WO2016194440A1 - 吸収性物品の個包装体 - Google Patents

吸収性物品の個包装体 Download PDFInfo

- Publication number

- WO2016194440A1 WO2016194440A1 PCT/JP2016/058855 JP2016058855W WO2016194440A1 WO 2016194440 A1 WO2016194440 A1 WO 2016194440A1 JP 2016058855 W JP2016058855 W JP 2016058855W WO 2016194440 A1 WO2016194440 A1 WO 2016194440A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- absorber

- slit

- absorbent article

- individual package

- slit portion

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/47—Sanitary towels, incontinence pads or napkins

Definitions

- the present invention relates to an individual package of absorbent articles.

- Patent Literature 1 discloses an individual package in which an absorbent article having a front surface material, a back surface material, and an absorbent body interposed between the two materials is folded along an individual folding line, and the absorbent article.

- a circumferential leak-proof groove is formed on the surface material side of the circumferential leak-proof groove, and the circumferential leak-proof groove has a constricted portion that enters inward in a plan view at the position of the individual folding line, and the circumferential leak-proof groove

- Patent Document 2 includes a liquid-retaining absorbent body, a top sheet disposed on the skin facing surface side of the absorbent body, and a back sheet disposed on the non-skin facing surface side of the absorbent body, and is worn when worn.

- An excretory part facing part arranged opposite to the excretion part of the person, a front part arranged on the abdomen side of the wearer from the excretion part facing part, and a rear side arranged on the back side of the wearer from the excretion part facing part

- An absorbent article having a longitudinal direction corresponding to the wearer's front-rear direction and a transverse direction orthogonal thereto, wherein the back sheet has moisture permeability

- the absorbent body is composed of a laminate of absorbent sheets, and slits penetrating the absorbent sheet closest to the top sheet are dispersed in both the longitudinal direction and the lateral direction in the excretory part facing part.

- the excretory part facing part has a multilayer part, and the multilayer part is a part in which the number of laminated absorbent sheets is larger than the part located around it, and the multilayer part has the absorption part as the slit. Having a through slit penetrating the body, located outside the periphery of the multilayer part, and penetrating the absorbent sheet closest to the top sheet to a portion where the number of laminated absorbent sheets is smaller than the multilayer part.

- An absorbent article is described having a non-penetrating slit that does not penetrate the absorber.

- JP 2010-178932 A Japanese Patent Laid-Open No. 2015-024000

- the absorbent article is formed in an arc-shaped central groove extending in the width direction, and an individual package formed in a region having the central groove and extending substantially parallel to the central groove. With body fold lines. Therefore, the absorbent article of Patent Document 1 is easily folded at the central groove due to the difference in rigidity between the central groove and other portions.

- the absorbent article of Patent Document 1 is plastically deformed when the central groove is fused to the upper and lower sheets, the wearer unpacks the individual package and flattens the absorbent article. When folded into a shape, the folded shape is maintained, and if the central groove is not fused to the sheet located above and below it, it will cause delamination and wrinkles. Difficult to shape. As a result, the absorbent article of Patent Document 1 was inferior in wearing feeling, and liquids such as menstrual blood tended to leak.

- the absorbent article disclosed in Patent Document 2 has a plurality of slits extending in the longitudinal direction (longitudinal direction) or the lateral direction (width direction).

- the absorbent article described in Patent Document 2 is easy to fold in the width direction of the absorbent article with the slit as an axis when worn, The liquid tends to leak from the absorbent article.

- the slit is in the lateral direction, if the rigidity of the absorbent article is too low, the individual package is opened and the folded shape is maintained even if the absorbent article is expanded into a flat shape. In addition, it was necessary for the user to return the absorbent article to a planar shape.

- An object of the present invention is to provide an individual packaging body of an absorbent article that easily forms a folded shape and easily returns to a flat shape, improves a feeling of wearing in a fold line region, and hardly leaks liquid.

- the absorber has one surface and the other surface, and is formed by cutting in the folding line region from the one surface to the middle in the thickness direction of the absorber.

- At least one slit portion, the slit portion has an opening extending in the width direction on the one surface, and the absorber is at least in the thickness direction of the slit portion and the absorber.

- the said individual packaging body characterized by providing the high-density part in a comparison with the part which does not overlap in the thickness direction of the said slit part and the said absorber in the overlapping position was discovered.

- the absorbent article in the individual wrapping body of the present invention includes at least one slit portion in the fold line region, and the slit portion is provided in the width direction of the absorber, and the slit portion in the fold line region of the absorber.

- a difference in rigidity occurs between the portion provided with the portion and the other portion, and when folding into the individual packaging form, the slit portion serves as a folding point, and it is easy to form a folded shape.

- the slit portion is formed only halfway in the thickness direction of the absorber and there is a continuous region in the longitudinal direction, a force (restoring force) for returning to the planar shape works, and it is easy to return to the planar shape. .

- the absorbent article of the present invention includes a high-density part at least at a position overlapping with the slit part and the thickness direction of the absorber, a difference in rigidity occurs between the high-density part and its peripheral part, When folded into an individual packaging form, the high-density portion becomes a fold starting point, and it is easy to form a folded shape. Further, the high-density portion increases the rigidity of the portion at the position overlapping with the slit portion and the thickness direction of the absorber, so that a force (restoring force) for returning to the planar shape works, and it is easy to return to the planar shape.

