WO2016125712A1 - 電流検出回路、電流検出装置及び切替え装置 - Google Patents

電流検出回路、電流検出装置及び切替え装置 Download PDFInfo

- Publication number

- WO2016125712A1 WO2016125712A1 PCT/JP2016/052763 JP2016052763W WO2016125712A1 WO 2016125712 A1 WO2016125712 A1 WO 2016125712A1 JP 2016052763 W JP2016052763 W JP 2016052763W WO 2016125712 A1 WO2016125712 A1 WO 2016125712A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- current

- current path

- value

- detection circuit

- voltage value

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05F—SYSTEMS FOR REGULATING ELECTRIC OR MAGNETIC VARIABLES

- G05F1/00—Automatic systems in which deviations of an electric quantity from one or more predetermined values are detected at the output of the system and fed back to a device within the system to restore the detected quantity to its predetermined value or values, i.e. retroactive systems

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M3/00—Conversion of DC power input into DC power output

- H02M3/02—Conversion of DC power input into DC power output without intermediate conversion into AC

- H02M3/04—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters

- H02M3/10—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters using discharge tubes with control electrode or semiconductor devices with control electrode

- H02M3/145—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters using discharge tubes with control electrode or semiconductor devices with control electrode using devices of a triode or transistor type requiring continuous application of a control signal

- H02M3/155—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters using discharge tubes with control electrode or semiconductor devices with control electrode using devices of a triode or transistor type requiring continuous application of a control signal using semiconductor devices only

- H02M3/156—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters using discharge tubes with control electrode or semiconductor devices with control electrode using devices of a triode or transistor type requiring continuous application of a control signal using semiconductor devices only with automatic control of output voltage or current, e.g. switching regulators

- H02M3/157—Conversion of DC power input into DC power output without intermediate conversion into AC by static converters using discharge tubes with control electrode or semiconductor devices with control electrode using devices of a triode or transistor type requiring continuous application of a control signal using semiconductor devices only with automatic control of output voltage or current, e.g. switching regulators with digital control

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D41/00—Electrical control of supply of combustible mixture or its constituents

- F02D41/20—Output circuits, e.g. for controlling currents in command coils

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M7/00—Conversion of AC power input into DC power output; Conversion of DC power input into AC power output

- H02M7/42—Conversion of DC power input into AC power output without possibility of reversal

- H02M7/44—Conversion of DC power input into AC power output without possibility of reversal by static converters

- H02M7/48—Conversion of DC power input into AC power output without possibility of reversal by static converters using discharge tubes with control electrode or semiconductor devices with control electrode

-

- H—ELECTRICITY

- H03—ELECTRONIC CIRCUITRY

- H03M—CODING; DECODING; CODE CONVERSION IN GENERAL

- H03M1/00—Analogue/digital conversion; Digital/analogue conversion

- H03M1/06—Continuously compensating for, or preventing, undesired influence of physical parameters

- H03M1/0602—Continuously compensating for, or preventing, undesired influence of physical parameters of deviations from the desired transfer characteristic

- H03M1/0609—Continuously compensating for, or preventing, undesired influence of physical parameters of deviations from the desired transfer characteristic at two points of the transfer characteristic, i.e. by adjusting two reference values, e.g. offset and gain error

-

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02M—APPARATUS FOR CONVERSION BETWEEN AC AND AC, BETWEEN AC AND DC, OR BETWEEN DC AND DC, AND FOR USE WITH MAINS OR SIMILAR POWER SUPPLY SYSTEMS; CONVERSION OF DC OR AC INPUT POWER INTO SURGE OUTPUT POWER; CONTROL OR REGULATION THEREOF

- H02M1/00—Details of apparatus for conversion

- H02M1/0003—Details of control, feedback or regulation circuits

- H02M1/0009—Devices or circuits for detecting current in a converter

Definitions

- the present invention relates to a current detection circuit that outputs a voltage value corresponding to a current value flowing through a current path, a current detection device including the current detection circuit, and a current path through which a current flows to a voltage value output by the current detection circuit.

- the present invention relates to a switching device that switches in response.

- Patent Document 1 As a power supply device mounted on a vehicle, a power supply device (see, for example, Patent Document 1) in which power is supplied to a load via two current paths has been proposed.

- a DCDC converter is provided in one of the two current paths.

- the DCDC converter transforms an applied voltage and applies the transformed voltage to a load. As a result, the load is fed.

- the other current path is not provided with a DCDC converter, and is directly supplied to the load.

- the current path used for power supply to the load is switched to one of the two current paths described above.

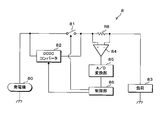

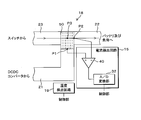

- FIG. 1 is a block diagram showing a main part configuration of a conventional power supply device 8.

- the conventional power supply device 8 one end of the generator 80 is connected to one end of each of the switch 81 and the DCDC converter 82, and the other end of each of the switch 81 and the DCDC converter 82 is connected to one end of the resistor R8. .

- the other end of the resistor R8 is connected to one end of the load 83.

- the other ends of the generator 80 and the load 83 are grounded.

- One end and the other end of the resistor R8 are connected to the plus terminal and the minus terminal of the differential amplifier 84, respectively, and the output terminal of the differential amplifier 84 is connected to an A / D (Analog / Digital) converter 85.

- the A / D conversion unit 85 is further connected to the control unit 86.

- the control unit 86 controls on / off of the switch 81 and operation / stop of the DCDC converter 82.

- the control unit 86 turns off the switch 81 to operate the DCDC converter 82

- the DCDC converter 82 steps down the direct current output voltage output from the generator 80, and passes the stepped down voltage through the resistor R8. Supply to load 83.

- the control unit 86 turns on the switch 81 to stop the operation of the DCDC converter 82, the generator 80 supplies the output voltage to the load 83 via the switch 81 and the resistor R8.

- the differential amplifier 84 amplifies the voltage value across the resistor R8 and outputs the amplified analog voltage value to the A / D converter 85.

- the A / D conversion unit 85 converts the analog voltage value into a digital voltage value, and outputs the converted digital voltage value to the control unit 86. Since the voltage value across the resistor R8 is proportional to the value of the current flowing through the resistor R8, the resistor R8, the differential amplifier 84, and the A / D converter 85 function as a current detection circuit.

- the control unit 86 normally turns off the switch 81 and operates the DCDC converter 82.

- the value of the current that can be passed through the DCDC converter 82 is limited to a predetermined value. Therefore, a first current value that is less than a predetermined value and a second current value that is less than or equal to the first current value are set.

- the switch 81 is off and the DCDC converter 82 is operating, the current flowing through the resistor R8 is equal to or higher than the first current value, and the voltage value output from the A / D converter 85 is equal to or higher than the first voltage value.

- the control unit 86 stops the operation of the DCDC converter 82 and turns on the switch 81.

- the current path of the current flowing from the generator 80 to the load 83 is switched from the first path through which the current flows through the DCDC converter 82 to the second path through which the current flows through the switch 81.

