particularly preferably 2.50 to 4.50% by mass, and the Si content is in the range of 1.50 to 5.00%.

- the skin material can contain Fe.

- Fe contributes to the improvement of strength.

- the Fe content in the skin material is 1.50% by mass or less, preferably 0.10 to 0.70% by mass, and particularly preferably 0.10 to 0.50% by mass. is there.

- the Fe content in the skin material is within the above range, the effect of improving the strength can be easily obtained.

- the Fe content in the skin material exceeds the above range, the corrosion resistance is lowered and huge precipitates are likely to be generated.

- the skin material can contain Cu.

- Cu contributes to the improvement of strength.

- the Cu content in the skin material is 1.00% by mass or less, preferably 0.10 to 1.00% by mass.

- the Cu content in the skin material is within the above range, the effect of improving the strength can be easily obtained.

- the Cu content in the skin material exceeds the above range, intergranular corrosion is likely to occur.

- the skin material can contain any one or more of Ti, Zr and Cr.

- Ti, Zr and Cr exert the effect of improving the strength by strengthening the solid solution.

- the Ti content in the skin material is 0.30% by mass or less, preferably 0.10 to 0.20% by mass.

- the skin material contains Zr the Zr content in the skin material is 0.30% by mass or less, preferably 0.10 to 0.20% by mass.

- the skin material contains Cr the Cr content in the skin material is 0.30% by mass or less, preferably 0.10 to 0.20% by mass.

- Ti, Zr or Cr in the skin material is in the above range, the effect of improving the strength can be easily obtained.

- Ti, Zr or Cr in the skin material exceeds the above range, a giant intermetallic compound is likely to be formed during casting, and the plastic workability is lowered.

- the skin material can contain In.

- In In the aluminum alloy forming the skin material, In has the effect of preventing the heart material from corroding by lowering the potential of the skin material and preferentially corroding the core material.

- the In content in the skin material is 0.10% by mass or less, preferably 0.01 to 0.03% by mass.

- the In content in the skin material is within the above range, the effect of potential adjustment can be easily obtained.

- the In content in the skin material exceeds the above range, the natural electrode potential becomes too low and the corrosion resistance deteriorates.

- the skin material can contain Sn.

- Sn has an effect of preventing the heart material from corroding by lowering the potential of the skin material and preferentially corroding the core material.

- the Sn content in the skin material is 0.10% by mass or less, preferably 0.01 to 0.05% by mass.

- the Sn content in the skin material is within the above range, the effect of potential adjustment can be easily obtained.

- the Sn content in the skin material exceeds the above range, the natural electrode potential becomes too low and the corrosion resistance is lowered.

- the skin material contains 0.05% by mass or less of Ag, B, Be, Bi, Ca, Cd, Co, Ga, Ge, Li, Mo, Na, Ni, P, Pb, Sr, V, It may contain Hg.

- the aluminum alloy brazing sheet of the present invention has a volume change rate of 0.990 or less, preferably 0.700 to 0, with respect to the surface oxide film before brazing heat due to brazing heat in an inert gas atmosphere that does not use flux.

- the volume change rate of the oxide containing Mg, Li, and Ca after the brazing heat is within the above range with respect to the surface oxide before the brazing heat.

- the formation of an oxide containing particles of Mg, Li, and Ca effectively exposes the new surface of the brazing material during brazing heat, so that the aluminum alloy brazing sheet is excellent. Has brazing properties.

- the volume change rate of an oxide containing one or more of Mg, Li and Ca formed by brazing heat is formed on the surface of the brazing material before brazing.

- the rate of change in volume with respect to the oxide film which is "volume per oxygen atom of oxide particles containing one or more of Mg, Li and Ca formed by brazing heat / brazing before brazing. It is a value obtained by the formula of "volume per oxygen atom of the oxide film formed on the surface of the material". In the formula, the volume per oxygen atom is calculated by dividing the molecular weight of the oxide by the density of the oxide.