- the absorbent article in the individual package of the present invention includes the slit portion and the high-density portion at the same time, it has both the ease of forming the folded shape and the ease of returning to the planar shape.

- the individual package of the absorbent article of the present invention is easy to form a folded shape and easily return to a planar shape.

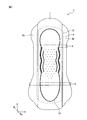

- FIG. 1 is a plan view of a state in which the individual package according to the first embodiment of the present invention is developed.

- FIG. 2 is a plan view of the absorbent article of the individual package according to the first embodiment of the present invention.

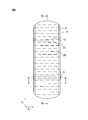

- FIG. 3 is a plan view of the absorbent body and the covering sheet used for the absorbent article of the individual package according to the first embodiment of the present invention.

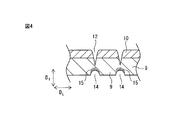

- FIG. 4 is a partial end view of the absorber and the covering sheet shown in FIG. 3 at the IV-IV end face.

- FIG. 5 is a partial end view at the VV end face of the absorbent body and the covering sheet shown in FIG.

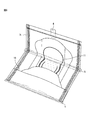

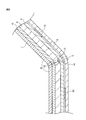

- FIG. 6 is a perspective view of a state in which the individual package according to the first embodiment of the present invention is folded in one fold line region.

- FIG. 1 is a plan view of a state in which the individual package according to the first embodiment of the present invention is developed.

- FIG. 2 is a plan view of the absorbent article of the individual package according to the first embodiment of the present invention

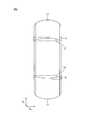

- FIG. 7 is a perspective view of a state in which the individual package according to the first embodiment of the present invention is folded in the entire fold line region.

- FIG. 8 is a partial cross-sectional view in a state where the individual package according to the first embodiment of the present invention is folded in one fold line region.

- FIG. 9 is a plan view of an absorbent body of an individual package according to the second embodiment of the present invention.

- An absorbent article having a longitudinal direction and a width direction and formed by folding an absorbent article including an absorbent body together with a packaging sheet in a fold line region extending in the width direction,

- the absorber has one surface and the other surface, and in the broken line region, a slit portion formed by cutting from the one surface to the middle in the thickness direction of the absorber.

- the slit portion has an opening extending in the width direction on the one surface,

- the absorber is provided with a high-density part in comparison with a part that does not overlap the slit part and the thickness direction of the absorber at least at a position that overlaps the slit part and the thickness direction of the absorber.

- the individual package of the absorbent article according to aspect 1 includes at least one or more slit portions in the fold line region, and the slit portions are provided in the width direction of the absorber.

- the slit portion becomes a folding point, and it is easy to form a folded shape.

- the slit portion is formed only halfway in the thickness direction of the absorber and there is a continuous region in the longitudinal direction, a force (restoring force) for returning to the planar shape works, and it is easy to return to the planar shape. .

- the absorbent article of the present invention includes a high-density part at least at a position overlapping with the slit part and the thickness direction of the absorber, a difference in rigidity occurs between the high-density part and its peripheral part, When folded into an individual packaging form, the high-density portion becomes a fold starting point, and it is easy to form a folded shape. Further, the high-density portion increases the rigidity of the portion at the position overlapping with the slit portion and the thickness direction of the absorber, so that a force (restoring force) for returning to the planar shape works, and it is easy to return to the planar shape.

- the absorbent article in the individual package of the present invention includes the slit portion and the high-density portion at the same time, there is an effect that both the ease of forming the folded shape and the ease of returning to the planar shape are obtained.

- the absorber includes a recess formed from the other surface to the middle in the thickness direction of the absorber at a position overlapping the slit portion and the thickness direction of the absorber on the other surface.

- the individual package Since the individual packaging body of the absorbent article according to the aspect 4 includes the concave portion at the position overlapping the slit portion and the thickness direction of the absorbent body, the rigidity difference between the portion and the other portion increases, and the individual packaging form When it is folded, the slit portion and the recess serve as folding points, so that the folded shape can be formed more easily.

- the individual wrapping body is formed by folding the absorbent article together with the wrapping sheet in a plurality of fold line regions, and the absorber includes at least one slit portion in each of the fold line regions.

- the said individual package provided with the above.

- the individual package of the absorbent article according to aspect 6 can be easily folded in any fold line region by providing at least one slit portion for each.

- the said absorbent article is a clothes contact surface of the said absorbent article, Comprising: The said part provided with the fixing

- FIG. 1 is a plan view of a state in which the individual package 1 is developed.

- the individual package 1 when deployed from the folded state, in plan view, an elongated shape with a width direction D W perpendicular to the longitudinal direction D L and the longitudinal D L Yes is doing.

- the individual package 1 is constituted by various members including a sanitary napkin 2, which is an absorbent article, a packaging sheet 3, and a tab 4.

- the sanitary napkin 2 and the packaging sheet 3 each have a fold line region 5 in the D W direction at a position where they overlap each other in the thickness direction, and are sequentially folded inward in the fold line region 5 as described later.

- the position to be formed can be changed as appropriate.

- the distance from the fold line of the napkin 2 to the first end in the width direction and the distance from the fold line of the napkin 2 to the second end in the width direction are both the same as the thickness of the absorber 9.

- region 5 is an area

- the thickness (mm) of an absorber is measured as follows.

- FS-60DS Measurement surface 44mm (diameter), measurement pressure 3g / cm2] manufactured by Daiei Kagaku Seisakusho Co., Ltd. is prepared, and the absorber is used under standard conditions (temperature 23 ⁇ 2 ° C, relative humidity 50 ⁇ 5%). The five parts with different pressures are pressurized, the thickness after 10 seconds of pressure at each part is measured, and the average value of the five measured values is taken as the thickness of the absorber.

- FIG. 2 is a plan view of the sanitary napkin 2 of the individual package 1 according to the first embodiment of the present invention.

- the napkin 2 in plan view, has an elongated shape with a width direction D W perpendicular to the longitudinal direction D L and longitudinal D L.

- the napkin 2 is positioned on the clothes side of the pair of left and right liquid-impermeable side sheets 6a and 6b positioned on the skin surface side of the wearer, and is a nonwoven fabric or a liquid-permeable plastic film.

- the sheet 10 includes various members.

- the napkin 2 is formed with a pressing groove 11 in a substantially annular shape.

- the pressing groove 11 is formed by pressing the top sheet 7, the covering sheet 10, and the absorbent body 9 in the thickness direction.

- the pressing groove 11 is formed by pressing the skin facing surface of the topsheet 7 of the napkin 2 and the skin non-facing surface of the absorbent body 9.

- the compression grooves 11 may not be circular, in a portion that overlaps the absorber 9 and the thickness direction, it may be formed over one to each linear at both ends of definitive width direction D w of the napkin 2.

- the compressed groove 11 is preferably formed in the broken line region 5 so as to be substantially orthogonal to the slit portion 12 in plan view, as will be described later.

- substantially orthogonal means not only a case where the angle formed by the slit portion 12 and the compressed groove 11 in the broken line region 5 is a right angle (90 °) in plan view, but an angle of 45 ° or more and less than 90 °, for example. It also includes the case of forming.

- FIG. 3 is a plan view of the absorbent body 9 and the covering sheet 10 used in the absorbent article (napkin 2) according to the first embodiment of the present invention.

- FIG. 4 is a plan view of the absorbent body 9 and the covering sheet shown in FIG. 10 is a partial end view of the IV-IV end surface of FIG.

- FIG. 5 is a partial end view at the VV end face of the absorbent body and the covering sheet shown in FIG.

- the absorber 9 and the covering sheet 10 is longer in the direction corresponding to the longitudinal direction D L of the napkin 2, and has a vertically long shape.

- the absorbent body 9 is a fiber structure including pulp in which a superabsorbent polymer is dispersed and held.

- the absorbent body used in the absorbent article of the present invention is a body fluid such as menstrual blood. Any absorbent material such as a nonwoven fabric may be used in addition to those obtained by dispersing and holding a superabsorbent polymer in the fiber structure containing pulp described above. Can do.

- a material obtained by compressing the above-described absorbent material with a press or the like can be preferably used because the absorbent body has high rigidity and is difficult to tear during use of the napkin.

- the basis weight of the absorbent body is not particularly limited as long as it is within the range of the basis weight in the case of being generally used as an absorbent body of the absorbent article.

- the covering sheet 10 is a liquid permeable sheet such as a nonwoven fabric made of synthetic fibers such as polyolefin fibers (for example, polyethylene and polypropylene) and polyester fibers (for example, polyethylene terephthalate).

- the covering sheet used in the absorbent article of the present invention is not particularly limited as long as it can permeate body fluid such as menstrual blood, and other than the above-mentioned non-woven fabric, any other plastic film or woven fabric can be used.

- the sheet material can be used.

- the basis weight of the fiber structure is also particularly within the range of the basis weight in the case where it is generally used as applied to absorbent articles. Not limited.

- the thickness of the cover sheet is not particularly limited, but is preferably 0.1 mm to 5.0 mm, and more preferably 0.2 mm to 2.0 mm.

- the covering sheet 10 is joined to the absorber 9 by an arbitrary adhesive such as hot melt. Since the absorbent body 9 and the covering sheet 10 are bonded via an adhesive, the absorbent body 9 and the covering sheet 10 are difficult to tear from a slit portion described later during use of the napkin 2. Moreover, in the absorbent article of this invention, in order to integrate an absorber and a coating sheet, you may use together crimping means, such as embossing, other than the above-mentioned adhesive agent. In particular, when embossing is used to integrate the absorbent body and the covering sheet, the absorbent body and the covering sheet are joined by a plurality of pressing parts formed by pressing with a plurality of embossed spins.

- embossing is used to integrate the absorbent body and the covering sheet, the absorbent body and the covering sheet are joined by a plurality of pressing parts formed by pressing with a plurality of embossed spins.

- the covering sheet 10 is disposed between the top sheet 7 and the absorbent body 9, but the covering sheet used for the absorbent article of the present invention is at a position at least partially covering the absorbent body. If there is no particular limitation, it can be arranged at any position according to the desired absorption performance, rigidity, etc. For example, even if the covering sheet is arranged between the absorber and the back sheet, You may arrange

- the covering sheet is not an essential component.

- the napkin excludes the covering sheet. It may be configured.

- the absorber 9 and the covering sheet 10 joined as described above penetrate the covering sheet 10 at least in the broken line region 5, and the thickness direction D T of the absorbing body 9 from the surface in contact with the covering sheet 10.

- the slit portion 12 formed up to the middle portion of the skin is provided on the skin facing surface and has an opening extending in the width direction. As shown in FIG. 3, in the first embodiment of the present invention, the slit portion 12 is disposed over substantially the entire surface of the absorber 9 and the covering sheet 10 in plan view.

- each of the plurality of slit portions 12 has a transverse direction perpendicular to the longitudinal direction of the absorber 9 and the covering sheet 10 (that is, the longitudinal direction D L of the napkin 2) in plan view, that is, It extends in a direction parallel to the width direction D w of the napkin 2.

- the slit part 12 and the non-slit part 120 exist alternately on the same line in the width direction.

- the length of the slit portion is not particularly limited, but is preferably 3 mm to 50 mm, and more preferably 5 mm to 15 mm.

- the length of the slit portion is 3 mm or more, it contributes to a decrease in the rigidity of the absorber, and the absorber can be easily folded.

- the length of the slit part is 50 mm or less, the resting force when the absorbent article is expanded from the folded state is left, leaving the part where the slit part is not formed at the end in the width direction of the absorber.

- the ratio of the total length of the slit portions on the same line in the width direction to the length in the width direction of the absorber is preferably 30 to 80% More preferably, it is 40 to 70%, and still more preferably 50 to 60%.

- the slit portion 12 penetrates the covering sheet 10 from the skin facing surface and extends in the thickness direction D T of the absorbent body 9 from the surface in contact with the covering sheet 10. It is formed up to the middle part.

- the depth of the slit portion of the absorbent body in the present invention is not particularly limited, but is, for example, 0.05 mm to 5.0 mm, preferably 0.1 mm to 3.0 mm from the viewpoint of easy folding of the absorbent article. It is. Further, the thickness of the slit portion may be 70% or less of the thickness of the absorber, or may be half or less of the thickness of the absorber.

- the depth of a slit part means the distance between the plane along the surface of the side which has a slit part, and the deepest part in a slit part, and specifically, the following measuring methods Refers to the depth required by.

- An absorber and a covering sheet (hereinafter referred to as “absorber or the like”) having a slit portion are cut along a plane perpendicular to the direction in which the slit portion extends.

- a cross section of the cut absorber or the like is observed with an electron microscope such as a scanning electron microscope, and the thickest part located between any two adjacent slits (hereinafter, “thickest part”) The thickness (mm) is measured.

- the thickness (mm) of any 10 thickest portions is measured, and the average value is defined as the thickest portion average thickness (mm).

- each of the plurality of slit portions 12 extends in a direction parallel to the width direction D W of the napkin 2 in plan view.

- the absorbent body is easily bent in the longitudinal direction D L of the napkin 2, easily folded at fold line region 5.

- the plurality of slit portions 12 are arranged in a staggered manner over substantially the entire surface of the absorber 9 and the covering sheet 10 in plan view. Further, the plurality of slit portions 12 are intermittently extended in the width direction of the absorber 9 so that the other slit portions 12 extend discontinuously on an extension line of one slit portion in plan view. Has been placed. With such a plurality of slits are arranged, areas of high nonexistent rigidity of the slit portion 12 in the absorbent body, since it is not continuously formed in the longitudinal direction D L of the napkin 2, the napkin 2 to be deformed It becomes easy and the wearing feeling of the napkin 2 can be improved.

- the portion such effects is not limited to the staggered arrangement of the above, for example, a plurality of slits, the slit portions longitudinally adjacent D L of the napkin 2 is always overlapped in the longitudinal direction D L It can obtain by arrange

- the arrangement form of the plurality of slit portions is not limited to the zigzag shape described above, and may be any as long as it does not impair the ease of deformation of the absorber and the rigidity as the absorber.

- An arrangement form can be adopted.

- the means for forming the plurality of slit portions is not particularly limited, and any cutting means can be used.

- the plurality of slit portions are provided on the peripheral surface of the rotating cutting roll from above the covering sheet while conveying the absorbent body and the covering sheet after being joined as described above by any conveying means. It can be formed by pressing a plurality of cutting blades.

- the slit part can be formed so as not to penetrate the absorber by adjusting the clearance between the cutting blade of the cutting roll and the conveying means.

- step (c) of removing the cutting blade from the body there are a step (a) of transporting the integrated covering sheet and absorber by an arbitrary transporting means, and a plurality of processes from above the covering sheet while transporting the covering sheet and absorber.

- a high density part is a part with a high fiber density in comparison with the part which does not overlap in the thickness direction of a slit part and an absorber so that it may mention later.

- the fiber density can be compared by, for example, observing the measurement target site with an electron microscope and comparing the maximum diameter of the inter-fiber gap at the site.

- the extending direction of the slit portion is not limited to a direction parallel to the width direction D W of the absorbent article, and is a direction substantially parallel to the width direction D W of the absorbent article. including.

- the “direction substantially parallel to the width direction D W of the absorbent article” means that when the plurality of slit portions are formed to extend in such a direction, the absorber and The covering sheet refers to a direction in which it acts so as to be easily folded on the surface side having the slit portion (that is, is easily valley-folded on the surface side having the slit portion), for example, in the width direction D W of the absorbent article

- it is preferably a direction that forms an angle of 0 ° or more and less than 30 °, more preferably an angle of 0 ° or more and less than 20 °, and still more preferably an angle of 0 ° or more and less than 10 °.

- an angle of 0 ° or more and less than 30 ° with respect to the width direction D W of the absorbent article means that a straight line parallel to the width direction D W of the absorbent article intersects with the slit portion.

- the smallest angle among the angles formed by means that the angle is 0 ° or more and less than 30 °.

- the absorbent body has the width direction D W in the absorbent body. Since the oriented fibers are easily cut, the rigidity in the width direction of the absorbent body may be reduced.

- the extending direction of the slit portion is a direction substantially parallel to the width direction D W of the absorbent article

- the absorber and the covering sheet are easily folded to the surface side having the slit portion. Therefore, while making it easy to deform an absorber and a covering sheet along a wearer's body shape, it can prevent that the pulp etc. in an absorber are exposed from the slit part.

- the absorber 9 is further from the skin non-facing surface at a position corresponding to the slit portion 12 in the thickness direction of the absorber 9.

- a concave portion 14 formed halfway in the thickness direction is provided.

- the structure of the recess is not particularly limited as long as the ease of folding the absorber is not impaired, but the length in the width direction of the recess is a point such as ease of deformation along the body shape. From, for example, 3 mm to 60 mm, preferably 5 mm to 20 mm.

- the length of the concave portion in the longitudinal direction is not particularly limited, but is, for example, 0.1 mm to 5 mm, preferably 0.5 mm to 2 mm.

- the width of the recess is in such a range, it becomes easy to function as a starting point when the absorber is bent.

- the depth of the recess is not particularly limited, but is, for example, 0.05 mm to 5 mm, preferably 0.1 mm to 3 mm, from the viewpoint of easy folding of the absorbent body.

- the depth of a recessed part means the distance between the surface on the opposite side to the surface which has the slit part of the absorber 9, and the deepest part of a recessed part, and is the same as the depth of the above-mentioned slit part. It can obtain

- the distance (mm) from the virtual bottom surface to the deepest portion of the concave portion is measured, and the average value of the measured distance values obtained for any ten concave portions is obtained.

- the depth of the slit portion 12 is deeper than the depth of the concave portion 14.

- the absorbent body 9 is bent toward the surface side having the slit portion 12, so that the pulp and the like in the absorbent body 9 are exposed by the slit portion. As a result, durability as an absorber can be improved.

- the shape of the recess in plan view is not particularly limited, but preferably has substantially the same shape as the slit portion 12.

- the absorber can be folded with high accuracy starting from the portion between the slit portion and the recess.

- substantially the same shape means that each shape is the same type of shape, and the center lines of each shape overlap each other.

- the concave portion in the napkin 2 according to the first embodiment of the present invention can be easily formed by a pressing means such as embossing, for example.

- a pressing means such as embossing

- the concave portion is formed by pressing means such as embossing, in the thickness direction of the absorbent body 9, the portion between the bottom portion of the slit portion 12 that does not penetrate and the concave portion 14 is compressed and densified. Since a difference in rigidity occurs between the peripheral portion and the peripheral portion, the high-density portion 15 serves as a starting point for folding the absorber 9 and easily returns the absorber 9 to a planar shape.

- region which has the slit part 12 of the absorber 9 is strengthened by densifying the part between the bottom part of the slit part 12, and the recessed part 14, the durability as an absorber can also be improved. it can.

- the squeezing means can also be used as a means for forming the slit portion 12 described above. That is, the recess 14 can be formed simultaneously with the slit portion 12. That is, in the step of forming the slit portion 12 described above (the step (b)), the portion between the bottom portion of the slit portion 12 and the conveying means is squeezed by the pressing force of the cutting blade, and the high density portion 15 is formed, and the absorber 9 is deformed so as to protrude downward with the contact point of the cutting blade (that is, the bottom of the slit portion 12) as the center.

- the absorbent body 9 deformed in this way is restored to its original shape by the elastic force of the fibers constituting the absorbent body 9 when the pressing force of the cutting blade is removed in the step (c).

- the high-density part 15 between the bottom part of the part 12 and the conveying means is compressed and not restored, and the state where the part is adjacent to the bottom part of the slit part 12 is maintained, so that the concave part centered on the part. 14 is formed on the surface of the absorbent body 9 on the conveying means side (that is, the surface opposite to the surface having the slit portion 12).

- the slit portion 12 and the concave portion 14 are formed at the corresponding positions in the thickness direction of the absorber 9 so as to have substantially the same shape in plan view.

- the folding of the absorbent body starting from the portion between the bottom of the portion 12 and the recess 14 can be realized with high accuracy, and a comfortable wearing feeling can be provided to the wearer.

- the high density part 15 is formed between the bottom part of the slit part 12, and the recessed part 14, the same effect as the case where the pressing means by the above-mentioned embossing etc. is used can be acquired.

- FIG. 6 is a perspective view showing a state in which the napkin 2 according to the first embodiment of the present invention is folded together with the packaging sheet 3 in one fold line region 5

- FIG. 7 is a napkin according to the first embodiment of the present invention.

- FIG. 2 is a perspective view showing a state in which 2 is folded together with the packaging sheet 3 in the entire folding line region 5. As shown in FIG. 6, one fold line region 5 is formed at a position where the longitudinal ends 16 do not overlap when the napkin 2 and the packaging sheet 3 are folded in the other fold line region.

- the longitudinal end portion 16 folded first is used. However, it does not rip again in the broken line region 5, and the formed individual package 1 does not have to be bulky.

- FIG. 8 is a partial cross-sectional view in a state where the individual package 1 according to the first embodiment of the present invention is folded halfway in one fold line region 5.

- the top sheet 7 peels off the inner layer from the absorber 9 in the fold line region 5. Begins to wake up and rises slightly.

- the surface sheets 7 on the skin facing surface come into contact with each other and pressure is applied in the vicinity of the broken line region 5, the raised surface sheet 7 is broken.

- the surface sheet 7 inhibits the ease of folding of the napkin 2 by causing the raised portion when the napkin 2 is folded, and after the napkin 2 is folded, Keep the folded shape.

- a similar phenomenon can occur in the back sheet 8, the packaging sheet 3, and the like.

- the absorbent body 9 of the napkin 2 includes a slit portion 12, and the slit portion 12 is formed at least in the folding line region 5 in the width direction and through the covering sheet 10 to the middle portion of the absorbent body 9 in the thickness direction. Therefore, there is a difference in rigidity between the portion where the slit portion 12 is provided in the longitudinal direction of the fold line region 5 and the other portion, and when folding into the individual packaging form, the slit portion 12 serves as a folding point, and the folding is performed. Easy to form shape. Moreover, since the slit part 12 is cut into the skin-facing surface of the absorbent body 9, the surface sheet 7 is not raised, and the ease of folding the napkin 2 is not hindered.

- the absorber 9 includes the high-density portion 15 at least at a position overlapping with the slit portion 12 in the thickness direction of the absorber, a difference in rigidity occurs between the high-density portion 15 and its peripheral portion, When folded into the individual packaging form, the high density portion 15 becomes a folding point, and it is easy to form a folded shape.

- the high-density portion 15 increases the rigidity of the portion at the position overlapping the slit portion 12 and the absorber 9 in the thickness direction, so that a force (restoring force) for returning to the planar shape works, and the absorber 9 is planarly shaped. It functions as a mechanical element when returning to.

- the region including the high density portion 15 is formed from the outer peripheral surface of the concave portion 14 to an intermediate portion in the thickness direction of the absorber 9 in an arc shape.

- the region including the high-density portion 15 is formed in this way, when the absorber 9 is folded, the region including the high-density portion 15 and the U-shaped spring extend in the direction opposite to the bending direction.

- the force (restoring force) which acts and the absorber 9 returns to a planar shape acts more.

- the high density portion 15 is formed in a portion between the bottom portion of the slit portion 12 that does not penetrate and the concave portion 14 in the thickness direction of the absorber 9, and the region including the high density portion 15 is an outer peripheral surface of the concave portion 14.

- the region other than the region including the high density portion 15 in the absorber 9 is a low density portion.

- the configuration in which the absorber includes the recess 14 has been described.

- the absorber does not include the recess 14, and only the portion overlapping the slit portion in the thickness direction is the absorber.

- the basis weight is high, and a region including a high-density portion is formed by pressing the absorber uniformly.

- the depth of the slit portion in the present invention may be half or less of the thickness of the absorber 9, or 70% or less.

- the portion where the slit portion 12 is not formed occupies half or more of the thickness of the absorber 9, or 30% or more, so that the force (restoring force) to return to the planar shape is obtained. It works satisfactorily and can further improve the feeling of wearing the napkin 2 in the broken line region 5.

- a plurality of broken line regions in the present invention may be formed at a position where the absorbent article and the packaging sheet overlap.

- the slit portion may be formed such that the other slit portion extends intermittently on an extension line in the width direction of the one slit portion.

- the other slit portion extends discontinuously on the extension line of the one slit portion in the fold line region, so the non-slit portion is on the same line in the width direction. It exists, and the rigidity of the absorbent body is maintained as compared with the case where one slit portion extends continuously in the width direction.

- deploying from the state which the absorbent article was folded can be exhibited.

- Fixing portions 13 and 13 are formed.

- the fixing portions 13 and 13 are formed, for example, by applying a hot melt adhesive at a predetermined position on the clothing contact surface of the back sheet 8.