- the control unit 86 since the control unit 86 switches the current path, even when the load 83 needs to supply a current of a predetermined value or more, it is possible to continue supplying the current to the load 83.

- the switch 81 When the switch 81 is on and the operation of the DCDC converter 82 is stopped, the value of the current flowing through the second path is less than the second current value and the second voltage value output from the A / D converter 85.

- the control unit 86 turns off the switch 81 and operates the DCDC converter 82. Thereby, the current path of the current flowing from the generator 80 to the load 83 is switched from the second path to the first path. The voltage that is stepped down by the DCDC converter 82 is supplied to the load 83 again.

- the above-described current detection circuit and control unit 86 function as a switching device that switches the current path through which the current flows to the first path or the second path.

- the A / D conversion unit 85 performs processing such as rounding off or rounding down, and among the voltage values obtained by equally dividing the reference voltage value by a predetermined number, the voltage value output by the differential amplifier 84 is first or second.

- the voltage value output from the differential amplifier 84 is quantized to a close voltage value.

- a current less than the first current value flows through the first path, and a current greater than the second current value flows through the second path. Since the second path is provided for flowing a current equal to or higher than the first current value, a current equal to or higher than the first current value flows through the second path.

- the reference voltage value of the A / D converter 85 is set to 10 V or more.

- the reference voltage value is 10V and the A / D conversion unit 85 converts the voltage value into a 10-bit digital value

- the A / D conversion unit 85 sets 10V (reference voltage value) to 1023 (predetermined number).

- the voltage value output by the differential amplifier 84 is quantized to the voltage value first or second closest to the voltage value output by the differential amplifier 84. At this time, the interval between the scales is about 9.78 mV.

- the value of the current flowing through the first path varies in the range of zero to 100A.

- the reference voltage value of the A / D converter 85 can be set to 5 V.

- the A / D converter 85 is first or second closest to the voltage value output by the differential amplifier 84 among the voltage values obtained by equally dividing 5V (reference voltage value) by 1023 (predetermined number).

- the voltage value output from the differential amplifier 84 is quantized into the voltage value.

- the interval between the scales is about 4.89 mV.

- the reference voltage value is 5V, since the interval of the scale is small, the current detection circuit configured by the resistor R8, the differential amplifier 84, and the A / D conversion unit 85 can accurately determine the value of the current flowing through the first path. Can be detected.

- the reference voltage value of the A / D conversion unit 85 is set according to the maximum value of the current flowing through the second path. There is a problem that the value of the current flowing through the current cannot be detected with high accuracy. In this case, there is a possibility that the current path cannot be switched appropriately.

- the present invention has been made in view of such circumstances, and an object of the present invention is to provide an inexpensive current detection circuit capable of outputting a voltage value accurately indicating a current value flowing through each of two current paths.

- the present invention also provides a current detection device and a switching device including the current detection circuit.

- the current detection circuit corresponds to a current value flowing through the first current path from the first conductive plate to the second conductive plate and the second current path from the third conductive plate to the second conductive plate.

- the current detection circuit for outputting a voltage value further includes a potential difference detection unit that detects a value related to a potential difference between two points located on the plate surfaces of the first conductive plate and the second conductive plate.

- a current flows through the first current path from the first conductive plate to the second conductive plate or the second current path from the third conductive plate to the second conductive plate.

- a value relating to a potential difference between a point located on the plate surface of the first conductive plate and a point located on the plate surface of the third conductive plate is detected.

- the value relating to the potential difference between the two points varies according to the current value flowing through the first current path and the current value flowing through the second current path.

- a value related to a potential difference between two points detected when a certain value of current flows in the second current path is detected when a current of the same value flows in the first current path. Different from the value related to the potential difference between points.

- the value relating to the potential difference between the two points is a voltage value between the two points or a current value flowing between the two points.

- the voltage value output from the circuit is a voltage value based on a voltage value between two points or a current value flowing between the two points.

- a value related to a potential difference between two points when a current of 100 A flows in the first current path and a value related to a potential difference between two points when a current of 200 A flows in the second current path. can be matched.

- a voltage value that accurately indicates the current value flowing through each of the first current path and the second current path is output.

- pieces may be one, manufacturing cost is cheap.

- the current detection circuit includes a conducting wire connected between the two points, and the potential difference detection unit detects a current value flowing through the conducting wire.

- the value of the current flowing in the conducting wire connected between the point located on the plate surface of the first conductive plate and the point located on the plate surface of the second conductive plate is detected.

- the current detection circuit according to the present invention is characterized in that the potential difference detection unit detects a voltage value between the two points.

- a voltage value between a point located on the plate surface of the first conductive plate and a point located on the plate surface of the second conductive plate is detected.

- each of the first conductive plate and the third conductive plate is connected to the first conductive plate, the second conductive plate, and the third conductive plate through a resistance unit having a lower conductivity. It is characterized by being connected to the second conductive plate.

- each of the first conductive plate and the third conductive plate is connected to the second conductive plate via a resistance portion having a lower conductivity than the first conductive plate, the second conductive plate, and the third conductive plate. ing. For this reason, the voltage value between the point located in the board surface of a 1st electroconductive board and the point located in the board surface of a 2nd electroconductive board is large.

- the current detection device is a temperature detection that detects a temperature value of a conductor constituted by connecting the above-described current detection circuit and the first conductive plate and the third conductive plate to the second conductive plate. And a calculation unit that calculates a current value flowing through the first current path or the second current path based on the temperature value detected by the temperature detection unit and the voltage value output by the current detection circuit. It is characterized by that.

- the first conductive plate and the third conductive plate are connected to the second conductive plate, and the temperature value of the conductor constituted by the first conductive plate, the second conductive plate, and the third conductive plate is determined. To detect. Based on the detected temperature value and the voltage value output by the current detection circuit, the current value flowing in the first current path or the second current path is calculated.

- the current detection device includes the above-described current detection circuit, a temperature detection unit that detects a temperature value of the resistance unit, a temperature value detected by the temperature detection unit, and a voltage output by the current detection circuit. And a calculation unit that calculates a value of a current flowing through the first current path or the second current path based on the value.

- the temperature value of the resistance portion is detected, and the current value flowing through the first current path or the second current path is calculated based on the detected temperature value and the voltage value output by the current detection circuit. .

- a switching device includes the above-described current detection circuit and a switching unit that switches a current path through which a current flows to the first current path or the second current path, and the switching unit includes the first current path and the current path. Switching is performed based on which of the second current paths the current is flowing and the voltage value output by the current detection circuit.

- the current path through which the current flows should be switched to the second current path based on the voltage value output by the current detection circuit in the state where the current flows through the first current path.

- a determination is made as to whether or not the current path through which the current flows should be switched to the first current path based on the voltage value output by the current detection circuit in a state where the current is flowing through the second current path.

- the current path through which the current flows is appropriately switched by adjusting the positions of the two points so that the voltage value accurately indicating the current value flowing through each of the first current path and the second current path is output. It is possible.