- Mg, Li and Ca use flux because the free energy for oxide formation is smaller than that of Al, and not only can the oxide film be reduced, but also an oxide having a volume change rate of 0.990 or less can be formed. It is an element that is effective for exposing the new surface of the brazing material in the brazing heat in an inert gas atmosphere.

- the volume change rate of MgO is 0.994, but the volume change rate of MgAl 2 O 4 is 0.863, which is smaller than 0.990.

- Ba, Th, Nd and the like are elements having an oxide formation free energy smaller than Al, but are not effective contained elements because there is no oxide having a volume change rate of 0.990 or less.

- BaO is an oxide containing Ba

- volume change rate of the BaAl 2 O 4 are each a 2.366,1.377, there are oxides volume change rate becomes 0.990 or less in Ba do not do.

- An oxide film is formed on the surface of the brazing material of the aluminum alloy brazing sheet of the present invention.

- the molar ratio of Mg, Li, and Ca to Al of the oxide film formed on the surface of the brazing material of the aluminum alloy brazing sheet of the present invention is 0.50 or less.

- the molar ratio (for example, Mg / Al) of Mg, Li, and Ca of the oxide film formed on the surface of the brazing material to Al is within the above range, the surface of the brazing material before brazing

- the volume change rate of the oxide containing Mg, Li and Ca formed by the brazing heat added to the formed oxide film is 0.990 or less.

- the oxide film formed on the surface of the brazing material of the aluminum alloy brazing sheet of the present invention contains two or more elements of Mg, Li and Ca, each of Mg, Li and Ca with respect to Al is contained.

- the atomic conversion molar ratio of 0.50 or less means that the atomic conversion molar ratio of Mg, Li and Ca to Al is 0.5 or less for any of Mg, Li and Ca.

- the thickness of the oxide film formed on the surface of the brazing material of the aluminum alloy brazing sheet of the present invention is preferably 50 nm or less, and more preferably 10 nm or less in that the oxide film is easily broken. If the thickness of the oxide film formed on the surface of the brazing material exceeds 50 nm, the oxide film is less likely to be destroyed.

- the aluminum alloy brazing sheet of the present invention is suitably manufactured by the method for manufacturing an aluminum alloy brazing sheet of the present invention described below.

- the method for producing an aluminum alloy brazing sheet of the present invention is as follows: (1) a laminate in which a brazing ingot / a core ingot is laminated in this order, and (2) a brazing ingot / a core ingot / a brazing ingot.

- Aluminum is subjected to at least hot working and cold working on the laminate in which the ingots are laminated in this order or (3) the ingot for brazing material / ingot for core material / ingot for skin material.

- the ingot for the core material is aluminum or Fe of 1.50% by mass or less, Si of 1.50% by mass or less, Cu of 2.00% by mass or less, Mn of 2.00% by mass or less, 3.00% by mass.

- the ingots for brazing materials include 4.00 to 13.00% by mass of Si, Mg of more than 0.03% by mass and 3.00% by mass or less, and more than 0.03% by mass and 3.00% by mass or less. It is an aluminum alloy containing Li and any one or more of Ca of more than 0.03% by mass and 3.00% by mass or less, and composed of the balance aluminum and unavoidable impurities.

- the ingot for skin material is an aluminum alloy containing aluminum or an aluminum alloy containing 6.00% by mass or less of Zn, the balance of aluminum, and unavoidable impurities.

- intermediate annealing is performed by heating at 250-450 ° C for 1 hour or more in an atmosphere where the oxygen concentration is 10000 ppm or less and the dew point is controlled at 20 ° C or less, or the final After the cold working pass, final annealing by heating at 250 to 450 ° C. for 1 hour or more in an atmosphere where the oxygen concentration is 10000 ppm or less and the dew point is controlled to 20 ° C. or less, or rolling by cold working.

- Annealing is performed by heating at 250 to 450 ° C. for 1 hour or longer in an atmosphere in which the oxygen concentration is 10000 ppm or less and the dew point is controlled to 20 ° C. or less both between the passes and after the final cold working pass. This is a method for manufacturing an aluminum alloy brazing sheet.

- the method for producing an aluminum alloy brazing sheet of the present invention is as follows: (1) a laminate in which a brazing ingot and a core ingot are superposed, or (2) a brazing ingot on both sides of the core ingot.

- An aluminum alloy brazing sheet obtained by performing at least hot working and cold working on a laminate in which brazing material ingots, core material ingots, and skin material ingots are laminated in this order to obtain an aluminum alloy brazing sheet. It is a manufacturing method.

- the types of additive components of the ingot for the core material, the ingot for the brazing material and the ingot for the skin material and their contents are the core materials according to the aluminum alloy brazing sheet of the present invention.

- the components in the brazing material and the skin material and their contents are the same.

- the ingot for the core material is aluminum or 1.50% by mass or less, preferably 0.10 to 0.70% by mass, particularly preferably 0.20 to 0.60% by mass of Fe, 1.50% by mass.

- 1.00% by mass or less preferably 0.10 to 1.00% by mass of Bi, and 3.00% by mass or less, if necessary, with any one or more of the above.

- 0.10 to 1.80% by mass of Mg 3.00% by mass or less, preferably 0.10 to 1.80% by mass of Li and 3.00% by mass or less, preferably 0.10 to 1.

- It is composed of an aluminum alloy containing any one or more of 80% by mass of Ca, and the balance is aluminum and unavoidable impurities.

- Ingots for core materials contain 0.05% by mass or less of Ag, B, Be, Cd, Co, Ga, Ge, Mo, Na, Ni, P, Pb, Sr, V, Hg, and Y as unavoidable impurities. It may be included.

- the ingot for brazing material is 4.00 to 13.00% by mass, particularly preferably 4.50 to 12.00% by mass, and more than 0.03% by mass and 3.00% by mass or less, preferably 0. .10 to 1.80% by mass, particularly preferably 0.60 to 1.20% by mass, more than 0.03% by mass and 3.00% by mass or less, preferably 0.04 to 1.80% by mass, Particularly preferably 0.10 to 1.80% by mass of Li and more than 0.03% by mass and 3.00% by mass or less, preferably 0.05 to 1.80% by mass, particularly preferably 0.10 to 1. Any one or more of 80% by mass of Ca and, if necessary, 1.00% by mass or less, preferably 0.50% by mass or less, more preferably 0.05 to 0.40% by mass.

- % Especially preferably 0.10 to 0.30% by mass, and optionally 0.05% by mass or less, preferably 0.005 to 0.04% by mass, particularly preferably 0.007 to 0. .04% by mass Na, 0.05% by mass or less, preferably 0.005 to 0.04% by mass, particularly preferably 0.005 to 0.02% by mass of Sr, 0.05% by mass or less, preferably 0.005 to 0.04% by mass of Sb, 8.00% by mass or less, preferably 1.00 to 8.00% by mass, more preferably 2.00 to 8.00% by mass, particularly preferably 3.00.

- the brazing ingot is one or 2 of Ag, B, Be, Cd, Co, Ga, Ge, Mo, Ni, P, Pb, V, Hg, and Y as unavoidable impurities of 0.05% by mass or less. It may contain more than a seed.

- the ingot for the skin material is aluminum or Zn of 6.00% by mass or less, preferably 3.00% by mass or less, and if necessary, 2.00% by mass or less, 0.30 to 1.80% by mass.

- Mass% Si 1.50% by mass or less, preferably 0.10 to 0.70% by mass, particularly preferably 0.10 to 0.50% by mass Fe, 1.00% by mass or less, preferably 0. 10 to 1.00% by mass of Cu, 0.30% by mass or less, preferably 0.10 to 0.20% by mass of Ti, 0.30% by mass or less, preferably 0.10 to 0.20% by mass.

- Zr 0.30% by mass or less, preferably 0.10 to 0.20% by mass of Cr, 0.10% by mass or less, preferably 0.01 to 0.03% by mass of In and 0.10% by mass or less.