- the fixing portions 13 and 13 are clothing contact surfaces of the napkin 2 and are formed in a region other than the region where the fold line region 5 and the slit portion 12 overlap. By forming the fixing portions 13 and 13 in such a region, when the napkin 2 is folded, the fixing portions 13 and 13 do not exist in the fold line region 5 of the clothing contact surface of the napkin 2, so the absorber 9 The force to restore the planar shape (restoring force) is not hindered. If the fixing parts 13 and 13 exist in the fold line area

- the napkin 2 according to the first embodiment of the present invention does not have the slit portions 12 at both edges in the width direction D W of the absorber 9. Since the slits are not present at both the edges, the absorbent body 9 can ensure a predetermined strength at the edges, so that both the edges of the napkin 2 in the width direction D W are worn. Even if friction or the like occurs between the person's thighs, the absorber is difficult to tear, and the napkin 2 is folded, leaving a portion where the slit portion 12 is not formed at the end in the width direction of the absorber The resilience when unfolding from can be demonstrated.

- the absorbent body and the covering sheet are compressed and integrated with embossing or the like to form a plurality of compressed portions.

- the rigidity of the absorbent body may become too high, and the absorbent article may be difficult to deform following the wearer's body shape. Therefore, when forming a some pressing part in an absorber and a covering sheet, it is preferable to comprise so that at least one part of the said pressing part may overlap with a slit part.

- the rigidity of the absorbent body can be reduced by forming the slit part in at least a part of the compressed part, excessive rigidity of the absorbent body by a plurality of compressed parts can be suppressed within a certain range. , Suitable fit as an absorbent article can be obtained.

- the napkin 2 according to the first embodiment of the present invention is formed so that the compressed groove 11 is orthogonal to the plane direction with at least one slit portion 12 in the broken line region 5.

- the compressed groove 11 By forming the compressed groove 11 in this way, the rigidity of the napkin 2 in the longitudinal direction is reinforced, and when the planar shape napkin 2 is returned to the planar shape, the force (restoring force) to return to the planar shape is sufficient, and the broken line The feeling of wearing the napkin 2 in the region 5 can be further improved.

- the plurality of slit portions may be disposed only in a partial region of the absorber and the covering sheet.

- the plurality of slit portions have a fold line region or rigidity. You may arrange

- the amount of pulp in the absorbent body of the excretion opening contact area is more than the surrounding area.

- the rigidity of the excretory opening contact area increases.

- the absorbent article It is possible to suppress the increase in rigidity of the absorber while improving the absorption performance.

- region located in the both ends part side of the longitudinal direction of an absorbent article are areas corresponding to the part with a large curvature of a wearer's body shape, at least one of the said front area

- FIG. 9 is a plan view of the absorbent body 9 ′ of the individual package 1 ′ according to the second embodiment of the present invention.

- Absorber 9 'in this embodiment has the same configuration as that of the above-described embodiment except for the aspect in which slit portion 12' is formed.

- one or more slit portions 12 ′ are provided so as to have a convex shape toward the longitudinal end portion 17 of the absorber 9 ′ in the broken line region.

- slit part 12 'in this embodiment is provided in areas other than both edge parts in width direction DW of absorber 9', length and curvature can be changed suitably.

- the reason why the slit portions 12 'do not exist at both edge portions in this way is that, as described above, since a predetermined strength can be ensured at both edge portions, both the width directions DW of the napkin 2' can be secured. Even if friction or the like occurs between the edge and the wearer's thigh, the absorber is difficult to tear, and a portion where the slit portion 12 ′ is not formed is left at the end in the width direction of the absorber. This is so that the restoring force when 'is unfolded from the folded state can be exhibited.

- the broken line of the absorber 9 ′ connects the start point and the end point of the slit portion 12 ′, or It is induced to be formed in a convex part, and the absorber 9 'can be further easily folded.

- the shape of the slit portion in plan view is not limited to the above-described embodiment, and any shape can be used as long as the deformation of the absorber and the strength as the absorber are not impaired. Can be adopted.

- the shape of the slit portion include a V shape, a waveform, a zigzag shape, a circular shape, and a polygonal shape.

- the slit portion in the individual package according to another embodiment of the present invention It is formed on the non-facing surface. Even in this case, in the fold line region of the absorber, a difference in rigidity occurs between the portion where the slit portion is provided and the other portion, and the slit portion becomes the starting point. Moreover, a path part produced when an absorbent article is folded can be absorbed by forming a slit part in a skin non-opposing surface. By these actions, it is easy to form a folded shape when the absorbent article is folded into an individual packaging form.

- the present invention can be applied to various absorbent articles such as panty liners and incontinence pads in addition to the sanitary napkins of the above-described embodiments. Further, the absorbent article of the present invention is not limited to the above-described embodiment, and can be appropriately changed within the scope not departing from the object and spirit of the present invention.

Landscapes

- Health & Medical Sciences (AREA)

- Epidemiology (AREA)

- Engineering & Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Vascular Medicine (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Absorbent Articles And Supports Therefor (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015-110894 | 2015-05-29 | ||

| JP2015110894A JP6300757B2 (ja) | 2015-05-29 | 2015-05-29 | 吸収性物品の個包装体 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2016194440A1 true WO2016194440A1 (ja) | 2016-12-08 |

Family

ID=57442383

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2016/058855 Ceased WO2016194440A1 (ja) | 2015-05-29 | 2016-03-18 | 吸収性物品の個包装体 |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP6300757B2 (cg-RX-API-DMAC7.html) |

| TW (1) | TWI715588B (cg-RX-API-DMAC7.html) |

| WO (1) | WO2016194440A1 (cg-RX-API-DMAC7.html) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2019047891A (ja) * | 2017-09-08 | 2019-03-28 | 王子ホールディングス株式会社 | 折り装置及び吸収性物品の製造装置 |

| EP3968924A1 (en) * | 2019-05-15 | 2022-03-23 | The Procter & Gamble Company | Disposable absorbent article |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04131224U (ja) * | 1991-05-28 | 1992-12-02 | 花王株式会社 | 吸収性物品 |

| JP2001293029A (ja) * | 2000-04-17 | 2001-10-23 | Kao Corp | 使い捨ておむつの折り畳み方法 |

| JP2004141620A (ja) * | 2002-08-30 | 2004-05-20 | Uni Charm Corp | 吸収体の製造装置 |

| JP2008264076A (ja) * | 2007-04-17 | 2008-11-06 | Uni Charm Corp | 吸収体及び該吸収体の製造方法 |

| JP2009153735A (ja) * | 2007-12-27 | 2009-07-16 | Kao Corp | 吸収性物品の個装体 |

| JP2014100199A (ja) * | 2012-11-16 | 2014-06-05 | Kao Corp | 吸収性物品 |

| JP2015024000A (ja) * | 2013-07-26 | 2015-02-05 | 花王株式会社 | 吸収性物品 |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2931062B2 (ja) * | 1990-09-25 | 1999-08-09 | 松下電工株式会社 | 成形金型 |

-

2015

- 2015-05-29 JP JP2015110894A patent/JP6300757B2/ja not_active Expired - Fee Related

-

2016

- 2016-03-18 WO PCT/JP2016/058855 patent/WO2016194440A1/ja not_active Ceased

- 2016-05-27 TW TW105116825A patent/TWI715588B/zh active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04131224U (ja) * | 1991-05-28 | 1992-12-02 | 花王株式会社 | 吸収性物品 |

| JP2001293029A (ja) * | 2000-04-17 | 2001-10-23 | Kao Corp | 使い捨ておむつの折り畳み方法 |

| JP2004141620A (ja) * | 2002-08-30 | 2004-05-20 | Uni Charm Corp | 吸収体の製造装置 |

| JP2008264076A (ja) * | 2007-04-17 | 2008-11-06 | Uni Charm Corp | 吸収体及び該吸収体の製造方法 |

| JP2009153735A (ja) * | 2007-12-27 | 2009-07-16 | Kao Corp | 吸収性物品の個装体 |

| JP2014100199A (ja) * | 2012-11-16 | 2014-06-05 | Kao Corp | 吸収性物品 |

| JP2015024000A (ja) * | 2013-07-26 | 2015-02-05 | 花王株式会社 | 吸収性物品 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2016220984A (ja) | 2016-12-28 |

| TW201711653A (zh) | 2017-04-01 |

| TWI715588B (zh) | 2021-01-11 |

| JP6300757B2 (ja) | 2018-03-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5053765B2 (ja) | 生理用ナプキンの個装体 | |

| JP6219573B2 (ja) | 吸収性物品 | |

| JP5380095B2 (ja) | 吸収性物品の個包装体 | |

| TWI603722B (zh) | Absorbent article | |

| JP5944103B2 (ja) | 吸収性物品の包装体 | |

| TW201818896A (zh) | 獨立包裝吸收性物品、吸收性物品以及折疊吸收性物品的方法 | |

| JP5883681B2 (ja) | 吸収性物品 | |

| WO2015005502A2 (ja) | 吸収性物品 | |

| JP6118748B2 (ja) | 使い捨ておむつ | |

| JP6199646B2 (ja) | 吸収性物品 | |

| JP6030875B2 (ja) | 吸収性物品 | |

| JP6300757B2 (ja) | 吸収性物品の個包装体 | |

| JP6399827B2 (ja) | 吸収性物品 | |

| JP4128164B2 (ja) | 吸収性物品の個装体 | |

| JP6760038B2 (ja) | 吸収性物品及び吸収性物品の製造方法 | |

| US20150366722A1 (en) | Absorbent article | |

| JP2015100574A (ja) | 吸収性物品 | |

| JP2018079033A (ja) | 吸収性物品 | |

| JP2017113406A (ja) | 吸収性物品 | |

| JP5406963B2 (ja) | 吸収性物品 | |

| JP7164370B2 (ja) | 吸収性物品 | |

| JP3210014U (ja) | 吸収性物品 | |

| CN106456393B (zh) | 吸收性物品的制造方法 | |

| JP6577854B2 (ja) | 吸収性物品 | |

| JP2018079035A (ja) | 吸収性物品 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 16802879 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 16802879 Country of ref document: EP Kind code of ref document: A1 |