WO2019039340A1 - 保護シートおよび保護シート付積層体 - Google Patents

保護シートおよび保護シート付積層体 Download PDFInfo

- Publication number

- WO2019039340A1 WO2019039340A1 PCT/JP2018/030212 JP2018030212W WO2019039340A1 WO 2019039340 A1 WO2019039340 A1 WO 2019039340A1 JP 2018030212 W JP2018030212 W JP 2018030212W WO 2019039340 A1 WO2019039340 A1 WO 2019039340A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- adhesive layer

- protective sheet

- protected

- present disclosure

- resin

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J11/00—Features of adhesives not provided for in group C09J9/00, e.g. additives

- C09J11/08—Macromolecular additives

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J201/00—Adhesives based on unspecified macromolecular compounds

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J201/00—Adhesives based on unspecified macromolecular compounds

- C09J201/02—Adhesives based on unspecified macromolecular compounds characterised by the presence of specified groups, e.g. terminal or pendant functional groups

- C09J201/04—Adhesives based on unspecified macromolecular compounds characterised by the presence of specified groups, e.g. terminal or pendant functional groups containing halogen atoms

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/20—Adhesives in the form of films or foils characterised by their carriers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/30—Adhesives in the form of films or foils characterised by the adhesive composition

- C09J7/38—Pressure-sensitive adhesives [PSA]

Definitions

- the present disclosure relates to a protective sheet and a laminate with the protective sheet.

- the substrate may be damaged or contaminated with chemicals, or a chemical used in the manufacturing process or during the manufacturing process. Deterioration of the substrate may occur due to heating. Therefore, in the process of manufacturing the substrate, a technique using a protective sheet for protecting the surface of the substrate has been proposed for the purpose of preventing the above-mentioned damage, contamination, deterioration and the like (for example, Patent Document 1) ⁇ 3).

- a protective sheet has, for example, a substrate and an adhesive layer disposed on one side of the substrate.

- the protective sheet is a member which is finally peeled from the product which is a member to be protected.

- the protective sheet attached to the member to be protected is a member which is finally peeled off from the member to be protected. Therefore, it is preferable to use, for the protective sheet, an adhesive layer having a property capable of peeling the protective sheet from the member to be protected.

- a pressure-sensitive adhesive layer conventionally, a pressure-sensitive adhesive layer having a slight adhesion is used.

- the above-mentioned pressure-sensitive adhesive layer which has a slight adhesion, has an advantage of having a predetermined peel strength, but can not be sufficiently adhered to a member to be protected because the initial adhesion is a slight adhesion. There is a problem in the function of protecting members.

- a pressure-sensitive adhesive layer capable of reducing the adhesive force by the irradiation of energy rays and improving the peeling force.

- the above-mentioned adhesive layer which reduces the adhesive strength by the irradiation of the energy beam can increase the initial adhesive strength before the energy beam irradiation and reduce the adhesive strength after the energy beam irradiation from the initial adhesive strength. Therefore, the protective sheet using the adhesive layer can improve the adhesion to the member to be protected, and can easily be peeled off from the member to be protected.

- the main purpose is to provide a sheet.

- a pressure-sensitive adhesive layer and a base material disposed on one side of the pressure-sensitive adhesive layer are provided, and the pressure-sensitive adhesive layer has a property that the adhesion is reduced from the initial adhesion by the irradiation of energy rays.

- the pressure-sensitive adhesive layer provides a protective sheet containing a fluorine resin.

- the present disclosure is a laminate with a protective sheet in which a protective sheet and a member to be protected are laminated, and the protective sheet is an adhesive layer and a group disposed on one surface of the adhesive layer.

- the adhesive layer has a property that the adhesive force is reduced from the initial adhesive force by the irradiation of energy rays, and the adhesive layer provides a protective sheet-containing laminate containing a fluorocarbon resin.

- the protective sheet of the present disclosure has the effect of being able to more easily peel from the member to be protected using a pressure-sensitive adhesive layer capable of reducing the adhesive strength by irradiation of energy rays.

- the protective sheet of the present disclosure has a pressure-sensitive adhesive layer and a base material disposed on one side of the pressure-sensitive adhesive layer, and the pressure-sensitive adhesive layer loses adhesion from initial adhesion upon irradiation with energy rays. It is a member which has a characteristic and the said adhesion layer contains a fluorine resin.

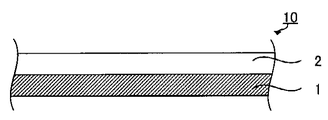

- FIG. 1 is a schematic cross-sectional view showing an example of the protective sheet of the present disclosure

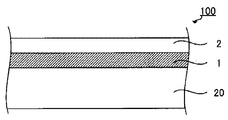

- FIG. 2 is a schematic cross-sectional view showing an example of a protective sheet-including laminate in which the protective sheet of the present disclosure is laminated on a protected portion.

- the protective sheet 10 of the present disclosure has an adhesive layer 1 and a substrate 2 disposed on one side of the adhesive layer 1.

- the adhesion layer 1 in this indication has the characteristic that adhesive force falls from initial stage adhesive force by irradiation of an energy ray, and the adhesive layer 1 contains a fluororesin.

- such a protective sheet of the present disclosure is a member that is attached to the surface of the protected member 20 and protects the surface of the protected member 20.