- Ingots for skin materials contain 0.05% by mass or less of Ag, B, Be, Bi, Ca, Cd, Co, Ga, Ge, Li, Mo, Na, Ni, P, Pb, Sr as unavoidable impurities.

- V, Hg, Y may be included.

- an aluminum alloy brazing sheet of the present invention (1) a laminate in which a brazing ingot / an ingot for a core material is laminated in this order, and (2) an ingot for a brazing material / an ingot for a core material / a casting for a brazing material.

- Hot rolling and cold rolling are performed on the laminate in which the ingots are laminated in this order or (3) the ingot for brazing material / ingot for core material / ingot for skin material.

- hot rolling a laminated plate is formed at 400 to 550 ° C., and then the plate is processed to a thickness of 2 to 3 mm while still hot.

- cold rolling rolling is performed in a plurality of passes in cold rolling to a predetermined thickness of an aluminum alloy brazing sheet.

- an aluminum alloy brazing sheet of the present invention at 250 to 450 ° C. in an atmosphere in which the oxygen concentration is 10000 ppm or less and the dew point is controlled to 20 ° C. or less during a plurality of rolling passes performed in cold working.

- Heat for 1 hour or more Intermediate annealing or after the final cold working pass heat at 250-450 ° C for 1 hour or more in an atmosphere where the oxygen concentration is 10,000 ppm or less and the dew point is controlled to 20 ° C or less.

- the final annealing is performed, or in an atmosphere where the oxygen concentration is 10,000 ppm or less and the dew point is controlled to 20 ° C. or less both between the rolling passes in the cold working and after the final cold working pass.

- Annealing is performed by heating at 250 to 450 ° C. for 1 hour or longer. Since the intermediate annealing or the final annealing is a high temperature process, it has a great influence on the state of the oxide film.

- the atmosphere of the intermediate annealing or the final annealing is an inert gas atmosphere such as nitrogen gas, argon gas, and carbon dioxide gas.

- the brazing material surface of the brazing sheet is etched with an acidic aqueous solution or an alkaline aqueous solution after intermediate annealing or final annealing. Good.

- the oxide film formed by heating in the intermediate annealing or the final annealing can be weakened or removed.

- the brazing property of the brazing sheet can be further improved.

- etching the surface of the brazing material if the brazing material is clad on one side of the core material, only the brazing material surface may be etched, or both the brazing material surface and the opposite surface may be etched. If brazing material is clad on both sides of the core material, both sides are etched.

- Examples of the acidic solution used for etching the brazing sheet include aqueous solutions of sulfuric acid, hydrochloric acid, nitric acid, phosphoric acid, hydrofluoric acid and the like. These acids may be used alone or in combination of two or more. From the viewpoint of more efficiently removing the oxide film, it is preferable to use a mixed aqueous solution containing hydrofluoric acid and an acid other than hydrofluoric acid as the acid, and a mixed aqueous solution of hydrofluoric acid and sulfuric acid or hydrofluoric acid and nitrate. It is more preferable to use a mixed aqueous solution of.

- alkaline solution used for etching the brazing sheet examples include aqueous solutions of sodium hydroxide, potassium hydroxide, calcium hydroxide and the like. These alkaline solutions may be used alone or in combination of two or more. When etching is performed using an alkaline solution, it is preferable to desmatte using an aqueous sulfuric acid solution or an aqueous nitric acid solution after etching.

- the method for producing an aluminum alloy brazing sheet of the present invention it is preferable to suppress the growth of the oxide film and the concentration of Mg, Li and Ca in the oxide film during the production process.

- the aluminum alloy brazing sheet of the present invention is used for brazing in an inert gas atmosphere that does not use flux.

- the aluminum alloy brazing sheet of the present invention is subjected to brazing heat in an inert gas atmosphere that does not use flux, so that the volume change rate with respect to the oxide film before brazing heat is 0.990 or less. Since the oxide particles containing Ca and Ca are formed on the surface, the new surface of the brazing material is easily exposed, and excellent brazing property is exhibited.