- the switching device includes the above-described current detection circuit, a switching unit that switches a current path through which a current flows to the first current path or the second current path, and the first conductive plate and the third conductive plate, respectively.

- a temperature detection unit that detects a temperature value of a conductor formed by being connected to the second conductive plate, and the switching unit determines whether the current flows in the first current path or the second current path. The switching is performed based on the voltage value output by the current detection circuit and the temperature value detected by the temperature detection unit.

- the first conductive plate and the third conductive plate are connected to the second conductive plate, and the temperature value of the conductor constituted by the first conductive plate, the second conductive plate, and the third conductive plate is determined.

- the current path through which the current flows should be switched based not only on whether the current flows through the first current path or the second current path and the voltage value output from the voltage detection circuit, but also based on the detected temperature value. Therefore, it is possible to more appropriately switch the current path through which the current flows.

- the switching device includes the above-described current detection circuit, a switching unit that switches the current path through which the current flows to the first current path or the second current path, and a temperature detection unit that detects a temperature value of the resistance unit.

- the switching unit includes a current value flowing through the first current path and a second current path, a voltage value output from the current detection circuit, and a temperature value detected by the temperature detection unit. Switching is performed based on this.

- the temperature value of the resistance portion is detected. Whether the current path through which the current flows should be switched based on the detected temperature value, whether the current flows in the first current path or the second current path, and the voltage value output by the voltage detection circuit. judge.

- the current path through which the current flows is appropriately switched by adjusting the positions of the two points so as to output a voltage value that accurately indicates the current value flowing through each of the first current path and the second current path. Is possible.

- the current path can be switched more appropriately.

- the switching device includes a switch that transforms an applied voltage, outputs and outputs the transformed voltage to the first conductive plate, and a switch having one end connected to the third conductive plate. The switching is performed by controlling on / off.

- the transformer transforms the applied voltage and outputs the transformed voltage to the first conductive plate.

- a current flows through the first current path while the transformer is operating.

- a current flows through the second current path while the switch is on.

- the current path through which the current flows can be switched to the first current path by operating the transformer and turning off the switch, and the current through which the current flows by stopping the transformer and turning on the switch. The path can be switched to the second current path.

- FIG. 10 is a block diagram showing a main configuration of a power supply device according to a third embodiment. It is explanatory drawing of electric current detection. 14 is a chart showing a first voltage threshold and a second voltage threshold in the fourth embodiment.

- FIG. 10 is an explanatory diagram of current detection in a fifth embodiment.

- FIG. 10 is a block diagram showing a main configuration of a power supply device according to a sixth embodiment.

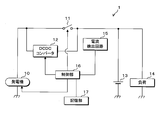

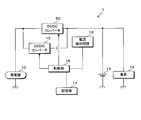

- FIG. 2 is a block diagram showing a main configuration of power supply device 1 according to the first embodiment.

- the power supply device 1 is suitably mounted on a vehicle and includes a generator 10, a switch 11, a DCDC converter 12, a battery 13, a load 14, a current detection circuit 15, a control unit 16, and a storage unit 17.

- One end of the generator 10 is connected to one end of each of the switch 11 and the DCDC converter 12.

- the other ends of the switch 11 and the DCDC converter 12 are connected to the positive electrode of the battery 13 and one end of the load 14.

- the other end of each of the generator 10 and the load 14 and the negative electrode of the battery 13 are grounded.

- the current detection circuit 15 and the storage unit 17 are connected to the control unit 16 separately.

- the generator 10 generates AC power in conjunction with an engine (not shown), rectifies the generated AC power into DC power, and smoothes the rectified power.

- the generator 10 supplies a DC voltage related to the smoothed DC power as an output voltage to the battery 13 and the load 14 via the switch 11.

- the generator 10 further applies an output voltage to one end of the DCDC converter 12.

- the generator 10 has a lowering instruction that instructs the output voltage value to be reduced to a predetermined first output voltage value, for example, 12 V, and the output voltage value is set to a second output voltage value that is higher than the first output voltage value.

- An ascending instruction for instructing raising is input from the control unit 16.

- the generator 10 reduces the output voltage value to the first output voltage value when a decrease instruction is input from the control unit 16, and converts the output voltage value to the second output voltage when the increase instruction is input from the control unit 16. Increase to value.

- the switch 11 is turned on / off by the control unit 16. When the switch 11 is on, the output voltage of the generator 10 is supplied to the battery 13 and the load 14 via the switch 11.

- the DCDC converter 12 transforms the output voltage of the generator 10 applied to one end to a predetermined voltage, and supplies the transformed voltage to the battery 13 and the load 14 from the other end.

- the value of the voltage transformed by the DCDC converter 12 is, for example, 12V.

- the DCDC converter 12 receives an operation instruction for instructing an operation and a stop instruction for instructing an operation stop from the control unit 16.

- the DCDC converter 12 operates when an operation instruction is input from the control unit 16, and stops operating when a stop instruction is input from the control unit 16.

- the output voltage is supplied to the battery 13 from the generator 10 via the switch 11 or the transformed voltage is supplied from the DCDC converter 12. Thereby, the battery 13 stores electricity.

- the load 14 is an electric device mounted on the vehicle.

- the output voltage value of the generator 10 is the second output voltage value, and the switch 11 is off.

- the voltage transformed by the DCDC converter 12 is supplied to the battery 13 and the load 14, and the battery 13 and the load 14 are supplied with power.

- the output voltage value of the generator 10 is the first output voltage value, and the switch 11 is on. At this time, the output voltage of the generator 10 is supplied to the battery 13 and the load 14, and the battery 13 and the load 14 are supplied with power. When the generator 10 stops generating power, the output voltage of the battery 13 is supplied to the load 14 and the load 14 is supplied with power.

- the current detection circuit 15 converts an analog value related to the current flowing to the battery 13 and the load 14 into a digital value, and outputs the converted digital value to the control unit 16.

- the control unit 16 has a CPU (Central Processing Unit) and executes processing by executing a control program stored in a ROM (Read Only Memory) (not shown). Based on the digital value input from the current detection circuit 15, the control unit 16 outputs a decrease instruction / up instruction to the generator 10, turns on / off the switch 11, and operates / stops the DCDC converter 12. The instruction is output.

- a CPU Central Processing Unit

- ROM Read Only Memory

- the storage unit 17 is a non-volatile memory, and the storage unit 17 stores data necessary for the control unit 16 to execute processing. Reading and writing of the contents stored in the storage unit 17 are performed by the control unit 16.

- FIG. 3 is an explanatory diagram of current detection.

- the power supply device 1 further includes a plate-like conductor 18 that connects the other ends of the switch 11 and the DCDC converter 12 to the positive electrode of the battery 13 and one end of the load 14.

- the conductor 18 includes a first conductive part 21, a second conductive part 22, and a third conductive part 23.

- Each of the first conductive portion 21, the second conductive portion 22, and the third conductive portion 23 is a so-called bus bar and has a plate shape.

- FIG. 3 shows the plate surfaces of the first conductive portion 21, the second conductive portion 22, and the third conductive portion 23.

- the first conductive part 21 and the third conductive part 23 are connected to the second conductive part 22.

- the other end of the switch 11 is connected to the third conductive portion 23.

- the other end of the DCDC converter 12 is connected to the first conductive portion 21.

- the positive electrode of the battery 13 and one end of the load 14 are connected to the second conductive portion 22.

- the DCDC converter 12 outputs the transformed voltage to the first conductive unit 21.

- the DCDC converter 12 functions as a transformer.

- the conductor 18 has a first current path through which current flows from the first conductive part 21 to the second conductive part 22 and a second current path through which current flows from the third conductive part 23 to the second conductive part 22.

- the current supplied from the DCDC converter 12 to the load 14 is limited.

- the control unit 16 performs a switching process for switching the current path through which the current flows in the conductor 18 to the first current path or the second current path.

- the control unit 16 changes the current path through which the current flows in the conductor 18 from the first current path to the second current when the value of the current flowing through the first current path is a first current threshold, for example, 100 A or more. Switch to the current path.

- the control unit 16 changes the current path through which the current flows in the conductor 18 from the second current path when the value of the current flowing through the second current path is less than a second current threshold, for example, 90 A. Switch to the first current path.

- the second current threshold is less than or equal to the first current threshold.

- the current detection circuit 15 includes a conducting wire 30, a current sensor 31, and an A / D conversion unit 32.

- the conducting wire 30 is connected between a point P1 located on the surface of the first conductive part 21 and a point P2 located on the surface of the second conductive part 22.

- the current sensor 31 has an annular shape and surrounds the conducting wire 30.

- the A / D conversion unit 32 is connected to the control unit 16 and the current sensor 31 separately. Points P1 and P2 correspond to two points in the claims.

- a current whose value is a first constant of a value of the current flowing through the first current path for example, 1/1000

- a current whose value is a second constant of a value of the current flowing through the second current path for example, 1/2000

- the second constant is larger than the first constant.

- Each of the first constant and the second constant depends on the ratio between the resistance value between the points P1 and P2 in the conductor 18 and the resistance value of the conductive wire 30.

- the second constant further depends on the position of the point P1.

- the second constant is larger as the point P1 is farther from the third conductive portion 23.

- the electrical resistivity of the conductor 18 depends on the temperature value of the conductor 18.

- the electrical resistivity of the conducting wire 30 depends on the temperature value of the conducting wire 30.

- the temperature values of the conductor 18 and the conducting wire 30 are substantially the same.

- the electrical resistivity of each of the conductor 18 and the conducting wire 30 varies in the same manner according to the variation in the temperature values of the conductor 18 and the conducting wire 30.

- the electrical resistivity of the conductor 18 becomes, for example, 1.1 times due to changes in the temperature values of the conductor 18 and the conductor 30, the electrical resistivity of the conductor 30 also becomes 1.1 times. For this reason, the ratio of the electrical resistivity of each of the conductor 18 and the conductor 30 is constant regardless of the temperature values of the conductor 18 and the conductor 30.

- a current whose value is one-first constant of the value of the current flowing through the first current path is independent of the temperature values of the conductor 18 and the conductor 30. It flows to 30.

- a current whose value is a second constant of a value of the current flowing through the second current path is independent of the temperature values of the conductor 18 and the conductor 30. It flows to the conducting wire 30.

- the current sensor 31 outputs a voltage value corresponding to the value of the current flowing through the conducting wire 30 to the A / D converter 32.

- the voltage value output by the current sensor 31 is an analog value, and becomes high / low according to the magnitude of the current flowing through the conducting wire 30.

- the voltage value output by the current sensor 31 depends on the potentials at the points P1 and P2.

- the A / D conversion unit 32 converts the analog voltage value input from the current sensor 31 into a digital voltage value, and outputs the converted digital voltage value to the control unit 16.

- the A / D conversion unit 32 presets the voltage value input from the current sensor 31 by performing processing such as rounding off or rounding down.

- the reference voltage value is quantized to a voltage value that is first or second closest to the voltage value input to the current sensor 31.

- the A / D conversion unit 32 outputs the converted digital voltage value to the control unit 16.

- the digital voltage value output from the A / D conversion unit 32 to the control unit 16 corresponds to a value related to the potential at the points P1 and P2.

- the current sensor 31 outputs an analog voltage value corresponding to the value of the current flowing through the lead wire 30 to the A / D conversion unit 32, and the A / D conversion unit 32 converts the analog voltage value input from the current sensor 31. Converting to a digital voltage value and outputting the converted voltage value corresponds to detecting the value of the current flowing through the conducting wire 30.

- the storage unit 17 includes a first conversion formula for converting the voltage value output from the A / D conversion unit 32 into the value of the current flowing through the first current path, and the voltage output from the A / D conversion unit 32.

- the second conversion formula for converting the value into the value of the current flowing through the second current path is stored.

- the control unit 16 converts the voltage value output from the A / D conversion unit 32 into the value of the current flowing in the first current path or the second current path using the first conversion formula or the second conversion formula.

- FIG. 4 is a flowchart showing the switching process executed by the control unit 16.

- the control unit 16 periodically performs the switching process when the generator 10 is generating power.

- the control unit 16 determines whether or not current is flowing through the first current path (step S1).

- the control unit 16 operates the DCDC converter 12 by outputting an operation instruction, and stops the operation of the DCDC converter 12 by outputting a stop instruction.

- the control unit 16 determines that a current is flowing through the first current path.

- the switch 11 is turned on and the operation of the DCDC converter 12 is stopped, the control unit 16 determines that no current is flowing in the first current path.

- the control unit 16 converts the voltage value output from the A / D conversion unit 32 into a current value using the first conversion equation.

- the current value is the value of the current flowing through the first current path.

- the control unit 16 determines whether or not the current path through which the current flows in the conductor 18 should be switched to the second current path (step S3).

- the control unit 16 determines that the current path should be switched to the second current path when the current value converted in step S2 is a first current threshold, for example, 100 A or more.

- the control unit 16 determines that the current path should not be switched to the second current path when the current value converted in step S2 is less than the first current threshold.

- the first current threshold is stored in the storage unit 17 in advance.

- the control unit 16 When it is determined that the current path should be switched to the second current path (S3: YES), the control unit 16 outputs a decrease instruction to the generator 10 (step S4). Thereby, the output voltage value of the generator 10 falls to the first output voltage value, for example, 12V.

- control unit 16 outputs a stop instruction to the DCDC converter 12 (step S5), and turns on the switch 11 (step S6). Thereby, a current flows from one end of the generator 10 to the third conductive part 23 and the second conductive part 22 via the switch 11. In other words, the current path through which current flows in the conductor 18 is switched to the second current path. As described above, the control unit 16 switches the current path through which the current flows from the first current path to the second current path by stopping the operation of the DCDC converter 12 and turning on the switch 11.

- the control unit 16 ends the process after determining that the current path should not be switched to the second current path (S3: NO) or after executing Step S6.

- the control unit 16 determines that no current flows in the first current path, that is, current flows in the second current path (S1: NO)

- the A / D conversion is performed using the second conversion formula.

- the voltage value output by the unit 32 is converted into a current value (step S7).

- the current value is the value of the current flowing through the second current path.

- control unit 16 determines whether or not the current path through which the current flows in the conductor 18 should be switched to the first current path (step S8).

- the control unit 16 determines that the current path should be switched to the first current path when the current value converted in step S7 is less than the second current threshold, for example, 90A.

- the controller 16 determines that the current path should not be switched to the first current path when the current value converted in step S7 is equal to or greater than the second current threshold.

- the second current threshold value is stored in advance in the storage unit 17.

- the control unit 16 When it is determined that the current path should be switched to the first current path (S8: YES), the control unit 16 turns off the switch 11 (step S9) and outputs an operation instruction to the DCDC converter 12 (step S10). Thereby, current flows from one end of the generator 10 to the first conductive part 21 and the second conductive part 22 via the DCDC converter 12. That is, the current path through which current flows in the conductor 18 is switched to the first current path. As described above, the control unit 16 switches the current path through which the current flows from the second current path to the first current path by turning off the switch 11 and operating the DCDC converter 12.

- control part 16 outputs a raise instruction

- the control unit 16 ends the process.

- the control unit 16 uses the current path through which the current flows in the conductor 18 and the current path through which the current flows based on the voltage value output by the A / D conversion unit 32 of the current detection circuit 15. It is determined whether or not to switch.

- the voltage value output by the A / D conversion unit 32 is a value related to the potentials at the points P1 and P2, and corresponds to the current value detected by the current detection circuit 15. Further, the current detection circuit 15, the control unit 16, and the storage unit 17 function as a switching device.

- the voltage value output from the A / D conversion unit 32 of the current detection circuit 15 becomes high / low according to the magnitude of the current flowing through the first current path. It becomes high / low depending on the magnitude of the current flowing through the second current path. Furthermore, the voltage value output from the current sensor 31 when a current having an It value of It flows through the first current path is equal to the voltage value output by the current sensor 31 when a current having the same It value flows through the second current path. Differs from the output voltage value.

- the value of the current flowing through the conducting wire 30 when a current of 100 A flows through the first current path, and the current flowing through the conducting wire 30 when the current of 200 A flows through the second current path are shown.

- the reference voltage value of the A / D converter 32 is set so that the voltage value output from the A / D converter 32 accurately indicates the value of the current flowing through each of the first current path and the second current path. be able to.

- the reference voltage value is set in this way, the current path through which current flows in the conductor 18 can be appropriately switched. Further, since there is no need to configure a circuit for detecting current separately for each of the first current path and the second current path, the switching device according to the first embodiment can be manufactured at low cost.

- control unit 16 is based on the current path through which the current flows and the voltage value output by the A / D conversion unit 32, that is, the current value detected by the current detection circuit 15. It is determined whether or not the current path should be switched. For this reason, the current path is switched with a simple configuration.

- the control unit 16 converts the voltage value output from the A / D conversion unit 32 into the value of the current flowing through the conductor 18.

- the voltage value output from the A / D conversion unit 32 when current flows through the first current path and the voltage value output to the A / D conversion unit 32 when current flows through the second current path are the same.

- a first voltage threshold and a second voltage threshold may be prepared, and the current path may be switched using the first voltage threshold and the second voltage threshold.

- the power supply device 1 according to the second embodiment is different from the power supply device 1 according to the first embodiment in the switching process executed by the control unit 16.

- Other configurations in the second embodiment are the same as those in the first embodiment.

- FIG. 5 is a flowchart showing the switching process executed by the control unit 16 according to the second embodiment. Also in Embodiment 2, the control part 16 performs a switching process periodically, when the generator 10 is generating electric power.

- steps S21 to S29 executed by the control unit 16 in the second embodiment steps S21, S23, S24, S25, S27, S28, and S29 are steps S1, S4 executed by the control unit 16 in the first embodiment. , S5, S6, S9, S10, and S11, the detailed description thereof is omitted.

- the controller 16 determines whether or not the current path through which current flows in the conductor 18 should be switched to the second current path (step S21). S22). The control unit 16 determines that the current path should be switched to the second current path when the digital voltage value output from the A / D conversion unit 32 is equal to or greater than the first voltage threshold. The control unit 16 determines that the current path should not be switched to the second current path when the digital voltage value output from the A / D conversion unit 32 is less than the first voltage threshold.

- the first voltage threshold is a voltage value output by the A / D conversion unit 32 when a current whose value is the first current threshold flows through the first current path.

- the first voltage threshold is stored in the storage unit 17 in advance.

- control unit 16 determines that the current path should be switched to the second current path (S22: YES), it executes Step S23. When it is determined that the current path should not be switched to the second current path (S22: NO), or after executing step S25, the control unit 16 ends the switching process.

- the control unit 16 sets the current path through which the current flows in the conductor 18 to the first current path. It is determined whether or not to switch to the current path (step S26). The control unit 16 determines that the current path should be switched to the first current path when the digital voltage value output from the A / D conversion unit 32 is less than the second voltage threshold. The control unit 16 determines that the current path should not be switched to the second current path when the digital voltage value output from the A / D conversion unit 32 is equal to or greater than the second voltage threshold.

- the second voltage threshold is a voltage value output by the A / D conversion unit 32 when a current whose value is the second current threshold flows through the second current path.

- the second voltage threshold is stored in the storage unit 17 in advance. Since the second current threshold is less than or equal to the first current threshold, the second voltage threshold is less than or equal to the first voltage threshold.

- Step S27 When the control unit 16 determines that the current path should be switched to the first current path (S26: YES), the control unit 16 executes Step S27. When it is determined that the current path should not be switched to the first current path (S26: NO), or after executing step S29, the control unit 16 ends the switching process.

- the control unit 16 is based on the current path through which current is flowing in the conductor 18 and the voltage value output by the A / D conversion unit 32 of the current detection circuit 15. It is determined whether or not the current path through which the current flows should be switched.

- the configuration other than the switching process executed by the control unit 16 is the same as that of the first embodiment. For this reason, in the second embodiment, the switching device including the current detection circuit 15, the control unit 16, and the storage unit 17 has the same effect as the first embodiment.

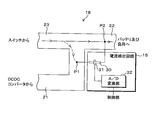

- FIG. 6 is a block diagram showing a main configuration of the power supply device 1 according to the third embodiment.

- the power supply device 1 in the third embodiment includes a generator 10, a switch 11, a DCDC converter 12, a battery 13, a load 14, a current detection circuit 15, a control unit 16, and a storage unit 17, which are the same as those in the first embodiment. It is connected to the.

- the power supply device 1 according to the third embodiment further includes a temperature detection circuit 19, and the temperature detection circuit 19 is connected to the control unit 16.

- the power supply device 1 according to the third embodiment differs from the power supply device 1 according to the first embodiment in that the temperature detection circuit 19 is provided and the current detection circuit 15 is configured.

- FIG. 7 is an explanatory diagram of current detection.

- the first conductive portion 21 and the third conductive portion 23 are connected to the second conductive portion 22, respectively.

- the first conductive portion 21, the second conductive portion 22, and the third conductive portion 23 are conductors.

- 18 is constituted.

- the temperature detection circuit 19 detects the temperature value of the conductor 18.

- the temperature detection circuit 19 includes a temperature sensor (not shown), an A / D conversion unit, and the like, and outputs the detected digital temperature value to the control unit 16.

- the temperature detection circuit 19 functions as a temperature detection unit.

- the current detection circuit 15 in the third embodiment includes an A / D conversion unit 32 and a differential amplifier 40 similar to those in the first embodiment.

- the plus terminal is connected to the point P1 located on the surface of the first conductive part 21, and the minus terminal is connected to the point P2 located on the surface of the second conductive part 22.

- the output terminal of the differential amplifier 40 is connected to the A / D converter 32.

- the A / D conversion unit 32 is further connected to the control unit 16.

- the differential amplifier 40 amplifies the voltage value between the points P1 and P2, and outputs the amplified analog voltage value to the A / D conversion unit 32.

- the A / D converter 32 converts the analog voltage value input from the differential amplifier 40 into a digital voltage value, and outputs the converted digital voltage value to the controller 16.

- the A / D conversion unit 32 performs a process such as rounding off or rounding down to set a voltage value input from the differential amplifier 40 in advance.

- the reference voltage value is quantized to a voltage value that is first or second closest to the voltage value input from the differential amplifier 40.

- the A / D conversion unit 32 outputs the converted digital voltage value to the control unit 16.

- the voltage value between the points P3 and P2 increases as the current value flowing through the second current path increases, and decreases as the current value flowing through the second current path decreases. .

- the voltage value between the points P1 and P2 is larger as the value of the current flowing through the second current path is larger, and smaller as the value of the current flowing through the second current path is smaller.

- the voltage value between the points P1 and P2 increases as the value of the current flowing through the first current path increases, and decreases as the value of the current flowing through the first current path decreases.

- the voltage value between the points P1 and P2 when the current having the current value It flows through the first current path is the point between the points P1 and P2 when the current having the same current value flows through the second current path. Higher than the voltage value.

- the digital voltage value output from the A / D conversion unit 32 to the control unit 16 corresponds to a value related to the potential at the points P1 and P2.

- the differential amplifier 40 amplifies the voltage value between the points P1 and P2, outputs the amplified analog voltage value to the A / D conversion unit 32, and the A / D conversion unit 32 receives the analog input from the differential amplifier 40. Converting the voltage value into a digital voltage value and outputting the converted voltage value corresponds to detecting the voltage between the points P1 and P2.

- the control unit 16 executes the same switching process as in the first embodiment. However, the specific conversion configuration performed in steps S2 and S7 is different from that of the first embodiment.

- the voltage value output from the A / D conversion unit 32 of the current detection circuit 15 to the control unit 16 and the temperature detection The temperature value output from the circuit 19 to the control unit 16 is a variable.

- Step S2 the control unit 16 converts the voltage value output from the A / D conversion unit 32 into a current value by using the first conversion formula into which the temperature value output from the temperature detection circuit 19 is substituted.

- the current value is the value of the current flowing in the first current path.

- the control unit 16 in the third embodiment determines that no current flows through the first current path, that is, current flows through the second current path (S1: NO)

- the temperature detection circuit 19 Is substituted into the second conversion equation, and then step S7 is executed.

- step S7 the control unit 16 converts the voltage value output from the A / D conversion unit 32 into a current value by using the second conversion formula into which the temperature value output from the temperature detection circuit 19 is substituted.

- the current value is the value of the current flowing in the second current path.

- the electrical resistivity of the conductor 18 is higher as the temperature value of the conductor 18 is higher.

- the current value converted in step S2 or S7 is smaller as the temperature value of the conductor 18 is higher and larger as the temperature value of the conductor 18 is lower.

- the current sensor 31 outputs a voltage value corresponding to the value of the current flowing through the conducting wire 30, and the A / D converter 32 converts the analog voltage value output from the current sensor 31 into a digital voltage value. Convert.

- the differential amplifier 40 amplifies the voltage value between the points P1 and P2, outputs the amplified voltage value, and the A / D converter 32 outputs the analog output from the differential amplifier 40. Is converted to a digital voltage value. For this reason, each of the first conversion formula and the second conversion formula in the third embodiment is different from the first conversion formula and the second conversion formula in the first embodiment.

- the control unit 16 detects the current path through which the current flows in the conductor 18, the voltage value output by the A / D conversion unit 32 of the current detection circuit 15, and the temperature detected by the temperature detection circuit 19. Whether or not the current path through which the current flows should be switched is determined based on the value.

- the voltage value output by the A / D conversion unit 32 is a value related to the potential at the points P1 and P2, and corresponds to the voltage value detected by the current detection circuit 15.

- the current detection circuit 15, the control unit 16, the storage unit 17, and the temperature detection circuit 19 function as a switching device.

- the voltage value output from the A / D converter 32 of the current detection circuit 15 becomes high / low according to the magnitude of the current flowing through the first current path, and the value of the current flowing through the second current path is large. / High / low depending on small.

- the voltage value output from the differential amplifier 40 when the current having the current value It flows through the first current path is the differential value when the current having the same current value flows through the second current path. It is different from the voltage value output from the amplifier 40.

- the voltage value between points P1 and P2 when a current of 100 A flows in the first current path and the voltage value between points P1 and P2 when a current of 200 A flows in the second current path.

- the voltage value can be matched.

- the reference voltage value of the A / D converter 32 is set so that the voltage value output from the A / D converter 32 accurately indicates the value of the current flowing through each of the first current path and the second current path. be able to.

- the reference voltage value is set in this way, the current path through which current flows in the conductor 18 can be appropriately switched. Further, since there is no need to configure a circuit for detecting current separately for each of the first current path and the second current path, the switching device according to the first embodiment can be manufactured at low cost.

- control unit 16 is based on the current path through which the current flows and the voltage value output by the A / D conversion unit 32, that is, the voltage value detected by the current detection circuit 15. It is determined whether or not the current path should be switched. For this reason, the current path is switched with a simple configuration. Further, the control unit 16 detects not only the current path through which the current flows and the voltage value detected by the current detection circuit 15 but also the temperature value output by the temperature detection circuit 19, that is, the temperature detection circuit 19 detects the current value. It is determined whether or not the current path should be switched based on the measured temperature value. For this reason, the current path through which the current flows in the conductor 18 is more appropriately switched.

- the ratio of the electrical resistivity of the conductor 18 and the conductor 30 depends on the temperature value of the conductor 18 and the conductor 30. To do. In the first embodiment, for example, since the materials used for the conductor 18 and the conductor 30 are different, the relationship between the temperature value and the electrical resistivity is different between the conductor 18 and the conductor 30. The ratio of the electrical resistivity of each of the body 18 and the conductor 30 depends on the temperature values of the conductor 18 and the conductor 30.

- the switching device in the first embodiment includes the temperature detection circuit 19 as in the third embodiment, and the A / D conversion unit 32 of the current detection circuit 15 is controlled by the control unit 16.

- the first conversion equation and the second conversion equation may be used in which the voltage value output to and the temperature value output from the temperature detection circuit 19 to the control unit 16 are variables.

- the switching device in the first embodiment includes a temperature detection circuit that detects the temperature values of the conductor 18 and the conductor 30, and the value of the current flowing through the conductor 30.

- the first conversion formula and the second conversion formula in which the temperature values of the conductor 18 and the conductive wire 30 are variables may be used.

- control unit 16 executes the switching process in the first embodiment.

- the switching process executed by the control unit 16 is not limited to the switching process in the first embodiment, and the same switching process as in the second embodiment may be executed.

- the switching process executed by the control unit 16 is different from that of the power supply device 1 according to the third embodiment.

- the control unit 16 in the fourth embodiment executes the same switching process as in the second embodiment.

- the configuration of determination performed in steps S22 and S26 is different from that of the second embodiment.

- the first voltage threshold used in step S ⁇ b> 22 varies depending on the temperature value output from the temperature detection circuit 19 to the control unit 16.

- the second voltage threshold value used in step S27 also differs depending on the temperature value output from the temperature detection circuit 19 to the control unit 16.

- FIG. 8 is a chart showing the first voltage threshold and the second voltage threshold in the fourth embodiment.

- the first voltage threshold value and the second voltage threshold value are associated with the temperature value output from the temperature detection circuit 19 to the control unit 16.

- the storage unit 17 stores a relationship between the temperature value and the first voltage threshold value, and a relationship between the temperature value and the second voltage threshold value.

- T1, T2, T3, T4 are temperature values, and V11, V12, V13... And V21, V22, V23,.

- T1 ⁇ T2 ⁇ T3 ⁇ T4 holds.

- the first voltage threshold and the second voltage threshold are V11 and V21, respectively.

- the first voltage threshold and the second voltage threshold are V12 and V22, respectively.

- the first voltage threshold and the second voltage threshold are V13 and V23, respectively.

- the control unit 16 in the fourth embodiment corresponds to the temperature value output from the temperature detection circuit 19 to the control unit 16 when it is determined that the current is flowing through the first current path (S21: YES).

- the first voltage threshold value is read from the storage unit 17, and then Step S22 is executed.

- the control unit 16 determines that the current path should be switched to the second current path when the digital voltage value output from the A / D conversion unit 32 is equal to or greater than the read first voltage threshold value.

- the control unit 16 determines that the current path should not be switched to the second current path when the digital voltage value output from the A / D conversion unit 32 is less than the read first voltage threshold.

- the first voltage threshold value is a voltage value output by the A / D conversion unit 32 when a current whose value is the first current threshold value flows in the first current path.

- step S ⁇ b> 26 the control unit 16 determines that the current path should be switched to the first current path when the digital voltage value output from the A / D conversion unit 32 is less than the read second voltage threshold.

- the control unit 16 determines that the current path should not be switched to the first current path when the digital voltage value output from the A / D conversion unit 32 is equal to or greater than the read second voltage threshold.

- the second voltage threshold is a voltage value output by the A / D conversion unit 32 when a current whose value is the second current threshold flows through the second current path.

- the control unit 16 detects the current path through which the current flows in the conductor 18, the voltage value output by the A / D conversion unit 32 of the current detection circuit 15, and the temperature detection. Based on the temperature value detected by the circuit 19, it is determined whether or not the current path through which the current flows should be switched.

- the configuration other than the switching process executed by the control unit 16 and the correspondence relationship shown in FIG. 8 stored in the storage unit 17 is the same as that of the third embodiment. Therefore, in the fourth embodiment, the switching device including the current detection circuit 15, the control unit 16, the storage unit 17, and the temperature detection circuit 19 has the same effect as that of the third embodiment.

- the switching device when the temperature value of the conductor 18 is different from the temperature value of the conductor 30 or when the relationship between the temperature value and the electrical resistivity is different between the conductor 18 and the conductor 30, the conductor The ratio of the electrical resistivity of each of 18 and the conductor 30 depends on the temperature values of the conductor 18 and the conductor 30.

- the switching device includes a temperature detection circuit 19 as in the fourth embodiment, and the relationship between the temperature value and the first voltage threshold, the temperature value, The relationship with the second voltage threshold value may be stored in the storage unit 17.

- step S22 when the control unit 16 determines that the current is flowing through the first current path (S21: YES), the control unit 16 sets the temperature value output to the control unit 16 by the temperature detection circuit 19. The corresponding first voltage threshold value is read from the storage unit 17, and then step S22 is executed. Further, when the control unit 16 determines that no current flows through the first current path, that is, current flows through the second current path (S21: NO), the temperature detection circuit 19 outputs to the control unit 16. The second voltage threshold value corresponding to the temperature value thus read is read from the storage unit 17, and then step S26 is executed.

- the switching device in the first embodiment includes a temperature detection circuit that detects the temperature values of the conductor 18 and the conductor 30, and each of the conductor 18 and the conductor 30.

- the relationship between the temperature value and the first voltage threshold value and the relationship between the temperature value of each of the conductor 18 and the conductive wire 30 and the second temperature value may be stored in the storage unit 17.

- the configuration for determining the first voltage threshold or the second voltage threshold is not limited to the configuration in which the storage unit 17 reads the first voltage threshold or the second voltage threshold associated with the temperature value.

- a relational expression between the first voltage threshold (or the second voltage threshold) and the temperature value detected by the temperature detection circuit 19 may be stored in the storage unit 17.

- the control unit 16 calculates the first voltage threshold (or the second voltage threshold) by substituting the temperature value detected by the temperature detection circuit 19 into the above-described relational expression, and calculates the calculated first The voltage threshold (or second voltage threshold) is used in step S22 (or step 26).

- the configuration for determining the first voltage threshold or the second voltage threshold is that the storage unit 17 associates with the temperature value.

- the configuration is not limited to reading the first voltage threshold or the second voltage threshold.

- the conductor 18 further includes a resistance portion having a lower conductivity than any of the first conductive portion 21, the second conductive portion 22, and the third conductive portion 23 so that the resistance value between the points P1 and P2 is increased. May be.

- the configuration of the conductor 18 and the object to be detected by the temperature detection circuit 19 are different from those in the power supply device 1 in the third embodiment.

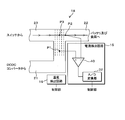

- FIG. 9 is an explanatory diagram of current detection in the fifth embodiment.

- the conductor 18 in the fifth embodiment includes a resistance unit 50 in addition to the first conductive unit 21, the second conductive unit 22, and the third conductive unit 23.

- the resistance portion 50 has a rectangular plate shape.

- An end portion of the third conductive portion 23 is connected to one side of the resistor portion 50, and an end portion of the second conductive portion 22 is connected to one side of the resistor portion 50 facing the one side.

- One side of the first conductive unit 21 is connected to one side of the other two sides of the resistance unit 50 except for the two sides to which the second conductive unit 22 and the third conductive unit 23 are connected.

- each of the first conductive portion 21 and the third conductive portion 23 is connected to the second conductive portion 22 via the resistance portion 50.

- FIG. 9 shows the plate surfaces of the first conductive portion 21, the second conductive portion 22, the third conductive portion 23, and the resistance portion 50.

- the point P1 is located at the connecting portion of the first conductive part 21 and the resistor part 50. Further, the point P ⁇ b> 2 is located at a connection portion between the second conductive portion 22 and the resistance portion 50.

- the temperature detection circuit 19 in the fifth embodiment detects the temperature value of the resistance unit 50.

- the temperature detection circuit 19 includes a temperature sensor (not shown), an A / D conversion unit, and the like, and outputs the detected digital temperature value to the control unit 16.

- the conductor 18 in the fifth embodiment when a current flows through the first current path, the current flows in the order of the first conductive portion 21, the resistance portion 50, and the second conductive portion 22. Further, in the conductor 18 according to the fifth embodiment, when a current flows through the second current path, the current flows in the order of the third conductive portion 23, the resistor portion 50, and the second conductive portion 22.

- the equipotential lines shown in FIG. 7 and FIG. 9 are equipotential lines when currents having the same value flow through the second current path in the third and fifth embodiments.

- the voltage difference between adjacent equipotential lines in FIG. 9 is the same as the voltage difference between adjacent equipotential lines in FIG.

- the conductivity of the resistance unit 50 is lower than any of the conductivity of the first conductive unit 21, the second conductive unit 22, and the third conductive unit 23. For this reason, when a current flows through the second current path as indicated by a solid arrow in FIG. 9, the voltage is greatly decreased between the points P ⁇ b> 1 and P ⁇ b> 2 by the resistance unit 50. This can also be seen from the fact that the number of equipotential lines in FIG. 9 between the points P3 and P2 is larger than the number of equipotential lines in FIG. 7 between the points P3 and P2.

- the voltage value between the points P1 and P2 increases as the value of the current flowing through the second current path increases as in the third embodiment. The smaller the value of the flowing current, the smaller.

- the voltage value between the points P1 and P2 increases as the value of the current flowing through the first current path increases, and the value of the current flowing through the first current path decreases. Small enough.

- the voltage value between the points P1 and P2 when the current having the current value It flows in the first current path is the same as the current value It in the second current path. Is larger than the voltage value between the points P1 and P2.

- the control unit 16 in the fifth embodiment performs a switching process similar to that in the third embodiment. However, since the temperature detection circuit 19 detects the temperature value of the resistance unit 50 as described above, the temperature value substituted into the first conversion formula and the second conversion formula before executing steps S2 and S7 is the resistance value. This is the temperature value of the part 50.

- the conductor 18 has a resistance unit 50. Furthermore, since the temperature value substituted into the first conversion formula and the second conversion formula is the temperature value of the resistance unit 50, it is stored in the storage unit 17 in the fifth embodiment. Each of the first conversion formula and the second conversion formula being performed is different from the first conversion formula and the second conversion formula stored in the storage unit 17 in the third embodiment.

- the current value converted in step S2 or S7 is smaller as the temperature value of the resistance unit 50 is higher and larger as the temperature value of the resistance unit 50 is lower.

- control unit 16 is configured to detect the current path through which the current flows in the conductor 18, the voltage value output by the A / D conversion unit 32 of the current detection circuit 15, and the temperature detection. Based on the temperature value detected by the circuit 19, it is determined whether or not the current path through which the current flows should be switched.

- the current detection circuit 15, the control unit 16, the storage unit 17, and the temperature detection circuit 19 function as a switching device.

- the voltage value output from the A / D converter 32 of the current detection circuit 15 becomes high / low according to the magnitude of the current flowing through the first current path, and the value of the current flowing through the second current path is large. / High / low depending on small.

- the voltage value output from the differential amplifier 40 when the current having the current value It flows through the first current path is the differential value when the current having the same current value flows through the second current path. It is different from the voltage value output from the amplifier 40.

- the voltage value can be matched.

- the reference voltage value of the A / D converter 32 is set so that the voltage value output from the A / D converter 32 accurately indicates the value of the current flowing through each of the first current path and the second current path. be able to.

- the reference voltage value is set in this way, the current path through which current flows in the conductor 18 can be appropriately switched. Further, since there is no need to configure a circuit for detecting current separately for each of the first current path and the second current path, the switching device according to the first embodiment can be manufactured at low cost.

- control unit 16 is based on the current path through which the current flows and the voltage value output by the A / D conversion unit 32, that is, the voltage value detected by the current detection circuit 15. It is determined whether or not the current path should be switched. For this reason, the current path is switched with a simple configuration. Further, the control unit 16 detects not only the current path through which the current flows and the voltage value detected by the current detection circuit 15 but also the temperature value output by the temperature detection circuit 19, that is, the temperature detection circuit 19 detects the current value. It is determined whether or not the current path should be switched based on the measured temperature value. For this reason, the current path through which the current flows in the conductor 18 is more appropriately switched.

- the control unit 16 determines whether or not the current path should be switched in the switching process. Furthermore, it can determine appropriately.

- the storage unit 17 may be configured similarly to the fourth embodiment, and the control unit 16 may execute the switching process in the fourth embodiment.

- the temperature value output from the temperature detection circuit 19 to the control unit 16 is not the temperature value of the conductor 18 but the temperature value of the resistance unit 50 as described above. Therefore, the first voltage threshold values V11, V12, V13,... And the second voltage threshold values V21, V22,... Stored in the storage unit 17 in association with the temperature values output from the temperature detection circuit 19 to the control unit 16 are stored. V23,... Are different from the fourth embodiment.

- control unit 16 in the fifth embodiment executes the switching process in the fourth embodiment, the same effects as those in the fifth embodiment described above are obtained.

- the position of the point P1 is not limited to the connecting portion between the first conductive portion 21 and the resistance portion 50, and may be the surface of the first conductive portion 21.

- the position of the point P ⁇ b> 2 is not limited to the connection portion between the second conductive portion 22 and the resistance portion 50, and may be on the surface of the second conductive portion 22.

- the shape of the resistance portion 50 is not limited to a rectangular plate shape, and may be, for example, a T shape or an L shape.

- one side to which the first conductive unit 23 is connected may not face the one side to which the second conductive unit 22 is connected.

- the first conductive part 21 and the third conductive part 23 may be connected to the second conductive part 22 via the resistance part 50.

- the switching device in the first embodiment includes the temperature detection circuit 19 or the temperature detection circuit that detects the temperature values of the conductor 18 and the conductor 30, the conductor 18 in the fifth embodiment is used. It may be done.

- the switching device according to the second embodiment includes the temperature detection circuit 19 or the temperature detection circuit that detects the temperature values of the conductor 18 and the conductor 30, the conductor 18 according to the fifth embodiment. May be used.