- the adhesive layer contains a hydrophobic resin having hydrophobicity

- the protective sheet is attached to the member to be protected and then the protective sheet is peeled off from the member to be protected, The adhesive strength can be reduced more satisfactorily, and it becomes possible to exhibit good releasability.

- the protective sheet is peeled off from the member to be protected when the protective sheet attached to the member to be protected is peeled off.

- the protective sheet can be easily peeled off from the member to be protected.

- the surface of the member to be protected itself or the surface of the member to be protected is easily broken, when peeling the protective sheet from the member to be protected, the load on the member to be protected is suppressed and the destruction of the member to be protected is suppressed. can do. This is considered to be caused by the fact that the surface free energy of the adhesive layer is reduced by containing the fluorocarbon resin in the adhesive layer.

- Adhesive Layer is a member disposed on one surface of a substrate.

- the adhesive layer is a member in close contact with the surface of the member to be protected.

- adhesion is a concept included in "adhesion”. While adhesion is used as a meaning of temporary adhesion phenomena, adhesion may sometimes be distinguished in that it is used as a meaning of permanent adhesion phenomena (Iwanami Shoten RIKEN Encyclopedia 5th Edition). "Tackiness” and “tack strength” refer to the property of adhering by pressure and the adhesion at that time.

- the adhesive layer in the present disclosure is a layer for attaching a protective sheet to a member to be protected.

- the adhesive layer has the characteristic that adhesive force falls from initial adhesive force by irradiation of an energy ray.

- the adhesive layer has removability which peels off from the member to be protected by the irradiation of energy rays.

- that the adhesive layer exhibits removability means that the protective sheet can be adhered and closely fixed to the member to be protected by the adhesive layer, and when the protective sheet is peeled from the member to be protected, It does not destroy a protection member, but suppresses generation

- the adhesive layer in the present disclosure can be sufficiently closely fixed to the surface of the member to be protected by the initial adhesive force.

- the adhesive force of the adhesive layer is reduced and the peelability is improved by irradiating the adhesive layer with energy rays, so that the adhesive residue on the surface of the member to be protected Can be easily peeled off the protective sheet.

- the pressure-sensitive adhesive layer in the present disclosure is peeled off from the member to be protected by energy beam irradiation means that the pressure-sensitive adhesive layer in the present disclosure exhibits strong adhesiveness and adheres tightly to the member to be protected before receiving energy beam irradiation.

- the adhesive strength is significantly reduced and it can be easily peeled off from the member to be protected.

- the adhesive layer in the present disclosure has an adhesive force before energy ray irradiation of 0.5 N / 25 mm or more and 20 N / 25 mm or less, and an adhesive force after energy ray irradiation of 2.0 N / 25 mm or less Is preferred.

- the adhesive strength of the adhesive layer is a polyester film as a substrate, and the adhesive layer in the present disclosure is formed on one side of the substrate so as to be within the thickness range described later, according to JIS Z0237. Then, the test piece can be measured by peeling the test piece in the lengthwise direction of the test piece under conditions of a peel angle of 180 ° and room temperature. Further, for such 180 ° peel strength measurement, for example, a universal tester 5565 manufactured by Instron can be used.

- Examples of the energy ray applied to the adhesive layer include light rays such as far ultraviolet rays, ultraviolet rays, near ultraviolet rays and infrared rays, and electromagnetic waves such as X rays and ⁇ rays, as well as electron rays, proton rays and neutron rays.

- light rays such as far ultraviolet rays, ultraviolet rays, near ultraviolet rays and infrared rays

- electromagnetic waves such as X rays and ⁇ rays, as well as electron rays, proton rays and neutron rays.

- ultraviolet light is preferable from the viewpoint of versatility and the like.

- the adhesive layer in the present disclosure preferably has a predetermined light transmittance.

- the haze value of the adhesive layer in the present disclosure according to JIS K-7136 is preferably 5% or less, more preferably 2% or less, and particularly preferably 1% or less. .

- the adhesive layer can have good light transmittance. Therefore, after the protective sheet is attached to the member to be protected, when the adhesive layer in the protective sheet is irradiated with energy rays to weaken the adhesion, the adhesive layers can be sufficiently irradiated with energy rays.

- light transmittance can be improved also as a protective sheet because an adhesive layer has favorable light transmittance.

- the haze value of the adhesive layer can be measured, for example, using a haze / transmittance meter (manufactured by Murakami Color Research Laboratory, product number: HM-150).

- composition of the pressure-sensitive adhesive layer in the present disclosure may contain a fluorine resin and may exhibit a predetermined adhesive strength before and after energy beam irradiation.

- a pressure-sensitive adhesive layer can be, for example, a composition containing at least a resin (pressure-sensitive adhesive main agent), an energy ray-polymerizable oligomer, and a polymerization initiator in addition to the fluorine resin.

- the energy beam polymerizable oligomer contained in the adhesive layer in the present disclosure can be cured by the irradiation of energy beam to reduce the adhesive force, and the cohesion force is increased at this time, so the transfer to the member to be protected Wearing hardly occurs and peeling becomes easy.

- the “fluororesin” in the present disclosure indicates a resin containing at least fluorine.

- a fluorine resin resin which has a fluorine group in frame of polyol resin is mentioned, for example.

- a fluoro alkylene group is mentioned, for example.