- the aluminum alloy sheet (A) of the present invention is an aluminum alloy sheet obtained by applying brazing heat to the aluminum alloy brazing sheet of the present invention in an inert gas atmosphere without using flux, and is an aluminum alloy sheet.

- This is an aluminum alloy sheet in which oxide particles containing Mg, Li, and Ca having a volume change rate of 0.990 or less with respect to the oxide of the aluminum alloy brazing sheet before brazing heat are formed on the surface of the aluminum alloy.

- the oxide containing Mg, Li and Ca formed on the surface of the aluminum alloy sheet (A) of the present invention is in the form of particles and changes in volume with respect to the oxide of the aluminum alloy brazing sheet before brazing heat.

- the ratio is 0.990 or less, a new surface of the aluminum alloy appears on a part of the surface of the brazing sheet during the brazing heat addition.

- the inert gas are nitrogen gas, argon gas and the like.

- the aluminum alloy sheet (A) of the present invention is an aluminum alloy sheet after the aluminum alloy brazing sheet is brazed.

- the ingots for core materials and the ingots for brazing materials having the compositions shown in Tables 1 and 2 are ingots by continuous casting, respectively.

- the obtained ingot was hot-rolled to a thickness of 3 mm at 500 ° C., cooled, and then cut into dimensions of 163 mm in length and 163 mm in width.

- the prepared ingots for brazing material and ingots for core material are superposed in the combination shown in Table 3, then hot rolling and cold rolling are performed, and final annealing is performed under the conditions shown in Table 4 to obtain a soft clad material.

- final annealing is performed under the conditions shown in Table 4 to obtain a soft clad material.

- intermediate annealing is performed under the conditions shown in Table 4

- cold rolling is performed to obtain a soft clad material

- hot rolling and cold rolling are performed.

- intermediate annealing was performed under the conditions shown in Table 4

- cold rolling was performed

- final annealing was performed under the conditions shown in Table 4 to obtain a soft clad material.

- washing was performed after annealing.

- the final plate thickness was 0.3 to 1.0 mm.

- the obtained clad plate material was used as a test material.

- the thickness of the oxide film on the brazing material surface of the test material was measured by XPS (X-ray photoelectron spectroscopy). Oxygen was analyzed from the surface of the material in the depth direction by XPS, and the position of the measured half-value width of the peak of oxygen was defined as the oxide film thickness.

- the atomic equivalent molar ratios for example, Mg amount / Al amount

- Mg, Li, and Ca to aluminum total of metallic aluminum and aluminum components in aluminum oxide

- the oxide film thickness is most preferably 10 nm or less, A is more than 10 nm and 50 nm or less is B, and C is more than 50 nm, and is described in the “Oxide film thickness” column of Table 4.

- 0.1 or less is A

- more than 0.1 and 0.5 or less is B

- more than 0.5 is C.

- the test piece used in the gap filling test is a furnace in a nitrogen gas atmosphere without using flux, by arranging 3003 bare material on a vertical plate and test material on a horizontal plate and assembling with a SUS jig. It was brazed.

- the oxygen concentration in the furnace is controlled to 50 ppm or less when the temperature of the test piece is 400 ° C. or higher during temperature rise, and the oxygen concentration is controlled to 10 ppm or less when the test piece temperature is 570 ° C. or higher.

- the temperature reached by the body was set to 600 ° C.

- the length of the vertical plate in the general gap filling test (LWS T8801) is 55 mm, but the length of the vertical plate of this test piece is 25 mm, and the gradient of the gap formed between the horizontal plate and the vertical plate is set.

- An evaluation method that simulates a heat exchanger with a large gap is adopted.

- the brazing property can be evaluated based on the length FL of the fillet formed after brazing.

- the "Brazing property" column in Table 3 the soundness of FL and fillet is described, and the case where it is 5 mm or more and there is no partial fillet cut is A, and the case where it is 5 mm or more and there is partial fillet cut.

- B and C the case where it is less than 5 mm, and A was judged to be a passing level among these.

- the volume change rate of the oxide particles containing Mg, Li and Ca formed after brazing with respect to the oxide film before heat of brazing is oxygen by dividing the molecular weight of the oxide by the density described in the known literature. The volume per atom was determined, and this was determined by dividing this by the volume per oxygen atom of the oxide film before the wax addition heat. The volume per oxygen atom of the oxide film before brazing heat is determined as Al 2 O 3 as the film component and its density is 3.0 g / cm 3 . Table 3 shows the analysis of the obtained clad plate material and the performance test results of brazing property.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Laminated Bodies (AREA)

- Details Of Heat-Exchange And Heat-Transfer (AREA)

Priority Applications (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE112020001012.0T DE112020001012T5 (de) | 2019-04-04 | 2020-04-03 | Aluminiumlegierungshartlotblech und verfahren zum herstellen desselben |

| CN202080026401.8A CN113710412B (zh) | 2019-04-04 | 2020-04-03 | 铝合金硬钎焊板及其制造方法 |

| JP2021512323A JP7603002B2 (ja) | 2019-04-04 | 2020-04-03 | アルミニウム合金ブレージングシート及びその製造方法 |

| US17/600,705 US11819956B2 (en) | 2019-04-04 | 2020-04-03 | Aluminum alloy brazing sheet and method for manufacturing the same |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2019071932 | 2019-04-04 | ||

| JP2019-071932 | 2019-04-04 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2020204167A1 true WO2020204167A1 (ja) | 2020-10-08 |

Family

ID=72669040

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2020/015339 Ceased WO2020204167A1 (ja) | 2019-04-04 | 2020-04-03 | アルミニウム合金ブレージングシート及びその製造方法 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US11819956B2 (enExample) |

| JP (1) | JP7603002B2 (enExample) |

| CN (1) | CN113710412B (enExample) |

| DE (1) | DE112020001012T5 (enExample) |

| WO (1) | WO2020204167A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023074289A1 (ja) * | 2021-10-29 | 2023-05-04 | 株式会社Uacj | アルミニウム合金ブレージングシート及びその製造方法 |

| US12508676B2 (en) | 2021-10-29 | 2025-12-30 | Uacj Corporation | Aluminum alloy brazing sheet and method for producing same |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117230331B (zh) * | 2023-06-05 | 2025-11-18 | 华峰铝业有限公司 | 一种耐磨铝合金材料及其制备方法 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10180489A (ja) * | 1996-12-20 | 1998-07-07 | Sky Alum Co Ltd | 非酸化性ガス雰囲気無フラックスろう付け用材料の製造方法およびろう付け方法 |

| JP2013220461A (ja) * | 2012-04-18 | 2013-10-28 | Mitsubishi Alum Co Ltd | アルミニウム材のフラックスレスろう付方法およびろう付構造体の製造方法 |

| WO2013168669A1 (ja) * | 2012-05-07 | 2013-11-14 | 住友軽金属工業株式会社 | アルミニウム合金ブレージングシート |

| JP2015058466A (ja) * | 2013-09-20 | 2015-03-30 | 株式会社Uacj | フラックスレスろう付け用アルミニウム合金ブレージングシートおよびその製造方法 |

| WO2017065190A1 (ja) * | 2015-10-16 | 2017-04-20 | 株式会社Uacj | アルミニウム合金ブレージングシート、その製造方法、アルミニウム合金シート及び熱交換器 |

| WO2018100793A1 (ja) * | 2016-11-29 | 2018-06-07 | 株式会社Uacj | ブレージングシート及びその製造方法 |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2321869B (en) * | 1997-02-10 | 2001-05-30 | Furukawa Electric Co Ltd | Aluminum alloy brazing sheet |

| JP3556827B2 (ja) | 1998-04-01 | 2004-08-25 | 古河スカイ株式会社 | 非酸化性ガス雰囲気無フラックスろう付け用材料の製造方法およびろう付け方法 |

