WO2019077950A1 - X線検査装置 - Google Patents

X線検査装置 Download PDFInfo

- Publication number

- WO2019077950A1 WO2019077950A1 PCT/JP2018/035629 JP2018035629W WO2019077950A1 WO 2019077950 A1 WO2019077950 A1 WO 2019077950A1 JP 2018035629 W JP2018035629 W JP 2018035629W WO 2019077950 A1 WO2019077950 A1 WO 2019077950A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- ray

- inspection

- image

- objects

- images

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N23/00—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00

- G01N23/02—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00 by transmitting the radiation through the material

- G01N23/04—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00 by transmitting the radiation through the material and forming images of the material

- G01N23/046—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00 by transmitting the radiation through the material and forming images of the material using tomography, e.g. computed tomography [CT]

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N23/00—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00

- G01N23/02—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00 by transmitting the radiation through the material

- G01N23/06—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00 by transmitting the radiation through the material and measuring the absorption

- G01N23/083—Investigating or analysing materials by the use of wave or particle radiation, e.g. X-rays or neutrons, not covered by groups G01N3/00 – G01N17/00, G01N21/00 or G01N22/00 by transmitting the radiation through the material and measuring the absorption the radiation being X-rays

Definitions

- the inventor of the present invention has an X-ray inspection that includes an X-ray generator 103, an X-ray detector 104, and a rotation table 105 and generates a CT image of the inspection object 102.

- the X-ray detector 104 is mounted while rotating a plurality of test objects 102 together on one rotation table 105 in order to enhance the inspection efficiency of the test object 102.

- An attempt was made to simultaneously acquire X-ray images of a plurality of test subjects 102.

- the X-ray detector 104 can simultaneously obtain X-ray images of the two inspection objects 102 while placing the two inspection objects 102 together on one rotation table 105 and rotating them. I tried.

- the rotary table 105 makes one rotation, the X-ray generator 103 and the X-ray detector 104 in the direction in which the X-ray generator 103 and the X-ray detector 104 face each other.

- the rotation of the rotary table 105 does not increase the intensity of the X-rays so that the X-rays pass through the two inspection objects 102 because the inspection objects 102 overlap (for example, see the two-dot chain line in FIG. 5). It has become clear that depending on the angle, fluoroscopic images of the two inspection objects 102 can not be projected onto the X-ray detector 104.

- the device sequentially acquires a plurality of two-dimensional X-ray images in which fluoroscopic images of a plurality of inspection objects are taken, and the control unit determines each of the plurality of inspection objects based on the acquired plurality of X-ray images It is characterized in that a CT image is generated.

- a plurality of inspection objects are disposed between the X-ray generator and the X-ray detector, and each of the plurality of inspection objects is individually mounted on the rotary table. ing. Further, in the present invention, when inspecting a plurality of inspection objects, the plurality of rotary tables rotate simultaneously, and the X-ray detector sequentially acquires a plurality of two-dimensional X-ray images in which the plurality of inspection objects appear The control unit generates a CT image of each of the plurality of test objects based on the plurality of acquired X-ray images. Therefore, according to the present invention, it becomes possible to simultaneously test a plurality of test objects, and as a result, it is possible to enhance the test efficiency of the test objects.

- the control unit when generating a CT image of one test object, is a fluoroscopic image of one test object from which a CT image is generated among each of a plurality of X-ray images.

- the CT image may be generated by cutting out a portion including “.” And performing a predetermined operation using only the cut out portion. Even in this case, it becomes possible to appropriately generate a CT image in a short time.

- the X-ray inspection apparatus of the present invention even if it is possible to enhance the inspection efficiency of the inspection object, it is necessary to increase the intensity of the X-rays so that the X-rays pass through the plurality of inspection objects. Also, it is possible to prevent the occurrence of metal artifacts in the generated CT image.

- the X-ray generator 3 emits conical X-rays (cone beams) toward the two inspection objects 2.

- the X-ray generator 3 is disposed such that the optical axis of the X-ray to be emitted is substantially parallel to the horizontal direction.

- the X-ray detector 4 is disposed so that the light receiving surface of the X-ray detector 4 is orthogonal to the horizontal direction and faces the X-ray generator 3 side.

- the rotation table 5 is connected to a rotation mechanism for rotating the rotation table 5.

- the rotary table 5 rotates with the vertical direction as the axial direction of rotation.

- the inspection object 2 is disposed on the axis L of rotation of the rotary table 5.

- a common rotation mechanism for rotating the two rotary tables 5 together may be connected to the two rotary tables 5 so that the two rotary tables 5 can be individually rotated.

- a separate rotation mechanism may be connected to each of the two rotary tables 5.

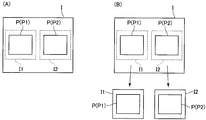

- the two rotary tables 5 are disposed at positions where the fluoroscopic images P1 and P2 of the two inspection objects 2 do not overlap each other and are projected to the X-ray detector 4. That is, the X-ray detector 4 is in a state (spaced state) in which the two rotary tables 5 are separated such that the fluoroscopic image P1 of the inspection object 2A and the fluoroscopic image P2 of the inspection object 2B do not overlap each other. It is placed at the position projected on the. Specifically, assuming that the X direction in FIG. 1 in which the X-ray generator 3 and the X-ray detector 4 face each other is the front and back direction, and the Y direction in FIG.