- the fluorine content of the fluorine resin that is, the content of the fluorine group in the skeleton of the polyol resin is, for example, preferably 0.5% by mass or more, and more preferably 1% by mass or more.

- the fluorine content of the fluorine resin that is, the content of the fluorine group in the skeleton of the polyol resin is, for example, preferably 100% by mass or less, and more preferably 80% by mass or less.

- the fall of compatibility with the other composition mentioned later can be controlled because the content rate of the fluorine machine in the frame of polyol resin has the above-mentioned upper limit.

- the weight average molecular weight (Mw) of the polyol resin can be, for example, 20000 or more and 400000 or less. When the weight average molecular weight of the polyol resin is in the above range, it is possible to suppress the decrease in the compatibility of the fluorine resin and the solvent or other crosslinking agent.

- the fluorine resin in the present disclosure is preferably a functional group-containing fluorine resin.

- the functional group-containing fluorine resin refers to a fluorine resin having a functional group.

- the fluorine resin has a crosslinkable functional group.

- the fluorine resin crosslinks and hardens the crosslinkable functional group described later with the composition to be described later, so that the adhesive strength of the adhesive layer can be reduced.

- a crosslinkable functional group a hydroxyl group or an alkoxy group etc. are mentioned, for example, Especially, it is preferable that it is a hydroxyl group.

- a hydroxyl group as a crosslinkable functional group.

- the hydroxyl value of the fluorine resin is, for example, preferably 5 mg KOH / g to 250 mg KOH / g, and more preferably 10 mg KOH / g to 200 mg KOH / g.

- the hydroxyl value of the fluorine resin has the above lower limit, a reduction in the crosslink density of the pressure-sensitive adhesive layer can be suppressed, so that it is possible to obtain a desired adhesive strength.

- the hydroxyl value of the fluorine resin has the above-mentioned upper limit, it is possible to suppress the decrease in the compatibility between the fluorine resin and the solvent.

- the functional group-containing fluorine resin is a siloxane graft polymer in which a fluorine resin and a siloxane are complexed.

- the functional group-containing fluorine resin has a molecular structure in which a siloxane group is used as a graft chain in the molecular skeleton of the fluorine resin.

- siloxane group a dimethylsiloxane group is mentioned, for example.

- the functional group-containing fluorine resin is a siloxane graft type polymer

- the adhesive layer in the protective sheet is irradiated with energy after the protective sheet is attached to the member to be protected, It becomes possible to reduce and to obtain favorable peelability.

- the content of the dimethylsiloxane group in the fluorine resin is, for example, preferably 5% by mass to 100% by mass, and more preferably 10% by mass to 90% by mass.

- the adhesive strength is sufficiently reduced when the adhesive layer in the protective sheet is irradiated with energy after the protective sheet is attached to the member to be protected It becomes possible to obtain good peelability.

- fluorine resin as described above, for example, commercially available products ZX-007C, ZX-001, ZX-017, ZX-022, ZX-022H, ZX-047D, ZX-058A, ZX-212, ZX-201, ZX-202 (Fluororesin-siloxane graft polymer manufactured by T & K TOKA), KP-911 (Fluorosilicone manufactured by Shin-Etsu Chemical Co., Ltd.), Lumiflon LF-100, LF-200, LF-302, LF- 400, LF-554, LF-600, LF-986N (manufactured by Asahi Glass Co., Ltd.) and the like.

- “containing a fluorine resin” indicates that the adhesive layer contains at least a fluorine resin.

- the content of the fluorine resin contained in the adhesive layer is preferably 0.1 parts by mass or more, and more preferably 0.5 parts by mass or more with respect to 100 parts by mass of the adhesive main agent of the adhesive layer. And particularly preferably 1.0 parts by mass or more.

- the adhesive force of the adhesive layer can be sufficiently reduced from the initial adhesive force when the adhesive layer is irradiated with energy rays, and the adhesive layer Can be improved well.

- the content of the fluorine resin contained in the adhesive layer is preferably 30 parts by mass or less, more preferably 20 parts by mass or less, and particularly 10 parts by mass with respect to 100 parts by mass of the adhesive main agent in the adhesive layer. It is preferable that it is less than part.

- the content of the fluorocarbon resin in the adhesive layer has the above-described upper limit, the initial adhesive strength of the adhesive layer is reduced due to an increase in the amount of fluorocarbon resin contained in the adhesive layer, thereby protecting the surface of the member to be protected It is possible to suppress the occurrence of the problem that the sheets can not be sufficiently adhered.

- the content of the fluorine resin in the adhesive layer has the above-described upper limit

- the occurrence of a defect that the fluorine resin becomes a residue and adversely affects other compositions can be suppressed.

- the content of the fluorocarbon resin in the adhesive layer has the above-mentioned upper limit, it is possible to suppress an increase in haze value due to the adhesive layer becoming cloudy.

- (B) Resin (adhesive main agent) As resin used as an adhesion main ingredient, acrylic resin is mentioned, for example.

- the acrylic resin is not particularly limited.

- (meth) acrylic acid ester polymer obtained by homopolymerizing (meth) acrylic acid ester, (meth) acrylic acid ester with (meth) acrylic acid ester as a main component, and the like

- the (meth) acrylic acid ester copolymer which copolymerized with these monomers is mentioned, A (meth) acrylic acid ester copolymer is preferable.