| JP4537019B2 (ja) | 2003-06-04 | 2010-09-01 | 古河スカイ株式会社 | アルミニウム材のろう付け方法 |

| FR2873718B1 (fr) * | 2004-07-28 | 2007-02-02 | Pechiney Rhenalu Sa | Procede de formation d'une couche de conversion sur un produit en alliage d'aluminium destine a etre brase |

| CN101124451A (zh) * | 2005-02-17 | 2008-02-13 | 住友轻金属工业株式会社 | 热交换器用铝合金硬钎焊散热片材料 |

| KR101527982B1 (ko) * | 2007-06-20 | 2015-06-10 | 알레리스 알루미늄 코블렌쯔 게엠베하 | 알루미늄합금 브레이징 시트 제품 및 그 제조방법 |

| JP4547032B1 (ja) | 2009-04-17 | 2010-09-22 | 三菱アルミニウム株式会社 | アルミニウム材のフラックスレスろう付け方法およびフラックスレスろう付け用アルミニウムクラッド材 |

| JP5429858B2 (ja) * | 2009-04-21 | 2014-02-26 | 株式会社Uacj | 熱交換器用アルミニウム合金クラッド材およびその製造方法 |

| JP6037542B2 (ja) | 2012-04-12 | 2016-12-07 | 三菱アルミニウム株式会社 | アルミニウム材のフラックスレスろう付方法、フラックスレスろう付用ブレージングシートおよびその製造方法 |

| US10661395B2 (en) * | 2014-07-30 | 2020-05-26 | Uacj Corporation | Aluminum-alloy brazing sheet |

| EP3205440A4 (en) * | 2014-10-09 | 2018-03-28 | UACJ Corporation | Aluminum alloy brazing sheet and brazing method |

| JP2017018996A (ja) * | 2015-07-13 | 2017-01-26 | 株式会社Uacj | アルミニウム合金ブレージングシート |

| JP2017074610A (ja) * | 2015-10-16 | 2017-04-20 | 株式会社Uacj | アルミニウム合金ブレージングシート及びろう付け方法 |

| JP6463262B2 (ja) * | 2015-12-28 | 2019-01-30 | 株式会社Uacj | アルミニウム合金ブレージングシート及びアルミニウム合金製熱交換器の製造方法 |

| US20180169797A1 (en) * | 2016-12-16 | 2018-06-21 | Kabushiki Kaisha Kobe Seiko Sho (Kobe Steel, Ltd.) | Aluminum alloy brazing sheet |

-

2020

- 2020-04-03 US US17/600,705 patent/US11819956B2/en active Active

- 2020-04-03 CN CN202080026401.8A patent/CN113710412B/zh active Active

- 2020-04-03 JP JP2021512323A patent/JP7603002B2/ja active Active

- 2020-04-03 WO PCT/JP2020/015339 patent/WO2020204167A1/ja not_active Ceased

- 2020-04-03 DE DE112020001012.0T patent/DE112020001012T5/de active Pending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10180489A (ja) * | 1996-12-20 | 1998-07-07 | Sky Alum Co Ltd | 非酸化性ガス雰囲気無フラックスろう付け用材料の製造方法およびろう付け方法 |

| JP2013220461A (ja) * | 2012-04-18 | 2013-10-28 | Mitsubishi Alum Co Ltd | アルミニウム材のフラックスレスろう付方法およびろう付構造体の製造方法 |

| WO2013168669A1 (ja) * | 2012-05-07 | 2013-11-14 | 住友軽金属工業株式会社 | アルミニウム合金ブレージングシート |

| JP2015058466A (ja) * | 2013-09-20 | 2015-03-30 | 株式会社Uacj | フラックスレスろう付け用アルミニウム合金ブレージングシートおよびその製造方法 |

| WO2017065190A1 (ja) * | 2015-10-16 | 2017-04-20 | 株式会社Uacj | アルミニウム合金ブレージングシート、その製造方法、アルミニウム合金シート及び熱交換器 |

| WO2018100793A1 (ja) * | 2016-11-29 | 2018-06-07 | 株式会社Uacj | ブレージングシート及びその製造方法 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023074289A1 (ja) * | 2021-10-29 | 2023-05-04 | 株式会社Uacj | アルミニウム合金ブレージングシート及びその製造方法 |

| JP2023066678A (ja) * | 2021-10-29 | 2023-05-16 | 株式会社Uacj | アルミニウム合金ブレージングシート及びその製造方法 |

| US12508676B2 (en) | 2021-10-29 | 2025-12-30 | Uacj Corporation | Aluminum alloy brazing sheet and method for producing same |

Also Published As

| Publication number | Publication date |

|---|---|

| DE112020001012T5 (de) | 2021-11-18 |

| JPWO2020204167A1 (enExample) | 2020-10-08 |

| CN113710412B (zh) | 2024-02-09 |

| JP7603002B2 (ja) | 2024-12-19 |

| US11819956B2 (en) | 2023-11-21 |

| CN113710412A (zh) | 2021-11-26 |

| US20220184750A1 (en) | 2022-06-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6468983B2 (ja) | アルミニウム合金ブレージングシート、その製造方法、アルミニウム合金シート及び熱交換器 | |

| JP5054404B2 (ja) | 熱交換器用アルミニウム合金クラッド材およびブレージングシート | |

| WO2020204168A1 (ja) | アルミニウム合金ブレージングシート及びその製造方法 | |

| JP6726370B1 (ja) | フラックスフリーろう付用アルミニウムブレージングシート | |

| JP3780380B2 (ja) | アルミニウム合金ブレ−ジングシ−ト、それを用いたろう付け方法、およびろう付け製品 | |

| CN112672845B (zh) | 硬钎焊片材及其制造方法 | |

| JP6474589B2 (ja) | 熱交換器用アルミニウム合金クラッド材 | |

| JP6174892B2 (ja) | アルミニウム合金製熱交換器及びその製造方法 | |

| JP7282468B2 (ja) | アルミニウムブレージングシートおよびアルミニウム部材のフラックスフリーろう付方法 | |

| WO2023074289A1 (ja) | アルミニウム合金ブレージングシート及びその製造方法 | |

| WO2020204167A1 (ja) | アルミニウム合金ブレージングシート及びその製造方法 | |

| JP2012050992A (ja) | アルミニウム材のフラックスレスろう付方法、フラックスレスろう付用アルミニウム合金ブレージングシートおよびフラックスレスろう付用アルミニウム合金ろう材 | |

| JP2012057183A (ja) | アルミニウム合金製クラッド材およびそれを用いた熱交換器 | |

| JP6763036B2 (ja) | アルミニウム合金ブレージングシート、その製造方法、アルミニウム合金シート及び熱交換器 | |

| WO2019044545A1 (ja) | 熱交換器フィン用ブレージングシート及びその製造方法 | |

| JP2011036915A (ja) | アルミニウム合金製ブレージングシート | |

| JP5917832B2 (ja) | アルミニウム材のフラックスレスろう付方法およびフラックスレスろう付用Al−Si系ろう材ならびにフラックスレスろう付用アルミニウムクラッド材 | |

| JP7231443B2 (ja) | 自己耐食性に優れるアルミニウム合金クラッドフィン材及びその製造方法 | |

| JP7231442B2 (ja) | 自己耐食性に優れるアルミニウム合金クラッドフィン材及びその製造方法 | |

| JP2010209426A (ja) | アルミニウム合金ろう付け体およびその熱処理方法ならびに熱交換器 | |

| JP7221631B2 (ja) | アルミニウム合金ブレージングシートおよびその製造方法 | |

| JP2023045026A (ja) | アルミニウム合金ブレージングシートおよびその製造方法 | |

| CN115151352A (zh) | 铝合金钎焊板及其制造方法 | |

| JP2024060897A (ja) | ろう付性に優れるアルミニウム合金とアルミニウム合金クラッド材 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 20782003 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2021512323 Country of ref document: JP Kind code of ref document: A |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 20782003 Country of ref document: EP Kind code of ref document: A1 |