- the two rotary tables 5 are arranged with a space in the left-right direction so that the two test objects 2 do not overlap in the front-rear direction even if the two rotary tables 5 make one rotation. Further, the two rotary tables 5 are arranged at the same position in the front-rear direction.

- control unit 6 when the control unit 6 generates a CT image of one test object 2A or 2B, one test object from which a CT image is generated in each of a plurality of X-ray images I A predetermined operation is performed using only the portion I1 or I2 including the fluoroscopic image P of 2A or 2B to generate a CT image.

- control unit 6 when the control unit 6 generates a CT image of one test object 2A or 2B, one test object from which a CT image is generated in each of a plurality of X-ray images I While cutting out the part I1 or I2 in which the fluoroscopic image P of 2A or 2B is included, a predetermined operation using only the cut out part I1 or I2 is performed to generate a CT image.

Landscapes

- Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Pathology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- Physics & Mathematics (AREA)

- General Health & Medical Sciences (AREA)

- Immunology (AREA)

- Engineering & Computer Science (AREA)

- Nuclear Medicine, Radiotherapy & Molecular Imaging (AREA)

- Pulmonology (AREA)

- Radiology & Medical Imaging (AREA)

- Theoretical Computer Science (AREA)

- Toxicology (AREA)

- Analysing Materials By The Use Of Radiation (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP18867989.8A EP3608658A4 (en) | 2017-10-17 | 2018-09-26 | X-RAY INSPECTION DEVICE |

| US16/605,654 US20200132611A1 (en) | 2017-10-17 | 2018-09-26 | X-ray inspection device |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017200834A JP6708857B2 (ja) | 2017-10-17 | 2017-10-17 | X線検査装置 |

| JP2017-200834 | 2017-10-17 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019077950A1 true WO2019077950A1 (ja) | 2019-04-25 |

Family

ID=66173702

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/035629 Ceased WO2019077950A1 (ja) | 2017-10-17 | 2018-09-26 | X線検査装置 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20200132611A1 (enExample) |

| EP (1) | EP3608658A4 (enExample) |

| JP (1) | JP6708857B2 (enExample) |

| WO (1) | WO2019077950A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114026411A (zh) * | 2020-03-11 | 2022-02-08 | 欧姆龙株式会社 | X射线检查装置以及x射线检查方法 |

| WO2025017090A1 (de) * | 2023-07-19 | 2025-01-23 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Röntgensystem und ct-system |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112053409B (zh) * | 2020-07-24 | 2024-05-28 | 重庆真测科技股份有限公司 | 基于双旋转台ct扫描系统的非对称数据重建方法 |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60256034A (ja) * | 1984-06-01 | 1985-12-17 | Toshiba Corp | 産業用ctスキヤナ |

| JPS61240145A (ja) * | 1985-04-17 | 1986-10-25 | Hitachi Medical Corp | 産業用x線ct装置 |

| JP2004245685A (ja) * | 2003-02-13 | 2004-09-02 | Toshiba It & Control Systems Corp | X線マイクロ断層撮影装置 |

| JP2006170876A (ja) * | 2004-12-17 | 2006-06-29 | Hitachi Ltd | Ct装置 |

| JP2007029168A (ja) * | 2005-07-22 | 2007-02-08 | Morita Mfg Co Ltd | X線ct撮影装置 |

| JP2008145394A (ja) | 2006-12-13 | 2008-06-26 | Shimadzu Corp | X線ct装置 |

| JP2008188279A (ja) * | 2007-02-06 | 2008-08-21 | Shimadzu Corp | X線ct装置 |

| JP2009014710A (ja) * | 2007-06-04 | 2009-01-22 | Shimadzu Corp | X線ct装置 |

| WO2009078415A1 (ja) * | 2007-12-17 | 2009-06-25 | Uni-Hite System Corporation | X線検査装置および方法 |

| JP2013061280A (ja) * | 2011-09-14 | 2013-04-04 | Omron Corp | X線検査装置、x線検査装置の制御方法、x線検査装置を制御するためのプログラム、および、当該プログラムを格納したコンピュータ読み取り可能な記録媒体 |

| JP2014134528A (ja) * | 2013-01-10 | 2014-07-24 | Toshiba It & Control Systems Corp | Ct装置 |

| JP2016538552A (ja) * | 2013-11-28 | 2016-12-08 | ニコン・メトロロジー・エヌヴェ | コンピュータ断層撮影の較正装置および方法 |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7356115B2 (en) * | 2002-12-04 | 2008-04-08 | Varian Medical Systems Technology, Inc. | Radiation scanning units including a movable platform |

| US7876875B2 (en) * | 2008-04-09 | 2011-01-25 | United Technologies Corp. | Computed tomography systems and related methods involving multi-target inspection |

| CN105717145B (zh) * | 2016-02-03 | 2019-01-01 | 北京航空航天大学 | 多联装三维锥束计算机层析成像方法及装置 |