- Specific examples of (meth) acrylic acid ester and other monomers include those disclosed in, for example, JP 2012-31316. Other monomers can be used alone or in combination of two or more.

- the main component here means that a copolymerization ratio is 51 mass% or more, Preferably it is 65 mass% or more.

- acrylic resin a (meth) acrylic acid ester copolymer as a main component and a (meth) acrylic acid ester copolymer obtained by the copolymerization of the (meth) acrylic acid ester and a copolymerizable hydroxyl group-containing monomer

- a (meth) acrylic acid ester copolymer obtained by copolymerizing the (meth) acrylic acid ester with the above-mentioned (meth) acrylic acid ester and a copolymerizable hydroxyl group-containing monomer and a carboxyl group-containing monomer as main components It can be used suitably.

- the copolymerizable hydroxyl group-containing monomer and the carboxyl group-containing monomer are not particularly limited, and for example, a hydroxyl group-containing monomer and a carboxyl group-containing monomer disclosed in JP-A-2012-31316 can be used.

- the mass average molecular weight (Mw) of the acrylic resin is preferably in the range of 200,000 to 1,000,000, and more preferably in the range of 200,000 to 800,000. By setting the mass average molecular weight of the acrylic resin within the above range, a sufficient initial adhesive strength can be exhibited.

- the acrylic resin is a (meth) acrylic acid ester copolymer of a hydroxyl group-containing monomer and a carboxyl group-containing monomer copolymerizable with (meth) acrylic acid ester

- the hydroxyl group-containing monomer and the carboxyl group are

- the mass ratio to the contained monomer is preferably in the range of 51:49 to 100: 0, and more preferably 75:25 to 100: 0. If the mass ratio of each monomer is within the above range, it is possible to expect an effective decrease in adhesion due to energy ray irradiation, and prevent adhesive residue from being generated on the side of the member to be protected when peeling the adhesive layer in the present disclosure. Because you can do it.

- the energy beam polymerizable oligomer is not particularly limited as long as it is polymerized by receiving energy beam irradiation.

- oligomers of Among them photoradically polymerizable oligomers are preferred.

- the curing speed is high, and it is possible to select from a wide variety of compounds, and furthermore, it is possible to easily control physical properties such as tackiness before curing and peelability after curing.

- Examples of the photoradically polymerizable oligomer include those disclosed in JP 2012-31316A, and these may be used alone or in combination of two or more.

- the mass-average molecular weight (Mw) of the energy ray-polymerizable oligomer is not particularly limited, but it is more preferably, for example, in the range of 250 to 8000, and more preferably in the range of 250 to 5000. If the mass average molecular weight is within the above range, the adhesive layer in the present disclosure exhibits desired adhesiveness before energy beam irradiation, and generation of adhesive residue on the side of the member to be protected after energy beam irradiation in the peeling step. It is because it is suppressed and it becomes easy to peel off.

- the pressure-sensitive adhesive composition can control the adhesion of the pressure-sensitive adhesive layer in the present disclosure after energy ray irradiation by adjusting the amount of energy ray-polymerizable oligomers.

- the content of the energy beam polymerizable oligomer in the pressure-sensitive adhesive composition is preferably 10 parts by mass or more and 180 parts by mass or less, and more preferably 20 parts by mass or more and 150 parts by mass or less with respect to 100 parts by mass of the acrylic resin. Is preferred. If the content is within the above range, the crosslink density of the pressure-sensitive adhesive layer of the present disclosure after energy beam irradiation will be sufficient, so that desired peelability can be realized. Moreover, generation

- production of the adhesive residue to the to-be-protected member side by the fall of the cohesion force of an adhesive composition can be suppressed.

- (D) Polymerization initiator As the above-mentioned polymerization initiator, a general photopolymerization initiator can be used. For example, depending on the type of substrate and the type of energy beam irradiated to the adhesive layer, it is possible to select any polymerization initiator suitable for the wavelength. In the case where the member to be protected is an optical member, the protective sheet is required to have an optical property. For example, it is preferable to use a photopolymerization initiator having a low yellow index value (YI value).

- the YI value of the photopolymerization initiator is, for example, preferably 2.0 or less.

- the YI value can be measured using a spectral color difference meter (SE6000 manufactured by Nippon Denshoku Co., Ltd.).

- SE6000 spectral color difference meter

- IRGACURE184 As a commercial item of such a polymerization initiator, IRGACURE184 (made by BASF Japan) etc. are mentioned, for example.

- the content of the polymerization initiator in the pressure-sensitive adhesive composition is 0.01 parts by mass or more and 10 parts by mass or less, and particularly 0.5 parts by mass or more with respect to a total of 100 parts by mass of the acrylic resin and the energy ray polymerizable oligomer It is preferable that it is 7 mass parts or less.

- the content of the polymerization initiator is less than the above range, the polymerization reaction of the energy ray polymerizable oligomer does not occur sufficiently, the adhesion of the adhesive layer in the present disclosure after energy ray irradiation becomes excessively high, and the releasability is realized

- the energy ray may reach only the vicinity of the energy ray irradiated surface, and the curing of the adhesive layer in the present disclosure may be insufficient.

- the cohesion of the pressure-sensitive adhesive composition may be reduced, which may cause adhesive residue.

- the pressure-sensitive adhesive composition contains an energy beam polymerizable oligomer and an energy beam polymerizable monomer described later, a total of 100 parts by mass of the acrylic resin, the energy beam polymerizable oligomer, and the energy beam polymerizable monomer

- the content of the polymerization initiator is preferably in the above range.

- the crosslinking agent is not particularly limited as long as it crosslinks at least acrylic resins, and examples thereof include isocyanate crosslinking agents and epoxy crosslinking agents.

- isocyanate-based crosslinking agent and the epoxy-based crosslinking agent those disclosed in JP 2012-31316A can be mentioned.

- a crosslinking agent can be used individually or in combination of 2 or more types, According to the kind etc. of acrylic resin, it can select suitably.

- the content of the crosslinking agent in the pressure-sensitive adhesive composition can be appropriately set according to the type of the crosslinking agent, and for example, 0.01 parts by mass or more and 20 parts by mass or less with respect to 100 parts by mass of acrylic resin. Among them, the amount is preferably 0.01 parts by mass or more and 15 parts by mass or less.

- the content of the crosslinking agent is less than the above range, the adhesion between the pressure-sensitive adhesive layer and the member to be protected according to the present disclosure is inferior, or when the protective sheet is peeled from the member to be protected There is a possibility that an adhesive residue may occur on the side of the member to be protected due to destruction.

- the crosslinking agent when the content of the crosslinking agent exceeds the above range, the crosslinking agent remains as an unreacted monomer in the adhesive layer in the present disclosure after energy beam irradiation, which causes the generation of adhesive residue due to the decrease in cohesion. It may be

- the pressure-sensitive adhesive composition may contain an energy ray polymerizable monomer in addition to the energy ray polymerizable oligomer described above.

- the adhesive composition is cured by three-dimensional crosslinking to reduce the adhesive force, and the cohesive force of the adhesive composition is enhanced to prevent transfer to the side of the member to be protected. It is because it can.

- the energy ray polymerizable monomer a photo radical polymerizable monomer is preferable, and among them, polyfunctional acrylate and polyfunctional methacrylate having three or more (meth) acryloyl groups in one molecule are preferable.

- energy beam polymerizable monomers described in JP-A-2010-173091 can be mentioned.

- the total content thereof is 10 parts by mass with respect to 100 parts by mass of the acrylic resin. It is more preferable that it is 180 parts by mass or less, and more preferably 20 parts by mass or more and 150 parts by mass or less.

- the crosslink density after energy beam irradiation becomes sufficient, and appropriate releasability can be realized, and the occurrence of adhesive residue on the side of the member to be protected due to the decrease in the cohesive force of the pressure-sensitive adhesive composition can be suppressed. It is because it can.

- the pressure-sensitive adhesive composition is, if necessary, a silane coupling agent, a tackifier, a metal chelating agent, a surfactant, an antioxidant, an ultraviolet absorber, a pigment, a dye, a coloring agent, an antistatic agent, a preservative, You may contain various additives, such as an antifoamer and a wettability regulator.

- the thickness of the pressure-sensitive adhesive layer in the present disclosure may be any size as long as sufficient adhesion can be obtained and energy rays can be transmitted to the inside, specifically, 3 ⁇ m to 125 ⁇ m.

- the thickness is preferably 5 ⁇ m or more and 100 ⁇ m or less.

- the pressure-sensitive adhesive composition in the present disclosure can be prepared by mixing the above-described components and kneading or dispersing as necessary.

- the kneading or dispersing method is not particularly limited, and, for example, a conventionally known kneading and dispersing machine disclosed in JP-A-2014-234460 can be applied.

- the pressure-sensitive adhesive composition may be mixed with each component by adding a dilution solvent for viscosity adjustment.

- the protective sheet of the present disclosure has a substrate on one side of the adhesive layer.

- the substrate is preferably a layer capable of supporting the adhesive layer.

- the base material in the present disclosure is a member that can impart heat resistance, chemical resistance, and the like to a protective sheet. Therefore, for example, in the manufacturing process of the member to be protected, in order to prevent the surface of the member to be protected from being deteriorated or contaminated by heating or chemicals in the manufacturing process, a protective sheet having a base on the surface of the member to be protected When pasted, the member to be protected can be well protected from heat and medicine.

- the substrate in the present disclosure preferably has heat resistance.

- the heat resistance of the substrate is, for example, that the thermal expansion coefficient of the substrate material in the range of 150 ° C. to 250 ° C. is in the range of 5 ppm / ° C. to 50 ppm / ° C., in particular in the range of 10 ppm / ° C. to 30 ppm / ° C. Is preferred.

- the substrate may or may not have flexibility.

- examples of such a substrate include inorganic substrates such as quartz glass, Pyrex (registered trademark) glass and synthetic quartz plates, and resin substrates such as resin films and resin plates for optics.

- the resin used for the resin substrate those showing the above-mentioned thermal expansion coefficient are preferable.

- those showing the above-mentioned thermal expansion coefficient are preferable.

- they are a polyimide-type resin, polyphenylene sulfide-type resin, polyester-type resin, and glass epoxy resin (glass epoxy) from the point which is also excellent.

- the resin substrate may be a single layer made of one type of resin, or may be a multilayer body in which two or more types of resin substrates are laminated.

- the thickness of the substrate is not particularly limited, and can be appropriately selected according to the material, the presence or absence of flexibility, and the type of the adhesive layer.

- the form of the substrate is not particularly limited, and examples thereof include plate-like, sheet-like, film-like, and tape-like depending on the presence or absence of flexibility.

- the base material may be in a roll shape or in a sheet shape.

- the substrate preferably has transparency.

- An energy ray sufficient to reduce the adhesive strength of the adhesive layer can be irradiated from the substrate side.

- the light transmittance of the base material at this time may be appropriately set as long as a desired amount of energy rays can be transmitted.

- the surface of the base on which the adhesive layer is to be formed may be subjected to surface treatment such as corona treatment or primer treatment in order to enhance the adhesion to the adhesive layer.

- the protective sheet of the present disclosure may have the above-described adhesive layer and substrate, but may have other configurations as needed.

- the protective sheet of the present disclosure may have other configurations between the adhesive layer and the substrate, and may have other configurations on the surface of the substrate opposite to the adhesive layer.

- a separator is mentioned, for example.

- a separator is normally arrange

- the protective sheet of the present disclosure may have a separator on the surface of the adhesive layer opposite to the substrate.

- the separator is provided so as to be peelable from the pressure-sensitive adhesive layer, and is peeled from the pressure-sensitive adhesive layer when the protective sheet is attached to the member to be protected.

- separator for example, conventionally known separators such as a release film, separate paper, separate film, sepa paper, release film, release paper and the like can be used. Specifically, polypropylene, polyethylene, a fluorine film, etc. are mentioned.

- the separator may have releasability in the single layer exemplified above, but the release layer may be formed on one side or both sides of a release paper base material such as high quality paper, coated paper, impregnated paper, plastic film, etc.

- the laminated body which formed the may be used.

- the release layer is not particularly limited as long as it is a material having releasability, and, for example, silicone resin, organic resin modified silicone resin, fluorine resin, amino alkyd resin, melamine resin, acrylic resin, polyester resin, long chain There is an alkyl resin etc.

- silicone resin organic resin modified silicone resin

- fluorine resin amino alkyd resin

- melamine resin amino alkyd resin

- acrylic resin polyester resin

- any of emulsion type, solvent type or non-solvent type can be used.

- the separator is subjected to an easy peeling process on the surface in contact with the adhesive layer.

- the separator may have moisture resistance. It is because a contact with an adhesion layer and moisture can be prevented until it sticks a protection sheet to a to-be-protected member via an adhesion layer because a separator has moisture resistance. It is preferable that the separator has moisture resistance, for example, the water vapor transmission rate of the separator at a temperature of 40 ° C. and a humidity of 90% RH is 1 g / m 2 / day or less, and more preferably 0.1 g / m 2 / day or less Is preferred.

- the water vapor permeability can be measured in accordance with JIS K7129.

- Examples of the moisture-proof separator include an aluminum vapor-deposited film, a silica vapor-deposited film, an aluminum foil, a polyethylene film having a thickness of 0.1 mm or more, a film containing a moisture-proof filler, etc.

- the separator may have a light shielding property depending on the type of material contained in the adhesive layer and the construction environment. It is because it can suppress that an adhesive layer receives irradiation, such as an ultraviolet-ray, and is degraded until it sticks a protective sheet to a to-be-protected member through an adhesive layer.

- a light-shielding separator an aluminum foil separator, an aluminum vapor deposition film, a paper separator, a coloring separator, a film separator containing an ultraviolet absorber, etc. are mentioned, for example.

- the protective sheet of the present disclosure can be used as a member for protecting a protected member. Specifically, it can be used for the purpose of protection at the time of processing of a member to be protected.

- the protective sheet of the present disclosure may be used as a member for transporting a protected member, or may be used as a support film. That is, the protective sheet of the present disclosure also has application as a carrier film.

- the protective sheet with laminate of the present disclosure is a laminate obtained by laminating a protective sheet and a member to be protected, and the protective sheet comprises an adhesive layer and one surface of the adhesive layer.

- the adhesive layer has a characteristic that the adhesive strength is reduced from the initial adhesive strength by the irradiation of energy rays, and the adhesive layer is a laminate containing a fluorocarbon resin.

- the present disclosure by using the above-described protective sheet, it is possible to more easily perform peeling from the member to be protected using the adhesive layer capable of reducing the adhesive force by the irradiation of energy rays. It can be made a sheeted laminate.

- description of the detailed effect in this indication can be made to be the same as that of the content demonstrated by the term of the "A. protection sheet” mentioned above, the description here is abbreviate

- the protective sheet in the present disclosure is a member to be laminated on a member to be protected.

- the protective sheet has a pressure-sensitive adhesive layer and a base material disposed on one side of the pressure-sensitive adhesive layer, and the pressure-sensitive adhesive layer has a characteristic that the adhesion is reduced from the initial adhesion by the irradiation of energy rays.

- the adhesive layer is a member containing a fluorocarbon resin.

- the protective sheet in the present disclosure can be the same as the contents described in the section “A. Protective sheet” described above, and thus the description here is omitted.

- the protected member in the present disclosure is a member on which the above-described protective sheet can be laminated, and is not particularly limited. Among them, products such as FPCs and PCBs that require surface protection in the manufacturing process are preferable. In addition, those having terminals are preferable, and examples thereof include semiconductor chips such as IC chips and LSI chips, semiconductor packages, chip capacitors, chip resistors, transistors, inductors, and the like, and electronic devices such as image display devices, Building materials and cars etc. can be mentioned.

- the protected member is preferably a product having a large area surface. In the case of the to-be-protected member which has a large area surface, the more favorable peelability is calculated

- the present invention is not limited to the above embodiment.

- the above embodiment is an exemplification, and it has substantially the same configuration as the technical idea described in the claims of the present invention, and any one having the same function and effect can be used. It is included in the technical scope of the invention.

- the above-mentioned adhesive composition is coated by comma coating on a polyethylene terephthalate (PET) separator (Toyobo Co., Ltd. trade name: E7304 thickness: 50 ⁇ m) so that the thickness after drying is 75 ⁇ m, and an adhesive layer is formed. did. After drying of the adhesive layer, a substrate (made by Toyobo Co., Ltd. trade name: A4100 thickness: 50 ⁇ m) was laminated to obtain a protective sheet of the present disclosure.

- PET polyethylene terephthalate

- A4100 thickness 50 ⁇ m

- a protective sheet was obtained in the same manner as in the example except that the pressure-sensitive adhesive composition did not contain a fluorine resin.

- the pressure-sensitive adhesive layer contains a fluorine resin

- the surface free energy of the pressure-sensitive adhesive layer can be reduced, and the adhesion after energy irradiation can be further lowered.

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Adhesive Tapes (AREA)

- Laminated Bodies (AREA)

- Adhesives Or Adhesive Processes (AREA)

- Materials For Medical Uses (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017161243A JP6693487B2 (ja) | 2017-08-24 | 2017-08-24 | 保護シートおよび保護シート付積層体 |

| JP2017-161243 | 2017-08-24 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2019039340A1 true WO2019039340A1 (ja) | 2019-02-28 |

Family

ID=65440090

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/030212 Ceased WO2019039340A1 (ja) | 2017-08-24 | 2018-08-13 | 保護シートおよび保護シート付積層体 |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP6693487B2 (enExample) |

| TW (1) | TWI786165B (enExample) |

| WO (1) | WO2019039340A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2020189764A1 (ja) * | 2019-03-20 | 2020-09-24 | 積水化学工業株式会社 | 粘着剤組成物、粘着テープ、及び、電子部品の処理方法 |

| US12509612B2 (en) | 2019-03-20 | 2025-12-30 | Sekisui Chemical Co., Ltd. | Adhesive composition, adhesive tape, and method for processing electronic component |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116323849B (zh) * | 2020-10-01 | 2025-05-16 | Dic株式会社 | 粘合剂组合物和使用了其的层叠薄膜 |

| KR102376882B1 (ko) * | 2021-02-10 | 2022-03-21 | (주)이녹스첨단소재 | 디스플레이용 점착 시트 |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10120994A (ja) * | 1996-10-23 | 1998-05-12 | Sekisui Chem Co Ltd | 硬化型粘接着シート及び部材の接合方法 |

| JP2003073629A (ja) * | 2001-09-03 | 2003-03-12 | Somar Corp | 粘着組成物及び粘着シート |

| JP2006225634A (ja) * | 2005-01-24 | 2006-08-31 | Denki Kagaku Kogyo Kk | 粘着剤、それを用いた粘着シート、及び粘着シートを用いた電子部品製造方法。 |

| JP2007123711A (ja) * | 2005-10-31 | 2007-05-17 | Tomoegawa Paper Co Ltd | 半導体装置製造用接着シート及び半導体装置並びにその製造方法 |

| JP2008138130A (ja) * | 2006-12-05 | 2008-06-19 | Nitto Denko Corp | 光硬化型粘着テープ又はシートの製造方法、及び光硬化型粘着テープ又はシート |

| JP2011184603A (ja) * | 2010-03-10 | 2011-09-22 | Furukawa Electric Co Ltd:The | 粘着テープおよび半導体加工用テープ |

| JP2013201349A (ja) * | 2012-03-26 | 2013-10-03 | Lintec Corp | ダイシングシート |

| JP2014503655A (ja) * | 2010-12-20 | 2014-02-13 | ヘンケル コーポレイション | 光硬化性ダイシングダイ接合テープ |

| JP2014047312A (ja) * | 2012-09-03 | 2014-03-17 | Dainippon Printing Co Ltd | 粘着剤組成物及び粘着テープ |

| JP2016044186A (ja) * | 2014-08-19 | 2016-04-04 | リンテック株式会社 | 表面保護フィルム |

| JP2017019158A (ja) * | 2015-07-09 | 2017-01-26 | 三菱樹脂株式会社 | 積層フィルム |

| WO2017150290A1 (ja) * | 2016-03-04 | 2017-09-08 | 日東電工株式会社 | 表面保護フィルム |

-

2017

- 2017-08-24 JP JP2017161243A patent/JP6693487B2/ja active Active

-

2018

- 2018-08-13 WO PCT/JP2018/030212 patent/WO2019039340A1/ja not_active Ceased

- 2018-08-15 TW TW107128404A patent/TWI786165B/zh active

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH10120994A (ja) * | 1996-10-23 | 1998-05-12 | Sekisui Chem Co Ltd | 硬化型粘接着シート及び部材の接合方法 |

| JP2003073629A (ja) * | 2001-09-03 | 2003-03-12 | Somar Corp | 粘着組成物及び粘着シート |

| JP2006225634A (ja) * | 2005-01-24 | 2006-08-31 | Denki Kagaku Kogyo Kk | 粘着剤、それを用いた粘着シート、及び粘着シートを用いた電子部品製造方法。 |

| JP2007123711A (ja) * | 2005-10-31 | 2007-05-17 | Tomoegawa Paper Co Ltd | 半導体装置製造用接着シート及び半導体装置並びにその製造方法 |

| JP2008138130A (ja) * | 2006-12-05 | 2008-06-19 | Nitto Denko Corp | 光硬化型粘着テープ又はシートの製造方法、及び光硬化型粘着テープ又はシート |

| JP2011184603A (ja) * | 2010-03-10 | 2011-09-22 | Furukawa Electric Co Ltd:The | 粘着テープおよび半導体加工用テープ |

| JP2014503655A (ja) * | 2010-12-20 | 2014-02-13 | ヘンケル コーポレイション | 光硬化性ダイシングダイ接合テープ |

| JP2013201349A (ja) * | 2012-03-26 | 2013-10-03 | Lintec Corp | ダイシングシート |

| JP2014047312A (ja) * | 2012-09-03 | 2014-03-17 | Dainippon Printing Co Ltd | 粘着剤組成物及び粘着テープ |

| JP2016044186A (ja) * | 2014-08-19 | 2016-04-04 | リンテック株式会社 | 表面保護フィルム |

| JP2017019158A (ja) * | 2015-07-09 | 2017-01-26 | 三菱樹脂株式会社 | 積層フィルム |

| WO2017150290A1 (ja) * | 2016-03-04 | 2017-09-08 | 日東電工株式会社 | 表面保護フィルム |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2020189764A1 (ja) * | 2019-03-20 | 2020-09-24 | 積水化学工業株式会社 | 粘着剤組成物、粘着テープ、及び、電子部品の処理方法 |

| JPWO2020189764A1 (enExample) * | 2019-03-20 | 2020-09-24 | ||

| CN113574083A (zh) * | 2019-03-20 | 2021-10-29 | 积水化学工业株式会社 | 粘合剂组合物、粘合带及电子部件的处理方法 |

| JP7433228B2 (ja) | 2019-03-20 | 2024-02-19 | 積水化学工業株式会社 | 粘着剤組成物、粘着テープ、及び、電子部品の処理方法 |

| JP2024036541A (ja) * | 2019-03-20 | 2024-03-15 | 積水化学工業株式会社 | 粘着剤組成物、粘着テープ、及び、電子部品の処理方法 |

| US12509612B2 (en) | 2019-03-20 | 2025-12-30 | Sekisui Chemical Co., Ltd. | Adhesive composition, adhesive tape, and method for processing electronic component |

Also Published As

| Publication number | Publication date |

|---|---|

| TWI786165B (zh) | 2022-12-11 |

| JP2019038922A (ja) | 2019-03-14 |

| JP6693487B2 (ja) | 2020-05-13 |

| TW201912407A (zh) | 2019-04-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR102180956B1 (ko) | 편광 필름, 점착제층 부착 편광 필름, 편광 필름의 제조 방법, 및 화상 표시 장치 | |

| JP7340997B2 (ja) | 粘着シートおよび光学積層体 | |

| KR20190098046A (ko) | 점착 시트 및 점착 시트 적층체 | |

| JP6866880B2 (ja) | 光硬化性粘着シート | |

| TWI780255B (zh) | 黏著片、構成體及其製造方法 | |

| JP6921586B2 (ja) | 粘着性組成物、粘着剤、粘着シートおよび表示体 | |

| KR20190024606A (ko) | 점착 시트, 표시체 및 표시체의 제조 방법 | |

| KR102817418B1 (ko) | 점착 시트 및 적층체 | |

| KR101766399B1 (ko) | 다이싱 시트 | |

| KR20200024088A (ko) | 적층체 | |

| WO2019039340A1 (ja) | 保護シートおよび保護シート付積層体 | |

| CN111534238A (zh) | 粘合片、光学层叠体以及图像显示装置 | |

| KR20250009569A (ko) | 표면 보호 필름 | |

| KR20220121181A (ko) | 대전 방지 표면 보호 필름의 제조 방법, 및 대전 방지 표면 보호 필름 | |

| JP5565173B2 (ja) | 耐熱仮着用粘着テープ | |

| KR20170141651A (ko) | 투명 도전성 필름용 캐리어 필름 및 적층체 | |

| KR102698704B1 (ko) | 적층체 및 보호 필름 | |

| JP2012031316A (ja) | 耐熱仮着用粘着テープ | |

| JP7239660B2 (ja) | 粘着フィルム及び表面保護フィルム | |

| TW201323552A (zh) | 用於光學用途之丙烯酸系黏著劑組成物、用於光學用途之丙烯酸系黏著薄片以及使用其固定與分離光學構件之方法 | |

| JP2019056052A (ja) | 保護シートおよび保護シート付積層体 | |

| WO2023153152A1 (ja) | 粘着剤および粘着シート | |

| JP2024106142A (ja) | 粘着シート、積層体および積層体の製造方法 | |

| CN120958095A (zh) | 粘着片及显示体 | |

| JP2019026803A (ja) | 保護シートおよび保護シート付積層体 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18848246 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 18848246 Country of ref document: EP Kind code of ref document: A1 |