-

2017

- 2017-10-17 JP JP2017200834A patent/JP6708857B2/ja active Active

-

2018

- 2018-09-26 EP EP18867989.8A patent/EP3608658A4/en not_active Withdrawn

- 2018-09-26 WO PCT/JP2018/035629 patent/WO2019077950A1/ja not_active Ceased

- 2018-09-26 US US16/605,654 patent/US20200132611A1/en not_active Abandoned

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60256034A (ja) * | 1984-06-01 | 1985-12-17 | Toshiba Corp | 産業用ctスキヤナ |

| JPS61240145A (ja) * | 1985-04-17 | 1986-10-25 | Hitachi Medical Corp | 産業用x線ct装置 |

| JP2004245685A (ja) * | 2003-02-13 | 2004-09-02 | Toshiba It & Control Systems Corp | X線マイクロ断層撮影装置 |

| JP2006170876A (ja) * | 2004-12-17 | 2006-06-29 | Hitachi Ltd | Ct装置 |

| JP2007029168A (ja) * | 2005-07-22 | 2007-02-08 | Morita Mfg Co Ltd | X線ct撮影装置 |

| JP2008145394A (ja) | 2006-12-13 | 2008-06-26 | Shimadzu Corp | X線ct装置 |

| JP2008188279A (ja) * | 2007-02-06 | 2008-08-21 | Shimadzu Corp | X線ct装置 |

| JP2009014710A (ja) * | 2007-06-04 | 2009-01-22 | Shimadzu Corp | X線ct装置 |

| WO2009078415A1 (ja) * | 2007-12-17 | 2009-06-25 | Uni-Hite System Corporation | X線検査装置および方法 |

| JP2013061280A (ja) * | 2011-09-14 | 2013-04-04 | Omron Corp | X線検査装置、x線検査装置の制御方法、x線検査装置を制御するためのプログラム、および、当該プログラムを格納したコンピュータ読み取り可能な記録媒体 |

| JP2014134528A (ja) * | 2013-01-10 | 2014-07-24 | Toshiba It & Control Systems Corp | Ct装置 |

| JP2016538552A (ja) * | 2013-11-28 | 2016-12-08 | ニコン・メトロロジー・エヌヴェ | コンピュータ断層撮影の較正装置および方法 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP3608658A4 |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114026411A (zh) * | 2020-03-11 | 2022-02-08 | 欧姆龙株式会社 | X射线检查装置以及x射线检查方法 |

| WO2025017090A1 (de) * | 2023-07-19 | 2025-01-23 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Röntgensystem und ct-system |

Also Published As

| Publication number | Publication date |

|---|---|

| JP6708857B2 (ja) | 2020-06-10 |

| JP2019074415A (ja) | 2019-05-16 |

| EP3608658A4 (en) | 2021-04-07 |

| EP3608658A1 (en) | 2020-02-12 |

| US20200132611A1 (en) | 2020-04-30 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4488885B2 (ja) | Ct装置 | |

| EP2466295A3 (en) | Method and apparatus for laminography inspection | |

| KR20180011868A (ko) | X선 검사 장치 및 x선 검사 방법 | |

| JPWO2016170685A1 (ja) | X線検査装置、x線検査方法および構造物の製造方法 | |

| TW200848723A (en) | X ray inspecting method and X ray inspecting device | |

| WO2019077950A1 (ja) | X線検査装置 | |

| JPWO2009078415A1 (ja) | X線検査装置および方法 | |

| JP4711759B2 (ja) | X線検査装置 | |

| JP5060862B2 (ja) | 断層撮影装置 | |

| KR102139661B1 (ko) | 회전 가능한 시준기를 구비한 ct 시스템 | |

| KR102548883B1 (ko) | 화상 취득 시스템 및 화상 취득 방법 | |

| JP2019074415A5 (enExample) | ||

| JP4300126B2 (ja) | X線ct装置および撮像方法 | |

| EP3037848A1 (en) | Dual-source security inspection ct scanning system and scanning method | |

| JP4016265B2 (ja) | X線ct装置 | |

| JP5125297B2 (ja) | X線検査装置およびx線検査方法 | |

| JP6920520B2 (ja) | 画像取得システムおよび画像取得方法 | |

| JP6376698B2 (ja) | X線検査装置およびx線検査装置の調整方法 | |

| JP6457854B2 (ja) | X線検査装置 | |

| JP6139820B2 (ja) | X線ct装置 | |

| JP2006071472A (ja) | Ct法およびct装置 | |

| JP2012137315A (ja) | X線断層撮像装置 | |

| JP4926645B2 (ja) | 放射線検査装置、放射線検査方法および放射線検査プログラム | |

| JP2007170926A (ja) | X線検査装置、断層画像異常表示装置、x線検査方法、断層画像異常表示方法、プログラム、および記録媒体 | |

| JP2009297292A (ja) | 放射線断層撮影装置、および放射線断層撮影装置におけるノイズの除去方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18867989 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 2018867989 Country of ref document: EP Effective date: 20191108 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |